Norsup PX Series Operation instructions

SWIMMING POOL HEAT PUMP TYPE PX

ORIGINAL MANUAL

ZWEMBAD WARMTEPOMP TYPE PX

GEBRUIKSAANWIJZING

SWIMMBAD-WÄRMEPUMPEN ART PX

ORIGINALBETRIEBSANLEITUNG

THERMOPOMPE POUR PISCINE TYPE PX

NOTICE ORIGINALE

VARMEPUMP TIL SWIMMINGPOOL

TYPE PX

BETJENINGSVEJLEDNING

VÄRMEPUMP FÖR SIMBASSÄNG

TYP PX

ANVÄNDARMANUAL

PART NO. TYPE

7024626 P13X/32

7024627 P17X/32

7024628 P20X/32

7024629 P20TX/32

7024630 P26X/32

7024631 P26TX/32

7024740 P35X/32

7024632 P35TX/32

Google Play Store Apple Appstore

DOWNLOAD NORSUPONE APP: www.norsup.eu

ENNL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PX 4

ORIGINAL MANUAL

ZWEMBAD WARMTEPOMP TYPE PX 38

GEBRUIKSAANWIJZING

SWIMMBAD-WÄRMEPUMPEN ART PX 72

ORIGINALBETRIEBSANLEITUNG

THERMOPOMPE POUR PISCINE

TYPE PX 106

NOTICE ORIGINALE

VARMEPUMP TIL SWIMMINGPOOL

TYPE PX 140

BETJENINGSVEJLEDNING

VÄRMEPUMP FÖR SIMBASSÄNG

TYP PX 174

ANVÄNDARMANUAL

EN

FR

DE

DA

SV

NL

DE

EN

NL

FR

DA

SV

EN

DE

45

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

1. PREFACE 6

2. SPECIFICATION 8

2.1 Performance data of swimming pool heat pump unit 8

2.2 The dimensions for swimming pool heat pump unit 12

3. INSTALLATION AND CONNECTION 13

3.1 Installation illustration 13

3.2 Swimming pool heat pumps Location 14

3.3 How close to your pool? 14

3.4 Swimming pool heat pumps plumbing 14

3.5 Swimming pool heat pumps electrical wiring 15

3.6 Initial startup of the unit 15

4. OPERATION AND USE 16

4.1 Color screen wire controller interface introduction 16

4.2 Color screen wire controller function introduction 16

4.3 Parameter list and breakdown table 20

4.4 Interface draw in 22

5. MAINTENANCE AND INSPECTION 26

6. APPENDIX 29

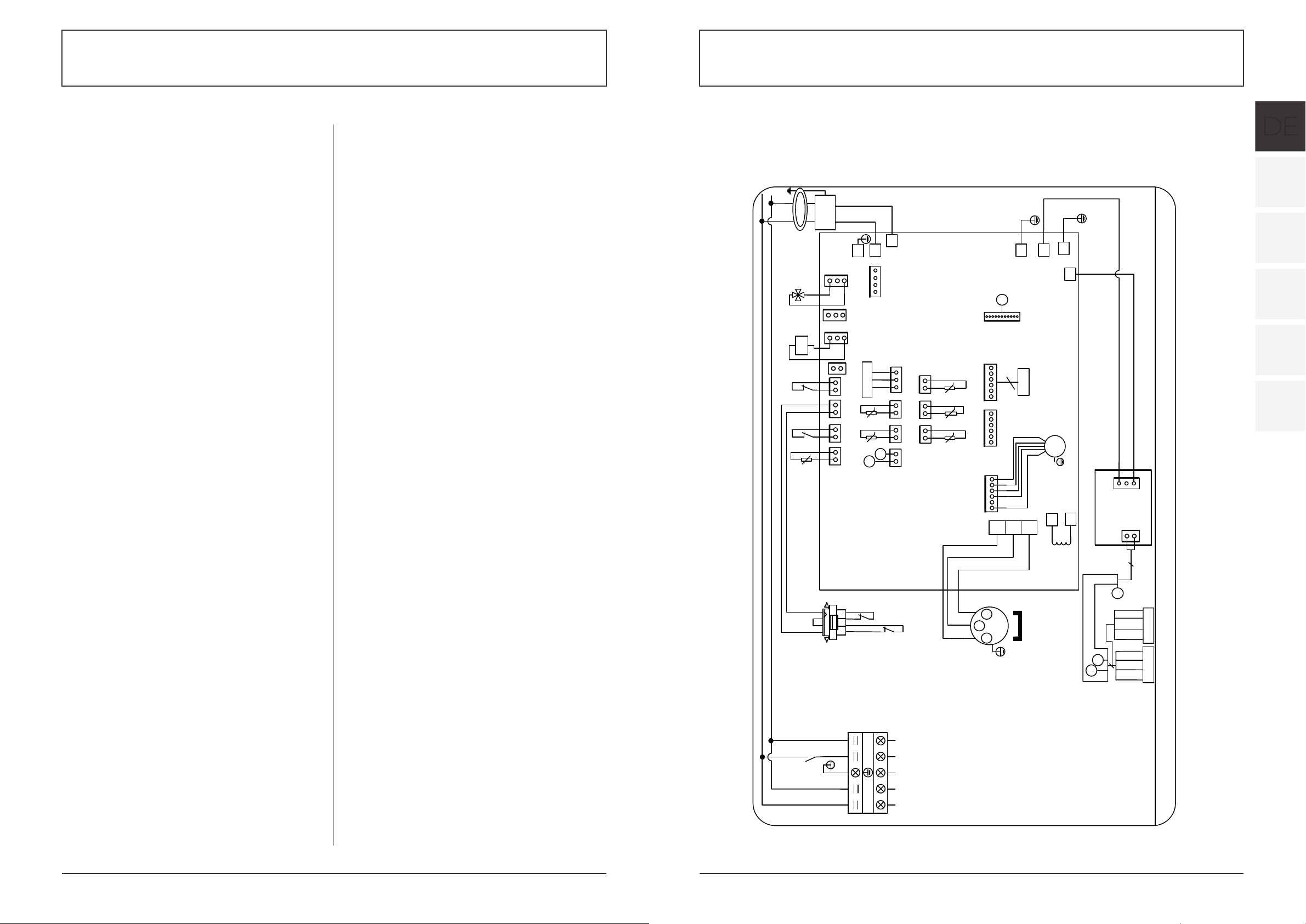

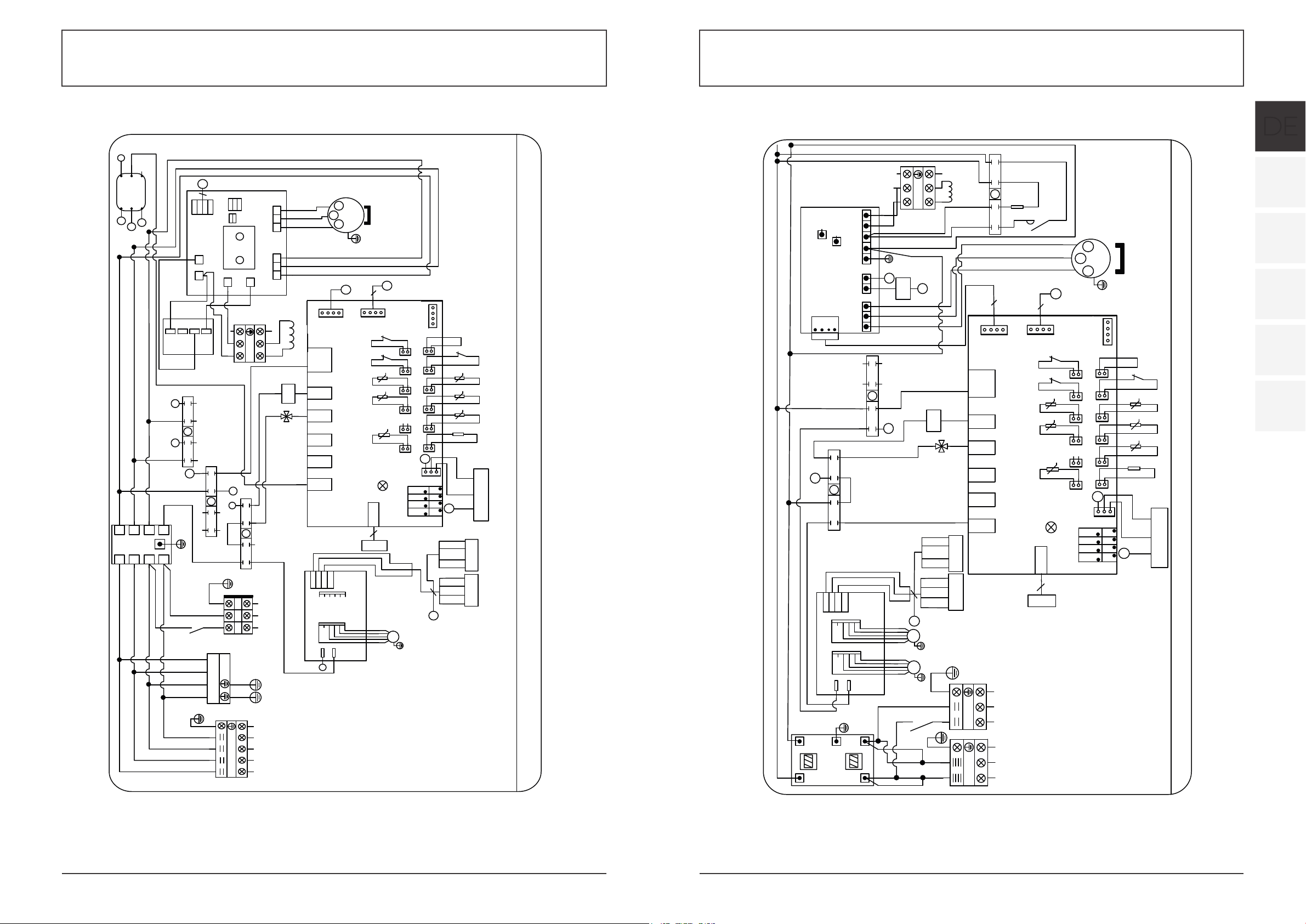

6.1 Circuit diagram 29

6.2 Cable specification 36

6.3 Comparison table of refrigerant saturation temperature 36

CONTENTS

Errors and technical modifications subject

to change, reproduction as well as electronic

duplication only with our written permission.

© NORSUP

Edition: 11.2020

PART NO. TYPE

7024626 P13X/32

7024627 P17X/32

7024628 P20X/32

7024629 P20TX/32

7024630 P26X/32

7024631 P26TX/32

7024740 P35X/32

7024632 P35TX/32

SWIMMING POOL HEAT PUMP TYPE PX

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

67

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

• An all-pole disconnection device which has at least

3mm clearances in all poles, and have a leakage

current that may exceed 10mA, the residual current

device (RCD) having a rated residual operating

current not exceeding 30mA, and disconnection

must be incorporated in the fixed wiring in

accordance with the wiring rules.

• Do not use means to accelerate the defrosting

process or to clean, other than those recommended

by the manufacturer.

• The appliance shall be stored in a room without

continuously operating ignition sources (for example:

open flames, an operating gas appliance or an

operating electric heater.)

• Do not pierce or burn.

