Nextron tracemate User manual

TRACE

MATE

OPERATOR’S MANUAL

ELECTRONIC THERMOSTAT

TRACE

MATE

Contents

1 Product Overview .................................................................................................................... 1.1

Introduction........................................................................................................................................................................ 1.1

Using this Manual ............................................................................................................................................................. 1.1

Features and Benefits....................................................................................................................................................... 1.1

Conventions....................................................................................................................................................................... 1.1

Specifications .................................................................................................................................................................... 1.2

2 Installation................................................................................................................................2.1

Unpacking the Controller.................................................................................................................................................. 2.1

Control Module.................................................................................................................................................................. 2.1

Mounting the Controller .................................................................................................................................................... 2.3

Wire Sizing ........................................................................................................................................................................ 2.3

Conduit and Cabling ......................................................................................................................................................... 2.3

Power Wiring..................................................................................................................................................................... 2.3

Heater Wiring .................................................................................................................................................................... 2.3

Ground Connection........................................................................................................................................................... 2.3

RTD Sensor Wiring ........................................................................................................................................................... 2.3

Alarm Wiring ..................................................................................................................................................................... 2.4

3 Applications .............................................................................................................................3.1

Mechanical Thermostat Replacement............................................................................................................................. 3.1

Alarm Annunciator ............................................................................................................................................................ 3.1

Switching Requirements................................................................................................................................................... 3.1

4 Operation .................................................................................................................................4.1

Alarms................................................................................................................................................................................ 4.1

Status Indicators ............................................................................................................................................................... 4.1

Alarm Reset....................................................................................................................................................................... 4.1

Heater Setpoint and Alarm Setpoints ............................................................................................................................. 4.1

5 Testing...................................................................................................................................... 5.1

Troubleshooting/System Integrity .................................................................................................................................... 5.1

Calibration ......................................................................................................................................................................... 5.1

Ground Fault Testing ........................................................................................................................................................ 5.2

Repairs............................................................................................................................................................................... 5.2

Warranty ....................................................................................................................... Back Cover

TRACE

MATE

1.1

Product Overview

Introduction

The TraceMate solid state heat tracing control is an

electronicthermostat designed tomaintain a singleheater

at a desired setpoint temperature. It is suitable for use

with mineral-insulated, self-regulating or constant-

wattage cable in applications such as freeze protection,

process control and instrument tracing. The TraceMate is

intended for indoor or outdoor installation in ordinary or

class 1, division 2 hazardous locations.

TraceMate offersmanyadvantagesover other heat tracing

control schemes, which generally use some combination

of mechanical thermostats, custom-built panels or

programmable controls to provide control, monitoring

and alarm functions.Wiring costs are minimized by

mounting the control in close proximityto the heat tracing

cable and pipe. ANEMA 4X enclosure and wide tempera-

ture range electronic components are used to make

mounting possiblein most locations.Temperature

sensing is achieved bymounting a 100 ohm platinum

(DIN 43760) RTD sensor on the pipe. Heater current is

controlled bya solid state switch rated 30A. The

temperature setpoint is digital for fast non-ambiguous

setting over a wide range. Maximum system reliabilityis

obtained from a comprehensive alarm package which

includes indicators for quick fault identification and a

ground fault trip tominimize fire hazards.

Bycombining the control, system monitoring and testing

requirements of a heat tracecontrol system into a general

purpose control, the TraceMate makes it possible to

significantly upgrade systems at low installed cost. In

addition, it is very flexible in its application to adapt to

specific user requirements. Using dip switch and jumper

connection, TraceMate provides users a comprehensive

method to adjust heater setpoint, lowtemperature alarm

setpoint,high temperaturealarmsetpoint, currentfail

alarm setpoint, and ground fault trip alarm setpoint. Their

respective factory default values are:

Heater setpoint: 20°C

Low temp alarm: 5°C

High temp alarm: 100°C

Current fail alarm: 0.3 A

Ground fault trip alarm: 30 mA

Using This Manual

Detailed information relating to switch and output

ratings, accuracy etc. are detailed in Chapter 1, Product

Overview.Chapter 2, Installation discusses important

mounting and wiring issues for reliable operation.

Chapter 4, Operation describes how to setup and operate

the controller. The remainder of this manual should be

read and kept for reference for optimal performance of

the TraceMate.

