Neptune MAH5500B Series Manual

16025861 1 December 2004

©2004 Maytag Services

Neptune Front Load Washer⎯⎯

⎯⎯

⎯Technical Information

MAH5500B*, MAH55FL*

• Due to possibility of personal injury or property damage, always contact an authorized technician

for servicing or repair of this unit.

• Refer to Service Manual 16010061 for detailed installation, operating, testing, troubleshooting, and

disassembly instructions.

All safety information must be followed as provided in Service Manual 16010061.

To avoid risk of electrical shock, personal injury or death; disconnect power to washer before servicing, unless

testing requires power.

CAUTION

!

!WARNING

Leaking

• Make sure supply hose connections are not

leaking. Check for rubber gasket damage due to

overtightening.

• Make sure end of drain hose is correctly inserted

and secured to drain facility.

• Avoid overloading which can push the door

partially open.

• Check internal hose connections

• Check tub cover. Remove, reposition and reinstall

the tub cover seal. Seal seam must be at the

top of the tub cover.

Display Lights Up When Door Opened

• This is normal behavior.

No Tumble

• Washer does not tumble for the first 30 seconds

after the door has been opened for safety pur-

poses.

• Fabric cycles such as DELICATES and HAND

WASH only tumble for a few seconds every 30

seconds.

• Check for loose connections at machine control

board, motor control board and motor.

• Perform Motor and Motor Control Test.

• Washer does not tumble during some drains and

rinse fills.

No Water Fill

• Check to make sure water supply turned on fully.

• Normal water level is only 2.5 to 5 inches inside

the spinner.

• Check for kinks in inlet hoses.

• Check for clogged inlet screens.

• Visually check hot and cold separately at

dispenser for proper flows.

• Go to No Fill Test page 6.

Noisy

• Clothes washer should be leveled properly as

outlined in installation instructions.

• Weak floors can cause vibration and walking.

• Check for loose lower front bracket

• Be sure rubber feet are installed on leveling legs.

• Check that the leveling leg lock nuts are

tightened.

• If complaint is a high-pitched noise during fill then

disconnect supply hoses and clean screens.

• Check for proper spring placement of outer tub

support springs.

• Check strut operation.

Tub is completely full of suds

• Run the clothes washer through another complete

cycle using cold water and no more detergent.

• Reduce detergent amount for that specific load size

and soil level. Towel loads have a minimal amount

of soil present and typically create more suds.

• Use high efficiency or low sudsing detergent

specially formulated for front load washers.

• Check for restricted drain system.

• Check for loose wire connections at control board

and pump.

• Check to see if belt fell off motor and pulley.

• Perform Motor and Motor Control Test.

Wet Clothes

• Very small clothes loads can cause unbalances

add additional towels.

• Excessive suds may have been present. Check

for diagnostic code 16.

• Check unbalance harness connections at all

switches and at Control Board.

.

December 2004 2 16025861

©2004 Maytag Services

• Check for restricted drain system.

• Perform Motor and Motor Control Test.

Will Not Lock

• Door not all the way closed.

• Check electrical connections at lock assembly and

machine control board. Go to Door Lock Test.

Will Not Unlock

• Unplug and reconnect the power cord and wait 2

minutes to see if machine unlocks.

• Check for door locked switch circuit to be closed

at machine control. (See board input/output chart)

• Check to make sure belt has not fallen off.

• Check for loose electrical connections at door lock

and at machine control board.

• Perform Motor and Motor Control Test.

Will Not Start

• Plug cord into live electrical outlet.

• Check fuse or reset circuit breaker.

• Push the START/PAUSE button to start the clothes

washer.

• Close door and push the START/PAUSE button to

start the clothes washer. START/PAUSE LED

should change from flashing to on continuously.

• Check to see if the washer is in a pause or soak

period in the cycle. Wait briefly and it may start.

• Check for restricted drain system.

Will Not Drain

• Check for restricted drain system.

• Check low and high water levels. Go to No Fill test

• Check for 120 VAC at the pump when a spin cycle

is selected.

Wrong Water Temperature

• Too Hot/Too Cold; since this product uses a low

amount of water, the board regulates the incom-

ing flow to temper the actual temperature of the

water in the tub. This may appear to be

significantly warmer/cooler than expected.

• Are both faucets on fully?

• Make sure temperature selection is correct.

• Make sure hoses are connected to correct

faucets and inlet connections. Flush water line

before filling washer.

• Check the water heater. It should be set to

deliver a minimum 120°F (49°C) hot water at the

tap. Also check water heater capacity and

recovery rate.

• If the water heater is located a long distance from

washer, water line may need to be purged prior to

starting wash cycle.

• Disconnect inlet hoses and clean screens.

• This washer can sense if the fill hoses have been

reversed between hot and cold. If the fill hoses on

the washer were previously installed incorrectly

and then corrected, the washer will need to be

run through a Hot / Cold cycle. If not resolved,

check for proper resistance on the water valve

thermistor. (See board input/output chart)

Codes Displayed On Console

If owner observes codes on display, see table

below.

Sd = Suds: Machine has detected high level of

suds. The machine will alter its cycle for

this situation. Use an HE detergent or cut

down on the amount of detergent slightly.

This can be more likely on towel loads,

consider HE detergent especially for these

loads.

do = Door is Open: The door of the machine is

open. Please make sure door is fully closed

before starting cycle.

Continued on next page..........

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

16025861 3 December 2004

©2004 Maytag Services

System Diagnostics

SERVICE MODE

The service mode provides service personnel the

ability to verify the operation of the washing machine.

The service mode can be entered in the middle of

any wash cycle. While in the service mode, the

servicer can start a variety of special service tests.

Accessing Service Mode:

Pressing down the delicates and heavy soil keys for

3 seconds places the machine in the service mode.

Motor speed will be displayed when started. To exit

Service Mode, press delicates and heavy soil keys

for 3 seconds again. The following table lists the

various tests available while in the Service Mode,

which can be accessed by pressing the following

keys:

Membrane Pad Check Test

While in service mode, pressing the wrinkle free

key will start a membrane pad switch check.

The membrane check involves turning all the em-

bedded LED lights on the membrane pad except

for the wrinkle free key. All the LEDs can be

toggled by pressing the key associated with the

LED. At any point, if there are 10 minutes of inactiv-

ity, then this test will exit. Press the off key twice

within 30 seconds to cancel test.

