Norsonic nor1217 User manual

INSTRUCTION

MANUAL

Outdoor microphone

nor1217

Outdoor microphone

nor1217

Nor1217 – User Guide

Im1217_1Ed1R1En – November 2013 edition

Norsonic is a registered trademark of Norsonic AS.

Every effort has been made to supply complete and ac-

curate information. However, Norsonic AS assumes no

responsibility for the use of – or for the consequential dam-

age resulting from the use of – this information and/or the

instrumentation described herein. Furthermore, Norsonic AS

assumes no responsibility for any infringement of the intel-

lectual property rights of third parties, wherever applicable,

which could result from such use.

Norsonic AS reserves the right to amend any of the informa-

tion given in this manual in order to take account of new

developments.

If you wish to communicate with us, please feel welcome

Our address is:

Norsonic AS, P.O. Box 24, N-3421 Lierskogen Norway,

Find us on the web: www.norsonic.com

Tel: +47 3285 8900

Fax: +47 3285 2208

E-mail: [email protected]

Copyright © Norsonic AS 2013

All rights reserved

v

Norsonic Nor1217

Instruction Manual

v

Contents

Chapter 1 Introduction ......................................................................................................... 1

Chapter 2 Assembling .......................................................................................................... 2

Grounding and lightning protection 3

Chapter 3 Microphone calibration....................................................................................... 4

Chapter 4 Technical description.......................................................................................... 5

Electrical description 6

System check 7

Frequency response 9

Self-noise 10

Cables and cable length 11

Directional response 12

Frequency response 13

Self-noise and wind 14

Chapter 5 Connecting the Nor1217 to Sound Analyser Nor140...............................................15

Chapter 6 Maintenance........................................................................................................17

Chapter 7 Specifications .....................................................................................................18

Mounting direction 18

Acoustic performance 18

General 18

Frequency response 18

Directional response 18

General 18

Conformity 19

Protection provided by the enclose 19

Accessories and spare parts 19

1

Norsonic Nor1217

Instruction Manual

1

Introduction

The outdoor microphone Nor1217 is a measurement

microphone protection kit for all-weather conditions. It

is mainly intended for temporary outdoor applications.

The microphone contains elements for protecting the

microphone cartridge from rain, snow, dust and insects,

satisfying IP 55 requirements. The Protection kit is

designed for use with the preamplifier Nor1209 and one

of the microphones Nor1225 or Nor1227.

Further, compared to a standard measurement micro-

phone, the Nor1217 improves the measurement accu-

racy by reducing the wind noise and by improving the

directional response for sound from different directions.

Combined with a suitable sound level meter including

a frequency response correcting function, the Nor1217

satisfy Class 1 specification requirements according to

IEC61672-1 and similar national standards for a sound

level meter class 1.

The microphone is intended for vertical mounting only

since the act of gravitation forms a part of the rain pro-

tection system. The reference direction may, however,

be selected to be vertical or horizontal based on the

applied frequency response compensation in the sound

level meter.

The outdoor microphone may be calibrated with a

normal sound calibrator suitable for ½” working stand-

ard microphones (WS2) and without the need for extra

accessories. Access to the microphone cartridge is

easily gained by dismounting the upper part of the

outdoor microphone.

The base of the Nor1217 is made of an electrical insulat-

ing material. The microphone body will be fully insulated

from the mounting mast thereby reducing pick-up of

electrical hum and noise.

The preamplifier Nor1209 used in the Nor1217 kit is

equipped with the standard 7-pin Lemo connector for

microphone preamplifiers. For verification of proper

operation, the preamplifier is equipped with a system

check facility, where an electrical signal applied on one

of the terminals are returned after passing through the

complete signal chain, thus verifying proper operation

of the microphone cartridge, preamplifier and micro-

phone cable.

Nor1217 is mainly designed to be used with the Nor140

Sound Analyser. This instrument has the requested fre-

quency compensation and delivers the required current.

2Chapter 2

Assembling

Assembling

The outdoor microphone Nor1217 normally shipped

without preamplifier and microphone, since these parts

is normally taken from the Nor140 Sound Analyser.

Depending on the application, you will need a mast

or tripod for mounting the microphone system and

possibly devices for proper grounding and lightning

protection, see below.

We recommend cable type Nor1408A, which

comes in standard lengths of 5, 10, 15, 20, 30 and 50

metres – other lengths are available on request. This

cable is Teflon®-insulated and hence absorbs very lit-

tle water, which is very important in order to retain high

insulation in all weather conditions. The mantle is made

of polyurethane to ensure a robust cable, yet flexible at

low temperatures.

