WASHER SAFETY

Save these instructions

To reduce the risk of fire, electrical shock, or injury when using your washer, adhere to the

following basic precautions.

Read all instructions before using your washer

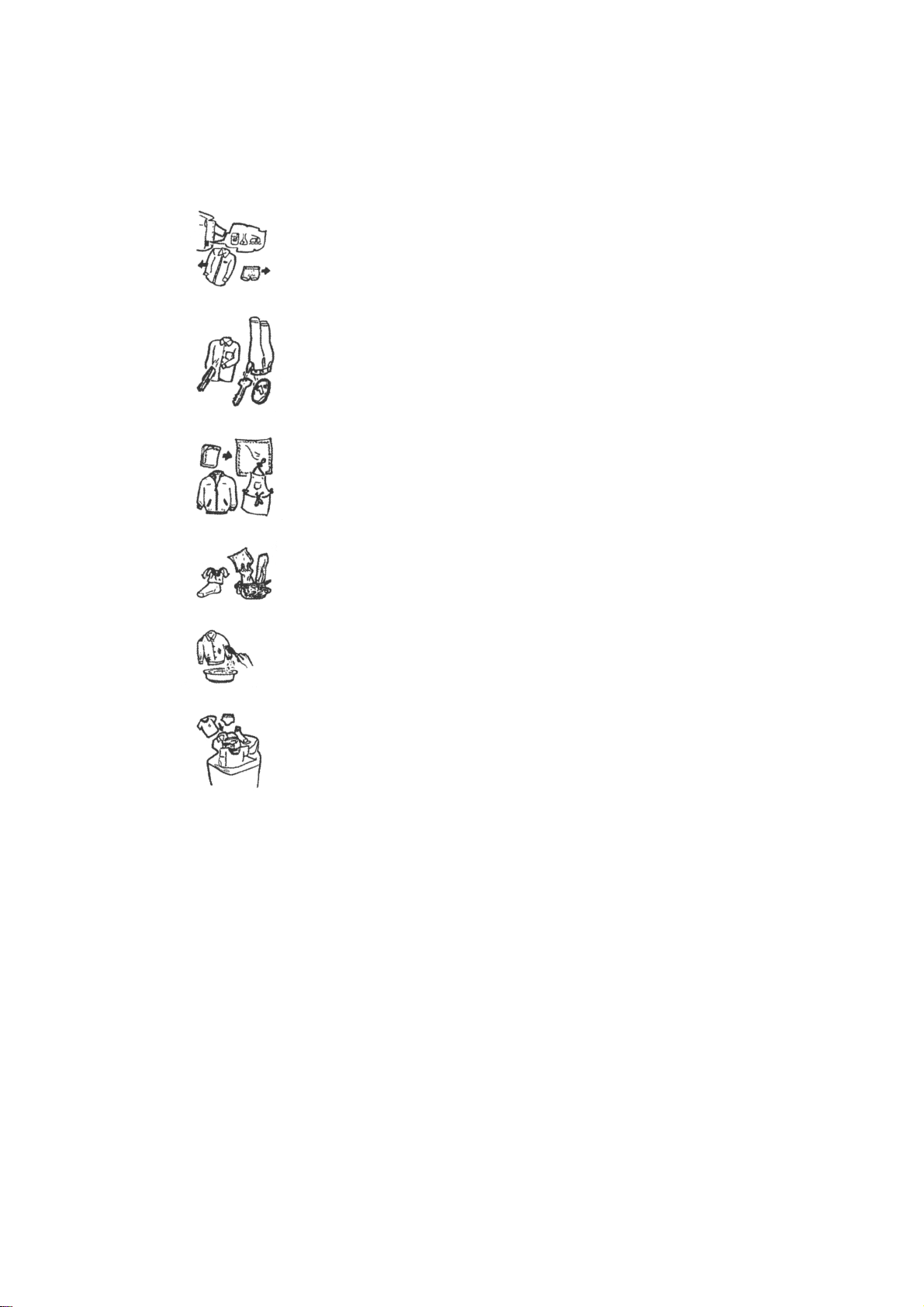

Flammable fluids (dry cleaning solvents,

kerosene, gasoline etc.) should not be

used or stored on or near your washer.

Do not add flammable fluids to your wash

water. These substances give off

vapours that can create a fire hazard or

explosion.

The appliance is not intended for use by

young children or infirm persons without

adequate supervisions.

Young children should be supervised to

ensure they do not play with the

appliance.