Fast Time Down Test

While in service mode, pressing the quick key

will advance the program to the next wash cycle.

CONSUMER CODES: Cont'd

od = Open the Door: The door has not been

opened since the end of the last cycle. As a

safety check the door must be opened at the

completion of every cycle.

nF = No fill: the machine has tried to fill but cannot.

See No Water Fill.

PF = Power failure: power to the machine has been

lost during the last cycle. This may occur on

start up of a new machine due to factory

testing.

LO = Locked: Door is locked (failed to unlock) - the

machine has repeatedly tried to unlock but

cannot. Push door closed to make sure

nothing from the inside is pressing against

the door which make keep it from unlocking.

FL = Failed to lock: the machine has repeatedly

tried to lock the door but cannot. Make sure

the door is shut completely

nd = No drain - the machine has tried to drain but

cannot.

Lr = Locked Rotor: the machine has repeatedly

tried to turn the motor but cannot.

retnEoT

syeKsserP

laicepS

noitcnuF/tseT

tixEoT

noitcnuF

lamroN rotoMswohS

euqroT

esuaP/tratS

eerFelknirW daPenar

bmeM

kcehC

ro.ces5tiaW

eciwtffOsserp

kciuQ nwoDemiTtsaF

tseT

esuaP/tratS

nipStseTnipSkciuQesuaP/tratS

lioSthgiL

s

yalpsiD

erawtfoS

noisiveR

rebmuN

esuaP/tratS

setacileD ecivreSkciuQ

elcyC esuaP/tratS

esniR tuptuOdraoB

tseT esua

P/tratS

kaoserP citsongaiD

sedoC esuaP/tratS

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

December 2004 4 16025861

©2004 Maytag Services

foegatS

elcyChsaW

oTsecnavdA

kaoserPkaoserPfodnE

hsaW fosetuniM5yrevE

emiThsaW

niarD/nipSehTfopetSyrevE

eliforP

nipS

esniResniRfodnE

egnaRdeepSdeyalpsiD

mpr99-0)a )lautca(99-0

mpr999-001)b 01/deepS

Quick Service Cycle

While in service mode, pressing the delicates key

will start a quick service cycle. This will be a quick

check of all systems.

The following steps will be followed.

1. Energize the cold and bleach water valves. Fill to

Low level, then turn bleach and cold off.

2. Energize the hot and fabric softener water valves. Fill

to high level, then turn all valves off.

3. Lock the door.

4. Tumble using 7/3 tumble pattern for 12 sec.

5. Turn the drain on.

6. Spin to 800 RPM using default rates.

7. End spin and coast down.

8. Unlock the door when the RPM is zero.

9. Display a ‘PA’ (Passed) on continuously for 10 sec-

onds if no diagnostic codes were logged during this

test.

The up arrow if pressed will advance to the next step.

The right most dot will be turned on as an indication

of failure and stay on until quick service cycle test

has reached the end. Any diagnostic code logged

during this test will result in failure of the test, but will

not necessarily stop the test. While in quick service

cycle, the pressing of the hand wash will suspend

the machine at this step for 30 minutes until the

Hand Wash key is pressed again. All LED’s will

flash on and off while the cycle is suspended, or on

hold.

Motor Drive System

To check the system, check the board for proper

output to the motor control. Performing a board

output test does this. Then perform the Motor

Control Board Output Test.

Motor Control Board Output Test

1. Disconnect power to the washer.

2. Remove the front panel and pull the JP4 Connector

from the motor control board.

The following Quick Spin test steps are as follows:

1) Lock the door.

2) Spin to 350 rpm and hold for 6 seconds.

3) Spin to 550 rpm and hold for 6 seconds.

4) Spin to 600 rpm and hold for 6 seconds.

5) Spin to 650 rpm and hold for 6 seconds.

6) Spin to 800 rpm and hold for 6 seconds.

If the Spin key is pressed again during the Quick Spin

test, the current speed will be held indefinitely. Press-

ing the Spin key again will allow the quick test to

proceed as listed above.

When the washer is in the Service Mode, the speed

will be displayed as a two digit number or a letter/

number.

Quick Spin Test

While in service mode, the pressing of spin key shall

start the washer in the quick spin mode.

3. Reconnect the washer power cord to supply

voltage. Make sure the door is closed.

4. Press delicates and heavy soil keys for 3 sec-

onds to activate Service Mode.

