Page 3

GENERAL REPAIR PROCEDURE WITH MAGNA STAKES

Insert stake into Electrodes (5) as shown in Figure 2. Three positions are

available to insert stakes at different angles.

Place stake against surface to be repaired while applying moderate

pressure. Depress the Trigger Button (3) to heat the stake.

While continuing to apply pressure, allow the stake to sink halfway

through the thickness of the work piece. After stake is inserted to proper

depth, twist the stake slightly to allow it to lock into the panel.

Allow the stake to cool for 2 or 3 seconds before removing tool. Trim

exposed ends of stake using wire cutters (Figure 3). Take care while

trimming stakes as flying pieces can cause injury to operator or

bystanders. Eye protection should be worn at all times (See Safety

Instructions).

Complete cosmetic repair on front of panel as needed.

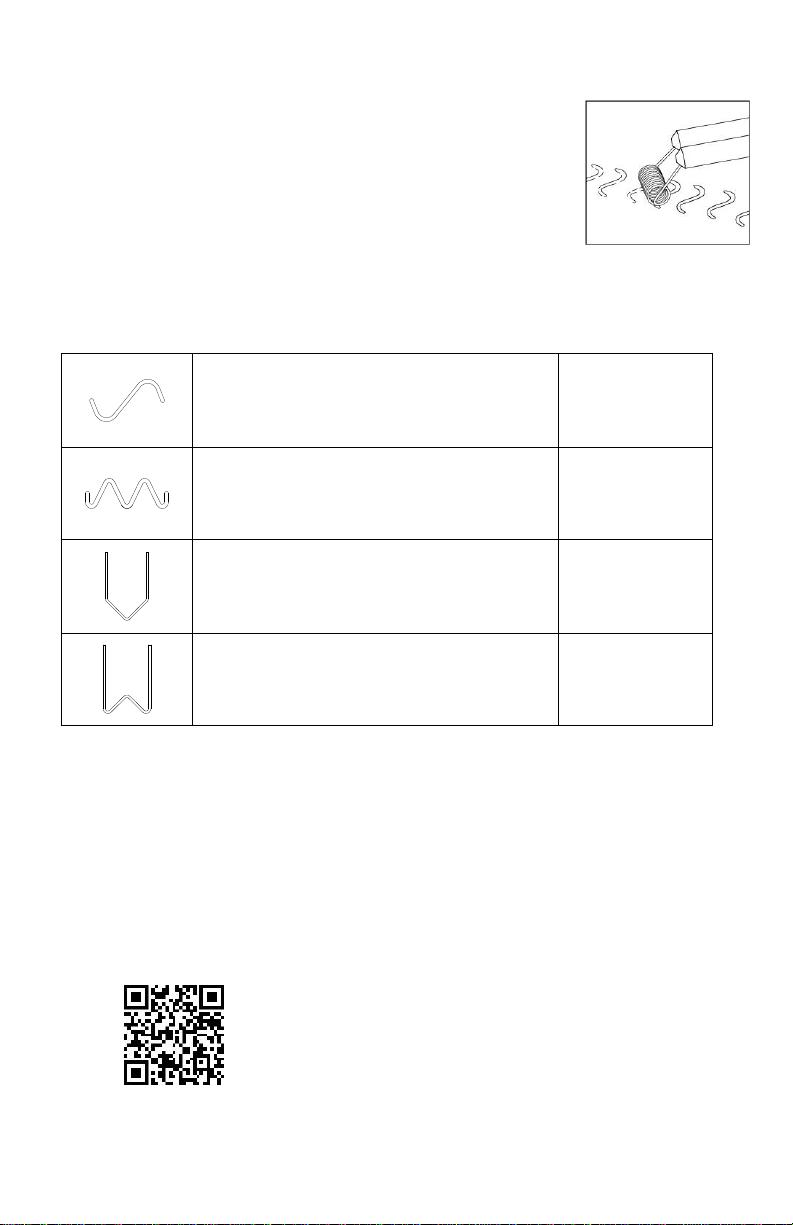

REPAIR OF FLAT AREAS

Prepare area to be repaired per instructions above. Insert an S-Shaped

Magna-StakeTM into the electrodes.

Set stake across crack as shown in Figure 4. Insert stake per instructions above, halfway through

panel thickness, and give stake a slight twist before allowing to cool. Space stakes on 1/2 to 3/4 inch

intervals or as needed for strength.

Trim stake ends and complete repair on front of panel as needed (See Safety Instructions).

REPAIR OF TABS AND THIN SECTIONS

Prepare area to be repaired per instructions above. Insert an M-Shaped

Magna-StakeTM into the electrodes.

Set stake across crack as shown in Figure 5. Insert stake per instructions

above, halfway through panel thickness, and add additional stakes as

needed for strength.

Trim stake ends and complete repair on front of panel as needed (See

Safety Instructions).

REPAIR OF INSIDE CORNERS

Prepare area to be repaired per instructions above. Insert a V-Shaped

Magna-StakeTM (MS2006) into the electrodes.

Set stake across crack as shown in Figure 6. Insert stake per

instructions above, halfway through panel thickness, and give stake a

slight twist before allowing to cool. Space stakes on 1/2 to 3/4 inch intervals or as needed for

strength.

Trim stake ends and complete repair on front of panel as needed (See Safety Instructions).

REPAIR OF OUTSIDE CORNERS

Prepare area to be repaired per instructions above. Insert a W-Shaped

Magna-StakeTM (MS2007) into the electrodes.

Set stake across crack as shown in Figure 7. Insert stake per

instructions above, halfway through panel thickness, and give stake a

slight twist before allowing to cool. Space stakes on 1/2 to 3/4 inch

intervals or as needed for strength.