• Appliance shall be installed, operated and stored in a

room with a floor area larger than X m2Be aware that

refrigerants may not contain an odour. The

installation of pipe-work shall be kept to a minimum

X m2Spaces where refrigerant pipes shall be

compliance with national gas regulations. Servicing

shall be performed only as recommended by the

manufacturer. The appliance shall be stored in a well-

ventilated area where the room size corresponds to

the room area as specified for operation. All working

procedure that affects safety means shall only be

carried by competent persons.

• Transport of equipment containing flammable

refrigerants Compliance with the transport

regulations Marking of equipment using signs

Compliance with local regulations Disposal of

equipment using flammable refrigerants

Compliance with national regulations Storage of

equipment/appliances The storage of equipment

should be in accordance with the manufacturer‘s

instructions. Storage of packed (unsold) equipment

Storage package protection should be constructed

such that mechanical damage to the equipment

inside the package will not cause a leak of the

refrigerant charge. The maximum number of pieces

of equipment permitted to be stored together will be

determined by local regulations.

CAUTION & WARNING

1. The unit can only be repaired by qualified installer

centre personnel or an authorized dealer (for

Europe market).

2. This appliance is not intended for use by persons

(including children) with reduced physical sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

(for Europe market) Children should be supervised

to ensure that they do not play with the appliance.

3. Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical

shock.

4. If the supply cord is damaged, it must be replaced

by the manufacturer or our service agent or similarly

qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE): The symbol depicting a

crossed-out waste bin that is underneath the appliance

indicates that this product, at the end of its useful life,

must be handled separately from domestic waste,

must be taken to a recycling centre for electric and

electronic devices or handed back to the dealer

when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is

compliant with directive 2002/95/EC (RoHs)

concerning restrictions for the use of harmful

substances in electric and electronic devices.

7. The unit CANNOT be installed near the flammable

gas. Once there is any leakage of the gas, fire can

be occur.

8. Make sure that there is circuit breaker for the unit, lack

of circuit breaker can lead to electrical shock or fire.

9. The heat pump located inside the unit is equipped

with an over-load protection system. It does not

allow for the unit to start for at least 3 minutes from

a previous stoppage.

10. The unit can only be repaired by the qualified

personnel of an installer center or an authorized

dealer. (for North America market)

11. Installation must be performed in accordance with

the NEC/CEC by authorized person only. (for North

America market)

12.USE SUPPLY WIRES SUITABLE FOR 75°C .

13.Caution: Single wall heat exchanger, not suitable for

potable water connection.

1. PREFACE

In order to provide our customers with quality,

reliability and versatility, this product has been made

to strict production standards. This manual includes

all the necessary information about installation,

debugging, discharging and maintenance. Please

read this manual carefully before you open or

maintain the unit. The manufacture of this product

will not be held responsible if someone is injured or

the unit is damaged, as a result of improper

installation, debugging, or unnecessary maintenance.

It is vital that the instructions within this manual are

adhered to at all times. The unit must be installed by

qualified personnel.

The unit can only be repaired by qualified installer

centre, personnel or an authorized dealer.

Maintenance and operation must be carried out

according to the recommended time and frequency,

as stated in this manual.

Use genuine standard spare parts only. Failure to

comply with these recommendations will invalidate

the warranty.

Swimming Pool Heat Pump Unit heats the swimming

pool water and keeps the temperature constant.

For split type unit. The indoor unit can be Discretely

hidden or semi-hidden to suit a luxury house.

Our heat pump has following characteristics:

1 Durable

The heat exchanger is made of PVC & Titanium tube

which can withstand prolonged exposure to

swimming pool water.

2 Installation flexibility

The unit can be installed outdoors or indoors.

3 Quiet operation

The unit comprises an efficient rotary/ scroll

compressor and a low-noise fan motor, which

guarantees its quiet operation.

4 Advanced controlling

The unit includes micro-computer controlling,

allowing all operation parameters to be set.

Operation status can be displayed on the LCD wire

controller. Remote controller can be chosen as

future option.

WARNING

It is recommended that your pool filtration pump and

your heat pump are wired independently. Wiring your

pool pump into the heat pump will result in your

filtration being switched off once the pool water has

reached temperature. Only wire the pool pump through

the heat pump if you have a pool pump for heating only

that is independent to your pool filtration system. Do

not use means to accelerate the defrosting process or

to clean, Other than those recommended by the

manufacturer. The appliance shall be stored in a room

without continuously operating ignition sources (for

example: open flames, an operating gas appliance or

an operating electric heater.) Do not pierce or burn.

Be aware that refrigerants may not contain an odour,

Appliance shall be installed, operated and stored in a

room with a floor area larger than X m2.

• This appliance can be used by children aged from

8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision

or instruction concerning use of the appliance in a

safe way and understand the hazards involved.

Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children

without supervision.

• If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

• The appliance shall be installed in accordance with

national wiring regulations.

• Do not operate your air conditioner in a wet room

such as a bathroom or laundry room.

• Before obtaining access to terminals, all supply

circuits must be disconnected.

NOTE

The manufacturer may provide other suitable

examples or may provide additional information

about the refrigerant odour.

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

89

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

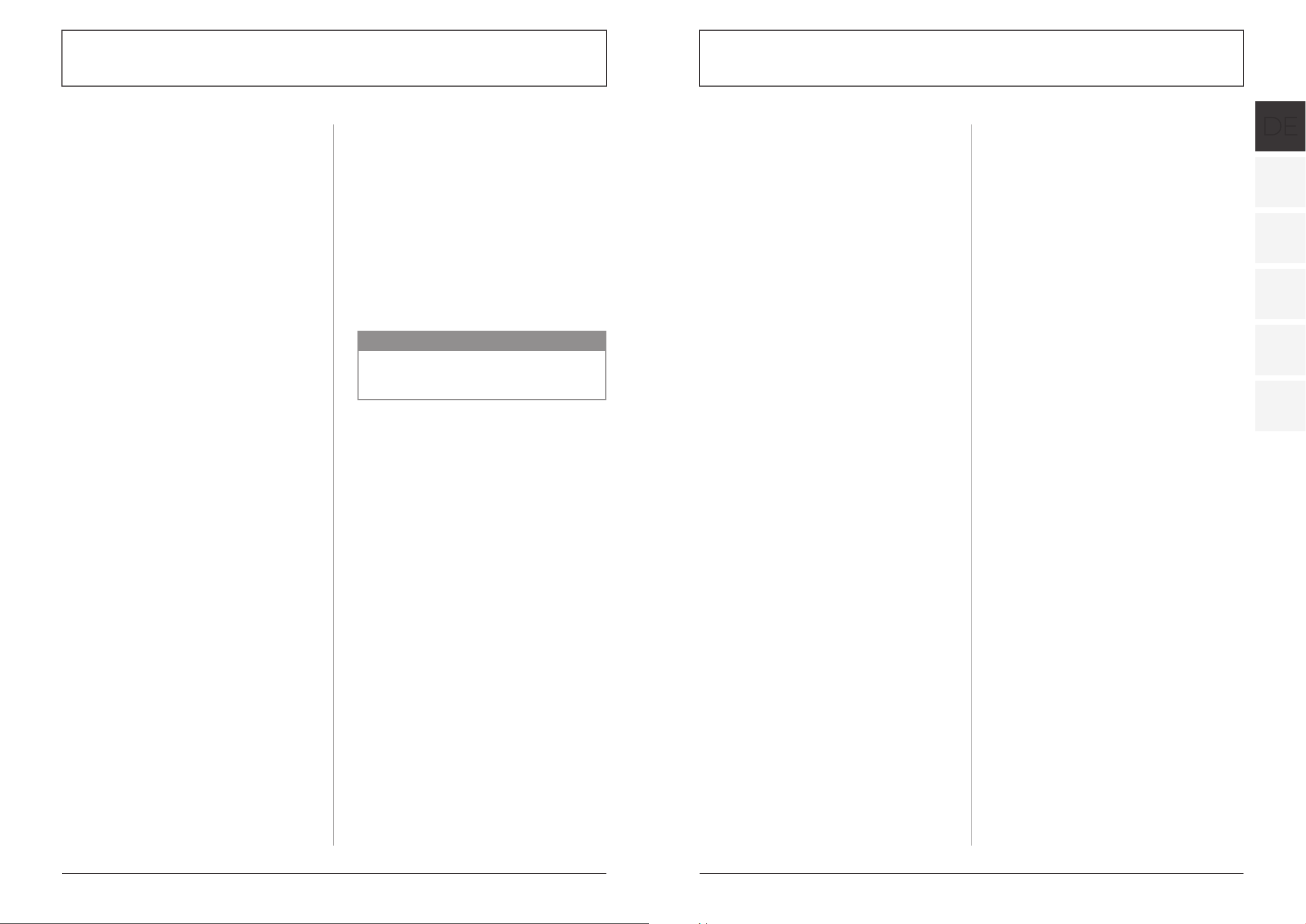

2. SPECIFICATION

2.1 PERFORMANCE DATA OF SWIMMING POOL HEAT PUMP UNIT

*** REFRIGERANT: R32

UNIT P13X/32 P17X/32

Part nr. 7024626 7024627

Heating capacity kW 3.0-13.0 3.8-17.0

(A27/W26) Btu/h 10236-44358 12966-58006

COP 16.0-6.7 16.0-6.7

Heating capacity kW 2.0-9.2 3.0-11.5

(A15/W26) Btu/h 6800-31280 10200-39100

COP 8.0-5.2 8.2-5.2

Heating capacity

(A10/W26)

kW 1.88-8 2.5-10.7

Btu/h 6392-27200 8500-36380

COP 5.7-4. 1 5.56-4.05

Heating power input kW 0.19-1.94 0.24-2.54

Power Supply 220-240V~/50Hz 220-240V~/50Hz

Compressor Quantity 1 1

Compressor rotary rotary

Fan Number 1 1

Noise dB(A) 42-52 44-53

Water Connection mm 50 50

Water Flow Volume m3/h 4.2 5.3

Water Pressure Drop(max) kPa 4.5 5

Unit Net Dimensions(L/W/H) mm See the drawing of the units

Unit Ship Dimensions(L/W/H) mm See package lable

Net Weight kg see nameplate

Shipping Weight kg see package label

Heating:

Outdoor air temp: 27°C/24.3°C, Inlet water temp: 26°C

Outdoor air temp: 15°C/12°C , Inlet water temp: 26°C

Outdoor air temp: 10°C/6.8°C , Inlet water temp: 26°C

Operating range:

Ambient temperature: -15 - 43°C

Water temperature: 9-40°C

Heating:

Outdoor air temp: 27°C/24.3°C, Inlet water temp: 26°C

Outdoor air temp: 15°C/12°C , Inlet water temp: 26°C

Outdoor air temp: 10°C/6.8°C , Inlet water temp: 26°C

Operating range:

Ambient temperature: -15 - 43°C

Water temperature: 9-40°C

*** REFRIGERANT: R32

UNIT P20X/32 P20TX/32 P26X/32

Part nr. 7024628 7024629 7024630

Heating capacity kW 4.6-20.0 4.6-19.5 6.8-26.0

(A27/W26) Btu/h 15696-68243 15696-66536 23202-88716

COP 16.0-6.7 16.0-6.7 16.0-6.7

Heating capacity kW 3.0-14 3.0-14 5.4-19

(A15/W26) Btu/h 10200-47600 10200-47600 18360-64600

COP 8.2-5.1 8.2-5.1 8.2-5.2

Heating capacity

(A10/W26)

kW 3.38-14.4 3.38-14.4 4.2-17.8

Btu/h 11492-48960 11492-48960 14280-60520

COP 5.45-3.98 5.45-3.98 5.6-4.05

Heating power input kW 0.29-2.98 0.37-3.54 0.43-3.88

Power Supply 220-240V~/50Hz 380V/3N~/50Hz 220-240V~/50Hz

Compressor Quantity 1 1 1

Compressor rotary rotary rotary

Fan Number 1 2 2

Noise dB(A) 45-56 45-56 46-57

Water Connection mm 50 50 50

Water Flow Volume m3/h 6.6 6.6 8.6

Water Pressure Drop(max) kPa 6 6 11

Unit Net Dimensions(L/W/H) mm See the drawing of the units

Unit Ship Dimensions(L/W/H) mm See package lable

Net Weight kg see nameplate

Shipping Weight kg see package label

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

10 11

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

UNIT P26TX/32 P35X/32 P35TX/32

Part nr. 7024631 7024740 7024632

Heating capacity kW 6.8-26.0 8.0-35.0 8.0-35.0

(A27/W26) Btu/h 23202-88716 27297-119425 27297-119425

COP 16.0-6.7 16.0-6.7 16.0-6.7

Heating capacity kW 5.4-19 5.6-24 5.6-24

(A15/W26) Btu/h 18360-64600 19040-81600 19040-81600

COP 8.2-5.2 8.2-5.2 8.2-5.2

Heating capacity

(A10/W26)

kW 4.2-17.8 4.9-20.8 4.9-20.8

Btu/h 14280-60520 16660-70720 16660-70720

COP 5.6-4.05 5.63-4.08 5.63-4.08

Heating power input kW 0.43-3.88 0.5-5.2 0.5-5.2

Power Supply 380V/3N~/50Hz 220-240V~/50Hz 380V/3N~/50Hz

Compressor Quantity 1 1 1

Compressor rotary rotary rotary

Fan Number 2 2 2

Noise dB(A) 46-57 48-58 48-58

Water Connection mm 50 50 50

Water Flow Volume m3/h 8.6 10 10

Water Pressure Drop(max) kPa 11 15 15

Unit Net Dimensions(L/W/H) mm See the drawing of the units

Unit Ship Dimensions(L/W/H) mm See package lable

Net Weight kg see nameplate

Shipping Weight kg see package label

Heating:

Outdoor air temp: 27°C/24.3°C, Inlet water temp: 26°C

Outdoor air temp: 15°C/12°C , Inlet water temp: 26°C

Outdoor air temp: 10°C/6.8°C , Inlet water temp: 26°C

Operating range:

Ambient temperature: -15 - 43°C

Water temperature: 9-40°C

*** REFRIGERANT: R32

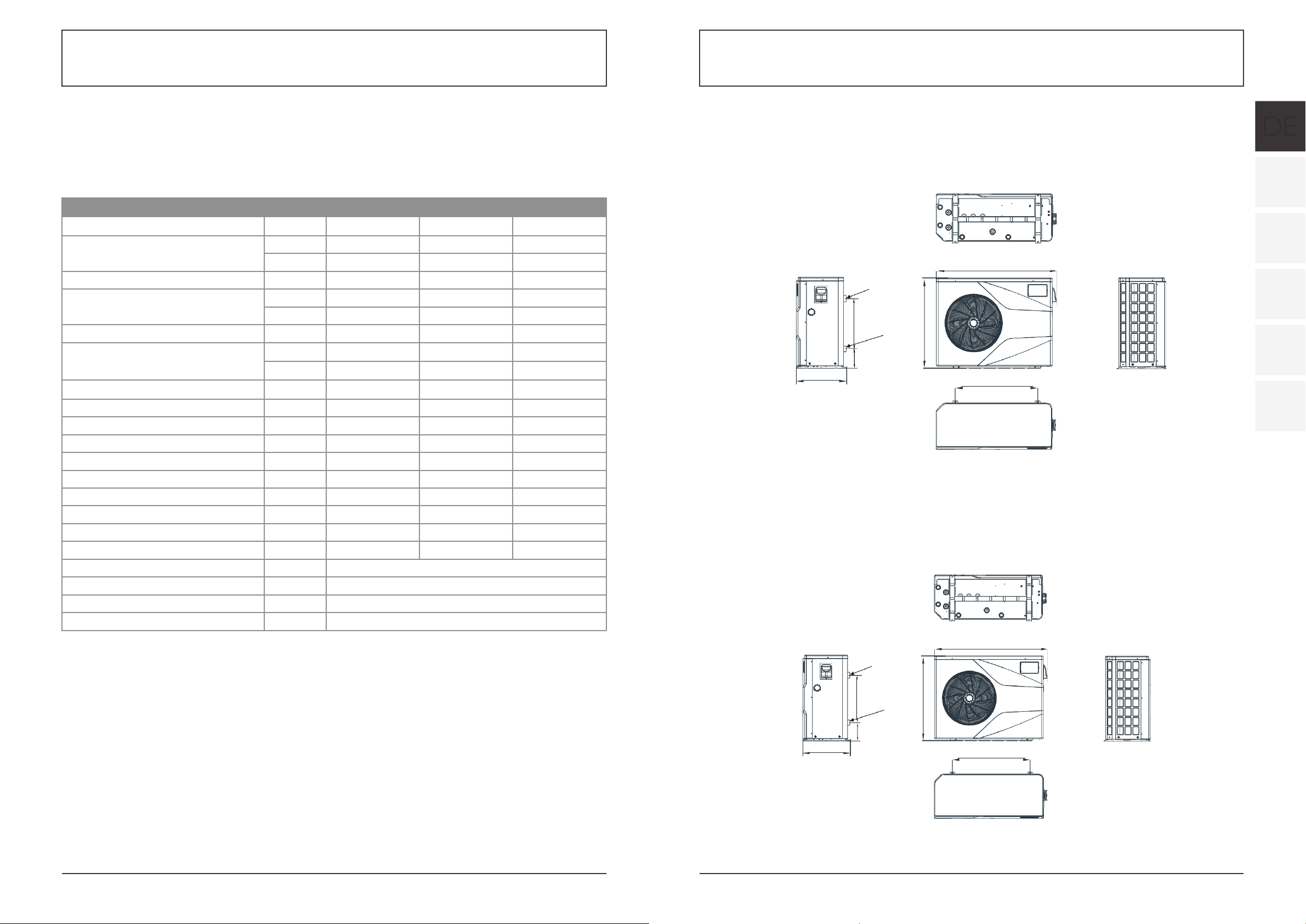

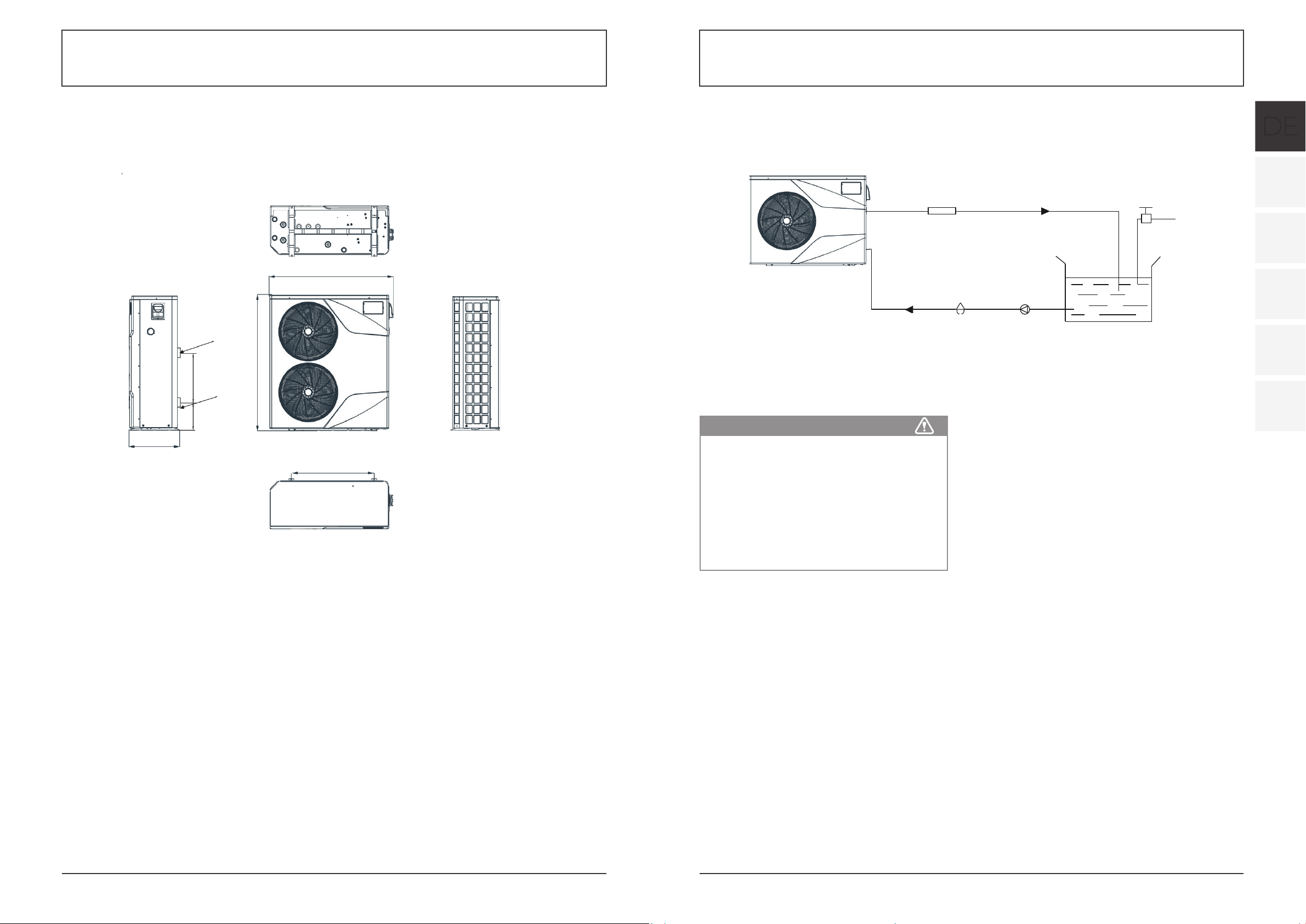

2.2 THE DIMENSIONS FOR SWIMMING POOL HEAT PUMP UNIT

7

2.SPECIFICATION

2.2 The dimensions for Swimming Pool Heat Pump Unit

UNIT: P13X/32 unit:mm

453

Water outlet

�50

Water inlet

�50

1046

615

UNIT: P17X/32

P20X/32/P20TX/32

unit:mm

490

Water outlet

�

50

Water inlet

�50

1161

790

101 350

97 465

868

768

7

2.SPECIFICATION

2.2 The dimensions for Swimming Pool Heat Pump Unit

UNIT: P13X/32 unit:mm

453

Water outlet

�50

Water inlet

�50

1046

615

UNIT: P17X/32

P20X/32/P20TX/32

unit:mm

490

Water outlet

�

50

Water inlet

�50

1161

790

101 350

97 465

868

768

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

12 13

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

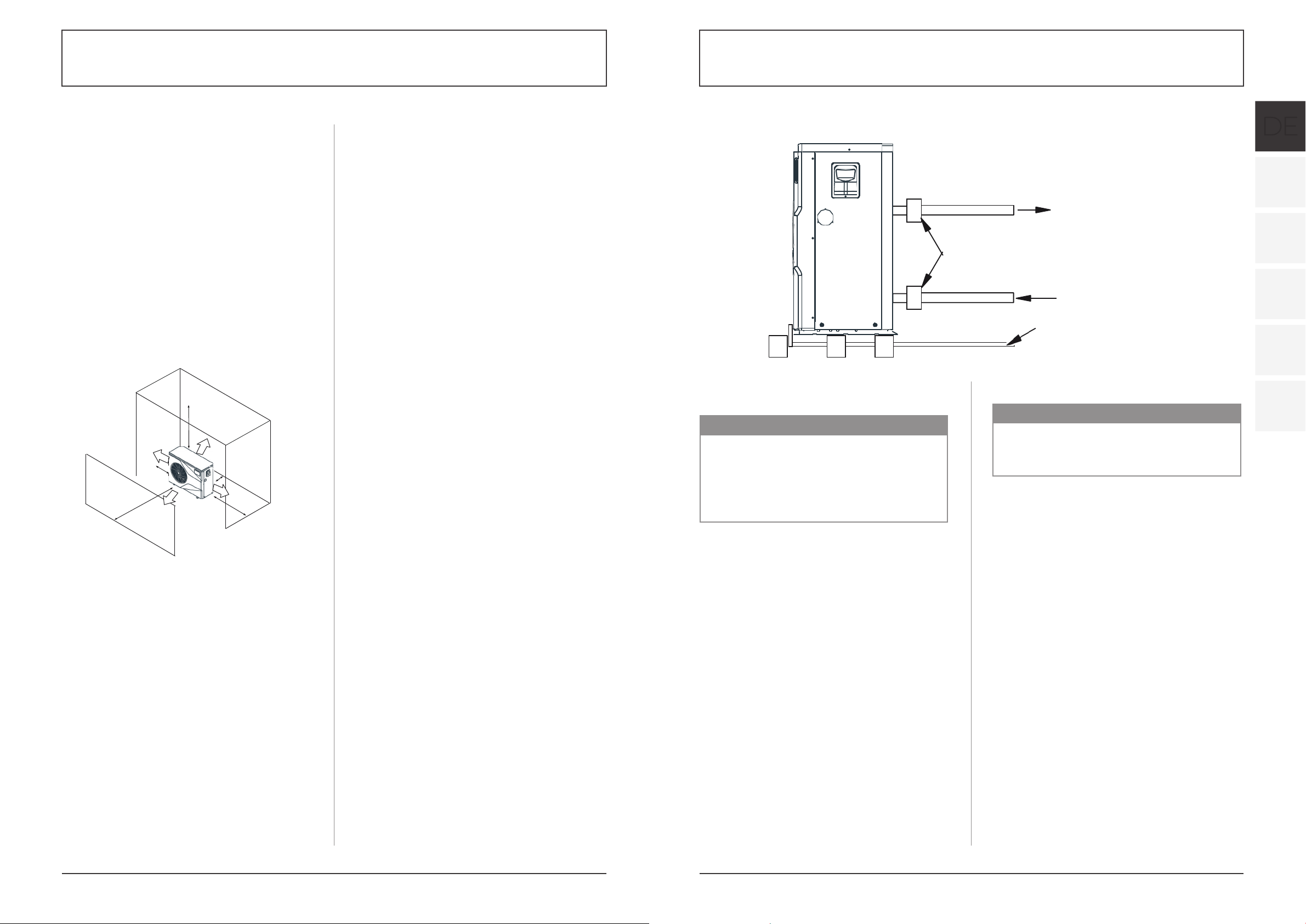

3. INSTALLATION AND CONNECTION

3.1 INSTALLATION ILLUSTRATION

Installation items

The factory only provides the main unit and the water

unit; the other items in the illustration are necessary

spare parts for the water system, that provided by

users or the installer.

The schematic diagram is for reference only. Please

check the water inlet/outlet label on the heat pump

while plumbing installation.

The controller is mounted on the wall.

3.INSTALLATION AND CONNECTION

3.1 Installation illustration

supply

Installation items:

The factory only provides the main unit and the water unit; the other items in the illustration are

necessary spare parts for the water system ,that provided by users or the installer.

Attention:

Please follow these steps when using for the first time

1.Open valve and charge water.

2.Make sure that the pump and the water-in pipe have been filled with water.

3.Close the valve and start the unit.

ATTN: It is necessary that the water-in pipe is higher than the pool surface.

The schematic diagram is for reference only. Please check the water inlet/outlet label on the

heat pump while plumbing installation.

The schematic diagram is for reference only. Please check the water inlet/outlet label on the

heat pump while plumbing installation.

The controller is mounted on the wall

Chlorinator cell

Water outlet

Valve

Water

Water inlet Sand filter

Water pump

Pool

(or other type filter)

ATTENTION

Please follow these steps when using

for the first time

1. Open valve and charge water.

2. Make sure that the pump and the water-in

pipe have been filled with water.

3. Close the valve and start the unit.

Attention

It is necessary that the water-in pipe is higher

than the pool surface.

�

2.SPECIFICATION

2.2 The dimensions for Swimming Pool Heat Pump Unit

UNIT: P26X/32/P26TX/32/P35X/32

P35TX/32

unitmm

Water outlet

Ő

50

Water inlet

Ő

50

1161

775

470

97 550

1274

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

14 15

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

3.5 SWIMMING POOL HEAT PUMPS ELECTRICAL

WIRING

The unit has a separate molded-in junction box with a

standard electrical conduit nipple already in place. Just

remove the screws and the front panel, feed your

supply lines in through the conduit nipple and wire-

nut the electric supply wires to the three connections

already in the junction box (four connections if three

phase). To complete electrical hookup, connect Heat

Pump by electrical conduit, UF cable or other suitable

means as specified (as permitted by local electrical

authorities) to a dedicated AC power supply branch

circuit equipped with the proper circuit breaker,

disconnect or time delay fuse protection.

Disconnect - A disconnect means (circuit breaker,

fused or un-fused switch) should be located within

sight of and readily accessible from the unit. This is

common practice on commercial and residential air

conditioners and heat pumps. It prevents remotely-

energizing unattended equipment and permits

turning off power at the unit while the unit is being

serviced.

3.6 INITIAL STARTUP OF THE UNIT

Start up Procedure - After installation is completed,

you should follow these steps:

1. Turn on your filter pump. Check for water leaks and

verify flow to and from the pool.

2. Turn on the electrical power supply to the unit, then

press the key ON/OFF of wire controller. It should

start in several seconds.

3. After running a few minutes make sure the air

leaving the top(side) of the unit is cooler (Between

5-10°C)

4. During the operation of the unit, if the filter pump

turns off, the unit should also turn off automatically.

5. Allow the unit and pool pump to run 24 hours per

day until desired pool water temperature is reached.

When the water-in temperature reaches this

setting, the unit will slow down for a period of time,

if the temperature is maintained for 45 minutes the

unit will turn off. The unit will now automatically

restart (as long as your pool pump is running) when

the pool temperature drops more than 0.2 below

set temperature.

Time Delay- The unit is equipped with a 3minute

built-in solid state restart delay included to protect

control circuit components and to eliminate restart

cycling and contactor chatter. This time delay will

automatically restart the unit approximately 3

minutes after each control circuit interruption. Even

a brief power interruption will activate the solid state

3minute restart delay and prevent the unit from

starting until the 5minute countdown is completed.

3.2 SWIMMING POOL HEAT PUMPS LOCATION

The unit will perform well in any outdoor location

provided that the following three factors are

presented:

1. Fresh Air - 2. Electricity - 3. Pool filter piping

The unit may be installed virtually anywhere outdoors.

For indoor pools please consult the supplier. Unlike a

gas heater, it has no draft or pilot light problem in a

windy area.

DO NOT place the unit in an enclosed area with a

limited air volume, where the units discharge air will

be re-circulated.

DO NOT place the unit to shrubs which can block air

inlet. These locations deny the unit of a continuous

source of fresh air which reduces it efficiency and may

prevent adequate heat delivery.

3.3 HOW CLOSE TO YOUR POOL?

Normally, the pool heat pump is installed within 7.5

metres of the pool. The longer the distance from the

pool, the greater the heat loss from the piping. For the

most part, the piping is buried. Therefore, the heat

loss is minimal for runs of up to15 meters (15 meters to

and from the pump = 30 meters total), unless the

ground is wet or the water table is high. A very rough

estimate of heat loss per 30 meters is 0.6 kW hour,

(2000BTU) for every 5°C difference in temperature

between the pool water and the ground surrounding

the pipe, which translates to about 3% to 5% increase

in run time.

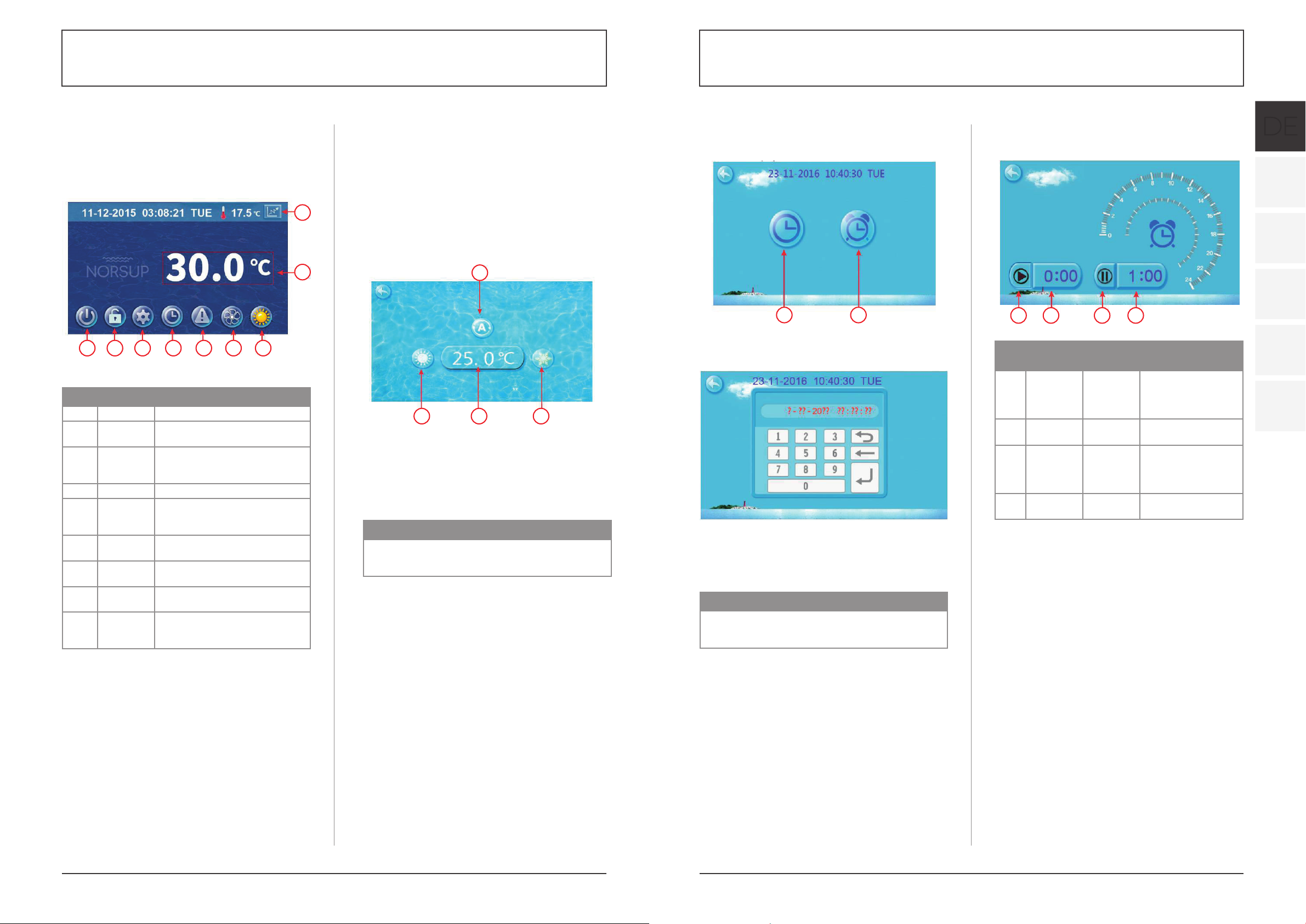

3.4 SWIMMING POOL HEAT PUMPS PLUMBING

The Swimming Pool Heat Pumps exclusive rated flow

titanium heat exchanger requires no special

plumbing arrangements except bypass (please set

the flow rate according to the nameplate). The water

pressure drop is less than 10kPa at max. Flow rate.