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

16025861 5 December 2004

©2004 Maytag Services

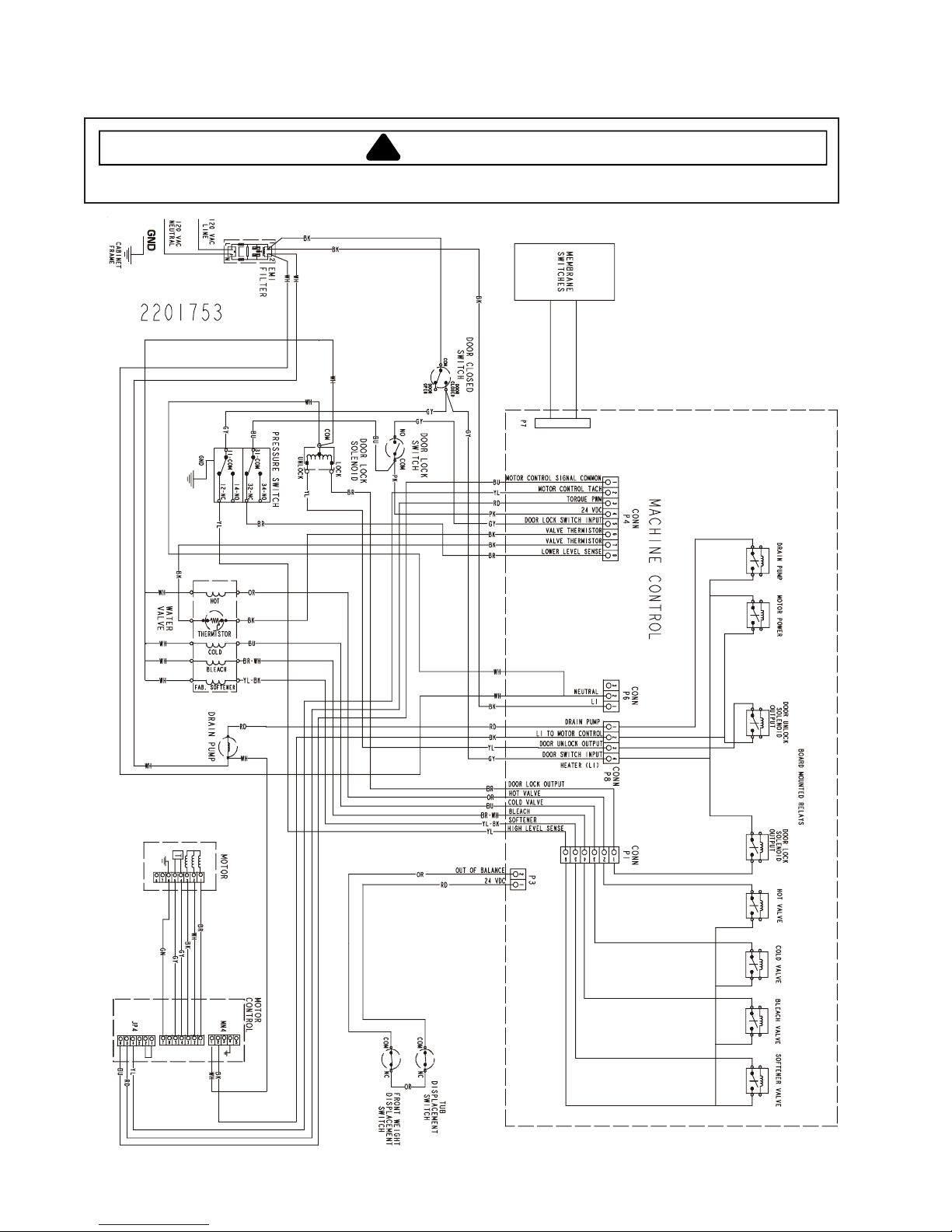

Figure 1

Motor Control Board/JP4 Connector

Figure 2– Schematic – Motor Harness

8. If motor does not run;

• Check for 120 VAC at the motor control board har-

ness. See Figure 1.

If voltage is present, then problem lies with the

motor and motor control system.

• Check for loose electrical connections at mo-

tor and motor control board.

• Check phase windings of the motor. See Fig-

ure 2. If motor windings are good, replace the

motor control board.

If voltage is not present;

• Check loose electrical connections at machine

control board or broken wires in harness.

• Check door actuator switch and related wiring.

Door Lock Test

Placing the washer into the Service Mode and

manually locking and unlocking the

door mechanism through the control panel can

verify the door lock. Note: The relay on the control

board for the door unlock mechanism is disabled if

the motor control board indicates the spinner speed

is > 7 RPM.

1. Place the washer into Service Mode. (See

Service Mode)

2. Advance to the Board Output Test and press

max extract to lock the door. A lock signal

will be sent to the solenoid every second for 10

seconds. If the door does not lock; use a

voltmeter, look for 120VAC, 60 millisecond

pulse to the locking solenoid.

7. Press stain cycle to start the motor control

output test. This will send 120VAC to the motor

control board. The motor control will immediately

execute a test routine and the motor should run,

rotating the spinner at 50 rpm.

3. If signal is present, then the door lock sole-

noid is bad and the door lock mechanism must

be replaced. (Assuming the door was fully

closed.) To stop the signal, press max extract

again.

4. If signal is not present, check electrical

connections at switch or at control board.

Check for proper outputs from the control board

at Conn P1(1) and Neutral leg of power cord. If

voltage is present, fix electrical connections or

change wire harness. If no voltage is found, go

to P8(4) and Neutral on power cord to verify

120VAC coming into the board. If voltage is not

present check the door actuator switch. (make

sure door is closed.) If voltage is present,

change machine control board.

5. Access Board Output Test by touching the rinse

key to activate.

6. The door must be locked to access Motor Con-

trol Board Output Test. To lock the door press

max extract. Press max extract again stop the

door lock output test once the door is locked.

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

December 2004 6 16025861

©2004 Maytag Services

5. Advance to the Board Output Test and press

extra rinse to unlock the door. An unlock

signal will be sent to the solenoid every second

for 10 seconds.

If the door does not lock, use a voltmeter, look

for 120VAC, 60 millisecond pulse to the locking

solenoid.

If signal is present, then the door lock sole-

noid is bad and the door lock mechanism must

be replaced. To stop the signal, press extra

rinse again.

If signal is not present, check electrical

connections at switch or at control board.

Check for proper outputs from the control board

at Conn P8(3) and Neutral leg of power cord. If

voltage is present, fix electrical connections or

change wire harness. If no voltage is found, go

to P8(4) and Neutral on power cord to verify

120VAC coming into the board. If voltage is not

present check the door actuator switch. (make

sure door is closed.) If voltage is present,

change machine control board.

No Fill Test

1. Close the door and start a spin cycle to drain all

water from the washer to reset the pressure switch.

2. Press Off and open door to verify all water is re-

moved from the washer. If water still present, go

to Will Not Drain diagnostics.

3. If water is drained out, close the door and go to

Service Mode, press delicates and heavy soils

keys for 3 seconds. If it is likely to need access to

the water valve for voltage checks, consider raising

the top cover now and close the door so that the

following steps will not need to be repeated.

4. While in service mode, press the hand wash key

places the washer into the Board Input test.

5. Check the lower water level by pressing the hand

wash key.

6. "_1" indicates the washer is full. If full, check the

lower water level input at the machine control board

by reading DC voltage between P4(4) and P4(8).

If voltage is present at the machine control board,

check voltage at pressure switch between BU and

BR . If voltage present at pressure switch, re-

place pressure switch. If voltage is not present at

pressure switch, check or replace harness. If no

voltage is present at the Machine control board,

replace the machine control board.

7. "_0" indicates the washer is empty: If empty,

press the wrinkle free key to check the high wa-

ter level.