Features and Benefits

Requirements TraceMate Features

Temperature

Control

*

*

*

*

0-511°C/0-511°F setpoint

Non-ambiguous, digital temperature

setpoint

100 ohm platinum RTD sensor

3-wire, lead resistance compensation

System Fault

Alarms

*

*

*

*

*

*

Breaker left off or tripped

Heater continuity or low current

Ground fault trip

Low temperature

High temperature

Broken sensor

Early Warning

*

*

*

Tracecheck exercises dormant

systems every 24 hours for early

warning to prevent shutdowns

Status indicators show cause of

alarms

Separate fail-safe local and remote

alarms

Remote

Monitoring *

*

Form C alarm dry contact output for

digital alarm interface

LED Alarm indicator viewable on

door

Hazardous/

Ordinary Area

Mounting

*

*

*

*

CSA approved for ordinary or Class

1, Division 2, Grps A,B,C,D

hazardous area

-40° to +50°C operating range

30 amps @120, 208 or 240VAC

rating

Weatherproof, Nema-4X enclosure

Easy retrofit replacement for

mechanical thermostat

Low Installed

Cost

*

*

*

*

Competitively priced

Self contained, no control panel to

build

Ground fault trip eliminates expensive

ground fault circuit breaker

Standard model simplifies spare

parts stocking

WarningStatement

VDC(DC Volatge)

Conventions

Thefollowing conventionsareused in thismanual:

V~

VAC(AC Volatge)

1.2

TRACE

MATE

Product Overview

Temperature Range

Range: -50°C to 500°C, -58°F to 932°F

Hysteresis: ±2°C, ±3.2°F

Absolute Accuracy: ±2.5°C, ±4.5°F

Repeatability: ±1°C, ±1.8°F

RTD: 100 ohm platinum, 3-wire 20 ohms

maximum lead resistance

Heater Switching

Configuration Single-pole

Dual-pole, Dual SCR, one per phase

Ratings: Single-pole, 120Vac @ 30 amps

Dual-pole, 208-240Vac @30amps

250 amp 1/2 cycle inrush

Line Frequency 50 or 60Hz

Control Power

Power Requirements Control power from heater voltage

Single-pole, 120Vac, 10VA

Dual-pole, 208-240VacC, 10VA

Protection Control power from heater voltage

protected by 2A fuse.

MOV transient protection and RC

snubber

User Interface

Heater Setpoint 12 position dip switch

Reset/Heater Test dip switch

Panel Indicators Power on

Heater on

Low temperature alarm

High temperature alarm

Current fail alarm

Ground fault trip alarm

RTD fail alarm

Environment

Approvals: CSA NRTL/C and FM

Class I, Div.2, Groups A,B,C,D

Class I, Zone 2, Groups IIC

Operating Range: Single-pole: -40°C to +50°C

Dual-pole: -40°C to +40°C

Heater current derated

Conformal Coating: Boards conformal coated for hostile

environments.

User-Definable Options

Heater Setpoint:

Low Temperature Alarm Setpoint:

High Temperature Alarm Setpoint: 0°C-511°C, 1°C steps

0°F-511°F, 1°F steps

Temperature Units: 0°C or °F

Current Fail Alarm Setpoint: 0.0A-30.0A, 1 A steps

Ground Fault Trip Alarm Setpoint: 0mA-511mA, 1 mA steps

Enclosure

Type: E5: Nema-4X steel, painted black

Size: Single-pole: 8”Hx6”Wx4”D

Dual-pole: 10”Hx8”Wx4”D

Features: Quick release latches to open door

One 3/4” conduit knockout for power

and two 1/2” conduit knocks for RTD

and signal wiring.

Alarms

Low Temperature: Actual temperature < low temperature

alarm setpoint

High Temperature: Actual temperature > high temperature

alarm setpoint

Current Fail: Heater current < current fail alarm

setpoint

Ground Fault Trip: Ground fault current > Ground fault trip

alarm setpoint

RTD Fail: RTD Open, RTD Short

Hardware: No incoming voltage

TraceCheck: Current Fail Alarm

Configurationt: NC/NO Contacts

Alarm Output Rating: Form C dry contact: 12-277Vac@ 0.5A,

30VDC/0.1A.

LED Indicator: 6VDC/50mA

Alarm Function

Temperature: Low Temperature Alarm

High Temperature Alarm

Current: Current Fail Alarm

Ground Fault Ground Fault Trip

Hardware RTD Open, RTD Short

Specifications

Heater Current Rating

1 and 2-Pole Switching

0

5

10

15

20

25

30

35

-10 0 10 20 30 40 50

Ambient Air Temp (°C)

Heater Current (Amps)

1-Pole

2-Pole

TRACE

MATE

2.1

Chapter 2

Installation

Unpacking the Controller

Check the shipping cartons for damage, or other signs of

rough handlingor abuse. Ifdamaged, notifytheshipping

carrier at once.

Carefullyremove theTraceMate from the shipping box.

Inspect face plate for shipping damage and check

electronics for loose wiring or damage. Report any

damage to the carrier at once.

