Network Computing Devices 2172 User manual

2172

21-8136 09-07 NCD-6029-3

INSTALLATION INSTRUCTIONS

Congratulations-yournewAirHelperSpringsarequality

products capable of improving the handling and comfort of

your vehicle. As with all products, proper installation is the

key to obtaining all of the benefits your kit is capable of

delivering. Please take a few minutes to read through the

instructions to identify the components and learn where and

howtheyareused. Itisagoodideatostartbycomparingthe

parts in your kit with the parts list below.

The heart of the air helper spring kit is, of course, the air

springs. Rememberthattheair helper springs must flex and

expand during operation, so be sure that there is enough

clearance to do so without rubbing against any other part of

the vehicle.

Besuretotakeallapplicablesafetyprecautionsduringthe

installationofthekit. Theinstructionslistedinthisbrochure

and the illustrations all show the left, or driver’s side of the

vehicle. To install the right side assembly simply follow the

same procedures.

Your kit includes separate inflation valves and air lines

for each air helper spring. This will allow you to level your

vehiclefromsidetosideaswellasfromfrontto back. If you

would rather have a single valve inflation system, your

dealer can supply the required "T" fitting.

IMPORTANT!

For your safety and to prevent possible damage to your

vehicle, do not exceed the maximum load recommended by

the vehicle manufacturer (GVWR). Although your Air Helper

Springs are rated at a maximum inflation pressure of 100

psi, this pressure may allow you to carry too great a load on

some vehicles. It is best to have your vehicle weighed once

it is completely loaded and compare that weight to the

maximum allowed. Check your vehicle owner’s manual for

maximum loads listed for your vehicle.

When inflating your Air Helper Springs, add air pres-

sure in small quantities, checking pressure frequently dur-

ing inflation. The air spring requires much less air volume

than a tire and, therefore, inflates much quicker.

TOOLS REQUIRED

• (2) 9/16" END WRENCHES • 5/16" DRILL BIT

• (2) 1/2" END WRENCHES • 3/8" DRILL BIT

• UTILITY KNIFE • ELECTRIC DRILL

WARNING:

Do not inflate this assembly when it is

unrestricted. The assembly must be restricted

by the suspension or other adequate structure.

Do not inflate beyond 100 psi Improper use or

over inflation may cause property damage or

severe personal injury.

