Furnaces installed in tight houses, in houses which have air-handling devices with unbalanced airflows, or

in enclosed spaces are very likely to have homeowners complain of smoke, fumes, burner lockouts, and

excessive fuel consumption. This is more prevalent in post 1985 construction due to the tighter building

construction as prescribed by the latest building codes. Regulations are relatively specific on the

minimum allowable quantities of ventilation and combustion air required once the space category is

determined. However, every house is subject to different internal and external conditions and regulations

vary among localities. With this in mind, Newmac recommends provision for combustion and ventilation

air as specified in Table 5. Table 5 is based on relevant commonly available codes and regulations.

Values indicated in Table 5 are based on the maximum input rating for this single appliance. However, in

making combustion and ventilation analysis the aggregate input rating of all appliances in the space must

be considered. The installation of additional oil-fired appliances may require more combustion and

ventilation air. When sizing combustion and ventilation air ducts, allowance must also be made for the

blocking effect of louvers, grilles and screens. If the design and free area is unknown, wood louvers

generally have 20-25% free area and metal louvers or grilles have 60-75% free area. Screens should not

be less than 1/4 inch mesh.

TABLE 5. COMBUSTION & VENTILATION AIR SIZING

FLOORAREA SPACE Vertical Ducts&Direct OpeningSizes Horizontal Duct Sizes(in.)

APPLIANCE (Squarefeet) CATEGORY FreeArea LXW(QTY) Dia.(QTY) FreeArea LXW(QTY) Dia.(QTY)

Total (in.2) (in.Xin.) (in.) Total(in.2) (in.Xin.) (in.)

morethan725 Unconfined 30 4x8(1) 6(1) 30 4x8(1) 6(1)

725orless Confined 72 4x9(2) 7(2) 145 4x18(2) 10(2)

morethan725 Unconfined 21 4x6(1) 5(1) 21 4x6(1) 5(1)

725orless Confined 52 4x7(2) 6(2) 105 6x 9(2) 8(2)

NH3

LFR

Freeareaofductsassumesairisconveyedfromoutside

The following should be kept in mind when using Table 5:

All applicable codes and regulations must be followed.

Free duct area is for ducts and opening to outdoors.

Unconfined free area values are based on 1 sq. in per 5,000 Btu/hr of the maximum input rating.

Confined free area of vertical ducts is based on 1 sq. in per 4,000 Btu/hr of the maximum input rating.

Confined free area of horizontal ducts is based on 1 sq. in per 2,000 Btu/hr of the maximum input

rating.

Two openings of equal size are required for confined spaces.

Maximum length of run for ducts is 50 ft. Duct size allowances must be made for longer runs.

Ducts should be designed or insulated to prevent condensation. If insulating, a minimum insulation

value of R-3 is required.

In the case where one opening or duct is specified and combustion and ventilation air is still

inadequate, a second duct may be required. Locate one high and the other low for air circulation.

It is particularly important to duct the cold air as close to the appliance as possible. A means of closing

the air openings when the appliance is not operating may be required. Except for an SVS sealed vent

installation, outside air ducts should not be connected either to the burner or to the appliance.

Guidelines to determine the need for additional combustion and ventilation air may not be adequate for

every situation. If in doubt, it is advisable to err on the safe side and provide additional air.

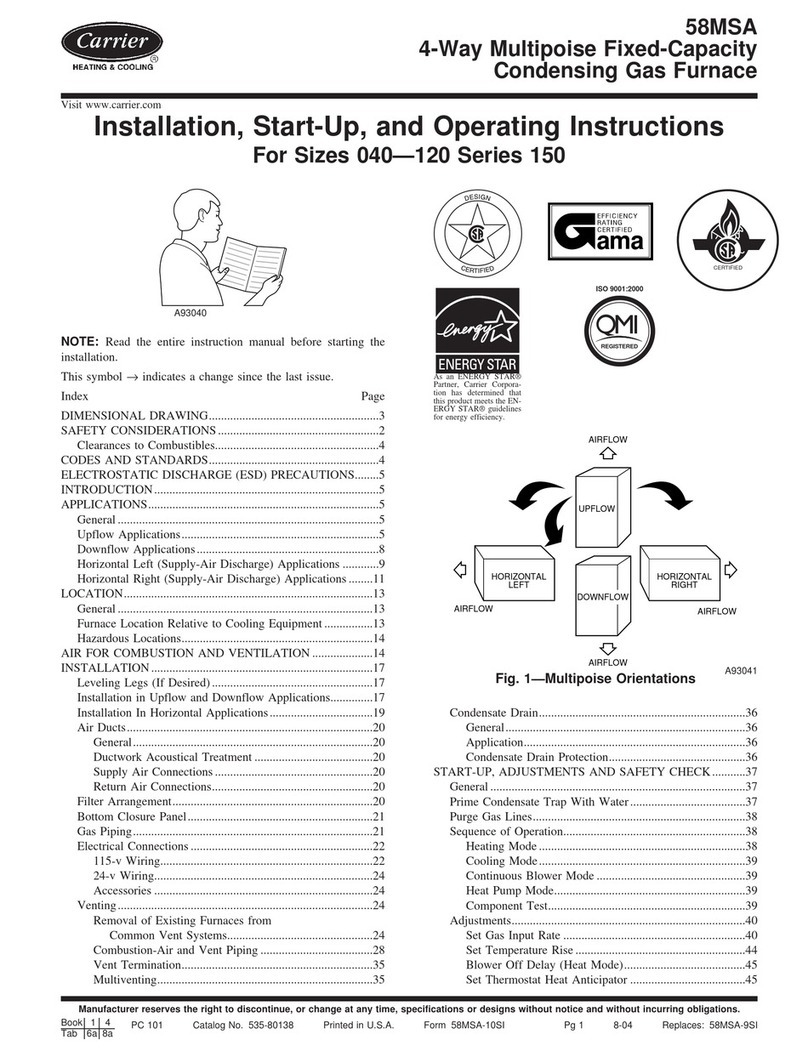

Fig. 5 shows a typical appliance installation. In this case there is a furnace and a water heater in an

enclosed space--both require ventilation and combustion air which is delivered by the top and bottom air

ducts.

As long as adequate combustion and ventilation air is supplied, the confined appliance room with ducted

air offers several advantages: