THERMOSTAT LOCATIO

For central heating applications a room thermostat is recommended to provide automatic

temperature control and efficient operation.

The thermostat should be mounted on an inside partition wall clear of drapes, heaters, doors and the

effects of external windows. Generally the thermostat is placed in the main living area.

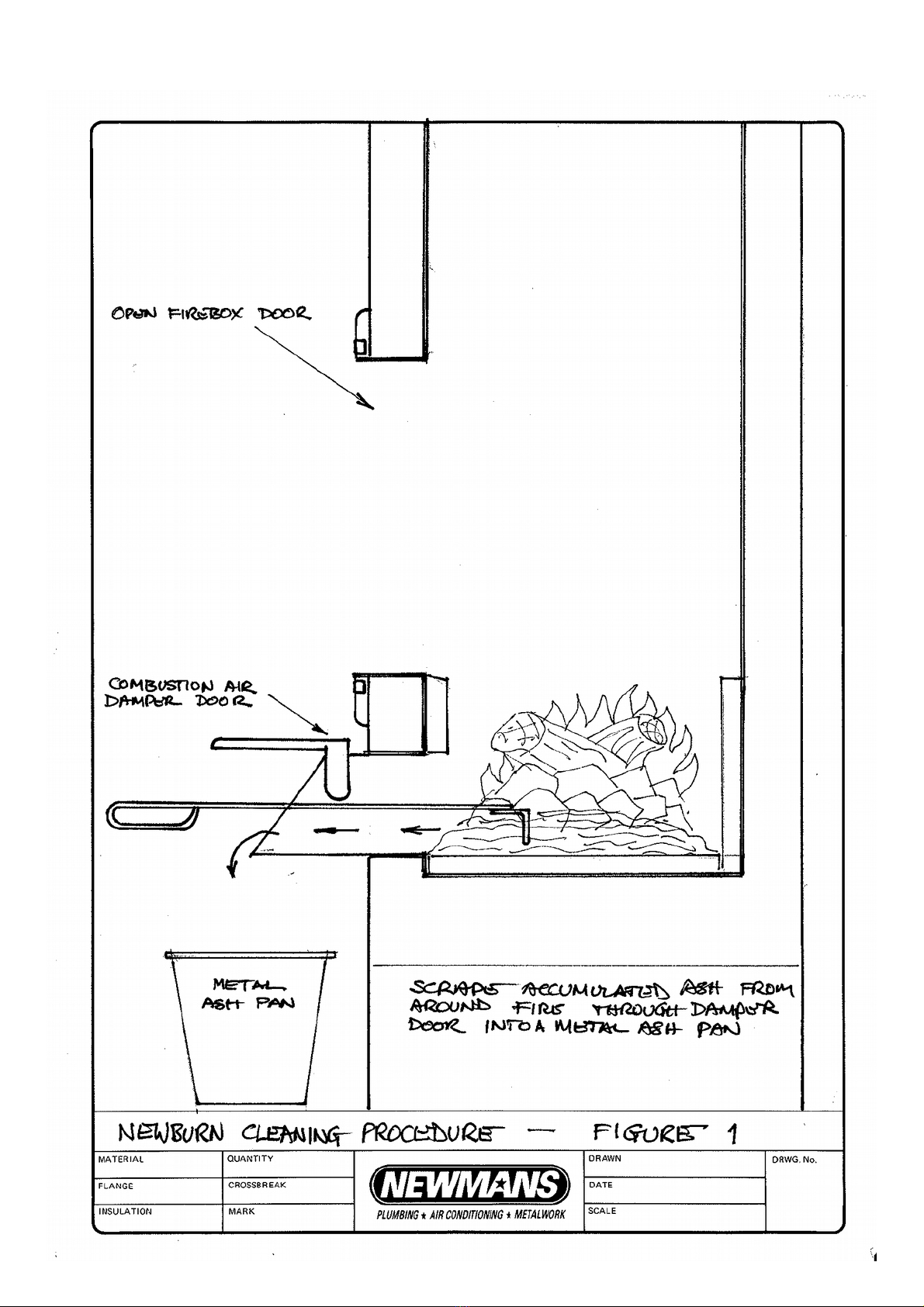

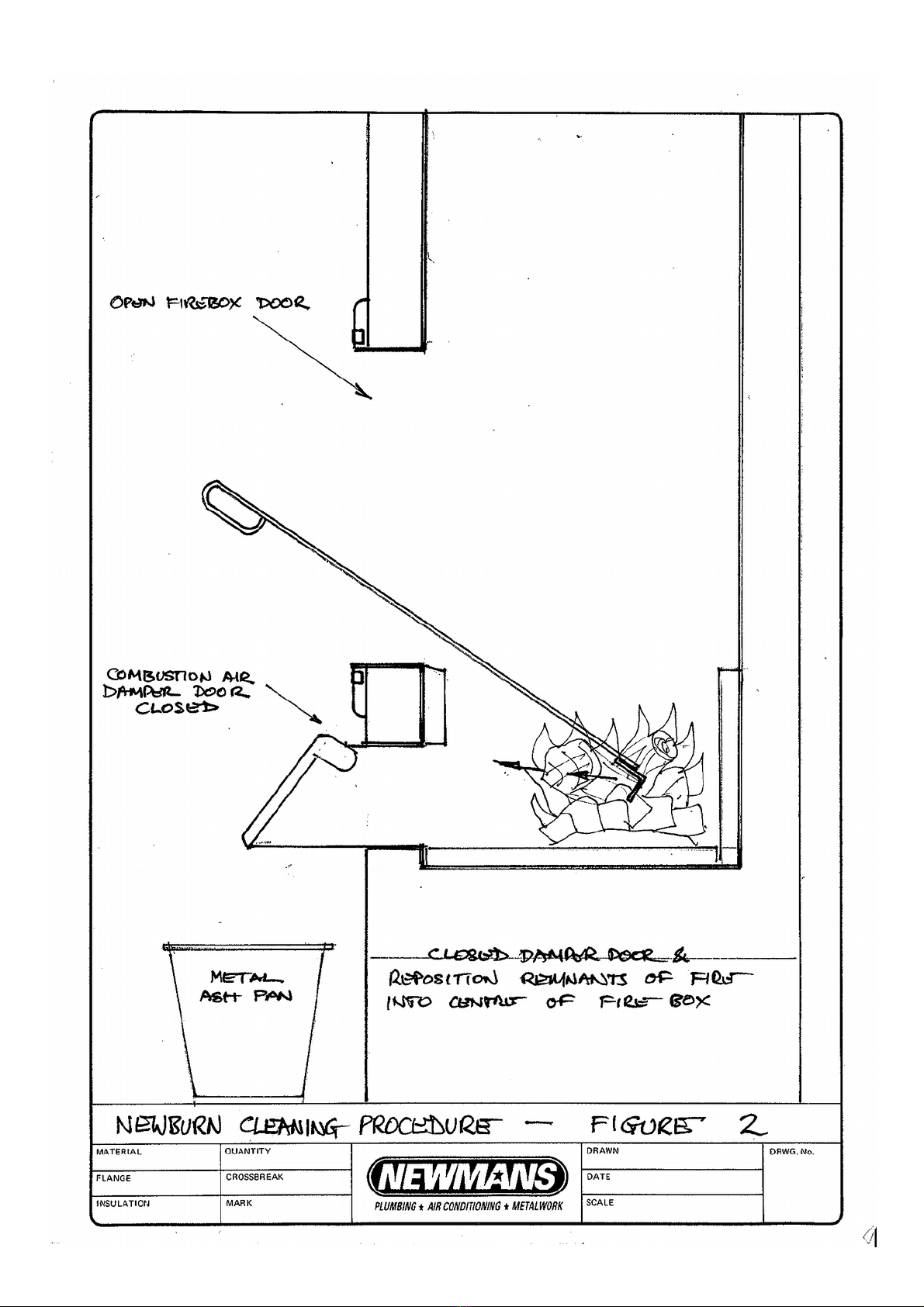

The thermostat controls the output from the heater by activating the combustion air damper. When

the thermostat calls for heat the combustion air damper opens which allows the fire to build up to

maximum temperature. When the room reaches the desired temperature the thermostat closes the

combustion air damper allowing the fire to reduce to slow combustion.

SUPPLY DUCTWORK

The ductwork must be fabricated from non combustible material, thermally insulated and designed

not to restrict the total air movement to the outlets and in no case start off less than 350 mm

diameter.

It is essential that at least five 300 x 100 floor outlets be left open at all times otherwise the ewburn

will overheat which will cause damage to the heat exchanger.

The ductwork must be designed to recognised standards and installed by competent tradesperson

with experience in this field to ensure correct operation.

RETUR AIR DUCT

For maximum economy it is recommended that a minimum 350 mm diameter return air duct be

connected to deliver room air back to the furnace for reheating. The return air duct should be

insulated for noise absorption and thermal insulation and connected into the side or rear of the fan

compartment.

Return Air is best collected at low level from within the house.

( ote : Return Air Grille not supplied with furnace).

ELECTRICAL REQUIREME TS

The heater requires a power supply to operate the combustion air damper motor and supply air fan.

Power supply to be 240 volts/50HZ.

A dedicated hard wired connection is recommended to avoid inadvertent switching off or unplugging

as may occur when connected to a general power outlet. Ensure the power supply is always

switched on prior to lighting the furnace.

It is important the room thermostat wiring circuit operates the combustion air damper only.

Control of the supply air fan is temperature actuated by the inbuilt heat exchanger thermostat

(Honeywell fan/limit controller) which is mounted on the right front of the ewburn.

Ensure this is set on Auto mode (out).