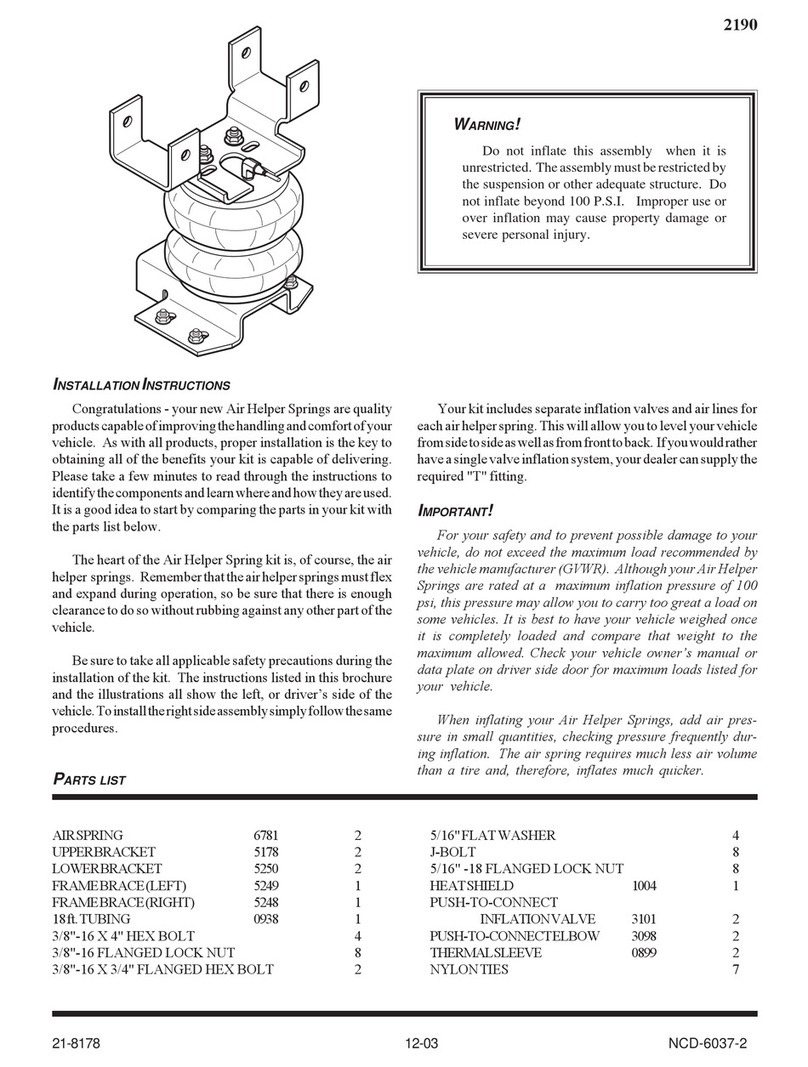

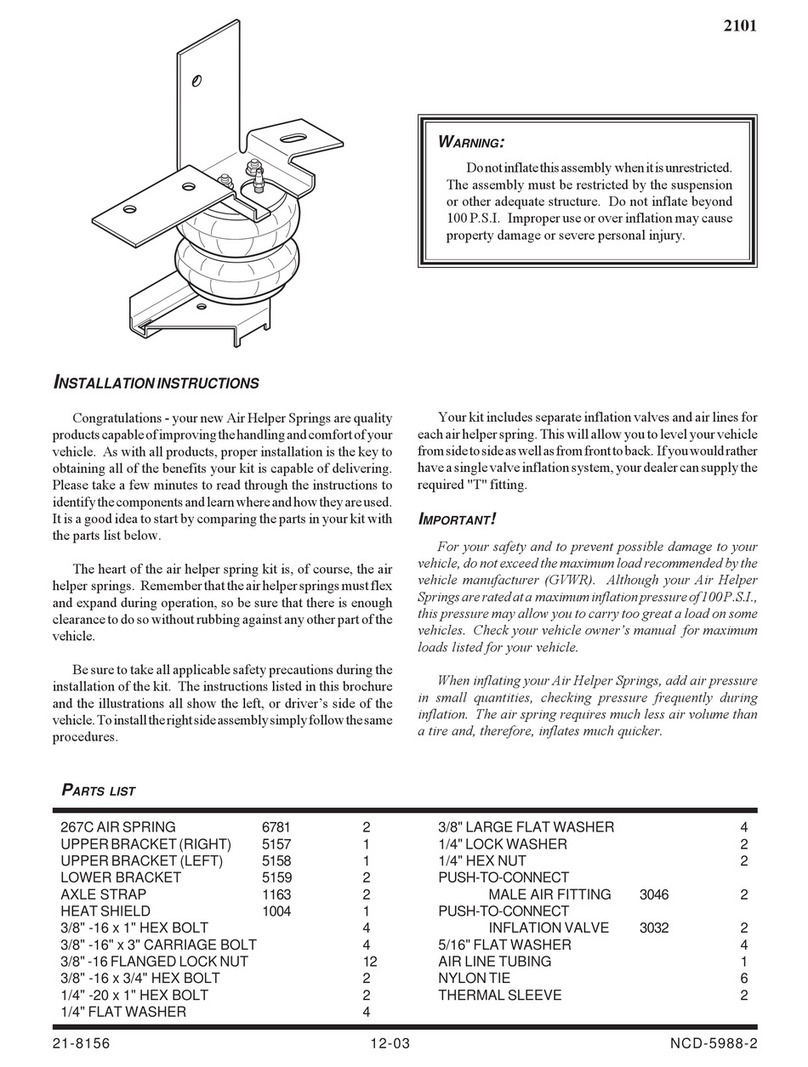

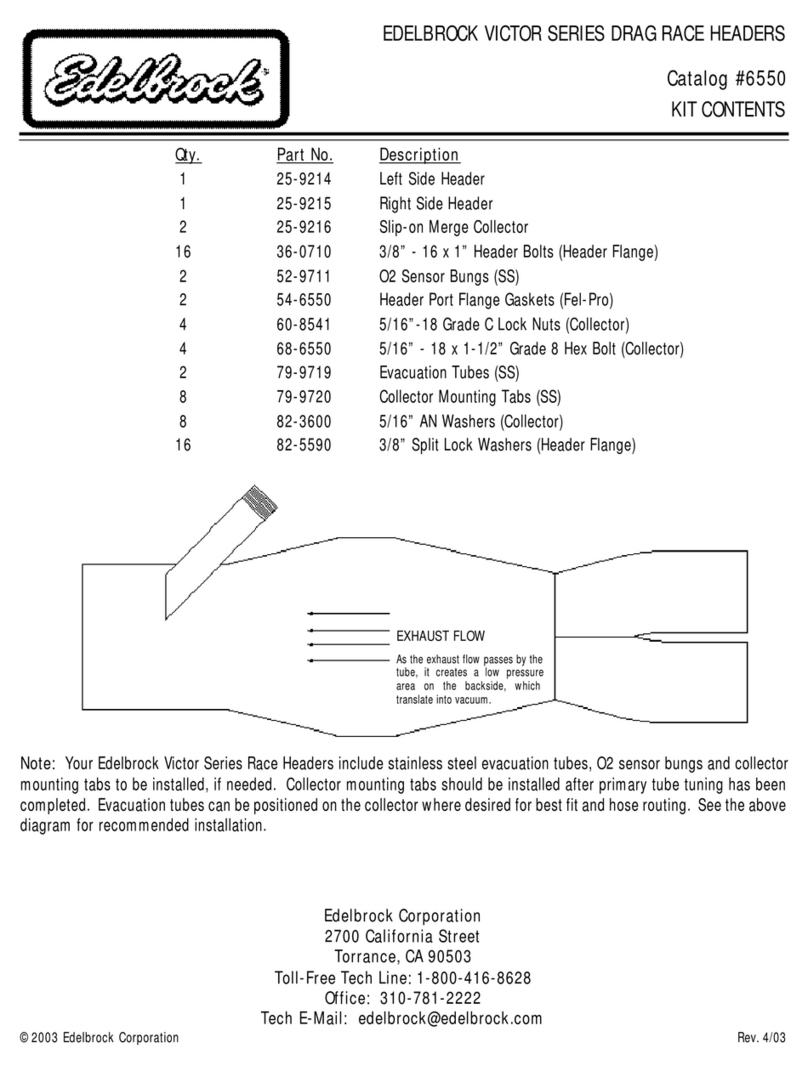

AIR SPRING 9001 2

UPPER BRACKET 5376 2

LOWER BRACKET 5092 2

BRACKET STRAP/SHIM 1/2" 5086 4

BRACKET STRAP/SHIM 1" 5093 4

AIR LINE TUBING 1

3/8"-16 FLANGE LOCK NUT 16

3/8"-16 X 3/4" FLANGE HEX BOLT 6

3/8"-16 x 4-1/2" CARRIAGE BOLT 8

3/8" SPECIAL WASHER 6

3/8" FLAT WASHER 2

3/8"-16 X 1 1/2 HEX BOLT 8

5/16" FLAT WASHER 4

PUSH-TO-CONNECT

INFLATION VALVE 2

INFLATION VALVE CAP 2

PUSH-TO-CONNECT

ELBOW FITTING 2

THERMAL SLEEVE 2

NYLON TIE 6

CAUTION TAG 2

PARTS LIST

Installation of this kit requires a

minimum of 6-1/2" of clearance between

the tire side wall and the frame.

DONOT INSTALL THIS KIT ON VEHICLES WITH

COMPOSITE LEAF SPRINGS. THIS KIT IS COMPATIBLE

WITH STEEL LEAF SPRINGS ONLY.

DRIVER'S SIDE

FRONT

FIGURE "B"

FIGURE "C"

FIGURE "D"

STEP 1 - PREPARE THE VEHICLE

Removethepositivebatterycable. Withthevehicle on a solid, level surface

chockthefrontwheels. Raisethevehiclebytheaxleandremovetherearwheels.