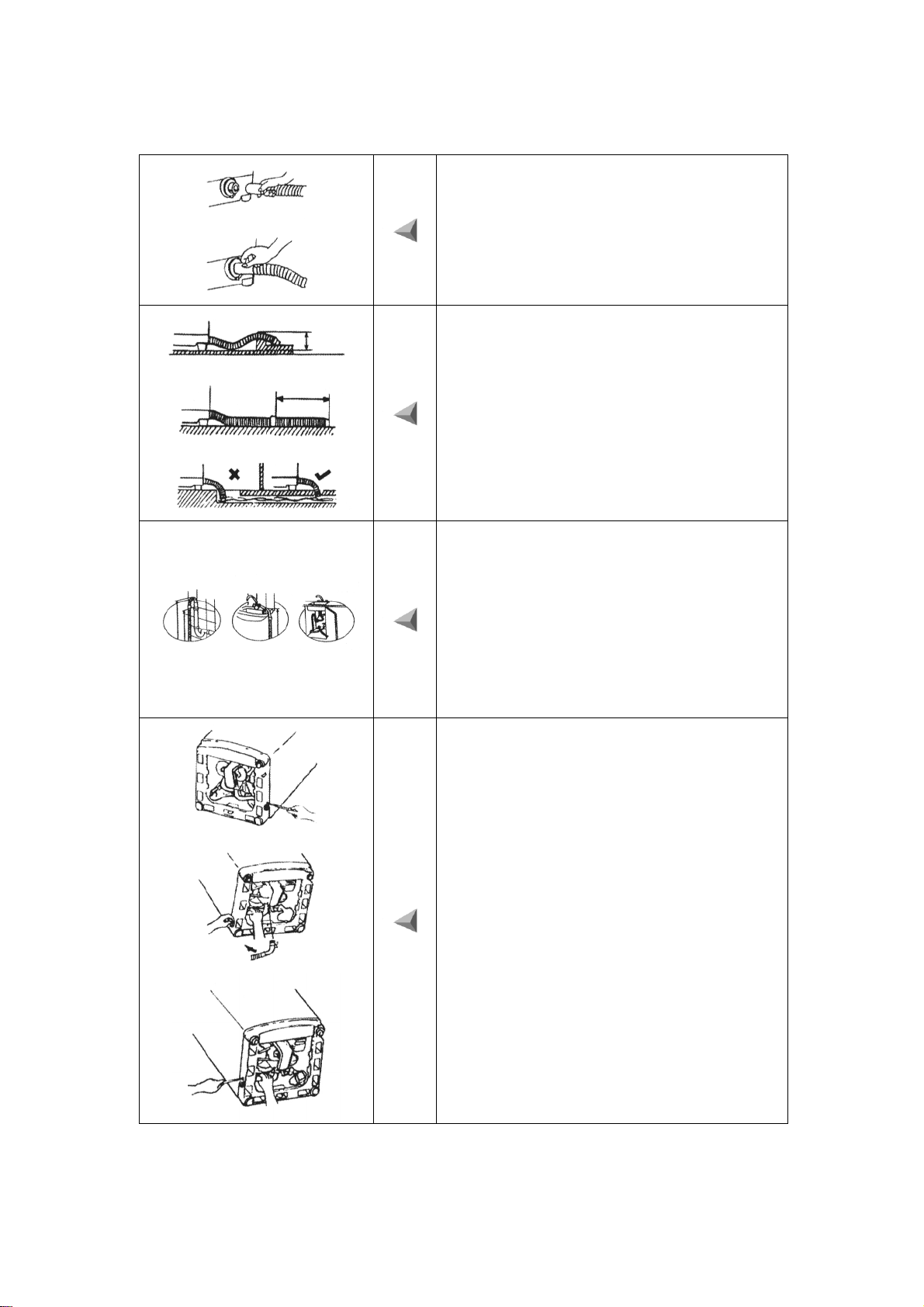

After starting a washing cycle, do not

reach into the spin basket until all motion

has stopped.

Do not tamper with the controls.

If the appliance is supplied from an

extension cord set or electrical portable

outlet device, it should be positioned so it

is not subjected to splashing or ingress

moisture.

If the supply cord is damaged, it must be

replaced by the manufacturer or qualified

service agent in order to avoid any

potential hazard.

Please….

