8Instructions Manual

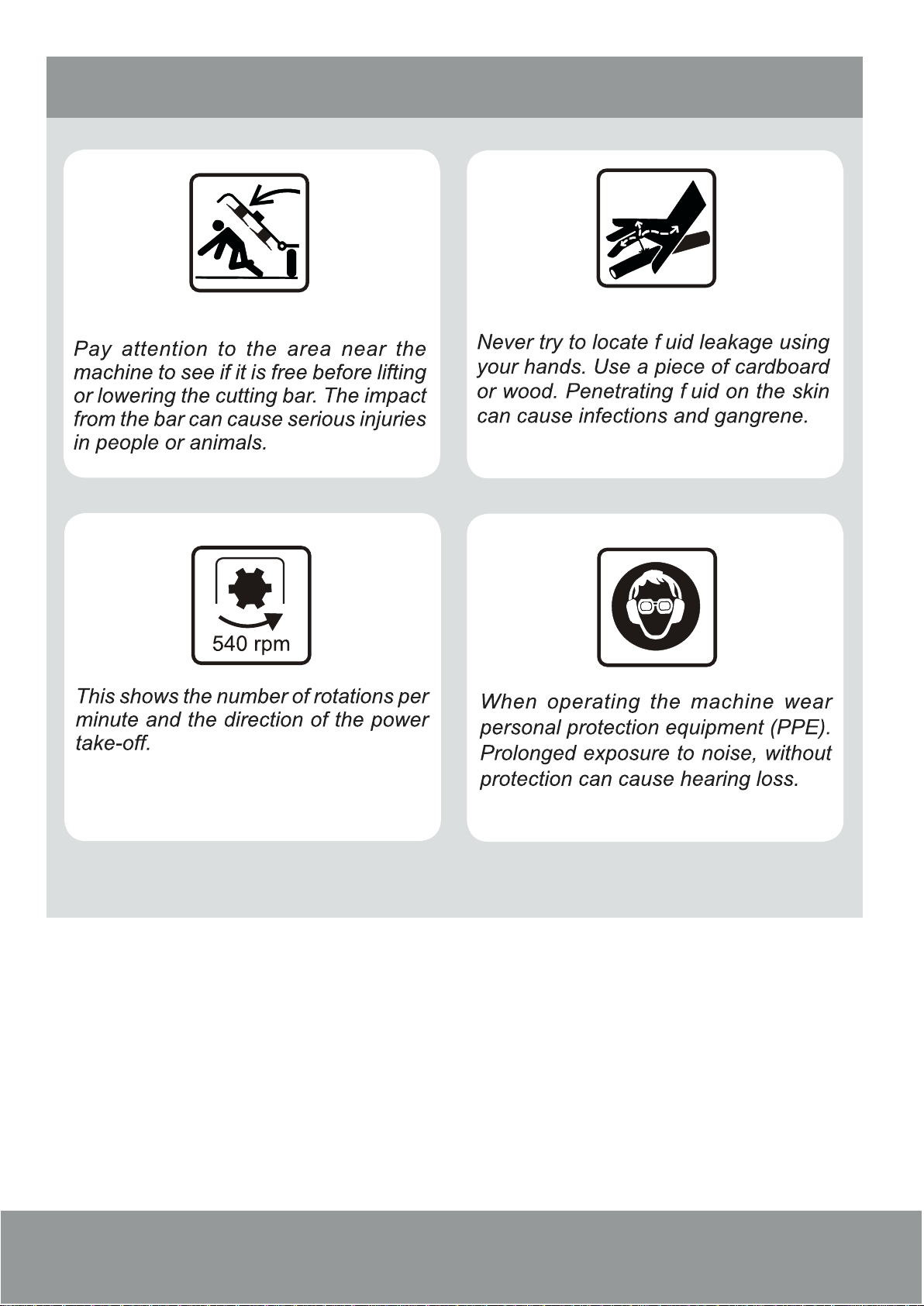

-Keepatasafedistancefromthemachinewhenitisoperating.

-Nevertrytousethemachinewithoutplacingtheprotectivecoveringtarp,asobjectscanbethrownby

the blades, which can injure people. Be especially careful when working around roadways and

constructions.

-Checktheterrainbeforestartingyourwork. Markthe dangerousareasorobstacleswhichmaymake

theworkdangerous.

-Beespeciallycarefulwhencouplinganduncouplingthemachinefromthetractor.

- Never operate the machine inside closed surrounding without ventilation, gases released from the

tractormotorareveryharmfultothehealthoftheoperator.

-Placethemachineinanappropriatepositionfortransporting.

-Whentransporting the machine on public roads, obey the local regulations ontrafficand safety. Find

out the legal limits on the maximum height and width for transport. Pay special attention to the height,

especiallywhengoingunderoverpasses.

- Never leave the tractor when the machine is turned on. Stop the motor, disconnect it from the power

take-off,engagetheparkingbrake,andremovethekeyfromtheignitionbeforegettingout.

- Leakage of the fluid from the hydraulic system is almost imperceptible. Use a piece of wood or

cardboard but never your hands to check for leakage. Protect your hands and body, as these fluids

may be released at high pressure and cause serious injuries. In case of any accident, consult with a

doctorimmediately.

-Alwaysadjustthespeedofthetractortothelocalconditions.Avoidsudden maneuvers, especially in

uneven locations. When the load hitched to the tractor is heavier than the tractor, do not exceed 16

km/hour.

- Pay double attention when working on sloped terrains and if you notice any signs of being

imbalanced,reduceacceleration.Keepthetractoralwaysengagedwhengoingdownslopes.

- The tractor must always be maneuverable. Place enough counterweights on the tractor, so the front

tiresstayinfirmcontactwiththeground.

-Bepreparedincaseofanaccident.Keepafirst-aidkitinaneasilyaccessiblelocation.Andknowhow

touseit.

-Complywiththe safetyrecommendationsandpayattention.Anylackofattention whileoperatingthe

machinecancauseaccidents.

Safety