8. "--1" indicates full. If full, check the high water

level input at the machine control board by

reading 120 VAC voltage between P1(4) and

Neutral P6(2). If120 VAC is not present at the

machine control board, check continuity at

pressure switch across GY and YL. If no

continuity, replace pressure switch. If continuity,

check door switch and harness to pressure switch

and harness from pressure switch to Machine

control board. If 120 VAC is present at the

Machine control board, replace the machine

control board.

9. "--0" indicates empty. If empty, exit board input

test mode by pressing the start/pause key. Then

enter board output test mode by pressing the rinse

key.

10. Turn the cold water valve on by pressing the wrinkle

free key. Check for cold water flow at the dispenser.

If no cold water flow, check the cold water valve for

120 VAC between BU and WH. If 120 VAC is

present at the cold valve, replace the water valve. If

120 VAC is not present at the cold valve, check for

120 VAC at the machine control board between

P1(3) and Neutral. If 120 VAC is present at the

machine control board, check or replace the

harness. If 120 VAC is not present at the machine

control board, replace the machine control board.

If cold water flows, turn the cold valve off by pressing

the wrinkle free button.

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

16025861 7 December 2004

©2004 Maytag Services

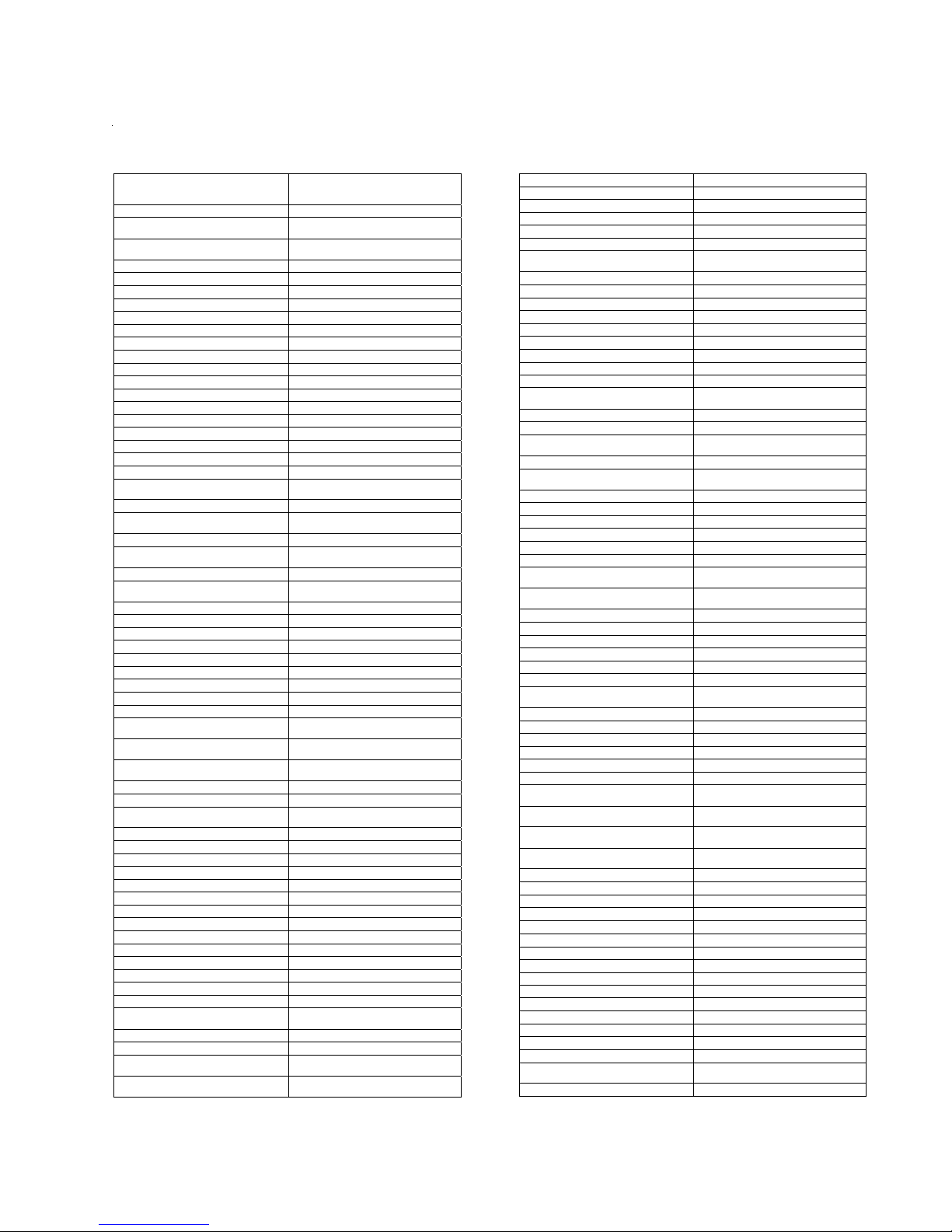

Description Connector/

Pin Number

Reference

To

Connector/

Pin Number

Voltage Comments

Bleach water valve output P1(4) P6(2) 120 VAC

Cold water valve output P1(3) P6(2) 120 VAC 500-1K ohms

Door Lock output P1(1) P6(2) 120 VAC 60 millisecond pulse

Door lock switch input P4(5) P4(4) 24 VDC

Door switch input P8(4) P6(2) 120 VAC

Door unlock output P8(3) P6(2) 120 VAC 60 millisecond pulse

Drain pump output P8(1) P6(2) 120 VAC

High water level - input P1(6) P6(2) 120 VAC

Hot water valve output P1(2) P6(2) 120 VAC 500 - 1K ohms

L1- machine control board P6(1) P6(2) 120 VAC

L1- motor control P8(2) P6(2) 120 VAC

Lower water level - input P4(8) P4(4) 24 VDC

Motor control tach P4(2) P4(4) 24 VDC

Neutral (120 VAC) P6(2) Neutral

Unbalance input P3(2) P4(4) 24 VDC

Softener water valve P1(5) P6(2) 120 VAC

Torque PWM P4(3) P4(4) 24 VDC

Water valve thermistor P4(6) P4(7) (10K-85K ohms)

Machine Control Board INPUT/OUTPUT

11.Turn the hot on by pressing the cotton sturdy key. Check for hot water flow at the dispenser. If no hot water

flow, check the hot water valve for 120 VAC between OR and WH. If 120 VAC is present at the hot valve, replace

the water valve. If 120 VAC is not present at the hot valve, check for 120 VAC at the machine control board

between P1(2) and Neutral. If 120 VAC is present at the machine control board, check or replace the harness.