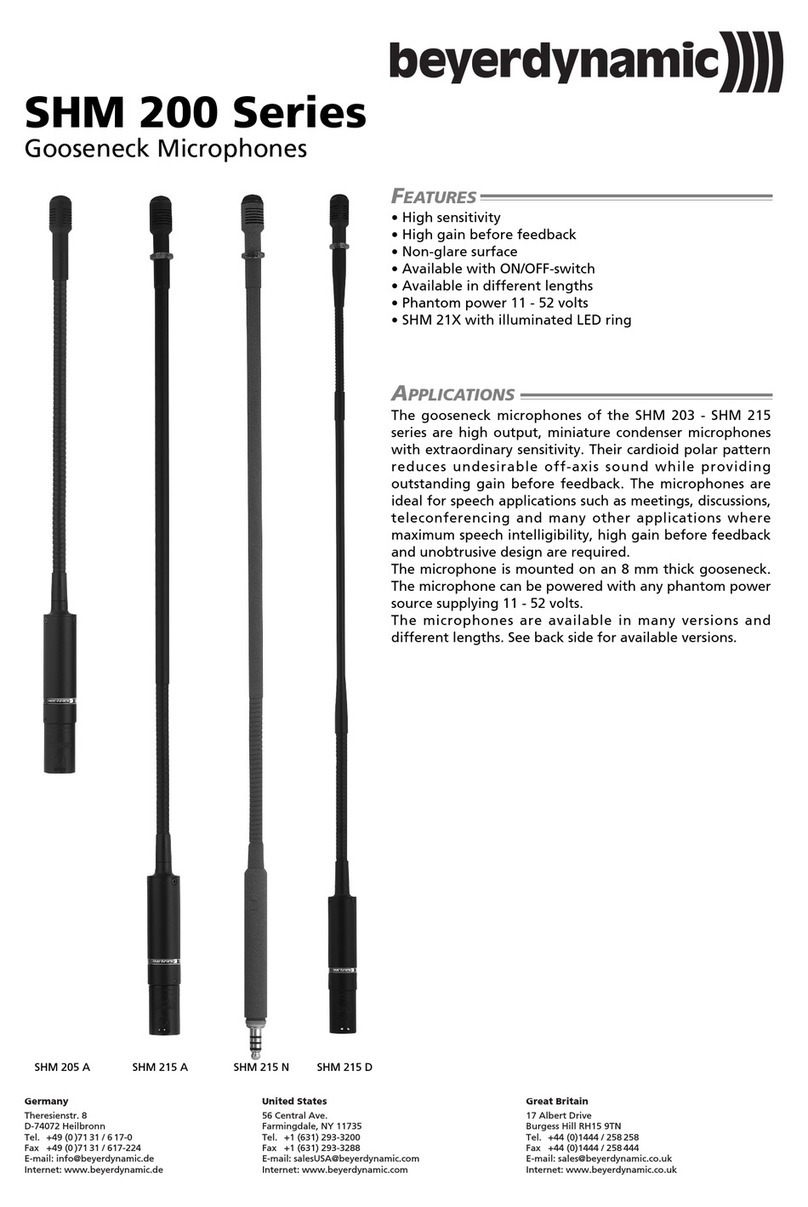

Birdspike

Wind, dust and

water protection

Upper part

Microphone cartridge

Microphone preamplifier

Nor1209

Base

Connector/cable

Optional tripod adaptor

with tension relief

O-ring

NOTE: You need to use the “A” version

of the 1408 cable (1408A). The cable

comes with a threaded female connec-

tor housing that fits to the 1209 preamp-

lifier lock nut. Older versions (not “A”) of the ca-

ble do not have this treads and will not fit into the

microphone kit. The rubber protection covering

the female connector housing must be removed

in order to fit into the microphone kit.

3

Norsonic Nor1217

Instruction Manual

Unscrew and remove the upper part consisting of

birdspike and windscreen as one unit. Do not remove the

windscreen from this upper part as this may destroy the

weather protection and alter the acoustic performance.

The unit is delivered with an adaptor for mounting

on a tripod. The cable is led through a slot in the side of

the adaptor. The base screw has a threaded hole like

those commonly used for cameras (3/8” UNC). The

base screw also forms a tension relief for the cable.

Remove the base screw and slide the cable through

the base unit. Assemble the microphone cartridge to

the preamplifier and connect the preamplifier to the

cable. We recommend to mount the supplied O-ring

between the microphone cartridge and the preamp-

lifier. Screw the lock nut on the preamplifier onto the

female connector on the 1408A cable. Push the pre-

amplifier carefully into the base unit. The preamplifier

and microphone is aligned in the correct position by

a spring force. After mounting the upper protection

part, the outdoor microphone unit will be ready for use.

However, we recommend that you test the unit togeth-

er with the measuring instrument by applying a calibra-

tor before the upper part is mounted.

Grounding and lightning protection

If the outdoor microphone assembly is the highest ob-

ject in the vicinity when mounted, it may be exposed

to lightning strokes. We recommend to use a conduc-

tivemast and to ground it properly. A rod in proper con-

tact with the conductive mast should be made at the

side and 50 cm above the tip of the microphone. The

rod should be placed at least 25 cm to the side of the

microphone assembly and have a diameter not more

than 10 mm in order not to interfere with the directional

properties of the microphone.