Control Module

See Figure 2.1 TraceMate Controls and Indicator Layout

to locate the following:

Switches and Jumpers

•S1-9Setpoint Number:

S1-9 consists of 9 switches.Theyare S1, S2, S3, S4,

S5, S6, S7, S8 and S9. These 9 switches generate a

Setpoint Number in a range of 0-511.The exact value

of this Setpoint Number equals the sum of the

contributions by each switch. If a switch is in OFF

position, its contribution is zero. If it is in ON position,

its contribution equals the value labeled on the board.

Ex. 1: If all 9 switches are in the ON position,

SetpointNumber=1+2+4+8+16+32+64+128

+ 256 = 511.

Ex. 2: If only switches 4 and 16 are in the ON position,

SetpointNumber=0+0+4+0+16+0+0+0+0

= 20.

•S10Temperature Units:

°C if S10 is on °C side.

°F if S10 is on °F side.

•S11RESET: Latched “Current fail” or “Ground Fault

Trip” alarms are cleared when S11 isswitched towards

the RESET sidemomentarilyif the alarm conditions

are no longer exist.

•S12TEST: Manually forces heater on when S12 is on

TEST side. Noeffect if the ground fault trip is active.

•JP1Setpoint Configuration:

LT: Setpoint Number generated byS1-9 is interpreted

as lowtemperature alarm setpoint in °C or °F.

HT: Setpoint Number generated by S1-9 is interpreted

as high temperature alarm setpoint in °C or °F.

GF: Setpoint Number generated byS1-9 is interpreted

as ground fault trip alarm setpoint in mA.

AMP: Setpoint Number generated by S1-9 is divided

by10 and interpreted as current fail alarm setpoint in

A.

SP: Setpoint Number generated byS1-9 is interpreted

as heater setpoint in °C or °F.

NONE: Setpoint Number generated by S1-9 has no

effects on any setpoints.

Warning -The ground fault trip function is

intended for equipment protection only and

should not be used in place of ground fault

protection for personnel protection where

thisis required.

There are no consumable components contained in any of

the models covered in this manual.

There is no cleaning requirements for anyof the modules

covered in this manual.

Terminals

Refer to Figure 2.2 Typical Wiring Diagram, for

power, heater and RTD field connections.

•T1Form C Alarm Dry Contacts: Both NO (terminals

10 and 11) and NC (terminals 12 and 11) are rated

•T2Alarm Light Output: The output is configured as

normally closed. Output is rated 6 Vdc @ 50 mA for

an LED type lamp (terminals 8+ and 9-).

•T3RTD Input: 3 wire RTD input. Lead resistance

compensated. (terminals 5,6,7).

•T4Ground Stud.

•T5Heater Power Input: 120VAC/30Amax for TM-

1SIH1-xx and 208-240VAC/30Afor TM-1DIH2

(terminals 1 and 2).

•T6Heater Power Output: 30A max (terminals 3 and 4).

StatusLights:

•L1HTR ON: Light is on calling for heat.

•L2RTD FAIL: Light is on when controller detects

open or short RTD inputs.

•L3LO TEMP: Light is on when controller detects a

lowtemperature alarm.

•L4HI TEMP: Light is on when controller detects a

hightemperaturealarm.

•L5AMPFAIL: Light is on when controller detects a

current fail alarm.

•L6GF: Light is on when controller detects a ground

faulttripalarm.

•L7PWRON: Lightisonwhencontrolpoweris

present.

Warning - During installation, disconnect

power supply.

2.2

TRACE

MATE Chapter 2

Installation

Figure 2.1 TraceMate Controls and Indicators

Figure 2.2Typical Wiring Diagram

TRACE

MATE

2.3

Chapter 2

Installation

Mounting the Controller

Mount the control panel with Unistrut brackets using 3/

8” bolts. The Unistrut (or equivalent) mounting allows

air circulation to cool the heat-sink. This is important to

ensure proper operation of the Tracemate. Mounting

dimensions are shown in Figure 2.5.

Wire Sizing

Conduit and Cabling

TraceMate comes with one 3/4” and 1/2” conduit

knockouts located on the bottom of the enclosure.

Conduit hubs should be NEMA-4X rated, such as T&B

H050-0.5 and H075-0.75 or Myers equivalent, to

maintain a watertight seal. Unused knockouts should be

sealed using NEMA-4X rated seals.

Power Wiring

The power input terminals supply power to both the heat

trace and controller. Size power input wires appropriately

tothe breaker size andmaximum ambientoperating

temperatures.Maximum breaker size is30A. Connect

power wires to input terminals 1 and 2. See Figure 2.2.The RTD probe is delicate and should not

be bent or used as a tool to puncture

insulation.

Wiring methods should comply with Canadian

Electrical or National Electrical Code and

local codes. Power and signal wires should not

be run in the same conduit system. Wiring

should be rated at least 90 °C.

