New Flyer Xcelsor 2019 User manual

SMB-189 1 of 12

SERVICE MANUAL BULLETIN

This Service Manual Bulletin is prepared by the Publications Department of New Flyer Industries

Canada ULC. Refer to details below.

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

ISSUE DATE: Dec 20 2019

SMB-189

APPLICABILITY

VEHICLE LENGTH 30ft. 35ft. 40ft. 60ft. ALL

VEHICLE TYPE Xcelsior®MiDi®Invero®

ALL

Low Floor High Floor

FUEL TYPE Diesel Diesel/Electric CNG LNG

ALL

Fuel Cell Trolley/Electric Battery/Electric

SUBJECT High Voltage Safety - Lockout / Tagout & De-Energizing & Energizing

Procedure

SECTION TITLE Lockout / Tagout & De-Energizing & Energizing Procedure

DETAILS This bulletin provides revised lockout / tagout and de-energizing and

energizing procedures on your New Flyer vehicles in Three Parts.

Make this Service Bulletin available to service personnel to inform them

of changed information.

2 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

PART ONE

1. Lockout / Tagout Procedure

for all Battery Electric

Vehicles

The following Lock Out / Tag Out proce-

dure should be followed when working on

or near the High Voltage components.

☞NOTE:

Use commercially available lock out equip-

ment and tags and be sure to follow any

local laws or workplace procedures.