Safety considerations may require the screen of the

microphone cable to be properly grounded and that

the internal conductors are clamped for high voltage

protection.

We recommend making the combined grounding

for the cable and instrument at one point only in order

to reduce the risk of pick-up of hum and electromag-

netic noise.

Verify the noise floor of the complete system after

installation is completed to ensure it is below the lower

end of the required measurement range. If a quiet lo-

cation is not available, the noise floor may be meas-

ured by substituting the microphone with a dummy mi-

crophone like Nor1448. As an alternative the Nor1447

adaptor terminated with a short-circuit or a 50 ohm

BNC termination is also a suitable device for making

this test. A sound calibrator in OFF-mode may also be

used to attenuate the external noise. A ½” microphone

normally requiring polarization voltage may also be

used without polarization voltage. It will then have a

very low sensitivity.

NOTE: Please note that the System

Check signal must be deactivated when

you want to calibrate the microphone with

an acoustical calibrator. Unless deacti-

vated, you will read unstable values due to the

interference between the System Check signal

and the signal from the sound calibrator.

4Chapter 3

Microphone calibration

Microphone calibration

The Nor1217 can be calibrated with a sound calibra-

tor for ½” microphones without the need for special

couplers. We recommend using Nor1251 (1000 Hz) or

Nor1253 (250 Hz).

Unscrew the upper part of the microphone to gain

access to the microphone cartridge. Mount the cali-

brator slowly and carefully while turning the calibrator

and switch it on. See figure.

If the calibrator frequency is 250 Hz, adjust the

reading to be the level stated for the calibrator, e.g.

124,0 dB for Nor1253 with 124 dB specified level.

If the calibrator frequency is 1000 Hz, adjust the

reading to be 0,1 dB below the stated calibrator level,

e.g. 113,9 dB for Nor1251 calibrator with a stated level

of 114 dB.

This is only valid if the frequency response correc-

tion is turned off. For the Nor140 the frequency cor-

rection is turned off, when entering into the calibration

menu. Perform calibration and calibrate the micro-

phone as a normal free field microphone. I.E. -0.1 dB

if using a 1000 Hz calibrator. When leaving the cali-

bration menu, you will observe that the level measured

with the calibrator on, is different from what obtained

in the calibration mode. This is correct, and is due to

the frequency correction added. If horizontal position

is selected, the signal will be about 0.1 dB higher than

the calibrated signal, in vertical position the signal will

be 0.3 dB lower than the calibrated level. This does

not apply if you calibrate with a 250 Hz calibrator since

there is no correction added at this frequency.

5

Norsonic Nor1217

Instruction Manual

Technical description

The outdoor microphone Nor1217 is based on a ½”

working standard microphone type WS2F according

to IEC 61094-4.

Two types of microphones is tested and is recom-

mended;

- Nor1225, a free field microphone requiring 200V

polarisation voltage.

- Nor1227, a free field self polarised microphone.

Both microphones have a nominal sensitivity of 50 mV/P

a. However, each microphone is individual calibrated

and may differ slightly from this value.

The upper part of the Nor1217 consists of wind-

screen, rain hood, dust mesh and birdspike and pro-

tects the microphone from rain, snow, dust and insects.

Both the rain hood and the dust mesh are made of a

water-repellent fabric open for the sound. The sound

is reaching the microphone through nine slots placed

equidistantly around the circumference of the circular

body of the upper part. The mechanical part with the

birdspike is also important for the directional response

of the complete microphone system.

The upper part may be removed as one unit and will

thus give easy access to the microphone cartridge for

testing and calibration.