Since there is no residual heat or flame Temperatures.

The unit does not need copper heat sink piping. PVC

pipe can be run straight into the unit.

Location: Connect the unit in the pool pump

discharge (return) line downstream of all filter and

pool pumps, and upstream of any chlorinators,

ozonators or chemical pumps. Standard model have

slip glue fittings which accept 32mm or 50 mm PVC

pipe for connection to the pool or spa filtration piping.

By using a 50 NB to 40NB you can plumb 40NB Give

serious consideration to adding a quick coupler fitting

at the unit inlet and outlet to allow easy draining of

unit for winterizing and to provide easier access

should servicing be required.

Condensation: Since the Heat pump cools down the

air about 4 -5, water may condense on the fins of the

horseshoe shaped evaporator. If the relative humidity

is very high, this could be as much as several litres an

hour. The water will run down the fins into the base

pan and drain out through the barbed plastic

condensation drain fitting on the side of the base pan.

This fitting is designed to accept 20mm clear vinyl

tubing which can be pushed on by hand and run to a

suitable drain. It is easy to mistake the condensation

for a water leak inside the unit.

NB: A quick way to verify that the water is

condensation is to shut off the unit and keep the pool

pump running. If the water stops running out of the

base pan, it is condensation. AN EVEN QUICKER WAY

IS to TEST THE DRAIN WATER FOR CHLORINE - if the

is no chlorine present, then it‘s condensation.

11

3.INSTALLATION AND CONNECTION

3.4

Swimming Pool Heat Pumps Plumbing

The Swimming Pool Heat Pumps exclusive rated flow titanium heat exchanger requires no

special plumbing arrangements except bypass(please set the flow rate according to the

nameplate). The water pressure drop is less than 10kPa at max. Flow rate. Since there is no

residual heat or flame Temperatures, The unit does not need copper heat sink piping. PVC pipe

can be run straight into the unit.

Location: Connect the unit in the pool pump discharge (return) line downstream of all filter

and pool pumps, and upstream of any chlorinators, ozonators or chemical pumps.

Standard model have slip glue fittings which accept 32mm or 50 mm PVC pipe for

connection to the pool or spa filtration piping. By using a 50 NB to 40NB you can plumb 40NB

Give serious consideration to adding a quick coupler fitting at the unit inlet and outlet to allow easy

draining of unit for winterizing and to provide easier access should servicing be

required.

To pool

PVC COUPLER

RECOMMENDED(Provided)

From pump

CONDENSATION

DRAIN

BARB FTG

Condensation: Since the Heat pump cools down the air about 4 -5

℃

, water may condense on the

fins of the horseshoe shaped evaporator. If the relative humidity is very high, this could

be as much as several litres an hour. The water will run down the fins into the basepan and

drain out through the barbed plastic condensation drain fitting on the side of the basepan. This

fitting is designed to accept 20mm clear vinyl tubing which can be pushed on by hand and run to

a suitable drain. It is easy to mistake the condensation for a water leak inside the unit.

NB: A quick way to verify that the water is condensation is to shut off the unit and keep the pool

pump running. If the water stops running out of the basepan, it is condensation. AN

EVEN QUICKER WAY IS to TEST THE DRAIN WATER FOR CHLORINE - if the is no chlorine

present, then it's condensation.

3.INSTALLATION AND CONNECTION

1

3.2

Swimming Pool Heat Pumps Location

The unit will perform well in any outdoor location provided that the following three factors are

presented:

1. Fresh Air - 2. Electricity - 3. Pool filter piping

The unit may be installed virtually anywhere outdoors. For indoor pools please consult the

supplier. Unlike a gas heater, it has no draft or pilot light problem in a windy area.

DO NOT place the unit in an enclosed area with a limited air volume, where the units

discharge air will be re-circulated.

DO NOT place the unit to shrubs which can block air inlet. These locations deny the unit of a

continuous source of fresh air which reduces it efficiency and may prevent adequate heat

delivery.

3.3

How Close To Your Pool?

Normally, the pool heat pump is installed within 7.5 metres of the pool. The longer the distance

from the pool, the greater the heat loss from the piping. For the most part ,the piping

is buried. Therefore, the heat loss is minimal for runs of up to15 meters(15 meters to and from the

pump = 30 meters total), unless the ground is wet or the water table is high. A very rough

estimate of heat loss per 30 meters is 0.6 kW-hour,(2000BTU) for every 5

℃

difference in

temperature between the pool water and the ground surrounding the pipe, which translates to

about 3% to 5% increase in run time.

Air inlet

Air outlet

500mm

700mm

700mm

1500mm

300mm

NOTE

Although the unit heat exchanger is electrically

isolated from the rest of the unit, it simply prevents

the flow of electricity to or from the pool water.

Grounding the unit is still required to protect you

against short circuits inside the unit. Bonding is

also required.

NOTE

In order for the unit to heat the pool or spa, the

filter pump must be running to circulate water

through the heat exchanger.

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

16 17

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

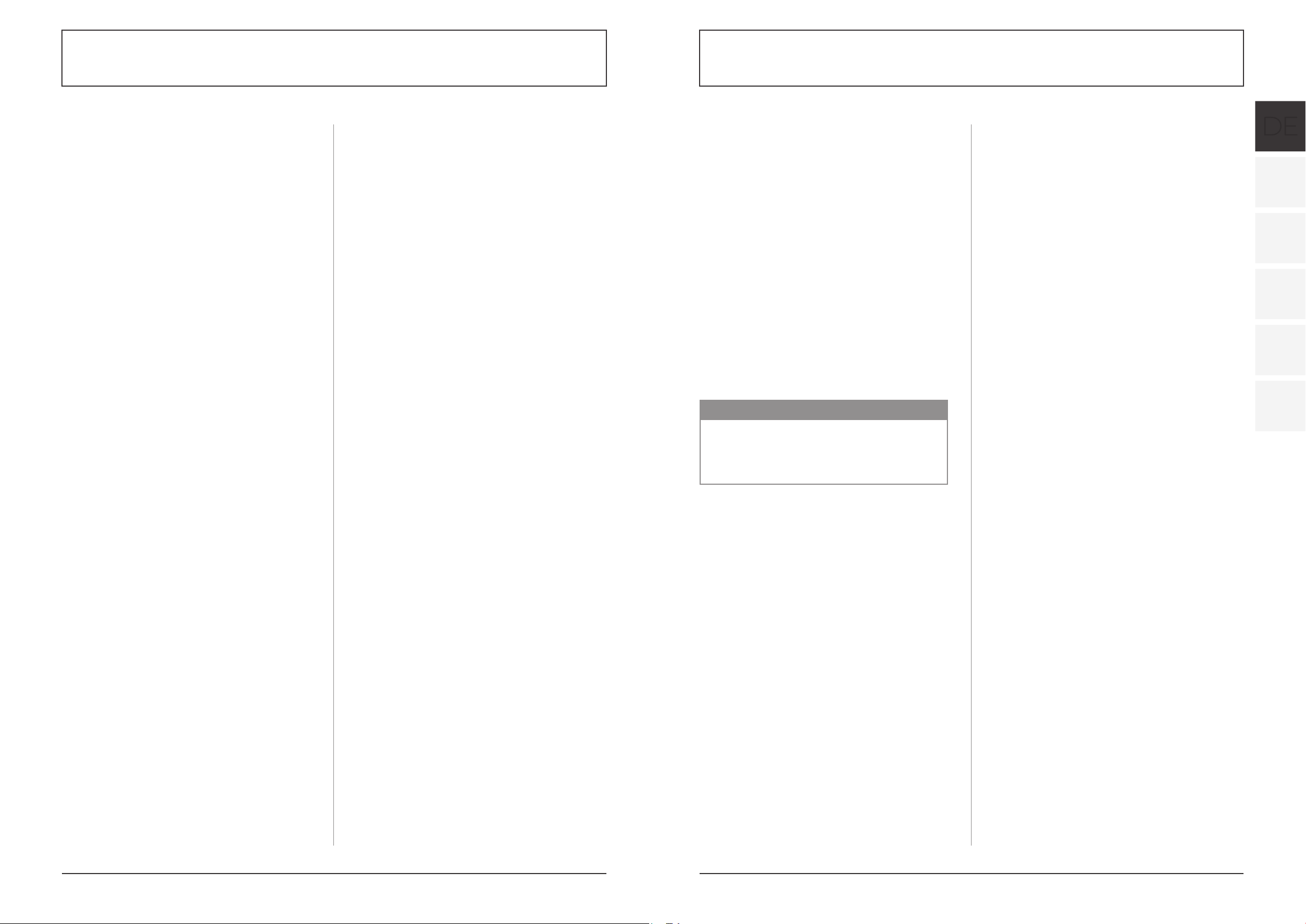

4. OPERATION AND USE

4.1 COLOR SCREEN WIRE CONTROLLER

INTERFACE INTRODUCTION

(1) Main interface

(2) Button Description

4.2 COLOR SCREEN WIRE CONTROLLER

FUNCTION INTRODUCTION

(1) Booting and shutdown

As shown in figure 1.1: In shutdown status, click 1

then the unit will be booted In booting status,

click 1 then the unit will be shut down.

(2) Mode switch and target temperature Setting

(2.1) Mode switch In the main interface, click mode

button or inlet water temperature setting button,

interface displays as follows:

Click the refrigeration mode button 1, automatic

mode button 2or heating mode button 3then

you can select the corresponding mode.

(2.2) Target temp. setting

Click the temperature set button 4, you can set

the target temperature.

(3) Clock setting

In the main interface, click on the clock Settings

button, interface displays as follows:

(3.1) The operation of time setting

Click on the time Settings button 1, interface

displays as follows:

Click the value to set time directly, the click confirm

button to save the Settings. For example: setup

time: the 30-11-2016 16:00:00, input 30 11 16 16 00

00, the time change then click confirm button.

(3.2) The operation of timing setting

Click the timing set button 2 to enter

timing setinterface.

NOTE

When the unit is designed for single automatic mode

or single thermal mode, the mode can not be switched.

NOTE

If the input format is not correct, the wrong time

will be saved by clicking confirm button.