Wire Size (AWG) Current Load (A) Max. Ambient

Tempera ture (°C)

63050

83040

10 24 50

12 16 50

The supply voltage must be 120VAC forTM-

1SIH1-E5-RTD ( Single-pole ) or 208-240VAC

for TM-1DIH2-E5-RTD ( Dual-pole ) and

rated voltage range of the heat trace cable.

Wiring methods must conform to Class 1,

Division II or Class 1, Zone II requirements.

Heater Wiring

Connect heating cablewiring to terminals 3 and 4. See

Figure 2.2. If the heating cable has a braid, it should be

terminated tothe ground stud using a ring terminal

suitable for #10 stud.

Figure 2.3 Ground Connection

Ground Connection

Connect the controller grounding stud directlyto a ground

bus using the shortest, practical path. Use a tinned copper,

braided bonding cable such as Belden 8660. As a guide-

line, the ground cablesshould be minimum 96 strands,

number 34AWGeach.

To install the ground connection, remove theoutside nut,

washer and #8 ring lug provided on the ground stud.

Crimp theground cableonto the ring lug and re-assemble

onto the ground stud using the washer and nut.

Figure 2.4 RTD Mounting

RTD Sensor Wiring

RTD sensors should be 3-wire, 100 ohm, platinum to

DIN standard 43760. Mount the RTD element on the

pipe, away from the heat trace and 30° to 45° from the

bottom of the pipe. The total circuit resistance per

conductor from the RTD to the control panel must be

less than 10 ohm. Exceeding this resistance will result in

a non-linear temperature measurement. Belden cable

8770 or equivalent allows RTDs to be placed up to 1,000

feet from the control panel. Complete all RTD wiring

according to Figure 2.2 Typical Wiring Diagram.

2.4

TRACE

MATE Chapter 2

Installation

You must install the RTD sensor on the pipe surface or

thermal well before the pipe insulation to ensure proper

thermal contact. The RTD position should be 180° from

the electric heat trace cable which is the coldest spot of

thepipe.TheRTDsensormaybesecuredtothepipeby

fiber-glass tape. Ifadditional wiring is required for the

RTD, shielded 3-lead wire sized 18 or 20AWG must be

used for the RTD sensor to minimize the effects of noise

pickup. Atypical RTD installation is shown in Figure 2.4.

Alarm Wiring

TraceMate has a form c dry alarm contact and an active

alarm output for driving an LED alarm indicator. The

alarm LED output is configured to turn on the alarm

indicator when there is no alarm. Refer to Figure 2.2for

contact and alarm output terminals.

The form c dry alarm contact is rated 0.5A 277Vac/0.1A

30Vdc.

The alarm LED output is rated 6Vdc, 50mA. It can drive

a 6Vdc LED indicator.

These alarm contact and output are designed as interface

to annunciator, PLC, DCS, or panels.

Figure 2.5 Enclosureand Mounting Dimensions

Warning - Explosion Hazard - Substitution

of components may impair suitability for

Class 1, Division 2 or Class 1, Zone 2.

Warning - Explosion Hazard - Do not

disconnect equipment unless power has

been switched off or the area is known to be

non-hazardous.

TRACE

MATE Chapter 3

APPLICATIONS

3.1

Mechanical Thermostat Replacement

Mount the control unit near the pipe being traced in a

location with easy access. Replace the thermostat

capillary tube with an RTD mounted on the pipe and

connect the existing heater and power wires to the

TraceMate as shown in Figure 3.1. A green alarm status

light, visible to maintenance personnel, is connected to

the TraceMate LED alarm output and should be always

on. If the light goes off, the following may have oc-

curred: (1) bulb burnt out (fail-safe indication); (2) no

control power available; (3) system fault. Examine the

LEDs inside the TraceMate to determine the cause of the

alarm.

Advantage of this scheme over mechanical thermostats

is: easy setpoint adjustment and early warning of system

faults with TraceCheck system exercising every 24 hours

and rapid fault diagnosis in the event of a problem.

Alarm Annunciator

If an alarm annunciator or programmable controller is

available, terminal 10, 11 &12 can be used as a low cost

digital interface. These terminals are form C dry con-

tacts. A separate voltage source must be connected across

these terminals as shown in Figure 3.2 for the annuncia-

tor to sense the alarm logic

Switching Requirements

Two different TraceMate models are available to accom-

modate different power configuration of electric heat

trace. The single pole switching model is used for phase

to neutral power feed such as 120VAC. 208 and 240VAC

are both phase to phase power feed and will require a two

pole switching model to ensure both lines are switched

off. Not only is this an electrical code requirement, but to

ensure both connections to the heater are not hot when

the controller is not calling for heat. This is especially

important for the ground fault function to operate

properlysince switching onlyone line there is a 50%

chance that the heater output is properlytripped.