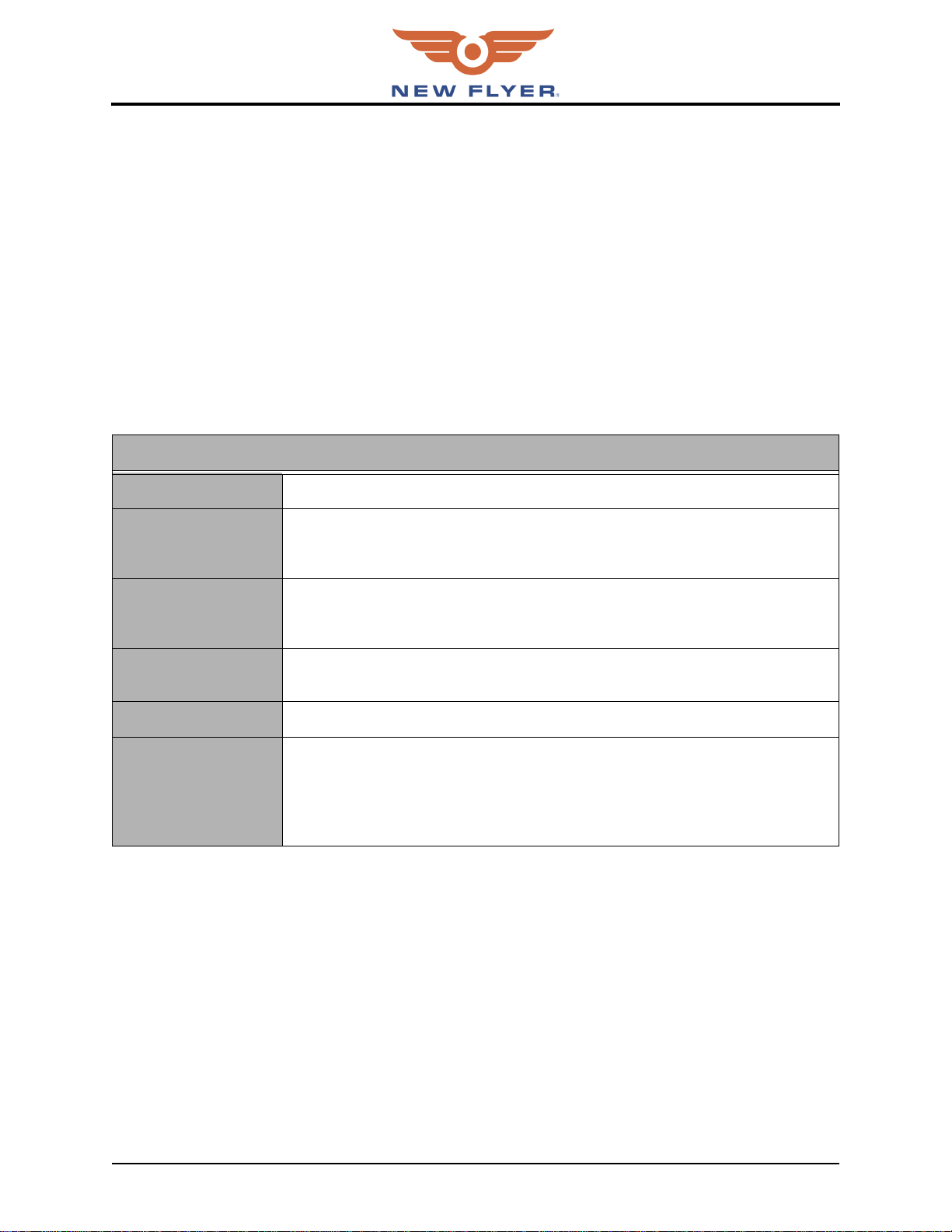

1.1. Locking / Tagging Out

1. Set the Master Run switch to the STOP-

SYSTEM position.

2. Rotate the 12/24 volt Battery switch to the

OFF position.

3. Lock and tag the switch and retain key.

See “Fig. 1: Locking / Tagging Out” on

page 2.

4. Switch the High Voltage Interlock switch to

the HV OFF position.

5. Lock and tag the switch and retain key.

6. Verify the low voltage and high voltage sys-

tems are de-energized. Refer to De-Ener-

gizing & Energizing Procedures in this

bulletin.

1.1.1. Locks / Tags Removal

1. The locks and tags shall be removed by

the installer of the locks and tags or shall

be removed under her / his supervision.

2. If the installer of the locks and tags is not

available, then her/his supervisor:

a. Ensures that the installer of the locks

and tags is not in the facility.

b. Contacts the installer to inform her/him

that the locks and tags will be removed.

c. Reminds the installer of the lock and

tag removal when she/he resumes

work.

Fig. 1: Locking / Tagging Out

+9

2))

s145303a.svg

SMB-189 3 of 12

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

PART TWO

2. De-Energizing & Energizing

Procedures for all Battery

Electric Vehicles equipped

with Manual Service

Disconnects (MSD)

NEVER try to connect or disconnect cir-

cuit components such as cables, fuses,

or connectors while there is current

flowing in the circuit.

2.1. De-Energizing Procedure

1. Prepare the work area. Refer to “Service

Preparation” in your New Flyer Service

Manual for information on how to safely

prepare the work area.

2. Ensure the DC high voltage charging

cables are disconnected from the vehicle.

3. Lock Out and Tag Out the Battery Discon-

nect and High Voltage Interlock switch.

Refer to 1. “Lockout / Tagout Procedure for

all Battery Electric Vehicles” on page 2 in

this bulletin for procedure.

4. Wear High Voltage Personal Protection

Equipment (PPE). Refer to “PPE Require-

ments” in your New Flyer Service Manual

for guidelines.

☞NOTE:

Refer to “Equipment Requirements” in your

New Flyer Service Manual for information

on the type of multimeter required for the

following test.