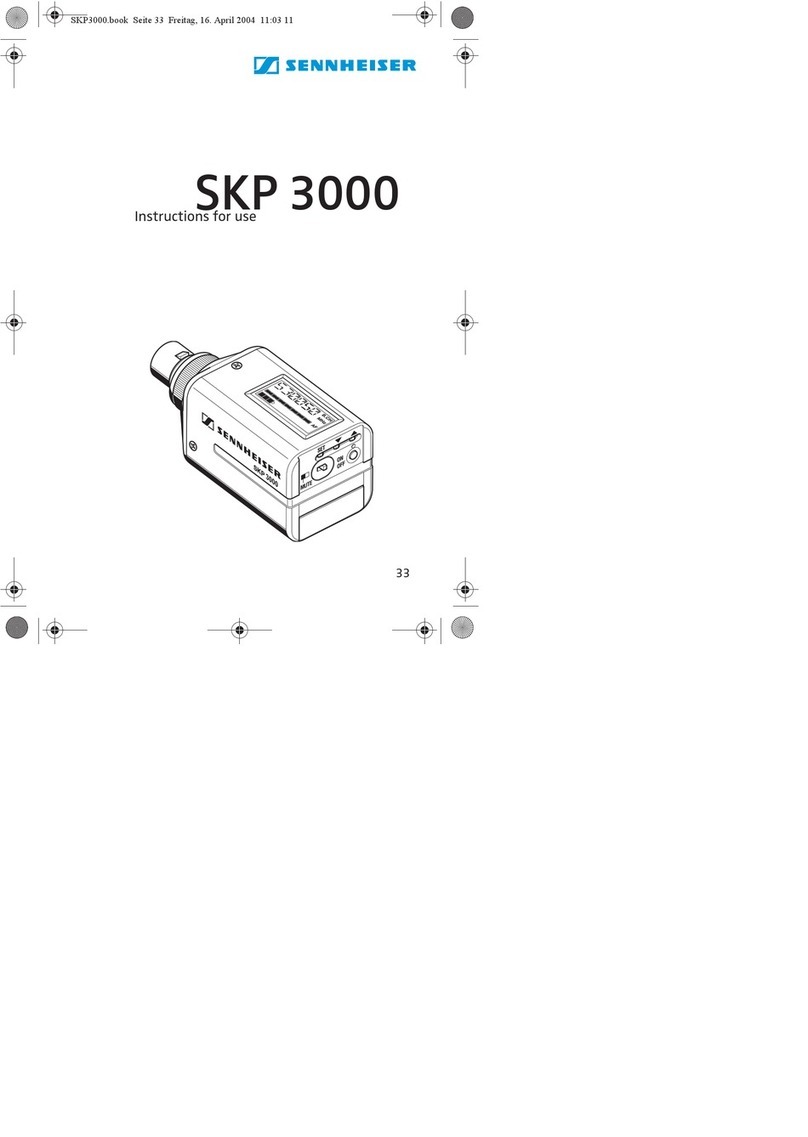

Birdspike

Windscreen

Microphone cartridge

Rain hood

Dust mesh

Preamplifier

Plate for type and

serial number

Base

Unscrew the

upper part

here!

Upper part

6Chapter 4

Technical description

The lower part consists of the base, the microphone

cartridge and the preamplifier Nor1209. A normal mi-

crophone cable supplied with Norsonic sound level

meters, like Nor1408A, should be used for connec-

tion to the sound level meter instrument. An adaptor

for mounting the outdoor microphone on a tripod is

included.

The base is made of black polyacetal (POM). The

material is durable and insulating, thus preventing

electric noise from ground loops through the mast.

Drops of water from rain are kept away from the mi-

crophone diaphragm by the combined act of the tubu-

lar windscreen, the rain hood and the dust mesh. The

upper part of the microphone cartridge is air- and wa-

ter tight, and the backside is vented to the air through

the preamplifier.

The Ingress Protection Category for the assembled

microphone is IP55 according to IEC 60529.

Consider the assembly of microphone cartridge

and preamplifier as a single unit when operated in the

field. If disassembled in the field, the performance may

be reduced due to contamination from dust and hu-

midity.

When Nor1217 substitutes a normal measurement

microphone on a sound level meter, a correction of the

frequency response is needed to retain the class of

accuracy for the sound level meter, see Specifications.

Based on the correction, the reference direction may

be selected to be either horizontal or vertical. Horizon-

tal reference direction is usually selected for sound

approaching the microphone mainly along a horizon-

tal axis like noise from industry or vehicles. A vertical

reference axis is usually used for measuring the noise

from aircraft.

The sound analyser Nor140 has a correction net-

work where the reference axis for the outdoor micro-

phone Nor1217 may be selected to be horizontal or

vertical

See separate description in this manual on how to con-

figure the Nor140, Chapter 5.

Electrical description

The power to the Nor1217 will normally be supplied

from a Norsonic sound analyser Nor140 instrument

and the user does not need detailed knowledge of the

interconnection. Alternatively, the microphone unit may

be supplied either from a single supply in the range 28

V to 120 V or a symmetric supply in the range ±14 V to

±60 V. The latter alternative is recommended. Required

current is 3mA. The connection is shown on the adjacent

figure. (Outside view for the connector).

Pin 3, allocated for polarization voltage, shall be ter-

minated to signal ground (pin 2) for the microphone

cartridge Nor1227. When the microphone unit is

equipped with the Nor1225 microphone cartridge where

polarization voltage is needed, 200 V must be supplied

to this terminal.

Rain hood

Microphone

cartridge

Dust mesh

Wind screen

7

Norsonic Nor1217

Instruction Manual

The supply voltage will affect the maximum sound pres-

sure that can be measured. For ±15 V or +30 V supply,

the maximum peak value exceeds 10 volt corresponding

to 140 dB peak sound pressure level for the Nor1227 /

Nor1225 microphone cartridge (50mV/Pa).

By the use of the “high level” option in Nor140, signals

with peak values up to 150 dB may be measured with

the microphone cartridge Nor1225.

The figure below shows a simplified electrical circuit

diagram of the complete outdoor microphone. The

microphone cartridge is connected to the preamplifier

input terminal. The figure below shows the output con-

nector seen from outside.

