I

Chapter 1: Introduction

About the text format ..........................................................................................1

Safety................................................................................................................. 2

Fasteners ...........................................................................................................3

Assembly Instructions ........................................................................................3

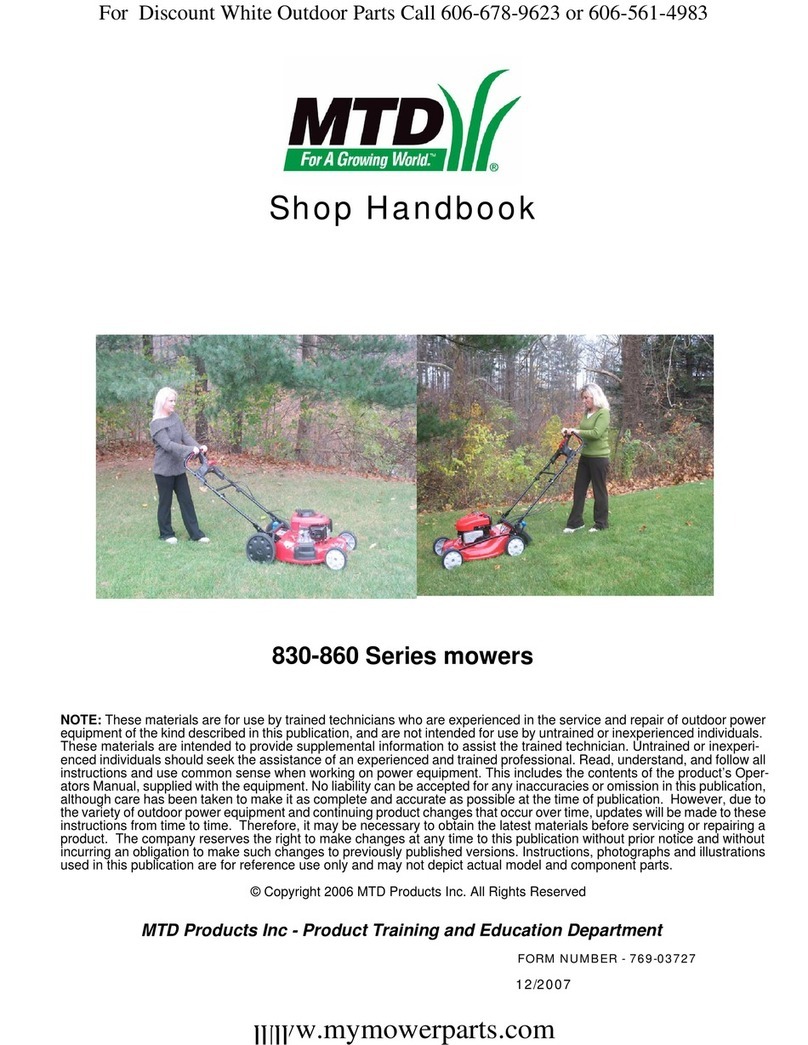

The “C” Series Mower ........................................................................................4

The “D” Series Mower ........................................................................................4

Understanding Model and Serial Numbers ........................................................5

Maintenance chart ..............................................................................................6

Fastener Tightening Torques .............................................................................6

Chapter 2: Blade and Belt

Blades ................................................................................................................ 7

Blade Removal ...................................................................................................8

Blade Sharpening .............................................................................................10

Belt Removal 1....................................................................................................1

Belt Replacement .............................................................................................14

Chapter 3: Controls and Cables

Engine Control Cable....................................................................................... 17

Drive Control Housing Assembly ......................................................................19

Drive Control Housing Removal and Disassembly ...........................................20

Drive Clutch Control Cable Removal and Replacement: ................................. 25

Drive Speed Control Cable Removal and Replacement:................................. 26

Chapter 4: Deck and transmission

Trail Shield .......................................................................................................27

Side Discharge Door / Mulch Plug ..................................................................28

Deckwash Fitting ..............................................................................................30

Rear Grass Door ..............................................................................................31

Front Wheels ....................................................................................................33

Front Axle .........................................................................................................36

Front Axle Cover ..............................................................................................39

Handlebars .......................................................................................................40

Transmission and Rear Axle Inspection ...........................................................41

Transmission and Rear Axle Removal .............................................................42

Transmission and variable speed pulley.......................................................... 45

Rear baffle removal ..........................................................................................49

Transmission Internal Workings....................................................................... 52

Table of Contents