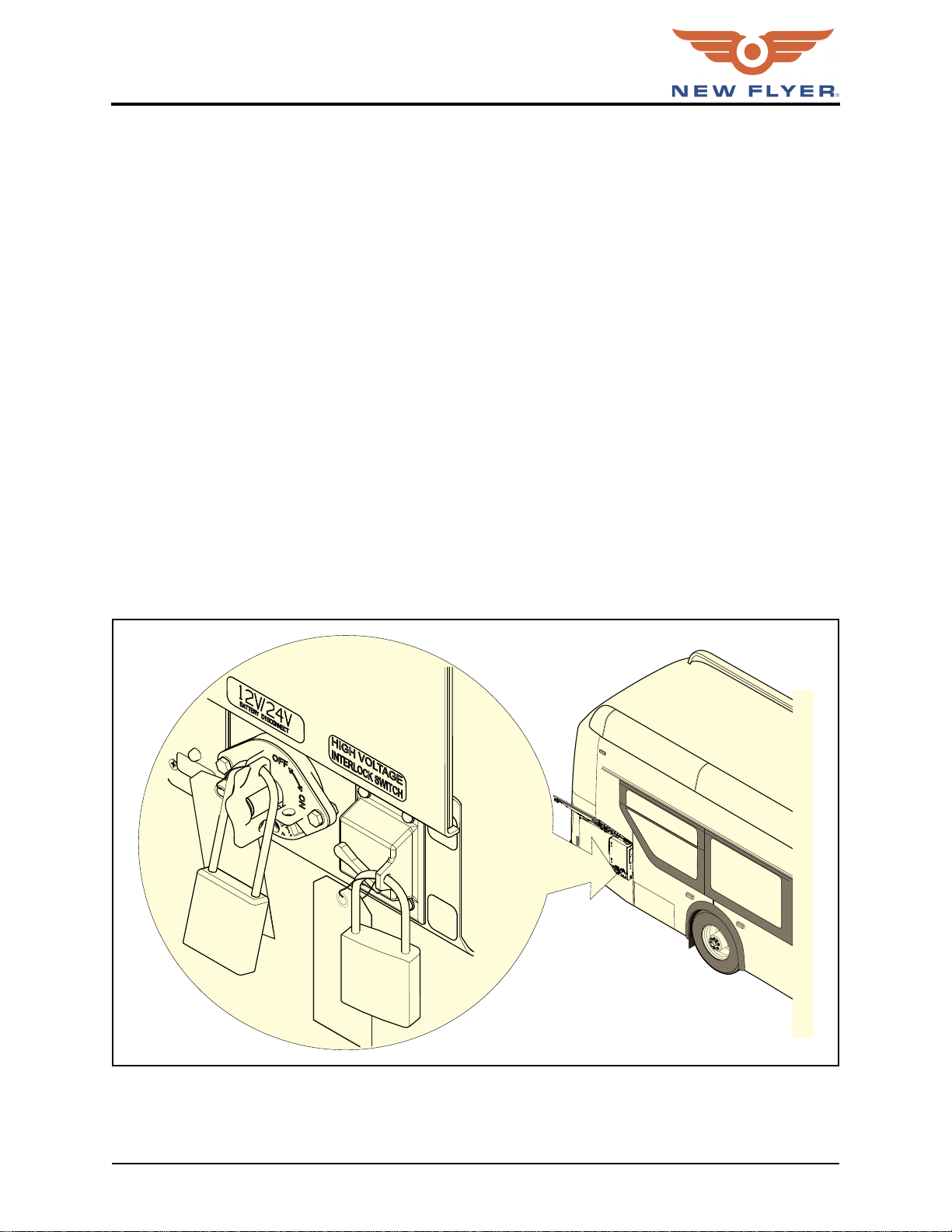

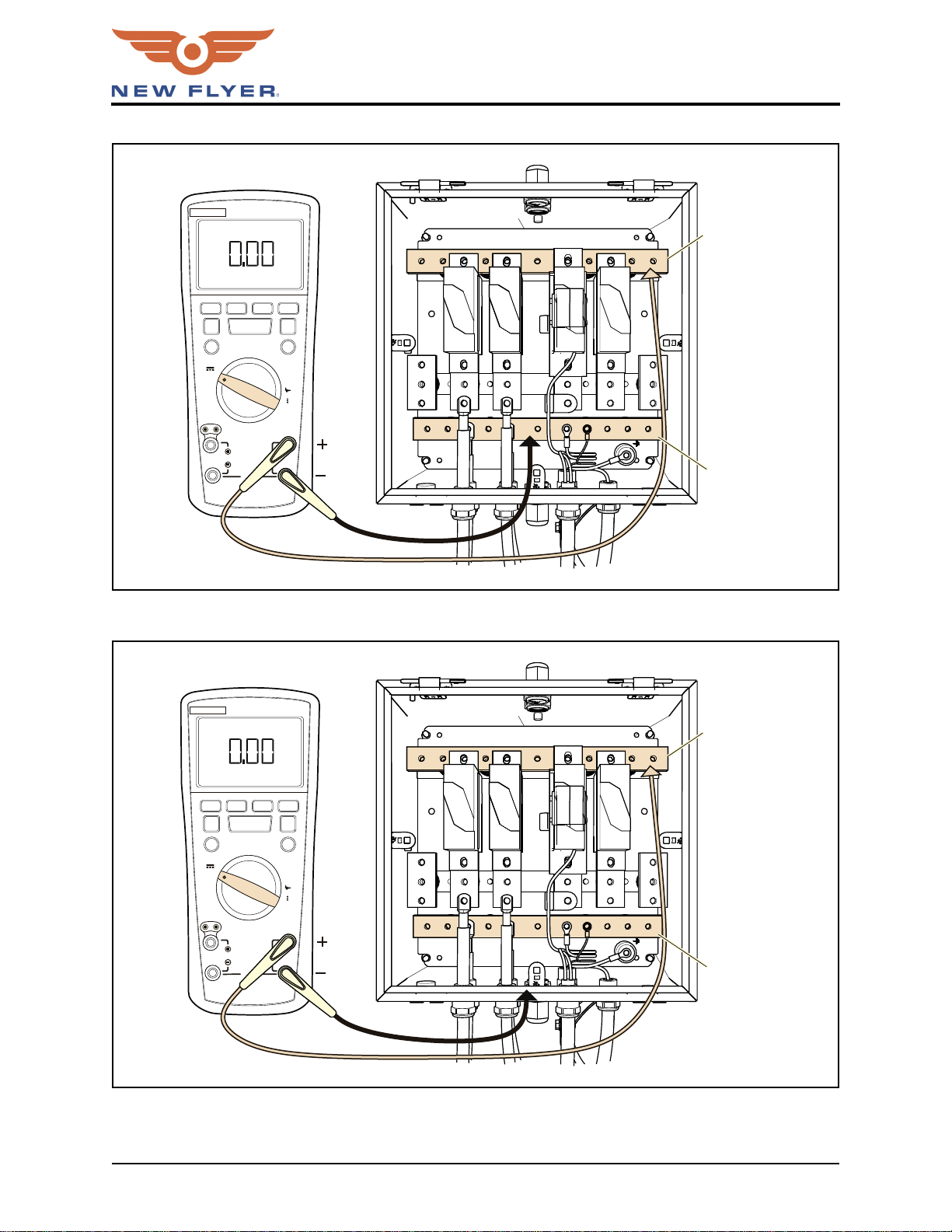

5. Ensure there is no voltage on the 12/24

VDC battery bus bars. Measure in the

main fusebox between the 24V bus bar

and the ground bar. See “Fig. 2: Low Volt-

age Verification” on page 3.

Fig. 2: Low Voltage Verification

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

s145301a.svg

4 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

6. Ensure there is no voltage on the High

Voltage System. Measure in the roof-

mounted high voltage fuse box as follows:

a. Measure from the positive bus bar to

the negative bus bar. See “Fig. 3: High

Voltage Verification - 1” on page 4.

b. Measure from the positive bus bar to

the grounded enclosure or roof rack

structure. See “Fig. 4: High Voltage Ver-

ification - 2” on page 5.

c. Measure from the ground bar to the

grounded enclosure or roof rack struc-

ture. See “Fig. 5: High Voltage Verifica-

tion - 3” on page 5.