NO. NAME NAME

1ON/OFF Press to start /shut off the unit

2Parameter Click this button to view the unit

state and the parameter

3CLOCK Press to set the clock, the timer on

or timer off. When the timer was

starting, the button is green

4Fault display Click to view fault history

5Silent

setting

Click to turn on/off silent function

and to set timing Low

speed function

6MODE Click to enter mode setting and the

target temp. Setting interface

7Temp. curve Click to view the temp. and power

curve

8Water Inlet

Temp.

Click to enter mode setting and the

target temp. Setting interface

9LOCK Click to lock the screen. Input “22”

to unlock the screen by press the

“lock button”

NO. NAME BUTTON

COLOR NAME

1Timing

table - Start:

green

- End:

gray

Click this button to

start or end

timing start setting

function

2Timing on

setting Click to set start time

of the timing

3Timing

end

button

- Open:

red

- End:

gray

Click this button to

start or end

timing end setting

function

4Timing off

setting Click to set end time

of the timing

1

2

3 4

1 9 2 3 4 5 6

8

7

1 2 1 2 3 4

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

18 19

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

When the timer was starting, the clock button is

green in the main interface.

(4) Silent setting and silent timing setting

Click the silent setting button, and the interface

displays as follows:

(4.1) The silent button

Click the silent button 1, the unit will enter the silent

mode, and interface displays as follows:

Click the silent button 1again, to exit the silent

mode.

(4.2) Timing silent function setting

Click timing silent button 2, and interface displays as

follows:

Start time and end time setting value must be among

the range of 0:00 -23:00, and setting value can be

precise to hour digit.

For example above, click “ON” to use timing silent,

the unit will start the silent at 0:00 points and end at

4:00; click “OFF” to unuse the timing silent, but if the

unit is in timing silent mode, it will exit silent timing

immediately.

(5) History of the fault

In the main interface click fault display key,

interface displays as follows:

If no failure, main interface displays static “ ”

When fault occurs, the fault icon will flash between

the “ ” “ ”, the failure interface will record time,

code, name of the fault.

After troubleshooting, if you do not check the

failure record, the main interface will display static “

”; if you check the failure record, the main

interface will displays static “ ”;

Failure record is in reverse order, according to the

happening time. Press the “Clean” key, you can

delete the fault record.

(6) Temperature curve

In the main interface, click the curve display button,

interface displays as follows:

(6.1) Temperature recording curve is as follows:

(6.2) The average power curve

Temperature curve automatically updates every one

hour, and the curve record can be stored for 60 days;

Start from the latest curve saved time, if power is off

and curve data collecting time is less than one hour,

the data in this period will not be saved;

20

4.OPERATION AND USE

(6) Temperature curve

In the main interface, click the curve display button,

interface displays as follows:

2.6.1 Temperature recording curve is as follows:

6-2 The average power curve

Temperature curve automatically updates every one hour,

and the curve record can be stored for 60 days;

Start from the latest curve saved time, if power is off and

curve data collecting time is less than one hour, the data

in this period will not be saved;

20

4.OPERATION AND USE

(6) Temperature curve

In the main interface, click the curve display button,

interface displays as follows:

2.6.1 Temperature recording curve is as follows:

6-2 The average power curve

Temperature curve automatically updates every one hour,

and the curve record can be stored for 60 days;

Start from the latest curve saved time, if power is off and

curve data collecting time is less than one hour, the data

in this period will not be saved;

21

1

2

3 4

NO. NAME COLOR NAME

1Timing

silent off

Used: red

Unused:

gray

Click to use or unuse

timing off function

2Timing

silent on

Use: green

Unused:

gray

Click to use or unuse

timing on function

3Timing

silent start

time

Click this button to set

the timing silent start

time

4Timing

silent end

time

Click this button to set

the timing silent end

time

Fault code The fault name

Fault time

day - month - year

hour: min

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

20 21

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

4.3 PARAMETER LIST AND BREAKDOWN TABLE

(1) Electronic control fault table

Can be judged according to the remote controller failure code and troubleshooting

FREQUENCY CONVERSION BOARD FAULT TABLE:

Protect/fault Fault

display Reason Elimination methods

Standby Non

Normal boot Non

Inlet Temp.

Sensor Fault P01 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

Outlet Temp.

Sensor Fault P02 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

Ambient Temp.

Sensor Fault P04 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

Coil Temp.

Sensor Fault P05 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

Suction Temp.

Sensor Fault P07 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

Discharge Temp.

Sensor Fault P081 The temp. Sensor is broken or short circuit Check or change the temp. Sensor

High Pressure

Prot. E01 The high-pressure switch is broken Check the pressure switch and cold

circuit

Low Pressure

Prot. E02 Low pressure1 protection Check the pressure switch and cold

circuit

Flow Switch

Prot. E03 No water/little water in water

system

Check the pipe water flow and

water pump

Anti-freezing

Prot. E07 Water flow is not enough Check the pipe water flow and whether

water system is jammed or not

Primary Anti-freezing

Prot. E19 The ambient temp. Is low

Secondary Anti-

freezing Prot. E29 The ambient temp. Is low

Inlet and outlet

temp. too big E06 Water flow is not enough

and low differential pressure

Check the pipe water flow and whether

water system is jammed or not

Low temperature

protection Non The environment temp. is low

Comp.

Overcurrent Prot. E051 The compressor is overload Check whether the system of the

compressor running normally

Exhaust Air over

Temp Prot. P082 The compressor is overload Check whether the system of the

compressor running normally

Communication

Fault E08 Communication failure between

wire controller and mainboard

Check the wire connection between

remote wire controller and main board

Antifreeze Temp.

Sensor Fault P09 antifreeze temp sensor is broken or

short circuited check and replace this temp sensor

Waterway

Anti-freezing Prot. E05 water temp. or ambient temp. is

too low

EC fan feedback

Fault F051 There is something wrong with fan

motor and fan motor stops running

Check whether fan motor is broken

or locked or not

Pressure sensor

Fault PP The pressure Sensor is broken Check or change the pressure

Sensor or pressure

Fan Motor1

Fault F031

1. Motor is in locked-rotor state 2.The wire

connection between DC-fan motor

module and fan motor is in bad contact

1. Change a new fan motor

2.Check the wire connection and make

sure they are in good contact

Fan Motor2

Fault F032

1. Motor is in locked-rotor state 2.The wire

connection between DC-fan motor

module and fan motor is in bad contact

1. Change a new fan motor

2.Check the wire connection and make

sure they are in good contact

Communication Fault

(speed

control module)

E081 Speed control module and main board

communication fail Check the communication connection

Protection/fault Fault

display Reason Elimination methods

Drv1 MOP alarm F01 MOP drive alarm Recovery after the 150s

Inverter offline F02 Frequency conversion board and main

board communication failure Check the communication connection

IPM protection F03 IPM modular protection Recovery after the 150s

Comp. Driver Failure F04 Lack of phase, step or drive hardware

damage

Check the measuring voltage Check

frequency conversion board hardware

DC Fan Fault F05 Motor current feedback open circuit or

short circuit

Check whether current return wires

connected motor

IPM Overcurrent F06 IPM Input current is large Check and adjust the current measurement

Inv. DC Overvoltage F07 DC bus voltage>Dc bus over-voltage

protection value Check the input voltage measurement

Inv. DC Less voltage F08 DC bus voltage<Dc bus over-voltage

protection value Check the input voltage measurement

Inv. Input Less voltage F09 The input voltage is low, causing the input

current is high Check the input voltage measurement

Inv. Input Overvolt. F10 The input voltage is too high, more than

outage protection current RMS Check the input voltage measurement

Inv. Sampling Volt. F11 The input voltage sampling fault Check and adjust the current measurement

Comm. Err DSP-PFC F12 DSP and PFC connect fault Check the communication connection

Input Over Cur. F26 The equipment load is too large

PFC fault F27 The PFC circuit protection Check the PFC switch tube short circuit or not

IPM Over heating F15 The IPM module is overheat Check and adjust the current measurement

Weak Magnetic Warn F16 Compressor magnetic force is

not enough

Inv. Input Out Phase F17 The input voltage lost phase Check and measure the voltage adjustment

IPM Sampling Cur. F18 IPM sampling electricity is fault Check and adjust the current measurement

Inv. Temp. Probe Fail F19 Sensor is short circuit or open circuit Inspect and replace the sensor

Inverter Overheating F20 The transducer is overheat Check and adjust the current measurement

Inv. Overheating Warn F22 Transducer temperature is too high Check and adjust the current measurement

Comp. Over Cur. Warn F23 Compressor electricity is large The compressor over-current protection

Input Over Cur. Warn F24 Input current is too large Check and adjust the current measurement

EEPROM Error Warn F25 MCU error Check whether the chip is damaged

Replace the chip

V15V over/

undervoltage fault F28 The V15V is overload or undervoltage Check the V15V input voltage in range

13.5v~16.5v or not

Meaning Default Remarks

Refrigeration target temperature set point 27°C Adjustable

Heating the target temperature set point 27°C Adjustable

Automatic target temperature set point 27°C Adjustable

(2) Parameter list

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

22 23

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

4.4 INTERFACE DRAW IN

(1) Wire control interface diagram and definition

Sign Meaning

V 12V (power +)

R No use

T No use

A 485A

B 485B

G GND (power-)

(2) Controller interface diagram and definition

Main board of the input and output interface instructions below

4.OPERATION AND USE

23

Sign Meaning

V 12V(power +)

R No use

T No use

A 485A

B 485B

G GND(power-)

V

R

T

A

B

G

(2) Parameter list

Meaning Default Remarks

Refrigeration target temperature set point

27

℃

Adjustable

Heating the target temperature set point

27

℃

Adjustable

Automatic target temerature set point

27

℃

Adjustable

4.4

Interface drawin

(1) Wire control interface diagram and definition

(2) Controller interface diagram and definition

AC-L OUT1

OUT2

CN2

CN8

CN13

OUT3

AC-N OUT4

OUT5

PC1004

CN9

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

AI/DI12

AI/DI11

AI/DI10

AI/DI09

AI/DI08

AI/DI07

AI/DI06

AI/DI05

AI/DI04

AI/DI03

AI/DI02

AI/DI01

0-10V_OUT

PWM_OUT

PWM_IN

+12V

GND

GND

GND

GND

+5V

AI/DI13

GND

GND

RS485_B_2

RS485_A_2

12V

GND

RS485_B_3

RS485_A_3

12V

GND

RS485_B_1

RS485_A_1

12V

Number Sign Meaning

01 OUT1 Compressor (output 220-230VAC)

02 OUT2 Water pump (output 220-230VAC)

03 OUT3 4-way valve (output 220-230VAC)

04 OUT4 High speed of fan (output 220-230VAC)

05 OUT5 Low speed of fan (output 220-230VAC)

06 AC-L Live wire (input 220-230VAC)

07 AC-N Neutral wire (input 220-230VAC)

08 AI/DI01 Emergency switch input

09 AI/DI02 Water flow switch input

10 AI/DI03 System low pressure input

11 AI/DI04 System high pressure input

12 AI/DI05 System suction temperature input

13 AI/DI06 Water input temperature input

14 AI/DI07 Water output temperature (input)

15 AI/DI08 System fan coil temperatureinput

16 AI/DI09 Ambient temperature input

17 AI/DI10 Mode switch input

18 AI/DI11 Master-slave machine switch / Antifreeze temperature input

19 AI12(50K) System Exhaust temperature input

20 0_5V_IN Compressor current detection/Pressure sensor (input)

21 PWM_IN Master-slave machine switch / Feedback signal of EC fan (input)

22 PWM_OUT AC fan control (output)

23 0_10V_OUT EC fan control (output)