Afterthe removal of thewheelslowerthe vehicle so theaxlerestsonjack stands

rated for your vehicles weight. This installation assumes that there is no load in

the bed of the truck.

STEP 2 - PRE-ASSEMBLE THE KIT

Select one air helper spring and an upper bracket from your kit. Before

attaching the air spring to the upper bracket, thread the air fitting into the spring

seeFigure"A".Tightenthe air fitting so as tomakecontactwiththenylon ring

and then tighten 1/4 turn to snug the fitting. No thread sealant is needed. Align

thethreadedmountingholesoftheairspringwiththemountingholesoftheupper

bracket and attach the upper bracket using the 3/8" -16 x 3/4" flanged hex bolts.

Selectonelowerbracketandplacethebracketsothelipofthelowerbracketwill

benext tothetire seeFigure"A". Fastenusinga3/8"-16x3/4"flangelockbolt

through the center slot into the threaded hole in the air spring (finger tight). Note

that this bolt will be tightened in Step 4.

STEP 3 - PRE-FIT AND MARK / DRILL HOLES

Position the air spring assembly on the leaf spring stack. The lower bracket

should straddle the leaf spring retainer and the upper bracket mounting flanges

shouldbe flush againsttheframe. Dependingon the application,thelowerbracket

mayhavetoberaised(i.e.interferencewith"U"-bolts,leafspringretainer,brakedrum,

etc...). Thiskit comes withtwo sets ofbracket straps/shims. These areincluded to

provideadequateclearancefortheairspringandlowerbracket,aswellas,anyother

componentonthevehicle. Onesetis1/2"tallwhiletheothersetisabout1"tall. To

raisetheairspringassemblytoitsmaximumheight,installthe1/2"shimbetween

thelower bracket and the leaf spring stack. The remaining 1" strap/shim will be

usedtoclampthe assemblytothe leafspringstack seeFigure"C". Thebracket

straps/shimsmaybeinterchangedtoprovidemaximumclearanceandproperair

springheight. Furthermore,theshimscanbemixed(i.e.usethe1/2"ononeside

and the 1" or none on the other) to adjust for leaf spring slant. Keep the upper

and lower brackets as parallel as possible.

Oncetheheightofthelowerbrackethasbeenestablished,adjusttheposition

of the upper bracket so that the mounting flanges are flush with the side of the

framerail. Itmaybenecessarytoslidetheentireassemblyforeoraftalongtheleaf

springinordertoprovidepropermounting. Beforemarkinganddrillingtheholes

for the upper bracket, make sure the mounted height of the air spring is between

7-1/4" - 8-1/2" seeFigure "C", and the upper and lower brackets are as parallel

andhighaspossible. Markthefourholestobedrilledwitha center punch using

the upper bracket as a template, then remove the air spring assembly. Before

drilling the holes make sure all electrical, brake and fuel lines are cleared from

thepathofthedrill. Damagetolinescanbeavoidedbyinsertingapieceofwood

betweentheframerailandanylinesinthepathofthedrill. Drillthefourholesin

theframe rail usinga 3/8" drill bit seeFigure"A".

STEP 4 - INSTALL THE ASSEMBLY TO THE VEHICLE

After drilling the holes in the frame rail place the assembled air spring and

brackets back on the leaf stack making sure the lower bracket is placed over the

retainer(seeFigure"A"&"B"). Installthe3/8"-16x1-1/2"hexboltsthroughthe

upperbracket holesandthe holesthatwere drilledinthe framerail. Next,fasten

the upper bracket to the frame rail using the 3/8"-16 flange lock nuts and flat

washers see Figure "A". On each side of the vehicle, substitute a standard

washer in place of the special washer in the upper rear location seeFigure"A".

Next,attachthelowerbrackettotheleafspringassembly. Usethebracketstrap/

shim that is not being used as a spacer and fasten the air spring assembly to the

leafstackusingthe 3/8"-16x4-1/2" carriageboltsand 3/8"-16flangedlock nuts

seeFigure"A". Tighten the air springto the lower bracket makingsure the air

spring is as vertical as possible.