1

2

3

4

5

7

6

Signal ground

Polarization voltage

Signal output

Not connected

Power supply +

Power supply -

5

6

1

4

3

7

2

V+

NC

System check

Output

Heater

resistor

Vpol

V-

GND

System check

The system check terminal, pin 1, shall be termi-

nated to signal ground or the signal output when the

microphone system is in normal use. For checking the

system, a test signal may be supplied, e.g. an AC sig-

nal of 1 volt – 1000 Hz. The signal is transmitted to the

preamplifier input through a capacitor with a very low

capacitance (about 0.8 pF) and further to the signal

output.

The system check is a robust and simple method

for verifying a microphone system. It measures the

change in the capacity of the microphone cartridge.

Nominal cartridge capacity of a ½” microphone is

18 pF. The test signal is feed through a fixed 0,8 pF

capacitor, and the system check voltage is measured

as a function of the attenuation between the 0,8 pF ca-

pacitor and the microphone cartridge with a nominal

capacitance of 18 pF.

8Chapter 4

Technical description

A typical level for the returned signal is 45 mV with

an excitation of 1 volt corresponding to a sound level

of 92 – 95 dB dependant of the microphone cartridge

capacitance. The signal may be used for verification of

correct operation of the cable and preamplifier. Even

a malfunctioning microphone may be detected since

this is normally accomplished by a change in the mi-

crophone capacitance. A very low signal is returned in

case of a short-circuit in the microphone.

A 200 V polarised microphone will show approxi-

mately 2 dB higher level if the 200 V disappear due to

the lost tension and thereby decreased capacity in the

diaphragm when the 200 V is off.

The sound analyser Nor140 has a build-in signal

generator that delivers the required signal for system

check. The signal is switched on/off from the instru-

ment menu. See separate description.

Pin 1, System

Check input Pin 4,

Output

Pin 2,

Ground

Microphone cartridge 18pF

0,8pF

9

Norsonic Nor1217

Instruction Manual

0.1

1 10 100

Frequency [Hz]