If 120 VAC is not present at the machine control board, replace the machine control board.

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

High Level Sense (HWL)

Softener Water Valve (SWV)

Bleach Water Valve ( BWV)

Cold Water Valve (CWV)

Hot Water Valve (HWV)

Door Lock Solenoid ( Lock or DL)

Door Switch (DS)

Door Unlock Solenoid (DUL)

Motor (MTR)

Drain Pump (DP)

L1

N

Lower Wash Level Sense (LWL)

Valve Thermistor (WT)

Valve Thermistor (WT)

Door Lock Actuator Switch (DLS)

+24 Volts (24V)

Torque PWM (PWM)

Motor Control Tach (Tach)

Mtr Control Signal Common (Comm)

P3

+24 Volts (24V)

Unbalanced Switches(UB)

Wiring Harness

Connections

Letters in parenthesis designate

markings on the Control Board

P4

December 2004 8 16025861

©2004 Maytag Services

DIAGNOSTIC CODES:

When a problem with the wash system is detected

a diagnostic code is assigned and logged into the

control board memory with the last cycle count at

which it occurred. An assigned diagnostic code

indicates the washer must be serviced. The control

board will allow as many diagnostics as possible

for the machine to continue running. In some

cases, when the washer shuts down, something

shall be displayed on the display until the con-

sumer selects the off key. See the table for specific

actions or references to where the proper action is

defined.

Accessing Diagnostic Codes

After the machine is in the service mode, pressing

presoak key will display a ‘d’ and turn the LED on

above the presoak key. The diagnostic codes can

be viewed by using the arrow keys. The down

arrow will go down the list.

Clearing Diagnostic Code List

While viewing the diagnostic code listing, the

diagnostic code list can be cleared from memory

by pressing the heavy soil and presoak keys for 3

seconds.

Board Output Test Table

Key Pressed: Function Performed

Cotton/sturdy Hot Water Valve

Wrinkle Free Cold Water Valve

Delicates Bleach Valve

Hand Wash Fabric Softener Valve

Presoak Drain Pump

Stain Cycle Motor Control

Extra Rinse

Unlock Door (Sends a

pulse every second for

10 seconds)

Max Extract

Lock Door (Sends a

pulse everysecond for

10 seconds)

Board Input Test

While in service mode, pressing the hand wash key

places the washer into the Board Input Test.

This test will turn on a specified input after a key

press. All output will be turned off after 10 minutes.

Board Output Test

While in service mode, pressing the rinse key

places the washer into the Board Output Test.

This test will turn on a specified output after a

key press. All outputs will continue on until the

key is pressed again, or it will turn off after 10

minutes. Note, to check the fabric and bleach

valves, you must turn on the hot or cold water

valves first.

**Two digit display = 0-99;

plus max extract LED =100,

plus max extract LED and extra rinse LED = 200.