7-1/4” - 8-1/2"

FRONT

AIR HOSE

INFLATION

VALVES

BUMPER

AIR

SPRINGS

AIR LINE

PUSH-TO-CONNECT

INFLATION VALVE

FLAT WASHER

HEX NUT

VALVE CAP

BODY OF

VEHICLE

FIGURE "E"

NOTE:

Oncethe air helper springs are installed, itis recommended that the vehicle not belifted by the frame, as over-extension

may occur, resulting in damage to the air helper springs. However, should it become necessary to raise the vehicle by the

frame, deflate both air helper springs completely.

STEP 5 - INSTALLATION OF THE PASSENGER'SSIDE ASSEMBLY

Reverse any orientations when assembling and installing the right, or passenger side of the vehicle.

STEP 6 - INSTALL THE AIR LINE AND THE INFLATION VALVE

Uncoilthe air line tubing andcutitinto two equallengths. DONOT FOLDORKINK THE TUBING. Trytomake thecutas

squareas possible. Insert one end of the tubing intotheelbowfittinginstalledinthetop of the air helper spring. Push the tubing

into the fitting as far as possible see Figure "A".

Select a location on the vehicle for the air inflation valves. The location can be on the bumper or the body of the vehicle, as

longas itisin aprotectedlocation sothevalvewill notbedamaged, butmaintainaccessibility fortheairchuckseeFigure"D".

Drill a 5/16" hole and install the air inflation valve using two 5/16" flat washers per valve as supports seeFigure "E". Run the

tubingfromtheairhelperspringtotheinflationvalve,routingittoavoiddirectheatfromtheengine,exhaustpipe,andawayfrom

sharp edges. Thermal sleeves have been provided for these conditions. If a thermal sleeve is required simply slide the sleeve

over the air line tubing to the location requiring protection. The air line tubing should not be bent or curved sharply as it may

buckle. Secure the tubing in place with the nylon ties provided. Push the end of the air line tubing into the inflation valve as

illustrated seeFigure "E".

STEP 7 - CHECK THE AIR SYSTEM

Once the inflation valves are installed inflate the air helper springs to 70 psi and check the fittings for air leaks with an

applied solution of soap and water. If a leak is detected at a tubing connection then check to make sure that the tube is cut as

square as possible and that it is pushed completely into the fitting. The tubing can easily be removed from the fittings by first

releasing the air pressure then push the collar towards the body of the fitting and then pulling out the tube. If a leak is detected

wherethe fitting screws into the spring, remove the tubingby pushing the collartowards the body of thefitting and then pulling

out the tube, then screw the brass fitting into the air spring or until the leak stops. Re-install the tubing and reinflate the air

springs and check for leaks as noted above.

Thisnowcompletestheinstallation. Installthewheelsandtorquethelugnutstothemanufacturesspecifications. Raisethe

vehicle by the rear axle and remove the jack stands and lower the vehicle back onto the ground. Re-attach the positive battery

cableandremove the wheel chocks fromthewheels. Before proceeding, check onceagainto be sure you haveproperclearance

aroundtheairsprings. Withaloadonyourvehicleandtheairhelperspringsinflated,youmusthaveatleast1/2"clearancearound

the air springs. As a general rule, the air helper springs will support approximately 25 lbs. of load for each psi of inflation

pressure (per pair). For example, 50 psi of inflation pressure will support a load of 1250 lbs. per pair of air helper springs.

FOR BEST RIDE use only enough air pressure in the air helper springs to level the vehicle when viewed from the side (front

to rear). This amount will vary depending on the load, location of load, condition of existing suspension and personal

preference.

NOTE:

Toomuchairpressureintheairhelperspringswillresultina firmerride,whiletoolittleairpressurewillallowtheairhelper

spring to bottom out over rough conditions. Too little air pressure will also not provide the improvement in handling that is

possible. TOPREVENTPOSSIBLEDAMAGEMAINTAINAMINIMUMOF10psiINTHEAIRHELPERSPRINGSAT

ALLTIMES.

NOTE:

MIN PRESSURE 5 PSI

MAX PRESSURE (LOADED) 100 PSI

www.riderite.com

This manual suits for next models

1

Other Network Computing Devices Automobile Part manuals