Fig. 3: High Voltage Verification - 1

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

1(*$7,9(

%86%$5

326,7,9(

%86%$5

s145302a.svg

SMB-189 5 of 12

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

Fig. 4: High Voltage Verification - 2

Fig. 5: High Voltage Verification - 3

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

1(*$7,9(

%86%$5

326,7,9(

%86%$5

s145304a.svg

1(*$7,9(

%86%$5

326,7,9(

%86%$5

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

s145305a.svg

6 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

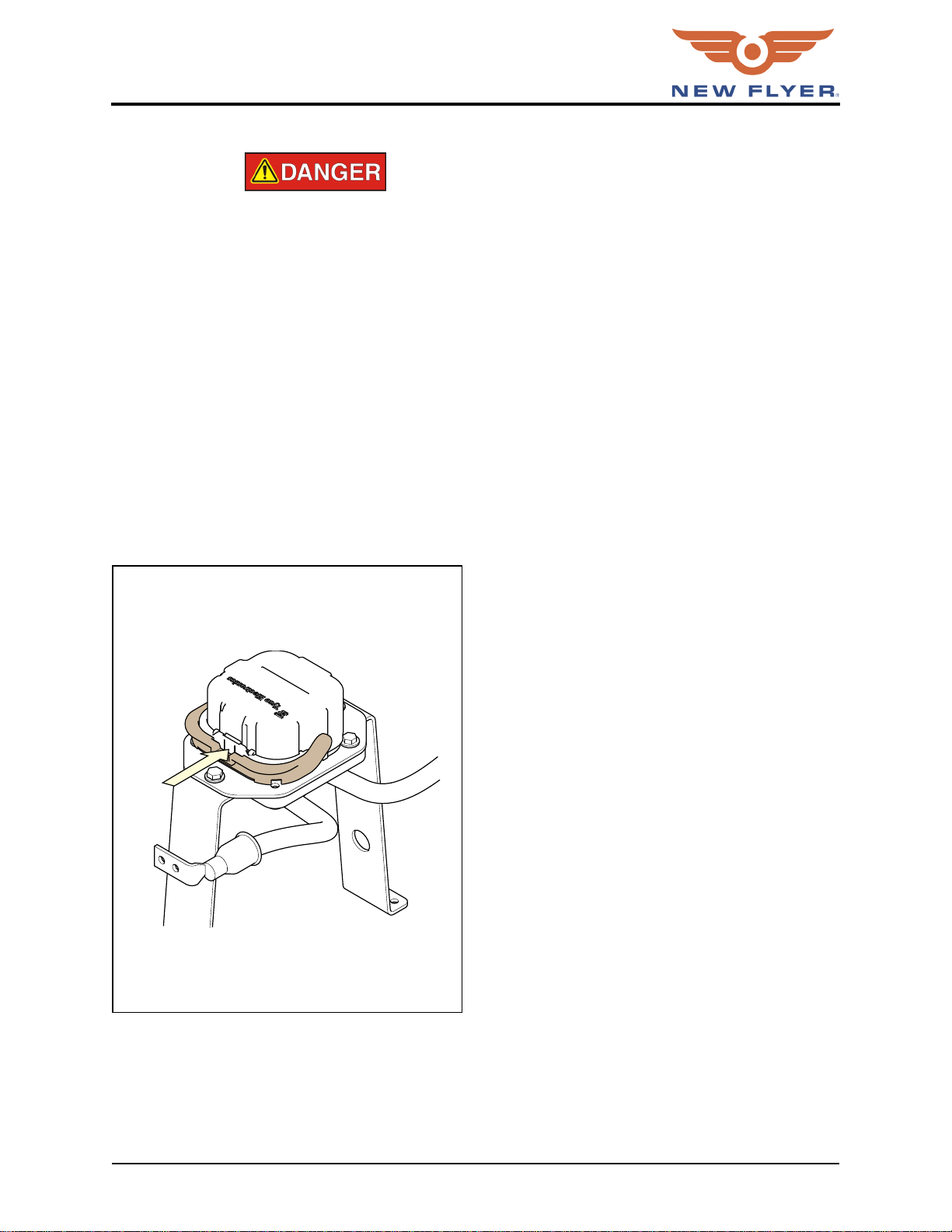

NEVER remove the ESS Manual Service

Disconnect plug while current is flow-

ing through it. The High Voltage may

create a long enough ionized gas path,

during circuit interruption, to bridge the

contacts of the switch base and there-

fore continue the current flow. This ion-

ized gas is very hot and can cause

burns, fire and electrical shock.

Using a clamp-on current probe and

DMM, ensure that there is no current

flowing in the cables connecting to the

ESS Manual Service Disconnect plug.