1k 10k 100k

8

7

6

5

4

3

2

1

0

1

2

dB

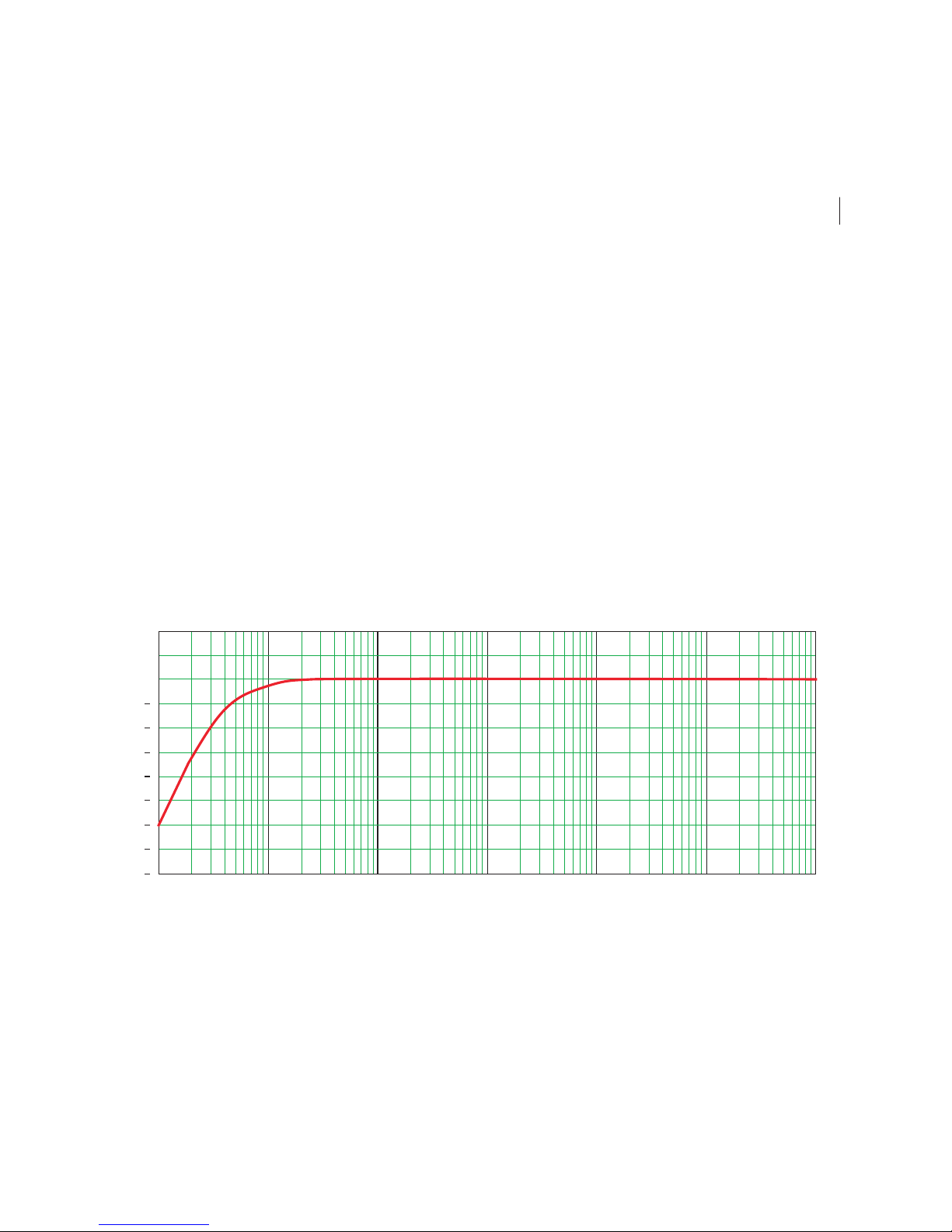

Typical frequency response for the preamplifier Nor1209A

Frequency response

The typical frequency response for the preamplifier

Nor1209 is shown below. The frequency response for

the outdoor microphone system is therefore mainly de-

termined by the microphone cartridge and the acous-

tic performance of the enclosure.

10 Chapter 4

Technical description

-10.0

-5.0

0.0

5.0

10.0

15.0

20.0

6.3 Hz

8.0 Hz

10 Hz

12.5 Hz

16 Hz

20 Hz

25 Hz

31.5 Hz

40 Hz

50 Hz

63 Hz

80 Hz

100 Hz

125 Hz

160 Hz

200 Hz

250 Hz

315 Hz

400 Hz

500 Hz

630 Hz

800 Hz

1.0 k

1.25 k

1.6 k

2.0 k

2.5 k

3.15 k

4.0 k

5.0 k

6.3 k

8.0 k

10.0 k

12.5 k

16.0 k

20.0 k

A C

Frequency [Hz] / Network

Level [dB]

Self-noise

The electrical noise when the microphone is substi-

tuted by an 20 pF capacitor is shown on the graph be-

low. 0 dB corresponds to 1 µV. For a microphone with

a sensitivity of 50 mV/Pa (Nominal value of Nor1225/

Nor1227), 0 dB voltage also corresponds to the normal

reference pressure for sound: 20 µPa and the noise

level may be compared with sound pressure level di-

rectly.

Typical self noise of the microphone system when the microphone is substituted by a capacitor with similar

capacitance as the microphone. Note that the acoustical self-noise for a real microphone will be higher due to

thermal noise in the microphone cartridge.

11

Norsonic Nor1217

Instruction Manual

140

130

120

110

100

90

10 m 50 m 100 m20 m 200 m 500 m

20 kHz

10 kHz

5 kHz

dB

Cable length (120 pF/m)