Figure 3.1 Thermostat Replacement

Figure 3.2 Alarm Annunciator

TRACE

MATE Chapter 4

Operation

4.1

Alarms

When an alarm condition occurs, the form c dry alarm

contact reacts and the corresponding alarm LED comes

on to indicate the cause of the alarm. Fault diagnosis for

these alarms is listed below.

RTD Fail: If the RTD sensor is not connected or

shorted, RTD FAIL alarm LED will turn on. Check that

the RTD sensor is properly connected. This alarm is not

latched and will be reset as soon as the RTD is properly

connected. In the event of an RTD failure, the heater

output isturned offto prevent a runawayheating

situation.

LowTemperature: Once the actual temperature is below

thelow temperature alarm setpoint, LOTEMPalarm

LED will turn on. This will normally indicate that the

heater circuit is not providing enough heat tomaintain the

setpoint. When a system is first turned on this alarm may

be activated. It is particularlyuseful in taking corrective

action in freezeprotection systems to prevent a burst

pipe. This alarm is not latched and will be reset as soon as

thealarm condition disappears.

High Temperature: Once the actual temperature is above

thehigh temperature alarm setpoint, HITEMPalarm

LED willturn on. This alarm is not latched and will be

reset as soon asthe alarm condition disappears.

Current Fail:This alarm is activated when the TraceMate

control calls for heat and a heater current less than the

current fail alarm setpoint flows. Either the continuity of

the wiring and heat tracing cable is defective or a very

small heater is being switched. In order to detect faults on

dormantsystems with theTraceCheck feature, which

turns on the heaters for several secondsevery24 hours,

this alarm is latched. Thus, once the condition is detected,

the alarm will remain on until it is reset.

Ground Fault Trip: This alarm is activated when the

ground fault current is above the ground fault trip alarm

setpoint. Aground fault is a current to ground caused by

moisture,corrosion or insulation breakdown. Often the

amount ofground fault current is not enough to trip the

heater circuit breaker but could result in a serious fire

hazard, especiallywith self-regulating cable.

When a ground fault is detected, the heater will be

switched off, even if the control is calling for heat. This

eliminates the need for an expensive ground fault circuit

breaker. Largeground fault currentswill trip theheater

circuit breaker, so an intentional time delayis allowed for

the breaker to clear high fault currents, which can occur

on solidly grounded systems.

Since the heater maybe shut off after a ground fault, it is

very important that the alarm outputs beused so

corrective action can be taken quicklyenough to prevent

a process shutdown due to the loss of heat to a pipe.

Ground fault detection only works with resistance or

solidly grounded systems. If the system is ungrounded, it

must be grounded or an artificial ground must be created

bymeans of a zip-zag transformer. Oncea ground fault

condition isdetected, it remains latched until it is reset.

Status Indicators

Power On Indicator: When incoming voltage is applied

to the TraceMate, the green PWR ON indicator LED

should be on. If this LED is not on, check that the

appropriate voltage is present by connecting a meter

across terminals 1 and 2. If voltage is present and the

LED is off, the controller should be replaced and sent to

the factory for service.

Heater On Indicator: Whenever the heater is on, the green

HTR ON indicator LED will be on. This is useful for

checking correct operation of the control. If the ground

fault alarm light or RTD fail alarm light is on, the heater

will not switch on even if the actual temperature is below

the setpoint.

Alarm Reset

The low/high temperature and RTD fail alarms reset as

soon asthe condition disappears.The ground fault trip

and current fail alarm arelatchedalarms.Alatchedalarm

will remain even if the alarm condition disappears. To

reset the latched alarms, remove incoming power for a

few seconds by opening and reclosing the circuit breaker.

Provided the alarm conditions are no longer present, the

alarms should all be reset when power is re-applied to the

TraceMate. It is also possible to reset the latched alarms

bymomentarilyswitching S11 towards itsON position (

refer to Figure 2.1 ) even if the TraceMate is at control

with power applied.

Heater Setpoint andAlarm Setpoints

As stated in chapter 2, five setpoints can be adjusted by

properlysetting up S1-9 and JP1 ( refer to Figure 2.1 ).

S1-9 consisits of 9 switches. Theyare S1, S2, S3, S4, S5,

S6, S7, S8 and S9. These 9 switches generate a Setpoint

Number in a range of0-511. The exact value of this

Setpoint Number equals the sum of the contributions by

each switch. Ifa switch isin ON position, its contribution

to the Setpoint Number equals its labelled value on the

board. Otherwise, its contribution is zero. For example, if

all 9 switches are in ON position, Setpoint Number =

1+2+4+8+16+32+64+128+256 = 511. If only switches

S3 and S5 are in ON position, Setpoint Number =

0+0+4+0+16+0+0+0+0 = 20.

