Aydınlı Mah. Tuzla Mermerciler Org. San. Bölgesi Mermerciler Cad. No:41 Tuzla / İSTANBUL

T: 0216 593 02 42 F:0216 593 02 43

www.ndustrio.com

PLEASE READ CAREFULLY BEFORE OPERATION

STRICTLY COMPLY WITH ALL INSTRUCTIONS!

1. INSTALLATION

1.1.Transportation

Do not tilt the device during transportation definitely, carry in upright position.

Use appropriate transportation vehicles to prevent damage to the device.

Do not transport the device by pushing or dragging it. Pay attention to prevent damage

to the feet of the device during transportation operations performed with pallet jack or

forklift.

The forklift movement position must be so as to handle the machine in balance.

The length of the forklift feet must be compliant with the machine depth.

The forklift feet must open so as to balance the machine.

The crane movement position must be so as to carry the machine in balance.

A balanced transportation operation must be performed by tying the crane to the rings

on the machine using ropes.

1.2 Connections

1.2.1 Electrical Connection

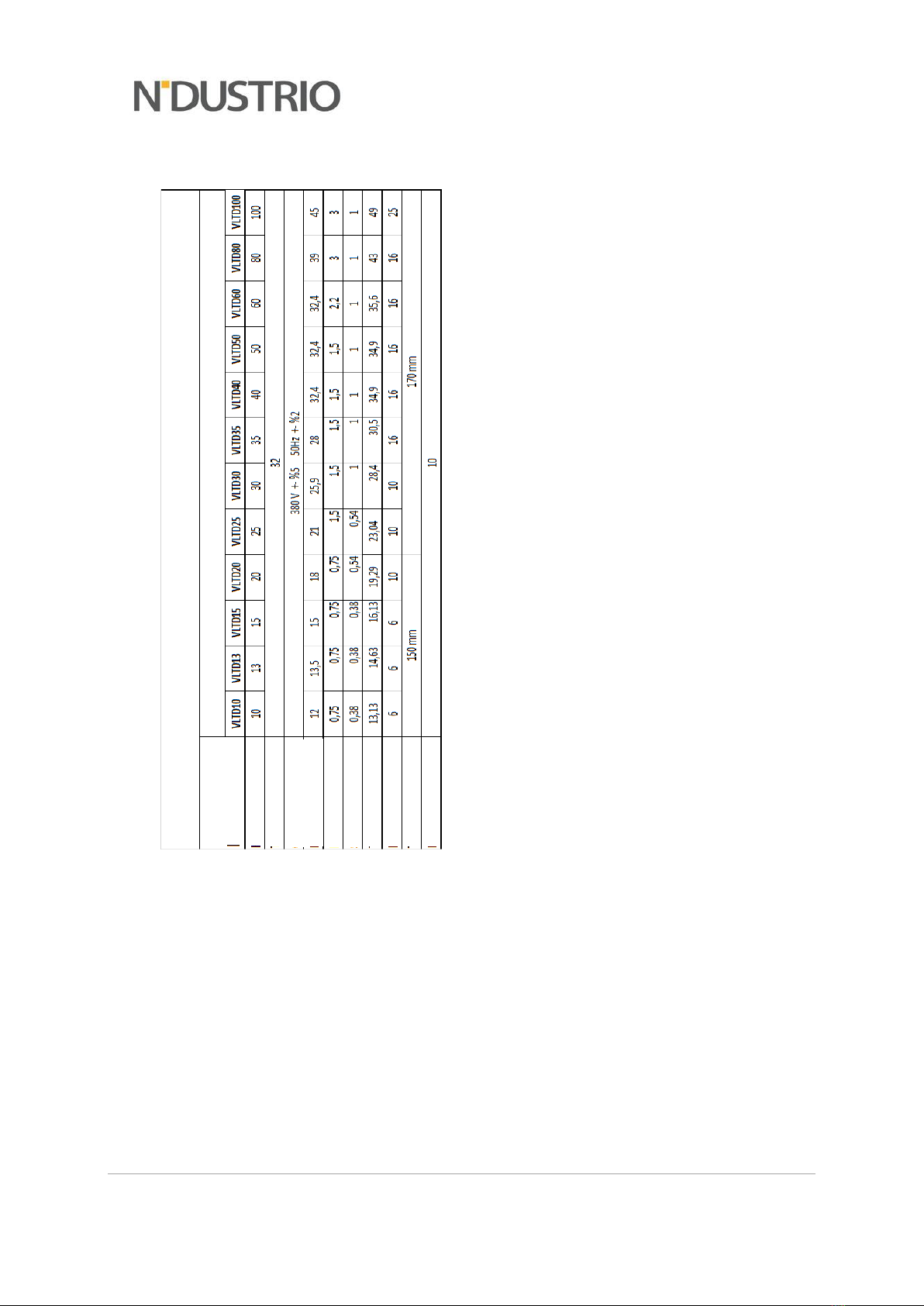

Before making the electrical connection of the device, check whether the electrical

distribution network and the device requirements are compliant and make the

connection using appropriate cables.

Make sure that the electrical connection is made in compliance with the standards

Feed the device with the network voltage written on the information label.

Make the connection to the electrical installation over an appropriate automatic fuse

and fix the fuse at an easily accessible position in case of danger.

The electrical installation of the device must include a ground line.

Do not place any flammable/ explosive material on or in the device.

Make sure that the electrical supply is in turned off position while checking the device.

If you are suspicious of an electrical leakage in the device, immediately call the

authorized service or call a competent electrician to check the device. While checking

the electrical leakage, do not directly touch the device with any of your organs.

The producer firm is not responsible for damages that may arise out of wrong electrical

connection of the device.

Before operating the device, check for appropriate grounding.

Make the device connection in accordance with the numbers on the supply cable.

Otherwise, your device will be out of the warranty scope.