24 +5V +5V (output)

25 +12V +12V (output)

26 GND

27 485_B1 Frequency conversion board communications

28 485_A1

29 12V

30 GND

31 485_B2 Color line controller communication

32 485_A2

33 12V

34 CN9 Electronic expansion valve

35 GND

36 485_B3 The port for centralized control system

37 485_A3

38 12V

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

24 25

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

Controller interface diagram and definition Main board of the input and output interface instructions below

Number Sign Meaning

01 P10-(U)

02 P10-(V) Compressor (output 220-230VAC)

03 P10-(W)

04 CN18(EMV) Water pump (output 220-230VAC)

05 CN13(HEAT) 4-way valve (output 220-230VAC)

06 CN96(H) High speed of fan (output 220-230VAC)

07 CN96(L) Low speed of fan (output 220-230VAC)

08 P1 (AC-L) Live wire (input 220-230VAC)

09 P2(AC-N) Neutral wire (input 220-230VAC)

10 CN99(PL) Pressure sensor

11 CN29(OVT) Water flow switch (input)

12 CN30(HP) High pressure switch (input)

13 CN31 (LP) Low pressure switch (input)

14 CN7(OAT) System suction temperature (input)

15 CN21 (RES1) Water input temperature (input)

16 CN22(RES2) Water output temperature (input)

17 CN8(OPT) System fan coil temperature (input)

18 CN12(PH) Ambient temperature (input)

19 CN9(OHT) System Exhaust temperature (input)

20 POO(GND) Earth wire

21 P01(GND) Earth wire

22 P13(L)

P14(L) Electric reactor

23 R485(B)

R485(A) Color line controller communication

24 CN15 Electronic expansion valve

CN21(RES1)

CN29(OVT)

CN30(HP)CN31(LP)

CN13(HEAT)

CN18(EMV)

CN66(RY)

CN11(FOUR)

C

CN96

N

P1(ACL)

CN7(OAT) CN8(OPT) CN99(PL)

L

H

P2(ACN)

RS485

GND 0-5V IN 5V

CN22(RES2

C

) N9(OHT)

CN12(PH)

P00(GND)

CN97

10

11

CN15

9

C24

8

7

6

D C B A 12V12V D C B A 12V12V

5

4

P10-1(U)

LED1

RESET

T-

RESET

TOOL0

3

EVDD

GND

P10-2(V)

P10-3(W)

2

1

P01(GND)

CN401

CN10

P14(L)

P13(L)

'(

4.OPERATION AND USE

Controller interface diagram and definition

2�

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

26 27

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

Repairs to sealed components

1 During repairs to sealed components, all electrical

supplies shall be disconnected from the equipment

being worked upon prior to any removal of sealed

covers, etc. If it is absolutely necessary to have an

electrical supply to equipment during servicing,

then a permanently operating form of leak detec-

tion shall be located at the most critical point to

warn of a potentially hazardous situation.

2 Particular attention shall be paid to the following to

ensure that by working on electrical components,

the casing is not altered in such a way that the level

of protection is affected. This shall include damage

to cables, excessive number of connec-

tions, terminals not made to original specification,

damage to seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely

Ensure that seals or sealing materials have not

degraded such that they no longer serve the purpose

of preventing the ingress of flammable atmospheres.

Replacement parts shall be in accordance with the

manufacturer‘s specifications.

Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance

loads to the circuit without ensuring that this will not

exceed the permissible voltage and current permitted

for the equipment in use. Intrinsically safe components

are the only types that can be worked on while live in

the presence of a flammable atmosphere. The test

apparatus shall be at the correct rating. Replace com-

ponents only with parts specified by the manufacturer.

Other parts may result in the ignition of refrigerant in

the atmosphere from a leak.

Cabling

Check that cabling will not be subject to wear, corrosion,

excessive pressure, vibration, sharp edges or any other

adverse environmental effects. The check shall also

take into account the effects of aging or continual

vibration from sources such as compressors or fans.

Detection of flammable refrigerants

Under no circumstances shall potential sources of

ignition be used in the searching for or detection of

refrigerant leaks. A halide torch (or any other detector

using a naked flame) shall not be used.

Leak detection methods

The following leak detection methods are deemed

acceptable for systems containing flammable re-

frigerants. Electronic leak detectors shall be used to

detect flammable refrigerants, but the sensitivity may

not be adequate, or may need re-calibration. (Detection

equipment shall be calibrated in a refrigerant-free area.)

Ensure that the detector is not a potential source of

ignition and is suitable for the refrigerant used. Leak

detection equipment shall be set at a percentage of

the LFL of the refrigerant and shall be calibrated to the

refrigerant employed and the appropriate percentage

of gas (25 % maximum) is confirmed. Leak detection

fluids are suitable for use with most refrigerants but

the use of detergents containing chlorine shall be

avoided as the chlorine may react with the refrigerant

and corrode the copper pipe-work. If a leak is suspected,

all naked flames shall be removed/ extinguished. If a

leakage of refrigerant is found which requires brazing,

all of the refrigerant shall be recovered from the

system, or isolated (by means of shut off valves) in a

part of the system remote from the leak. Oxygen free

nitrogen (OFN) shall then be purged through the

system both before and during the brazing process.

Removal and evacuation

When breaking into the refrigerant circuit to make

repairs or for any other purpose conventional

procedures shall be used. However, it is important

that best practice is followed since flammability is a

consideration. The following procedure shall be

adhered to:

- Remove refrigerant;

- Purge the circuit with inert gas;

- Evacuate;

- Purge again with inert gas;

- Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the

correct recovery cylinders. The system shall be „flushed“

with OFN to render the unit safe. This process may

need to be repeated several times. Compressed air or

oxygen shall not be used for this task. Flushing shall

be achieved by breaking the vacuum in the system

with OFN and continuing to fill until the working

pressure is achieved, then venting to atmosphere, and

finally pulling down to a vacuum. This process shall be

repeated until no refrigerant is within the system.

When the final OFN charge is used, the system shall

be vented down to atmospheric pressure to enable

work to take place. This operation is absolutely vital if

brazing operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not

close to any ignition sources and there is ventilation

available. working on them.

Labelling

Equipment shall be labelled stating that it has been

de-commissioned and emptied of refrigerant. The

label shall be dated and signed. Ensure that there are

labels on the equipment stating the equipment

contains flammable refrigerant.

5. MAINTENANCE AND INSPECTION

Check the water supply device and the release often.

You should avoid the condition of no water or air

entering into system, as this will influence unit‘s

performance and reliability. You should clear the pool/

spa filter regularly to avoid damage to the unit as a

result of the dirty of clogged filter.

The area around the unit should be dry, clean and well

ventilated. Clean the side heating exchanger regularly

to maintain good heat exchange as conserve energy.

The operation pressure of the refrigerant system should

only be serviced by a certified technician.

Check the power supply and cable connection often.

Should the unit begin to operate abnormally, switch it

off and contact the qualified technician.

Discharge all water in the water pump and water

system, so that freezing of the water in the pump or

water system does not occur. You should discharge the

water at the bottom of water pump if the unit will not

be used for an extended period of time. You should

check the unit thoroughly and fill the system with

water fully before using it for the first time

Checks to the area

Prior to beginning work on systems containing flammable

refrigerants, safety checks are necessary to ensure that

the risk of ignition is minimised. For repair to the

refrigerating system, the following precautions shall be

complied with prior to conducting work on the system.

Work procedure

Work shall be undertaken under a controlled procedure

so as to minimise the risk of a flammable gas or vapour

being present while the work is being performed

General work area

All maintenance staff and others working in the local

area shall be instructed on the nature of work being

carried out. Work in confined spaces shall be avoided.

The area around the workspace shall be sectioned off.

Ensure that the conditions within the area have been

made safe by control of flammable material.

Checking for presence of refrigerant

The area shall be checked with an appropriate refrigerant

detector prior to and during work, to ensure the technician

is aware of potentially flammable atmospheres. Ensure

that the leak detection equipment being used is

suitable for use with flammable refrigerants, i.e.

non-sparking, adequately sealed or intrinsically safe.

Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration

equipment or any associated parts, appropriate fire

extinguishing equipment shall be available to hand.

Have a dry powder or CO2 fire extinguisher adjacent to

the charging area.

No ignition sources

No person carrying out work in relation to a refrigeration

system which involves exposing any pipe work that

contains or has contained flammable refrigerant shall

use any sources of ignition in such a manner that it may

lead to the risk of fire or explosion. All possible ignition

sources, including cigarette smoking, should be kept

sufficiently far away from the site of installation, repairing,

removing and disposal, during which flammable refrige-

rant can possibly be released to the surrounding space.

Prior to work taking place, the area around the equip-

ment is to be surveyed to make sure that there are no

flammable hazards or ignition risks. “No Smoking” signs

shall be displayed.

Ventilated area

Ensure that the area is in the open or that it is adequately

ventilated before breaking into the system or conducting

any hot work. A degree of ventilation shall continue during

the period that the work is carried out. The ventilation

should safely disperse any released refrigerant and

preferably expel it externally into the atmosphere.

prolonged period of no usage.

Checks to the refrigeration equipment

Where electrical components are being changed, they

shall be fit for the purpose and to the correct specification.

At all times the manufacturer‘s maintenance and service

guidelines shall be followed. If in doubt consult the manu-

facturer‘s technical department for assistance. The

following checks shall be applied to installations using

flammable refrigerants: The charge size is in accordance

with the room size within which the refrigerant containing

parts are installed; The ventilation machinery and outlets

are operating adequately and are not obstructed; If an

indirect refrigerating circuit is being used, the secondary

circuit shall be checked for the presence of refrigerant;

Marking to the equipment continues to be visible and

legible. Markings and signs that are illegible shall be

corrected; Refrigeration pipe or components are installed

in a position where they are unlikely to be exposed to any

substance which may corrode refrigerant containing

components, unless the components are constructed of

materials which are inherently resistant to being corroded

or are suitably protected against being so corroded.

Checks to electrical devices

Repair and maintenance to electrical components shall

include initial safety checks and component inspection

procedures. If a fault exists that could compromise safety,

then no electrical supply shall be connected to the circuit

until it is satisfactorily dealt with. If the fault cannot be

corrected immediately but it is necessary to continue

operation, an adequate temporary solution shall be used.

This shall be reported to the owner of the equipment so

all parties are advised. Initial safety checks shall include:

- That capacitors are discharged: this shall be done in a

safe manner to avoid possibility of sparking;

- That there no live electrical components and wiring

are exposed while charging, recovering or purging the

system;

- That there is continuity of earth bonding.

NOTE

The use of silicon sealant may inhibit the

effectiveness of some types of leak detection

equipment. Intrinsically safe components do not

have to be isolated prior to on them.

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

28 29

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

Recovery

When removing refrigerant from a system, either for

servicing or decommissioning, it is recommended good

practice that all refrigerants are removed safely. When

transferring refrigerant into cylinders, ensure that only

appropriate refrigerant recovery cylinders are employed.