Depending on the jumper position of JP1, the Setpoint

Number generated by S1-9 can beinterpreted as either

heater setpoint,or lowtemperature alarm setpoint, or high

temperature alarm setpoint, or ground fault trip alarm

setpoint, or current fail alarm setpoint.

TRACE

MATE Chapter 4

Operation

4.2

Heater Setpoint: If the jumper on JP1 is at SP position,

the Setpoint Number generated by S1-9 is interpreted as

the heater setpoint. Whether the setpoint is in °C or °F

depends on the position of S10 ( refer to Figure 2.1 ).

The factory default value is 20°C.

LowTemperatureAlarm Setpoint: If the jumper on JP1 is

at LT position, the Setpoint Number generated byS1-9 is

interpreted as the low temperature alarm setpoint in °C or

°F. The factory default value is 5°C.

High TemperatureAlarm Setpoint: If the jumper on JP1

is at HT position, the Setpoint Number generated by S1-9

isinterpreted as thehigh temperaturealarm setpoint in °C

or °F. The factory default value is 100°C.

Ground Fault TripAlarm Setpoint: If the jumper on JP1

is at GF position, the Setpoint Number generated byS1-9

is interpreted as the ground fault trip alarm setpoint in

mA. The factory default value is 30 mA.

Current FailAlarm Setpoint: If the jumper on JP1 is at

AMP position, the Setpoint Number generated byS1-9 is

divided by10 and interpreted as the current fail alarm

setpoint in A. The factorydefault value is 0.3A.

NONE: If the jumper on JP1 is at NONE position, the

Setpoint Number generated byS1-9 has no effects on any

setpoints.

Once the jumper is at NONE position, all the adjusted

setpoints will be saved in EEPROM which means that

their values will not be changed even after power off.

TRACE

MATE Chapter 5

TESTING

5.1

Troubleshooting/SystemIntegrity

Amajor concern in heat tracing is knowing that the

control and heater cablearefunctioning normally. On

systems that sit idle for long periods, such as freeze

protection, faults usuallyshowup when the system is

needed most. Users often perform an annual check on

mechanical thermostats toensure that problems have not

developed. This is a tedious task because the controls are

often high off the ground in inaccessibleareas.

SincetheTraceMate controlusesanRTD,itcanbe

mounted in a convenient ground level location near other

controls for easy access. Indicator lights for HEATER ON

and POWER indicate the system status. If the RTD sensor

or wiring goes open/short circuit, the NO SENSOR LED

comes on indicating a fault. For this condition the actual

temperature output indicates a value out of the

temperaturemeasurement range, i.e. [-50°C-500°C] or

[-58°F-932°F].

The control can be forced on or off easily by changing the

heater setpoint switches to be above or below the actual

process temperature, noting the HEATER ON LED and

heater current with a clamp-on ammeter.

Calibration

Although theTraceMate control is constructed with

precision components and should give long service

without anyrecalibration necessary, users however may

wish to perform periodic calibration checks. When the

TraceMate control is first installed, or for periodic

maintenance checks, system operation can be verified by

adjusting the heater setpoint dip switch 2°C above and

below a known temperature on the RTD input to see if the

heater turns on and off . For example, if the RTD input

temperature is 25°C, setting the heater setpoint to 27°C

will force the heater on and conversely a 23°C setpoint

will forcethe heater off.

Bysubstituting a known resistor valuefor the RTD sensor

and looking up the equivalent temperature in tables 5.1

and 5.2, the calibration accuracyof the control can be

verified. This can be done in the field without removing

the controlusing a resistancesimulator box and a quality

digital multimeter.

Disconnect the incoming RTDwires andconnect a

resistance box. Simulatean RTD temperature using the

variable resistor or decade box and set the heater setpoint

dip switch 2°C above the simulated temperature. The

heater LED should turn on. Setting the heater setpoint dip

switch 2°C below the simulated temperature, heater LED

should turn off.

Table 5.1 Resistance versus Temperature in °F

(DIN 43760 RTD)

°F R (ohms) °F R (ohms) °F R (ohms)

-40 84.27 160 127.50 360 169.29

-30 86.47 170 129.62 370 171.34

-20 88.66 180 131.74 380 173.39

-10 90.85 190 133.86 390 175.43

0 93.03 200 135.97 400 177.48

10 95.22 210 138.08 410 179.51

20 97.39 220 140.18 420 181.55

30 99.57 230 142.29 430 183.58

40 101.74 240 144.38 440 185.61

50 103.90 250 146.48 450 187.63

60 106.06 260 148.57 460 189.65

70 108.22 270 150.66 470 191.67

80 110.38 280 152.74 480 193.68

90 112.53 290 154.82 490 195.69

100 114.68 300 156.90 500 197.69

110 116.83 310 158.97

120 118.97 320 161.04

130 121.10 330 163.11

140 123.24 340 165.17

150 125.37 350 167.23

Figure 5.1 RTD Simulation

TRACE

MATE Chapter 5

TESTING

5.2

Table 5.2 Resistance versus Temperature in °C

(DIN 43760 RTD)