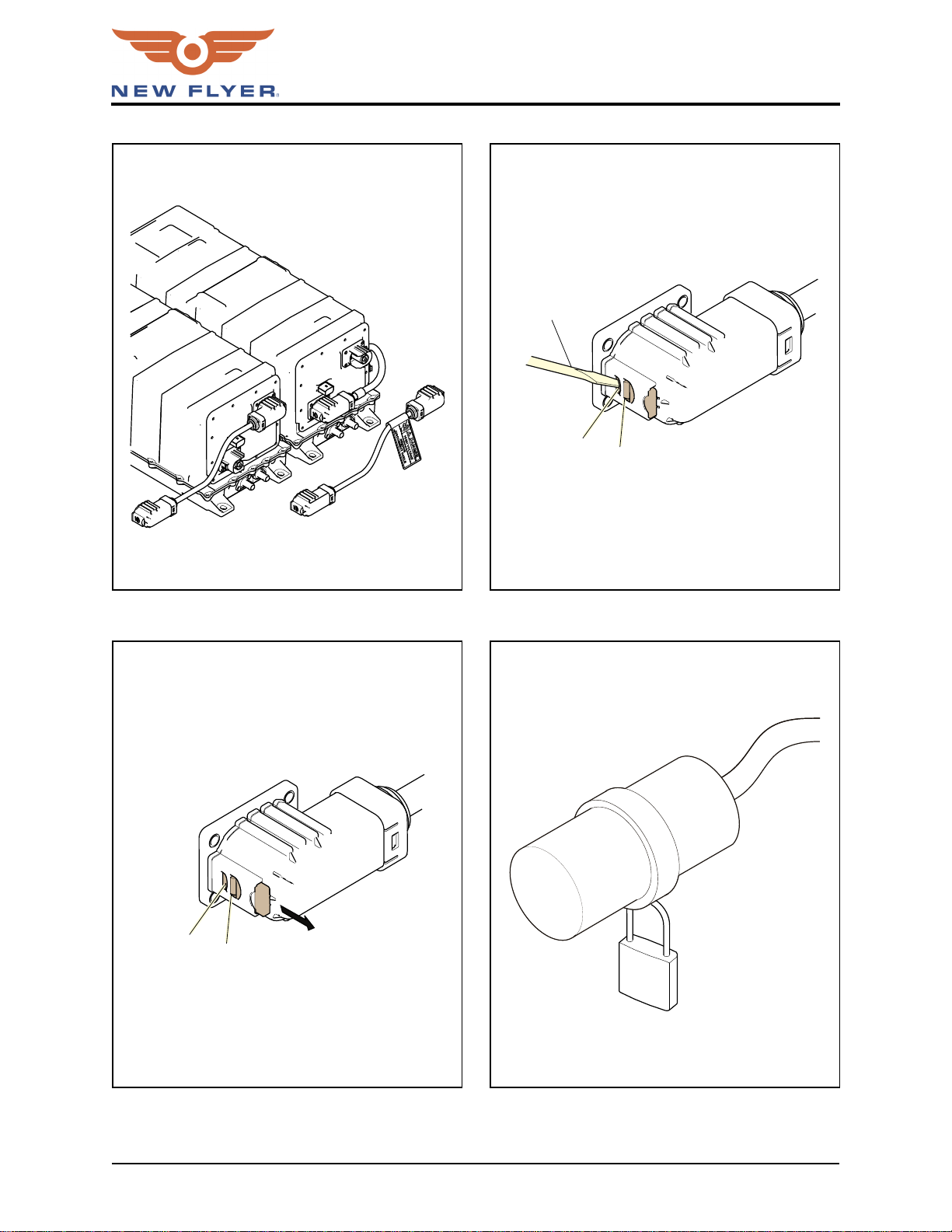

7. Remove all the ESS Manual Service Dis-

connect plugs as follows:

a. Press the locking tab and rotate the

MSD lever 45°. See “Fig. 6: Manual

Service Disconnect - 1” on page 6.

Fig. 6: Manual Service Disconnect - 1

b. Press the locking tab and rotate the

MSD lever to the 90° position. See “Fig.

7: Manual Service Disconnect - 2” on

page 7.

c. Remove the Manual Service Discon-

nects. See “Fig. 8: Manual Service Dis-

connect - 3” on page 7.

d. Install a yellow insulating cover, that is

open circuited in the Manual Service

Disconnect receptacle and lock it in

place. ☞NOTE:

Removing the Manual Service Discon-

nects reduces the ESS voltage but each

battery within the ESS remains a high volt-

age hazard at 88 volts.

8. Ensure that insulating covers are installed

in all ESS Manual Service Disconnect

receptacle locations.

9. Stow the removed MSDs in a locked loca-

tion to which only you have access.

10.Disconnect the high voltage cables at the

HV Junction Box on the side of the ESS.

35(66

+(5(

s145311a.svg

SMB-189 7 of 12

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

Fig. 7: Manual Service Disconnect - 2

Fig. 8: Manual Service Disconnect - 3

2.2. Energizing Procedure

Perform a visual check to ensure that all

possible HV compartments are closed and

there is no debris, tools or test equipment

lying on HV terminations before energizing

the vehicle.