Ensure that the correct number of cylinders for holding

the total system charge is available. All cylinders to be

used are designated for the recovered refrigerant and

labelled for that refrigerant (i.e. special cylinders for the

recovery of refrigerant). Cylinders shall be complete

with pressure relief valve and associated shutoff valves

in good working order. Empty recovery cylinders are

evacuated and, if possible, cooled before recovery

occurs. The recovery equipment shall be in good

working order with a set of instructions concerning

the equipment that is at hand and shall be suitable

for the recovery of flammable refrigerants. In addition,

a set of calibrated weighing scales shall be available

and in good working order. Hoses shall be complete

with leak-free disconnect couplings and in good

condition. Before using the recovery machine, check

that it is in satisfactory working order, has been

properly maintained and that any associated electrical

components are sealed to prevent ignition in the

event of a refrigerant release. Consult manufacturer if

in doubt. The recovered refrigerant shall be returned

to the refrigerant supplier in the correct recovery

cylinder, and the relevant Waste Transfer Note arranged.

Do not mix refrigerants in recovery units and especially

not in cylinders. If compressors or compressor oils are

to be removed, ensure that they have been evacuated

to an acceptable level to make certain that flammable

refrigerant does not remain within the lubricant. The

evacuation process shall be carried out prior to returning

the compressor to the suppliers. Only electric heating to

the compressor body shall be employed to accelerate

this process. When oil is drained from a system, it shall

be carried out safely.

Decommissioning

Before carrying out this procedure, it is essential that

the technician is completely familiar with the equipment

and all its detail. It is recommended good practice that

all refrigerants are recovered safely. Prior to the task

being carried out, an oil and refrigerant sample shall

be taken in case analysis is required prior to re-use of

reclaimed refrigerant. It is essential that electrical

power is available before the task is commenced.

A Become familiar with the equipment and its

operation.

B Isolate system electrically.

C Before attempting the procedure ensure that:

- Mechanical handling equipment is available,

if required, for handling refrigerant cylinders;

- All personal protective equipment is available

and being used correctly;

- The recovery process is supervised at all times

by a competent person;

- Recovery equipment and cylinders conform

to the appropriate standards.

D Pump down refrigerant system, if possible.

E If a vacuum is not possible, make a manifold so that

refrigerant can be removed from various parts of

the system.

F Make sure that cylinder is situated on the scales

before recovery takes place.

G Start the recovery machine and operate in

accordance with manufacturer‘s instructions.

H Do not overfill cylinders. (No more than 80 %

volume liquid charge).

I Do not exceed the maximum working pressure of

the cylinder, even temporarily.

J When the cylinders have been filled correctly and

the process completed, make sure that the

cylinders and the equipment are removed from site

promptly and all isolation valves on the equipment

are closed off.

K Recovered refrigerant shall not be charged into

another refrigeration system unless it has been

cleaned and checked.

Charging procedures

In addition to conventional charging procedures, the

following requirements shall be followed.

- Ensure that contamination of different refrigerants

does not occur when using charging equipment.

Hoses or lines shall be as short as possible to

minimise the amount of refrigerant contained in

them.

- Cylinders shall be kept upright.

- Ensure that the refrigeration system is earthed

prior to charging the system with refrigerant.

- Label the system when charging is complete (if not

already).

- Extreme care shall be taken not to overfill the

refrigeration system. Prior to recharging the system

it shall be pressure tested with OFN. The system

shall be leak tested on completion of charging but

prior to commissioning. A follow up leak test shall

be carried out prior to leaving the site.

- The safety wire model is 5*20_5A/250VAC. And must

meet the explosion-proof requirements

6.APPENDIX

6.1 CIRCUIT DIAGRAM

6.APPENDIX

6.1 Circuit diagram

32

8:

LN 12

L

N

RED

BLU

Y/G

K2

CN21

RES1

CN29

OVT

CN30

HP

CN31

LP CN13

HEAT CN18

EMV

CN66

RY

CN11

FOUR

CN96

OT(RED)

3/

3/

CN7

OAT

CN8

OPT

CN22

RES2 CN9

OHT

CN12

PH

FS LP

A B

RS485

CN15

LEV1

CN24

LEV2

AT(WHT)

4V

K2

$&/

$&1

L

N

*1'

A

B

reactor

EEV

5

*1'

COMP

89:

UW

V

RED BLK WHT

FM

9

CODE˖20190330-0001

FILTER

L

BLU

BRN

N

AB

RED

WHT

YEL

BLK

$&/

$&1

IT(BLU)

SUT(GRN)

CT(YEL)

Magetic ring

HP

HP

EP

EP

HP

EP

GRN

t

50K

ET(GRY)

DCFAN

CN97

SPS

CN2 CN1

2AC32I12WO1

L

N

P

N

220-240V~/50Hz

TO POWER

SUPPLY

TO PUMP

<10A

CN99

PL

RED

WHT

BLK

PS

3

BRN BLU

t

5K

t

5K

t

5K

t

5K

t

5K

OT˖Outlet water temperature

4V˖4 way valve

AT˖Ambient temperature

COMP˖Compressor

CT˖Coil temperature

FM˖Fan motor

IT˖Inlet water temperature

LP˖Low pressure protection

FS˖Flow switch

HP˖High pressure protection

ET˖Exhaust temperature

EEV˖Electronic expansion valve

SPS˖Switching power supply

K2˖Realy of pump

EP˖Exhaust protection

SUT˖Suction temperature

PS˖Pressure sensor

CN10

G

2

G

4V 4V

4

YEL 485B-

RED 12V

WHT 485A+

BLK GND

WiFi

BLK GND

YEL 485B-

WHT 485A+

RED 12V

Controller

P13X/32

8:

LN 12

L

N

RED

BLU

Y/G

K2

CN21

RES1

CN29

OVT

CN30

HP

CN31

LP CN13

HEAT CN18

EMV

CN66

RY

CN11

FOUR

CN96

OT(RED)

3/

3/

CN7

OAT

CN8

OPT

CN22

RES2 CN9

OHT

CN12

PH

FS LP

A B

RS485

CN15

LEV1

CN24

LEV2

AT(WHT)

4V

K2

$&/

$&1

L

N

*1'

A

B

reactor

EEV

5

*1'

COMP

89:

UW

V

RED BLK WHT

FM

9

CODE˖20181206-0001

FILTER

L

BLU

BRN

N

AB

RED

WHT

YEL

BLK

$&/

$&1

IT(BLU)

SUT(GRN)

CT(YEL)

Magetic ring

HP

HP

EP

EP

HP

EP

GRN

t

50K

ET(GRY)

DCFAN

CN97

SPS

CN2 CN1

2AC32I12WO1

L

N

P

N

220-240V~/50Hz

TO POWER

SUPPLY

TO PUMP

<10A

CN99

PL

RED

WHT

BLK

PS

3

4

YEL 485B-

RED 12V

WHT 485A+

BLK GND

WiFi

BLK GND

YEL 485B-

WHT 485A+

RED 12V

BRN BLU

t

5K

t

5K

t

5K

P17X/32

t

5K

t

5K

Controller

CN10

G

2

G

OT˖Outlet water temperature

4V˖4 way valve

AT˖Ambient temperature

COMP˖Compressor

CT˖Coil temperature

FM˖Fan motor

IT˖Inlet water temperature

LP˖Low pressure protection

FS˖Flow switch

HP˖High pressure protection

ET˖Exhaust temperature

EEV˖Electronic expansion valve

SPS˖Switching power supply

K2˖Realy of pump

EP˖Exhaust protection

SUT˖Suction temperature

PS˖Pressure sensor

DE

EN

NL

FR

DA

SV

EN

DE

SWIMMING POOL HEAT PUMP TYPE PXSWIMMING POOL HEAT PUMP TYPE PX

30 31

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

6.APPENDIX

6.1 Circuit diagram

33

CODE˖20181109-0005

K2

N

13

24

5

6

7

8

01

N

L

N

NN

N

N

4V

13

24

5

6

7

8

02

N

L

Y/G

YEL

P

L

N

RED

BLU

$

*1'

9

%

3

:893 3( $&1 $&/ / /

&1

&1

&1

&1 &1 &1

3

3

/

1

8

9

:

$&,:0

COMP

89:

UW

V

RED BLK WHT

PTC

K2

N

N

N

13

24

5

6

7

8

03

L4

/

/

/

3

L

3

1

K1

L

N

N

K1˖Relay of compressor

SUT˖Suction temperature

AT˖Ambient temperature

COMP˖Compressor

CT˖Coil temperature

FM˖Fan motor

IT˖Inlet water temperature

LP˖Low pressure protection

OT˖Outlet water temperature

FS˖Flow switch

HP˖High pressure protection

EEV˖Electronic expansion valve

4V˖4 way valve

ET˖Exhaust temperature

PM˖Phase monitor

K2˖Relay of pump

P20X/32

K2

1

N

N

LL

$&/RXW

$&1RXW

$&1LQ

$&/LQ

(0,

CN1

FM1

ZL10

1

GND

485A1

12V

N

L

485B1

Y/G

WHT

BLK

CN4

L

/

4V

4

RED

BLK

WHT

Pressure sensor

᧤SUT᧥

CN9

3

RLY1

OUT2

OUT3

AC-N1

OUT4

OUT5

CN2

PC1004

CN8

4

CN13

A1A3A5A7A9

A11

t

5K

SUT LP

Remote

ON/OFF

A4A6A8A10

A12 A2

FS

HP

t

5K

IT

t

5K

CTET

t

50K

t

5K

OT

t

5K

AT

6.8K

CN11

A13

GND

GND

GND

GND

+12V

0~10V-OUT

PWM-IN

PWM-OUT

9

9

L

/

K1

EEV

5

LN 12

4

N

L

N

220-240V~/50Hz

TO POWER

SUPPLY

TO PUMP

<10A

4

Controller

YEL 485B-

BLK GND

RED 12V

WHT 485A+

WiFi

BLK GND

YEL 485B-

WHT 485A+

RED 12V

HOHFWULFUHDFWRU

LN

/

/

/

R

S

T

N

RED

BLK

WHT

BLU

RSTN

R

N

4V

13

24

5

6

7

8

02

N

N14

N

N

N

N

N

N

K2

4V

N

R

13

24

5

6

7

8

01

L3(C)

L2(B)

L1(A) 11

14

12

PM

N

N14

R

RR

4

CODE˖20181109-0007

RED

BLK

WHT

Pressure sensor

᧤SUT᧥

Y/G

&203

89:

8

9

:

K2

'ULYHUPRGXOHERDUG

DCN-IN

8 9:567

DCP-IN

DCN-OUT

DCP-OUT

B

A

GND

12V

CN602

GND

CN605

5V

JP601

HOHFWULFUHDFWRU

5

6

7

RED

BLK

WHT

R

S

T

N

1

N

1

R

RST

P20TX/32

DC+

DC1+

DC-

DC1-

EEV

5

CN9

3

RLY1

OUT2

OUT3

AC-N1

OUT4

OUT5

CN2

PC1004

CN8

4

A1A3A5A7A9

A11

t

5K

SUT LP

Remote

ON/OFF

A4A6A8A10

A12 A2

FS

HP

t

5K

IT

t

5K

CTET

t

50K

t

5K

OT

t

5K

AT

6.8K

CN11

A13

GND

GND

GND

GND

+12V

0~10V-OUT

PWM-IN

PWM-OUT

9

9

$ % & 1

1&%$

(0,

),

4

TO POWER SUPPLY

380V/3N~/50Hz

CN1

FM1

ZL10

5

1

GND

485A1

12V

N

L

485B1

Y/G

WHT

BLK

CN4

YEL

4

Controller

YEL 485B-

BLK GND

RED 12V

WHT 485A+

CN13

LN

13

24

5

6

7

8

03

ST

SS

5

6 7

T

T

6

75

5

N

L1N

R

S

T