°C R (ohms) °C R (ohms) °C R (ohms)

-40 84.27 80 130.89 200 175.84

-30 88.22 90 134.70 210 179.51

-20 92.16 100 138.50 220 183.17

-10 96.09 110 142.29 230 186.82

0 100.00 120 146.06 240 190.46

10 103.90 130 149.82 250 194.08

20 107.79 140 153.58 260 197.69

30 111.67 150 157.32 270 201.30

40 115.64 160 161.04 280 204.88

50 119.39 170 164.76 290 208.46

60 123.24 180 168.47 300 212.03

70 127.07 190 172.16

Ground Fault Testing

It is possible to simulate a ground fault bycreating a

situation where the current from the two heater terminals

1and2isnotequal.Asshowninfigure5.2,thisisdone

byconnecting a resistor across terminals 1 and 4.

Followthese steps to test the ground fault circuit:

1. Turn on incoming power. Set thegound fault trip

alarm setpoint to 30mA ( default ).

2. Turn off incoming power.

3. Connect a resistor between terminals 1 and 4.

This allows ground fault current I

G

to flow,

which will be seen bythe ground fault sensor as

a ground fault. Sizethe resistor according to the

Heater Voltage 110 240 208 AC Volts

Resistance 2700 6200 5100 Ohms

Wattage 5 10 10 Watts

Voltage Rating 250 500 500 DC Volts

table to ensure sufficient ground fault current of

30mA± 25%.

4. Apply power. The ground fault indicator should

come on after a short delay. It should not be

possible to turn on the heater even if the actual

temperature is belowthe setpoint. The

TraceMate acts a ground fault circuit breaker.

5. Turn off incoming power.

6. Remove the ground fault resistor between

terminals 1 and 4.

7. Re-applypower.All alarm indicatorsshould be

off.

Repairs

In the event of a hardware failure, system operation can

be restored quicklyby following this procedure:

1. Turn off incoming heater and alarm power.

2. Ensure that all wires are correctlymarked for the

corresponding terminals.

3. Disconnectall wires to theterminals.

4. Remove any screws holding the TraceMate

controller and return it tothe factoryfor repair.

5. Install a replacement TraceMate controller.

6. Reconnect the wires, apply power and follow

the testing procedure for a new control.

Figure 5.2 Ground Fault Simulation

Warranty

The manufacturer warrantseach control that it manufactures to be free from

defective material or workmanship for a period of 12 months from date of

purchase.

Under this warranty, the obligation of the manufacturer is limited to repairing

or replacing the defective control at its option, when returned to the manufac-

turer’s factory with shipping charges prepaid.

If failure has been caused by misuse, incorrect application or alteration of the

control,thiswarranty will bevoid.

UNLESS SPECIFICALLY PROVIDED FOR IN WRITING IN THIS WAR-

RANTY, EACH CONTROL IS PROVIDED WITHOUT ANY WARRANTY OF

ANY KIND EITHER EXPRESSED OR IMPLIED. IN PARTICULAR, WITH-

OUT LIMITING THE GENERALITY OF THE FOREGOING, THE FOLLOW-

ING IMPLIED WARRANTIESAND CONDITIONSARE EXPRESSLY DIS-

CLAIMED:

a). ANY IMPLIED WARRANTYOR CONDITION THAT THE CON-

TROL WILL MEET YOUR REQUIREMENTS.

b). ANY IMPLIED WARRANTY OR CONDITION THAT THE OP-

ERATION OF THE CONTROL WILL BE UNINTERRUPTED OR

ERROR FREE; AND

c). ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY OR FITNESS FORAPARTICULAR

PURPOSE.

The user shall be made aware that if the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may

be impaired.