Level

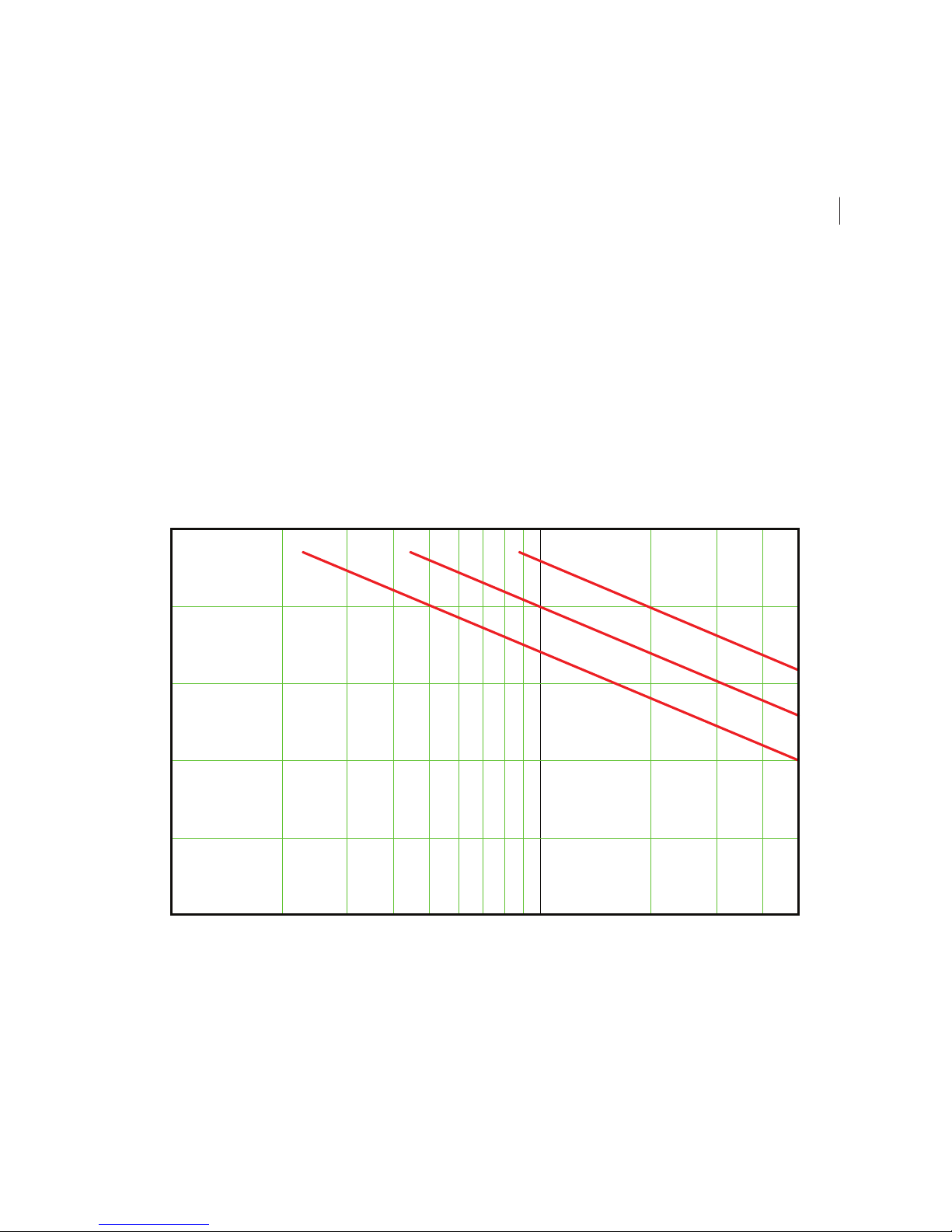

Cables and cable length

The Nor1217 with its preamplifier Nor1209 has excel-

lent driving capability for long cables. The signal output

from the microphone preamplifier will be loaded by the

capacitance of the cable between the microphone sys-

tem and the instrument. The capacitance will increase

proportionally with the length of the cable. A typical

value for microphone cables from Norsonic is 120 pF

per metre. Hence, a cable with length 100 m, will load

the output with a capacitance of 12 nF. For lower fre-

quencies there are seldom problems with long cables.

However, when the signal contains the combination

of high amplitude and high frequency, the capacitive

loading will lead to high output current. A limited cur-

rent capacity will set limits for the maximum slew-rate

for the signal. The figure below shows the maximum

level as function of cable length and frequency. 20 kHz

corresponds to the bandwidth of the microphone sys-

tem with the normal microphone Nor1225 or Nor1227..

12 Chapter 4

Technical description

100 10 k 20 k

1 k

0

1

2

3

4

Frequency [Hz]

+/- 30 deg – Horizontal reference

Directional response

An outdoor microphone system like Nor1217 may

form a part of a sound level meter when applied for

environmental noise monitoring. The combination of

microphone and instrument shall therefore satisfy all

requirements in the international standards for sound

level meters, specified in IEC 61672-1. The Nor1217

in combination with Nor140 is type approved by PTB,

Germany. Ideally, the microphone shall have the same

sensitivity for sound from any direction. The IEC 61672-

1 specifies tolerance limits for the directional response.

The directional response of a microphone is the ratio

of the free field response at a particular frequency as

a function of angle of sound incidence to the response

in the reference direction.

The upper adjacent figure shows the directional re-

sponse for Nor1217, when the reference axis is verti-

cal, for the frequencies 1000 Hz, 4000 Hz and 8000

Hz.

IEC 61672-1 specifies tolerance limits for any frequen-

cy. The limits are depending on the angle from the ref-

erence axis and the standard specify tolerance limits

for angles up to ± 30°, up to ± 90° and up to ± 150°

from the reference axis. The lower adjacent figure

shows the typical max. deviation for the sector up to

± 30° from a horizontal reference axis together with the

applicable tolerance limits for a Class 1 sound level

meter.

13

Norsonic Nor1217

Instruction Manual

Frequency response

The figure below shows the typical frequency re-

sponse for sound approaching the microphone in two

directions. The response marked “Vertical” is the re-

sponse for sound approaching the microphone from

above along the bird spikes, when the microphone is

in the recommended vertical direction. The response

marked “Horizontal” is the response for sound ap-

proaching the microphone in a horizontal direction

when the microphone is mounted in the same recom-

mended vertical direction.

Due to the lower sensitivity for higher frequencies, as

shown on the figure, it is recommended to correct the

frequency response to ensure that the response is

within the requirement for Class 1 sound level meters

specified in the international standard IEC 61672-1.

10 10 0 1k 10 k 20 k

30−

25−

20−

15−

10−

5−

0

5

10

Vertical

Horizontal

Sensitivity level [dB]

Frequency [Hz]

When the microphone system is used in connection

with the precision sound analyser Nor140 (for program

version 3.0 and above), just select 1214/1216/1217

Vertical or Horizontal in the input setup menu to enable

the right settings. Turn the polarization voltage On if

you use a Nor1225 and Off if you use a Nor1227.