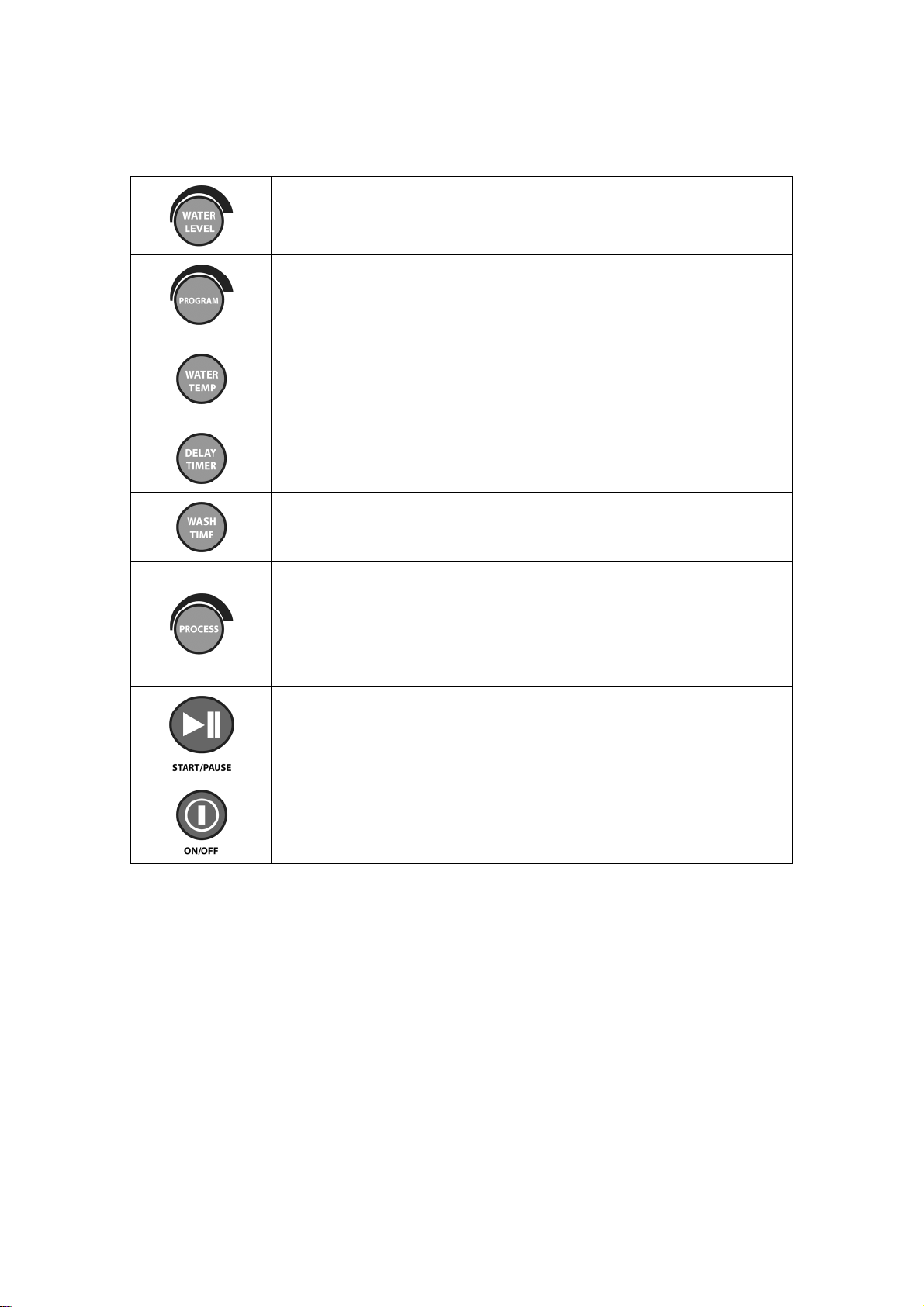

Have only a qualified person install,

repair, or replace parts on the washer.

Maintain washer properly.

Protect washer from the weather and

keep it where the temperature will not fall

below freezing.

Do no install the washer at a place of

extremely high humidity. It could cause

an electrical shock or a short circuit.

Connect washer to the correct outlet,

electrical supply, water supply, and drain

supply.

Ground washer properly.

Understanding your responsibilities

Do not use chlorine bleach and ammonia or acid (such as vinegar or rust remover) in the

same wash. Hazardous fumes can form.

Do not wash fibreglass materials. Small particles can stick to fabrics washed in following

loads and cause skin irritation.

Do not use hot water if standard temperature is over 50C (122F). It could cause

deformation of plastic parts.

Do not spray water on the control panel and back cover of the washer. It could cause fire

or electric shock.

In case of the dual valve model, if you can connect the cold-water inlet only, while the

temperature is selected as hot or warm, there can be water leakage from the

unconnected water valve.