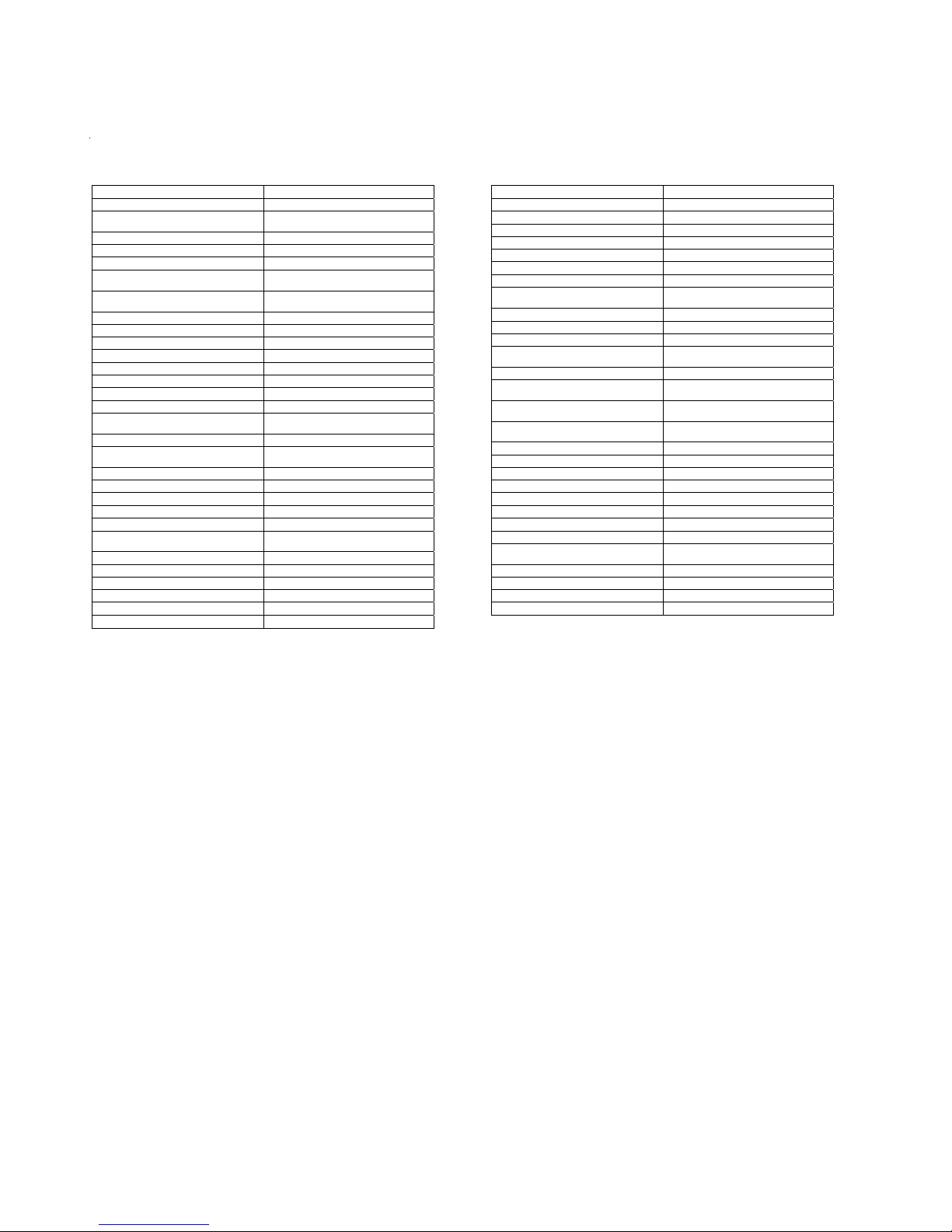

Board Input Test Table

Action Press Key Feedback

Door Position cotton/sturdy

dO

Open

Latch Position delicates

LO

Unlocked

Ll

Locked

High Water

Level

wrinkle free

--

O

Below Level

--

l

Above Level

Low Water

Level

hand wash

_O

Below Level

_l

Above Level

Unbalance

Circuit

temp down

uO

Balanced

ul

Unbalanced

Water Inlet Temp temp up Degrees

o

F

Vibration Signal spin 0-225**

Brown out rinse 0-225**

Accelerometer

circuit

quick

PA

=Passes

FA

=Fails

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

16025861 9 December 2004

©2004 Maytag Services

Diag.

Code

Description Trigger Action to be Taken

01 No drain The water level fails to

drop below the low

water level in final spin

Will display "

nd

"

Go to "

Will Not Drain

"page3.

02 The door fails to

unlock

Door failed to unlock

after 11 attempts

Will display "

LO

"

Go to "

Will Not Unlock

"page3.

03 No fill Continuous fill of 12

minutes.

Will display "

nF

"

Go to "

No

Water

Fill

"page2.

04 The door fails to

lock

Door failed to lock

after 11 attempts

Will display "

FL

"

Go to "

Will Not Unlock

"page

3.

.

05 Continuous

unbalanced circuit

(Duringspinonly)

See section for

unbalanced loads.

Go to "

Wet Clothes

"page

2

.

06 Locked rotor Motor not turning after

10 consecutive retry

attempts

Will display "

Lr

"

Go to "

Motor Control Board Output

Test

"page

5

.

07

(Not Used)

DIAGNOSTIC CODES:

Number of Cycles Since Code Assigned

While the Diagnostic code is displayed, if the

cotton/sturdy key is pressed and held, the machine

shall display the number of cycles ago the code

occurred while the key is held. Also, while this key

is being held, the key will turn on the LED. When

this key is let up, then the code is again displayed.

If there are no codes available, ‘- -‘ will be displayed

while this key is pressed. If the code is over 99

cycles ago, then ‘- -‘ will be displayed.

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

December 2004 10 16025861

©2004 Maytag Services

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

Diag.

Code

Description Trigger Action to be Taken

08 Water sensor level

fault

The low water level is

not satisfied before the

high water level

contacts are opened

in the pressure switch

Go to "

No Water Fill Test

" page 2.

09 (Not Used)

10 Low rpm

unbalanced load

Never reached 400

rpm due to an

unbalanced load

Go to "

Wet Clothes

"page2.

11 Non-volatile

memory error

Difficulty in reading

memory

1. Go to "

Clearing Diagnostic Code

"

page 9.

2. Unplug and replug in power cord

washer at power supply outlet

3. If a condition still exists, replace

machine control board.

12-14 (Not Used)

15 Stuck key A key is sensed to be

pressed for more than

75 seconds, the key

shall be assumed to

be stuck

Replace console/membrane switch.

16 High speed not

achieved due to

high motor torque

Speed never went over

400rpmduringamain

wash cycle because

the maximum torque

was seen for too long

Go to "

Wet Clothes

"page2.

17 Door actuator

switch was not

seen open since

the last final spin

The door has not been

opened after a

complete wash cycle.

Will display "

od

"

Check for:

- Customer may have tried to repeat

wash cycle without opening door

-Go to "

Door Lock Test

" page 6.

18 Door lock switch

seen open during

cycle

Door lock switch is

read as open with

motor running

- Clear the diagnostic code, page 9.

recheck;

"Go to "

Door Lock Test

"page6.

16025861 11 December 2004

©2004 Maytag Services

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Troubleshooting

Diag.-

Code

Description Trigger Action to be Taken

19 Door lock sense or

motor control relay

failed

Door lock sense switch

on machine control

board is read as open

with motor running

See list for diagnostic code 18

20 Door switch input

seen open during

cycle

Door switch is open Go to "

Door Lock Test

", page 6.

21 Door sense switch

failed on machine

control board

Door sense switch is

read as open and the

door locked switch is

read as locked

Go to

"Door Lock Test

", page 6.

22 Door switch seen

open during cycle

Door switch is read as

open and the door

locked switch is read

as locked

Go to "

Door Lock Test

", page 6.

23 Door failed to

unlock

Door lock is locked

and a user tries to

start a cycle

Go to "

Will Not Unlock

"page3.

24 Motor over speed Motor tach signal is

seen at maximum

speed

- Replace motor control board

25 Motor tach signal

exists without

motor running

Tach signal exists

without torque

commanded.

- Replace motor control board

26-27 (Not Used)

28 Valve thermistor

failure

Abnormal high/low

temperature or ohm

resistance seen

Go to "

Wrong Water Temperature

"page

3.

December 2004 12 16025861

©2004 Maytag Services

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing,

unless testing requires it.