TRACE

MATE

ELECTRONIC THERMOSTAT

P/N: 1501-0012_1 TMII 02/09 Printed in Canada

Nextron Limited 6120 11

th

Street S.E., Calgary, Alberta, T2H 2L7, Tel:(403) 735-9555, Fax: (403) 735-9559

Table of contents

Other Nextron Thermostat manuals

Popular Thermostat manuals by other brands

Pro1 Technologies

Pro1 Technologies RZ251W Operation manual

ICM Controls

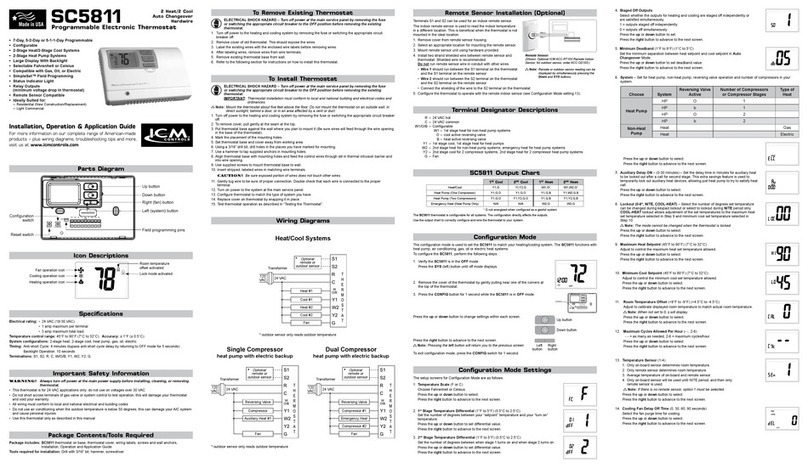

ICM Controls SC 5811 Installation, operation & application guide

Daikin

Daikin TSTATD2200C-2 Owner's manual and installation instructions

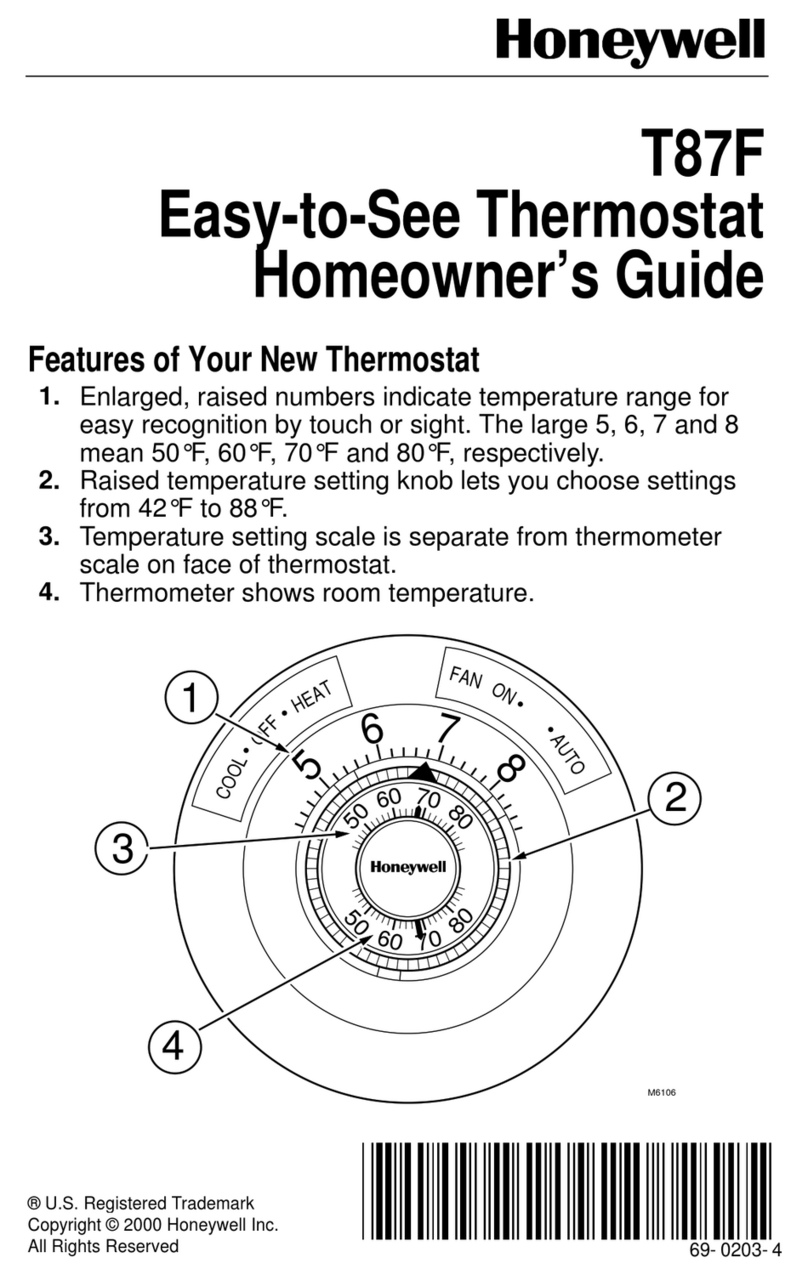

Honeywell

Honeywell T87F Homeowner's guide

ELEKTROBOCK

ELEKTROBOCK BPT010 manual

Ducasa

Ducasa TP520 user manual