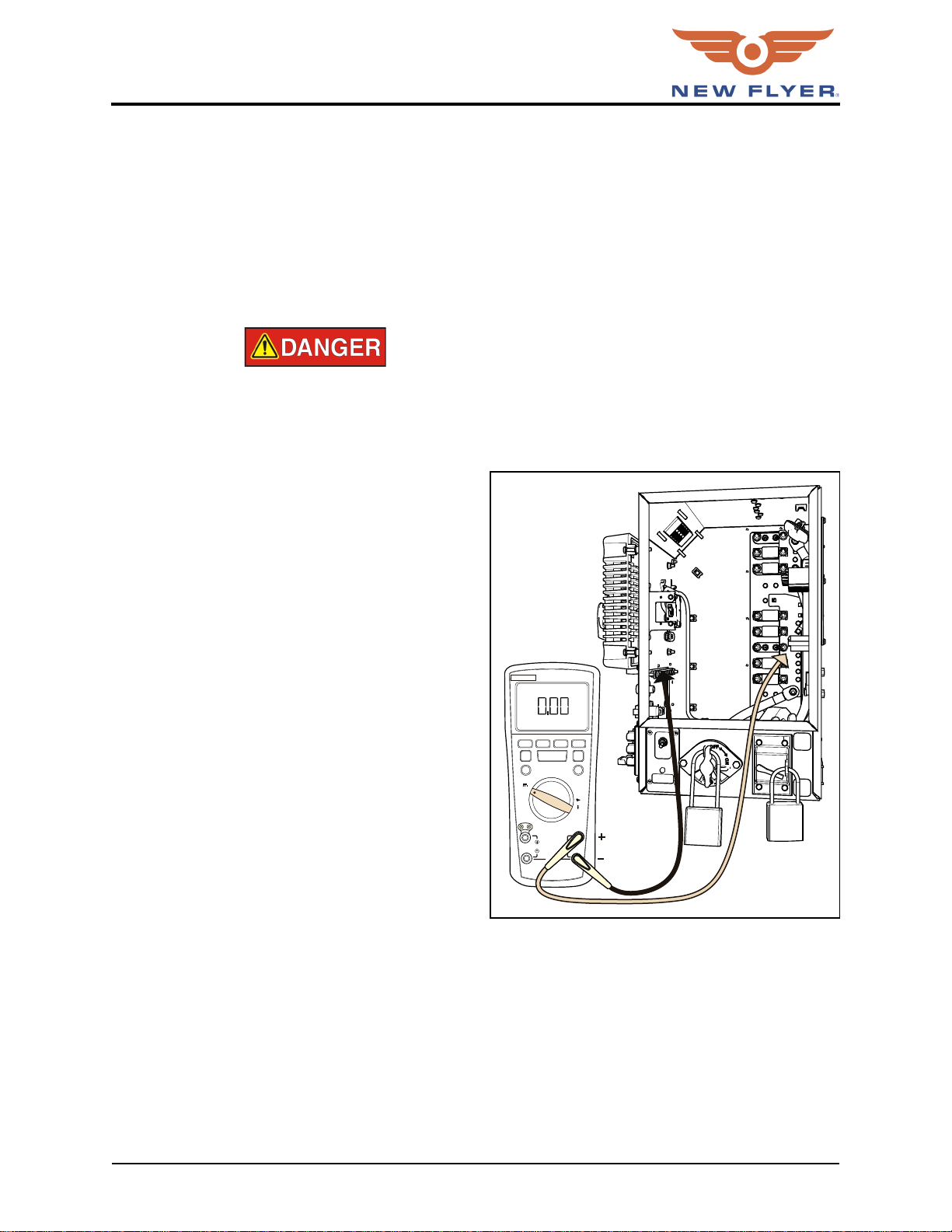

DO NOT touch cable terminations until

checking to ensure there is no voltage

between any of these cables and with

respect to vehicle chassis.

While connecting HV cables continu-

ously monitor, with the DMM, for the

inadvertent appearance of HV. If HV

appears troubleshoot why the HV

appeared and resolve before proceed-

ing.

1. Using insulated tools, reconnect all high

voltage cables.☞NOTE:

For the following devices, use a phase

rotation meter to ensure correct cable

sequences:

❒Air Compressor

❒ESS Heat Exchanger

❒HVAC Unit

2. Reinstall high voltage junction box covers.

3. Install the ESS Manual Service Disconnect

plugs.

4. Close all HV access panels, doors, enclo-

sures.

5. Remove the lockout / tagout from the 12/24

volt Battery Disconnect switch and turn the

switch to the ON position.

6. Remove the lock/tag from the High Voltage

Interlock switch and set the switch to the

HV ON position.

7. Set the Master Run switch to the DAY-RUN

or NIGHT-RUN position.

8. Remove “Safety Barricade” with warning

lights and “Danger High Voltage” signs

around the vehicle perimeter.

35(66

+(5(

s145312a.svg

38//725(029(

s145313a.svg

8 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

PART THREE

3. De-Energizing & Energizing

Procedures for all Battery

Electric Vehicles without

ManualServiceDisconnects

(MSD)

NEVER try to connect or disconnect cir-

cuit components such as cables, fuses,

or connectors while there is current

flowing in the circuit.

3.1. De-Energizing Procedure

1. Prepare the work area. Refer to “Service

Preparation” in your New Flyer Service

Manual for information information on how

to safely prepare the work area.

2. Ensure the DC high voltage charging

cables are disconnected from the vehicle.

3. Lock out and Tag Out the Battery Discon-

nect and High Voltage Interlock switch.

Refer to 1. “Lockout / Tagout Procedure for

all Battery Electric Vehicles” on page 2 in

this bulletin for procedure.

4. Wear High Voltage Personal Protection

Equipment (PPE). Refer to “PPE Require-

ments” in your New Flyer Service Manual

for guidelines. ☞NOTE:

Refer to “Equipment Requirements” in your

New Flyer Service Manual for information

on the type of multimeter required for the

following test.

5. Ensure there is no voltage on the 12/24

VDC battery bus bars. Measure in the

main fusebox between the 24V bus bar

and the ground bar. See “Fig. 9: Low Volt-

age Verification” on page 8.