Wiring Diagram

16025861 13 December 2004

©2004 Maytag Services

Traduction du schéma/de l'e

s

quisse de l'anglais au fran

ç

ais

©2004 Maytag Services

Technical Sheet Supplement1

14 PIN UPPER TO LOWER HARNESS

CONNECTOR

CONNECTEUR DE LIAISON DE

FAISCEAUX SUPÉRIEUR À

INFÉRIEUR À 14 BROCHES

AUGER MOTOR (MTR) MOTEUR POUR AGITATEUR (MTR)

AUGER MOTOR HARNESS

FAISCEAU DE MOTEUR

D’AGITATEUR

AUTOMATIC ICE MAKER

MACHINE À GLAÇONS

AUTOMATIQUE

BASE PAN GROUND TERRE DU PLATEAU

BLACK (BK) NOIR (NR)

BLEACH VALVE ROBINET D’EAU DE JAVEL

BLOWER MOTOR MOTEUR DU VENTILATEUR

BLUE (BU) BLEU (BL)

BOARD MOUNTED RELAYS RELAIS MONTÉS SUR TABLEAU

BODY BÂTI

BOOSTER COIL BOBINE DE SURTENSION

BROWN (BR) MARRON (MA)

CABINET HARNESS FAISCEAU D’ARMOIRE

CAP COND

CAPACITOR CONDENSATEUR

CAVITY HEATER CHAUFFERETTE À LOBE

CIRCUIT BOARD CARTE DE CIRCUITS IMPRIMÉS

CIRCUIT DIAGRAM SCHÉMA DU CIRCUIT

COLD VALVE ROBINET D'EAU FROIDE

COM COM

COMP GROUND

TERRE DE CIRCUIT DE

COMPENSATION

CONDENSER CONDENSATEUR

CONDENSER FAN MOTOR

MOTEUR DE VENTILATEUR DU

CONDENSEUR

CONTROL BOARD TABLEAU DE COMMANDE

CONTROL BOARD AND DISPLAY TABLEAU DE COMMANDE ET

AFFICHEUR

CONTROL CIRCUIT CIRCUIT DE COMMANDE

CONTROL CIRCUIT DIAGRAM

SCHÉMA DU CIRCUIT DE

COMMANDE

CONTROL HARNESS FAISCEAU DE COMMANDE

DAMPER REGISTRE

DEFROST TERMINATOR TERM INATEUR DE DÉGIVRAGE

DISPENSER DISTRIBUTRICE

DISPLAY HARNESS FAISCEAU D’AFFICHEUR

DISPLAY PCB AFFICHEUR PCB

DOOR CLOSE SWITCH CONTACTEUR DE PORTE FERMÉE

DOOR CLOSED PORTE FERMÉE

DOOR HINGE CHARNIÈRE DE PORTE

DOOR LOCK SOLENOID OUTPUT

SORTIE SOLÉNOÏDE DE

VERROUILLAGE DE PORTE

DOOR LOCK SWITCH

CONTACTEUR DE PORTE

VERROUILLÉE

DOOR LOCK SWITCH INPUT

ENTRÉE DE CONTACTEUR DE

VERROUILLAGE DE PORTE

DOOR SOLENOID SOLÉNOÏDE DE PORTE

DOOR SWITCH CONTACTEUR DE PORTE

DOOR UNLOCK SOLENOID OUTPUT

SORTIE SOLÉNOÏDE DE

DÉVERROUILLAGE DE PORTE

DRAIN PUMP POMPE D’ÉVACUATION

DRIP TRAY PLATEAU D’ÉGOUTTOIR

DRYER MOTOR MOTEUR DE SÉCHEUSE

ELECTRONIC CONTROL COMMANDE ÉLECTRONIQUE

ELECTRONIC SWITCH CONTACTEUR ÉLECTRONIQUE

EMI FILTER FILTRE EMI

EVAPORATOR FAN VENTILATEUR ÉVAPORATEUR

FA FA

FABRIC SOFTENER ADOUCISSEUR DE TISSUS

FF THERMISTOR THERMISTANCE À BASCULE

FLAT WIRE FIL MÉPLAT

FLOAT SWITCH CONTACTEUR À FLOTTEUR

FOUNTAIN DISPLAY AFFICHEUR DE FONTAINE

FOUNTAIN LIGHT VOYANT DE FONTAINE

FRONT WEIGHT DISPLACEMENT

SWITCH CONTACTEUR DE DÉSÉQUILIBRE

DU POIDS AVANT

FUSE FUSIBLE

FUSE BLOCK BLOC FUSIBLES

FZ LITE SWITCH

CONTACTEUR DE VOYANT DU

CONGÉLATEUR

FZ. DOOR HARNESS

FAISCEAU DE PORTE DU

CONGÉLATEUR

GAS HEATER CHAUFFERETTE AU GAZ

GRAY (GY) GRIS (GR)

GREEN (GN) VERT (VE)