When used with Nor118 we recommend the following

corrections:

Vertical: Random response correction (R) and

Windscreen correction (W)

Horizontal: Random response correction (R)

Please note that the frequency compensation applied

using the Nor118 does not fulfil the class 1 require-

ments, but is just a “best fit” method.

14 Chapter 4

Technical description

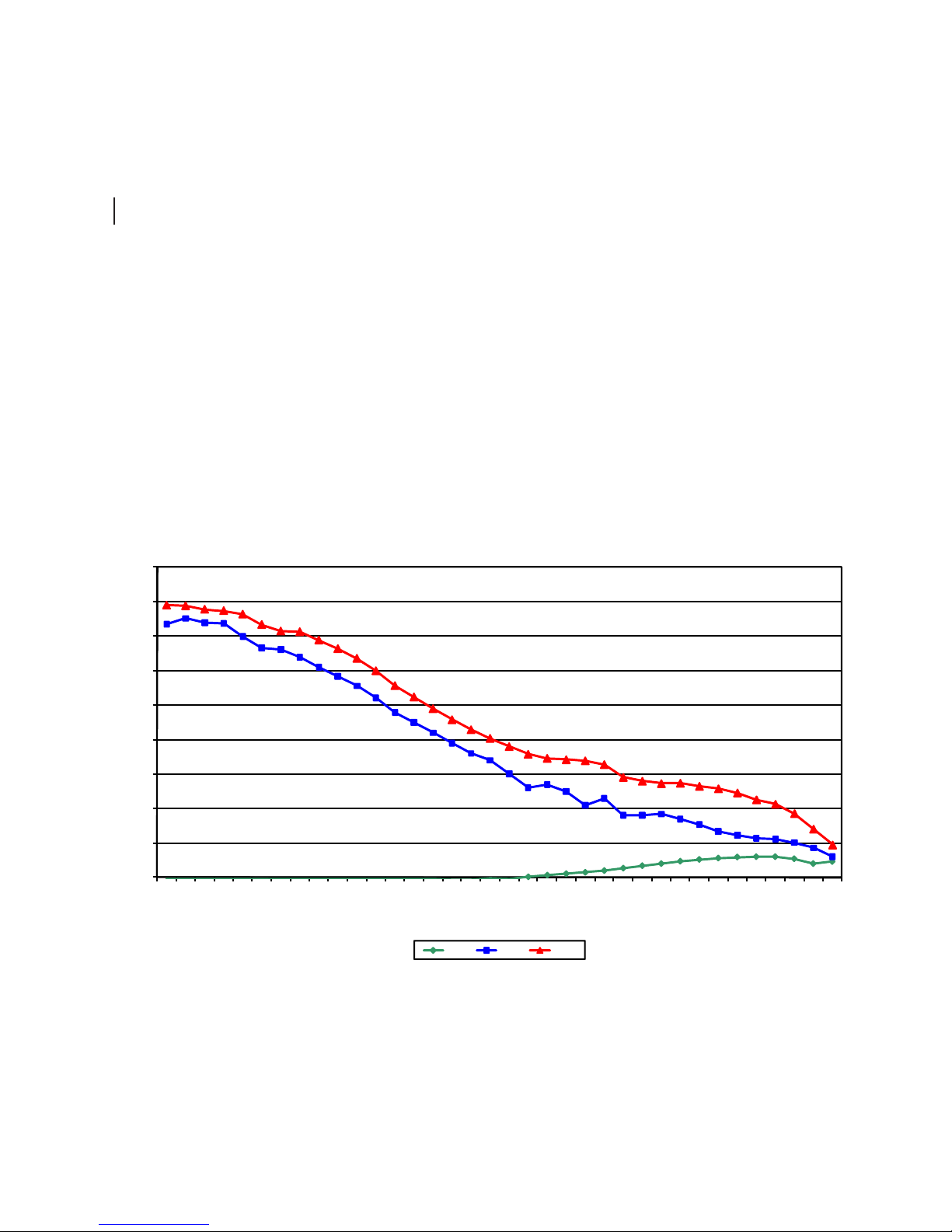

Self-noise and wind

The figure below shows typical self-noise for the mi-

crophone system as levels for the various 1/3-octave

frequency bands re. 20 µPa when the microphone is

placed in a horizontal, laminar flow of air with speed 0,

5 and 10 m/s, respectively. The levels are measured

without frequency compensation. The correspond-

ing A-weighted levels are 16 dB, 40 dB and 48 dB.

Depending on the wind speed, the noise levels are

typically 20 dB to 30 dB lower than for an unprotected

microphone.

0

10

20

30

40

50

60

70

80

90

6,3

8

10

12,5

16

20

25

31,5

40

50

63

80

100

125

160

200

250

315

400

500

630

800

1 k

1.25 k

1.6 k

2 k

2.5 k

3.15 k

4 k

5 k

6.3 k

8.3 k

10 k

12.5 k

16 k

20 k

Sound pressure level [dB]

1/3 octave frequency band [Hz]

0 m/s 5 m/s 10 m/s

Table of contents

Other Norsonic Microphone manuals