6. Ensure there is no voltage on the High

Voltage System. Measure in the roof-

mounted high voltage fuse box.

a. Measure from the positive bus bar to

the negative bus bar. See “Fig. 10: High

Voltage Verification - 1” on page 9.

b. Measure from the positive bus bar to

the grounded enclosure or roof rack

structure. See “Fig. 11: High Voltage

Verification - 2” on page 9.

c. Measure from the ground bar to the

grounded enclosure or roof rack struc-

ture. See “Fig. 12: High Voltage Verifi-

cation - 3” on page 10.

Fig. 9: Low Voltage Verification

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

s145301a.svg

SMB-189 9 of 12

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

Fig. 10: High Voltage Verification - 1

Fig. 11: High Voltage Verification - 2

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

1(*$7,9(

%86%$5

326,7,9(

%86%$5

s145302a.svg

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

1(*$7,9(

%86%$5

326,7,9(

%86%$5

s145304a.svg

10 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

Fig. 12: High Voltage Verification - 3

7. Using a clamp-on current probe and DMM,

ensure that there is no current flowing in

the mid-string cable or cables inside the

ESS enclosure.☞NOTE:

The battery strings inside the ESS have a

mid-string cable identified with a label.

Removing this cable as a service discon-

nect will reduce the voltage approximately

in half. Each battery remains at a high volt-

age of 88V so continued caution is

required.

8. Disconnect the mid-string cable for all bat-

tery strings located inside the ESS com-

partment. See “Fig. 13: Mid-String Cable”

on page 11.

9. Remove the cable connectors as follows:

a. Pull tab #1 up. See “Fig. 14: Release

Connector Tab #1” on page 11.

b. Using an insulated flat-bladed screw

driver, press on tab #2 and release tab.

See “Fig. 15: Release Connector Tab

#2” on page 11.

c. Pull the high voltage connector off the

battery pack.

10.Cover the connector on the cable with a

locking cover to prevent it from being rein-

stalled until after the service work is com-

plete. See “Fig. 16: Locking Cable Cover”

on page 11.

Removing the mid-string cable will

reduce the high voltage risk but not

eliminate it. Continue to use caution

while disconnecting any other cables

from the batteries or while working on

any other components within the ESS.

11.Repeat this procedure to disconnect the

most positive and most negative cable in

the battery string (or strings) located in the

ESS.

1(*$7,9(

%86%$5

326,7,9(

%86%$5

2))

9

9

,168/$7,21

,168/$7,21

7(67

,168/$7,21

08/7,0(7(5

9

,168/$7,21

9&$7

9&$7

P$

)86('

s145305a.svg

SMB-189 11 of 12

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

Fig. 13: Mid-String Cable

Fig. 14: Release Connector Tab #1

Fig. 15: Release Connector Tab #2

Fig. 16: Locking Cable Cover

s145307a.svg

7$% 7$%

s145309a.svg

,168/$7('

)/$7+($'

6&5(:'5,9(5

7$% 7$%

s145308a.svg

s145410a.svg

12 of 12 SMB-189

SERVICE MANUAL BULLETIN

SMB-189

The New Flyer vehicles described in this manual may be protected by one or more

patents and design applications or registrations in the United States and Canada,

and in other countries. Refer to “Vehicle Patent Information” in this manual.

Copyright © 2019 New Flyer Industries Canada ULC

3.2. Energizing Procedure

Perform a visual check to ensure that all

possible HV compartments are closed and

there is no debris, tools or test equipment

lying on HV terminations before energizing

the vehicle.

DO NOT touch cable terminations until

checking to ensure there is no voltage

between any of these cables and with

respect to vehicle chassis.

While connecting HV cables continu-

ously monitor, with the DMM, for the

inadvertent appearance of HV. If HV

appears troubleshoot why the HV

appeared and resolve before proceed-

ing.

1. Using insulated tools, reconnect all high

voltage cables.

☞NOTE:

For the following devices, use a phase

rotation meter to ensure correct cable

sequences:

❒Air Compressor

❒ESS Heat Exchanger

❒HVAC Unit

2. Reinstall high voltage junction box covers.

3. Close all HV access panels, doors, enclo-

sures.

4. Remove the lockout/tagout from the 12/24

volt Battery Disconnect switch and turn the

switch to the ON position.

5. Remove the lock/tag from the High Voltage

Interlock switch and set the switch to the

HV ON position.

6. Set the Master Run switch to the DAY-RUN

or NIGHT-RUN position.

7. Remove “Safety Barricade” with warning

lights and “Danger High Voltage” signs

around the vehicle perimeter.

Table of contents

Other New Flyer Bus manuals