HEAT SINK DISSIPATEUR DE CHALEUR

HEATER CHAUFFERETTE

HEATER RELAY RELAIS DE CHAUFFERETTE

HEATER W ITH STEAMER ASSEMBLY

ENSEMBLE CHAUFFERETTE /

ÉTUVEUSE

HIGH HEAT TEMPÉRATURE ÉLEVÉE

HIGH LEVEL SENSE CAPTEUR DE HAUT NIVEAU

HIGH T'STAT THERMOSTAT SUR HAUT

HIGH VOLTAGE HAUTE TENSION

HOLDING COIL BOBINE DE MAINTIEN

HOT VALVE ROBINET D’EAU CHAUDE

HV PCB HARNESS FAISCEAU HT PCB

IGNITOR DISPOSITIF D’ALLUMAGE

IM VALVE ROBINET DE MACHINE À GLAÇONS

INERTIAL BALANCE SWITCH

CONTACTEUR D’ÉQUILIBREUR

D’INERTIE

INPUT ENTRÉE

INTERLOCK SWITCH INTERRUPTEUR D’INTERDICTION

INTERLOCK SWITCH SCHEMATIC

SCHEMA INTERRUPTEUR

D’INTERDICTION

LAMP LAMPE

LID LOCKED INPUT

ENTRÉE DE COUVERCLE

VERROUILLÉ

LINE FILTER FILTRE DE LIGNE

LOCKING VERROUILLAGE

LOGIC BOARD CARTE LOGIQUE

LOW HEAT TEMPÉRATURE BASSE

LOW VOLTAGE BASSE TENSION

LOWER DRYER SIDE CÔTÉ INFÉRIEUR DE LA SÉCHEUSE

LOWER FREEZER LIGHT

VOYANT DU CONGÉLATEUR

INFÉRIEUR

LOWER HARNESS CONNECTOR

CONNECTEUR DE FAISCEAU

INFÉRIEUR

LOWER LEVEL SENSOR CAPTEUR DE NIVEAU INFÉRIEUR

MACHINE CONTROL COMMANDE DE MACHINE

MAG TCO MAG TCO

MAGNETRON MAGNÉTRON

MAIN PRINCIPAL

MAIN VALVE ROBINET PRINCIPAL

MC HARNESS

FAISCEAU DE COMPARTIMENT DE

MACHINE

MEMBRANE SWITCHES CONTACTEURS À MEMBRANE

MICROFARAD MICROFARAD

MONITOR SWITCH INTERRUPTEUR DE SURVEILLANCE

MOTOR MOTEUR

MOTOR CAPACITOR CONDENSATEUR DU MOTEUR

MOTOR CONTROL COMMANDE DE MOTEUR

MOTOR CONTROL SIGNAL COMMON

COMMUN DU SIGNAL DE

COMMANDE DE MOTEUR

MOTOR CONTROL TACH

TACHYMÈTRE DE COMMANDE DE

MOTEUR

MOTOR HARNESS CONNECTIONS

CONNEXIONS DU FAISCEAU DU

MOTEUR

MOTORIZED DAMPER

REGISTRE À ENTRAÎNEMENT

MÉCANIQUE

NEUTRAL NEUTRE

NOISE FILTER FILTRE ANTIPARASITES

OPTION OPTION

ORANGE (OR) ORANGE (OR)

OUT OF BALANCE DÉSÉQUILIBRE

OUTPUT SORTIE

OVEN LIGHT LUMIÈRE DU FOUR

OVEN THERMAL LINK LIAISON THERMIQUE DU FOUR

OVERLOAD SURCHARGE

OVERLOAD PTC RELAY RELAIS CTP DE SURCHARGE

PCB CONTROL COMMANDE PCB

PINK (PK) ROSE (RO)

POWER ALIMENTATION

POWER CORD CORDON D’ALIMENTATION

POWER RELAY RELAIS D’ALIMENTATION

POWER TRANSFORMER

TRANSFORMATEUR

D’ALIMENTATION

PRE VALVE (BLEACH) PRÉ-LAVAGE (JAVEL)

December 2004 14 16025861

©2004 Maytag Services

Traduction du schéma/de l'esquisse de l'anglais au français

Technical Sheet Supplement

©2004 Maytag Services

2

PRESSURE SWITCH MANOSTAT

PRESSURE VALVE SOUPAPE DE PRESSION

PRIMARY INTERLOCK SWITCH

INTERRUPTEUR D’INTERDICTION

PRIMAIRE

REACTOR BOBINE DE RÉACTANCE

RECTIFIER REDRESSEUR

RED (RD) ROUGE (RO)

REF LIGHTS HARNESS

FAISCEAU DE VOYANTS DU

RÉFRIGÉRATEUR

REF. DOOR HARNESS

FAISCEAU DE PORTE DU

RÉFRIGÉRATEUR

RELAY 1 RELAIS 1

RELAY 2 RELAIS 2

RELAY BOARD CARTE DE RELAIS

RES RÉS

RESISTANCE RÉSISTANCE

RIBBED CANNELÉ

ROTOR ROTOR

RUN CAP CONDENSATEUR DE MARCHE

SCHEMATIC CONDITIONS: DOOR

OPEN CONDITIONS DU SCHÉMA : PORTE

OUVERTE

SECOND COIL DEUXIÈME BOBINE

SECONDARY INTERLOCK SWITCH

INTERDICTION D’INTERDICTION

SECONDAIRE

SENSOR BARS BARRES DE CAPTEUR

SHAKER ASSEMBLY ENSEMBLE D'AGITATEUR

SNUBBER AMORTISSEUR

SOFTENER VALVE ROBI NET D’ADOUCISSEUR

SOLENOID SOLÉNOÏDE

SPORTS FILL SWITCH

INTERRUPTEUR DE REMPLISSAGE

UNIPOLAIRE - UNIDIRECTIONNEL

STATOR STATOR

SUPER COOL TRÈS FRAIS

SUPPLY LINE CONDUITE D’ALIMENTATION

SYSTEM RELAY RELAIS DE SYSTÈME

TAN (TN) BRONZE (BR)

TCO (MAG) TCO (MAG)

TERM BLOCK BORNIER

TERMINAL BOX BOÎTIER DE CONNEXIONS

THERMAL FUSE FUSIBLE THERMIQUE

TOROID TORE

TORQUE COUPLE

TOUCH CONTROL COMMANDE TACTILE

TOUCH PAD PAVÉ TACTILE

TRIAC TRIAC

TUB DISPLACEMENT SWITCH

CONTACTEUR DE DÉPLACEMENT

DE CUVE

TUB SENSOR CAPTEUR DE CUVE

TUB SHIELD PROTECTEUR DE CUVE

TUBE LIGHT LAMPE TUBE

TUMBLE DRYER SENSOR

CAPTEUR DE TAMBOUR DE

SÉCHEUSE

TUMBLER MOTOR MOTEUR DE TAMBOUR

UPPER DRYER SIDE

CÔTÉ SUPÉRIEUR DE LA

SÉCHEUSE

UPPER FREEZER LIGHT

VOYANT DU CONGÉLATEUR

SUPÉRIEUR

UPPER HARNESS CONNECTOR

CONNECTEUR DU FAISCEAU

SUPÉRIEUR

VENT ÉVENT

VIOLET (VT) VIOLET (VT)

VOLTS VOLTS

WASH HEATER CHAUFFERETTE DE LAVAGE

WASH MOTOR MOTEUR DE LAVAGE

WATER SENSOR CAPTEUR D’EAU

WHITE (WH) BLANC (BL)

WIRE CODE CODAGE DES CONDUCTEURS

WIRES SHOWN FROM INSERTION

SIDE

FILS MONTRÉS DU CÔTÉ

INSERTION

WIRING COLOR CODE CODE COULEURS DU CÂBLAGE

WIRING DIAGRAM SCHÉMA DE CÂBLAGE

WIRING DIAGRAM PART NO. RÉ F. SCHÉMA DE CÂBLAGE

YELLOW (YL) JAUNE (JA)

This manual suits for next models

1

Table of contents

Popular Washer manuals by other brands

Amana

Amana NTW4600VQ0 User instructions

Fisher & Paykel

Fisher & Paykel WL26CW1 Installation instructions & user guide

ALLIANCE

ALLIANCE HWF561*E1102 Service

LG

LG WM2688H Series Specifications

VOX electronics

VOX electronics WM1410-YT1D operating instructions

Whirlpool

Whirlpool AWM 9100 GH Instructions for use