North Slope Chillers NSC0500 User manual

Freeze Owner’s Manual 1 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Freeze Owner’s Manual 2 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Table of Contents

Applications

Cautions/Warnings

Specification sheet 4

Chiller Component Overview 5

Installation 8

User Interface 9

Modifying Parameters 9

Display Unit 9

Thermostat Differential 9

Upper and Lower limit of Thermostat Set Point 10

Troubleshooting 11

STANDARD PRODUCT WARRANTY 1

1. LIMIT D WARRANTY 13

2. LIMITATION OF LIABILITY 13

3. R TURNS 13

4. IND MNIFICATION 14

Freeze Owner’s Manual | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Applications

This owner’s manual is to be used for the following North Slope Chillers:

TYPE

MODEL NUMBER

COOLING CAPACITY

(BTU/HR)

Freeze

NSC0500

6,000 (1/2 ton)

Freeze

NSC1000

12,000 (1 ton)

Freeze

NSC2000

24,000 (2 ton)

Freeze

NSC5000

60,000 (5 ton)

Freeze

NSC10000

120,000 (10 ton)

Deep Freeze

NSC0500

-

LT

6,000 (1/2 ton)

Deep Freeze

NSC1000

-

LT

12,000 (1 ton)

Deep Fre

eze

NSC2000

-

LT

24,000 (2 ton)

Deep Freeze

NSC5000

-

LT

60,000 (5 ton)

Deep Freeze

NSC10000

-

LT

120,000 (10 ton)

Cautions/Warnings

1. Power (ALWAYS check the Chiller Parameter tag and verify operational voltage before plugging in chiller)

a. Only connect North Slope Chillers to a properly grounded circuit

b. Never connect your North Slope Chiller to voltage that is outside the acceptable voltage range.

Connecting your chiller to any voltage outside of these ranges will damage the compressor.

i. 110V model will operate on voltages between 100 ~ 130V

ii. 230V model will operate on voltages between 200 ~ 250V

iii. 460V model will operate on voltages between 440 ~ 480V

c. Only use power sources that are 60Hz, running the chiller at 50Hz will void the warranty and will

damage the compressor

2. Never run the pump dry, only turn on chiller after the fluid reservoir has been filled. Running the chiller without

fluid will permanently damage the pump and void the warranty

3. This chiller is air cooled and must have good ventilation. For proper function there must be a minimum of 1

foot clearance on both sides and 2 foot clearance at the back of the chiller

4. Flush chiller prior to use. North Slope Chillers tests every chiller on site prior to shipping. During testing North

Slope Chillers uses a water/glycol mix to test their chillers. There will always be a small amount of water/glycol

remaining in the system. Since not all glycols are compatible with each other and vary by manufacture each

chiller should be flushed with water for 10 minutes prior to use.

Freeze Owner’s Manual 4 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Specification sheet

Model

NSC0500

-

110/1

NSC0500

-

LT

-

110/1

NSC1000

-

230/1

NSC1000

-

LT

-

230/1

NSC2000

-

230/1

NSC2000

-

LT

-

230/1

Voltage

110 VAC, SINGL

PHAS , 60 Hz

110 VAC, SINGL

PHAS , 60 Hz 230VAC, SINGL PHAS , 60 Hz

Compressor Power

½ HP

½ HP

1 HP

2

HP

Cooling Capacity

(BTU/hr)

6,000 BTU/hr

90F ambient

65F Fluid Temp

6,000 BTU/hr

90F ambient

65F Fluid Temp

12,000 BTU/hr

90F Ambient

65F Fluid Temp

12,000 BTU/hr

90F Ambient

40F Fluid Temp

24,000 BTU/hr

90F Ambient

65F Fluid Temp

24,000 BTU/hr

90F Ambient

40F Fluid Temp

Fluid Temp Range

40F

–

80F

10F

–

60F

40F

–

80F

10F

–

60F

40F

–

80F

10F

–

60F

Refrigerant

R

-

134a

R404a

R

-

134a

R

-

404a

R

-

134a

R

-

404a

Metering Device

TXV

Pump Power

1/3 HP

3/4 HP

Pump Specs

4 GPM up to 50 PSI, Fixed Displacement

10GPM

@ 28 PSI (Centrifugal)

Glycol %

70/30

(Water/Glycol)

50/50

(Water/Glycol)

70/30 (Water/Glycol)

50/50 (Water/Glycol)

70/30 (Water/Glycol)

50/50 (Water/Glycol)

Acceptable Fluids

thylene Glycol or Propylene Glycol*

North Slope Chillers recommends using distilled water to maximize life and performance of chiller

Consult North Slope Chillers prior to using other fluids in the chiller

Tank Capacity

3.5 Gallons

15 Gallons

Inlet and Outlet

1/2” NPT

3/4” NPT

Dry Weight (lbs)

220 lbs

360 lbs

550 lbs

Dimension

s

28¼"L x 22½"W x 32½"H

34½"L x 28¼"W x 39"H

34¾"L x 43¼"W x 40"H

Model

NSC5000

-

460/3

NSC5000

-

LT

-

460/3

NSC10000

-

460/3

NSC1000

-

LT

-

460/3

Voltage

460 3 Phase

Compressor Power

5 HP

10 HP

Cooling Capacity

(BTU/hr)

60,000 BTU/hr

90F ambient

65F Fluid Temp

60,000 BTU/hr

90F ambient

40F Fluid Temp

120,000 BTU/hr

90F Ambient

65F Fluid Temp

120,000 BTU/hr

90F Ambient

40F Fluid Temp

Fluid Temp Range

40F

–

65F

10F

–

45F

40F

–

65F

10F

–

45F

Refrigerant

R404a

Metering Device

TXV

Pump Power

2 HP

Pump Specs

15

GPM @ 39 PSI

30 GPM @ 35 PSI

45 GPM @ 28 PSI

60 GPM Max

Glycol %

70/30

(Water/Glycol)

50/50

(Water/Glycol)

70/30 (Water/Glycol)

50/50 (Water/Glycol)

Acceptable Fluids

thylene Glycol or Propylene Glycol*

North Slope Chillers recommends using

distilled water to maximize life and

performance of chiller

Tank Capacity

55 Gallons

55 Gallons

Inlet and Outlet

1

-

1/4” NPT

Dry Weight (lbs)

1000 lbs

1150 lbs

Dimensions

34"L x 65"W x 62"H

North Slope Chillers tests every chiller on site prior to shipping. During testing North Slope Chillers uses a water/glycol

mix to test their chillers. Since not all glycols are compatible with each other and vary by manufacture each chiller

should be flushed with water for 10 minutes prior to use.

*The mix of Glycol to Water should be proportional to the desired freeze point. Always select a Glycol/Water mix that

will prevent freezing at 25F below your set point. This will prevent freezing from occurring in the heat exchanger and

prevent damaging the system. For example if your setpoint is 10F you should select a glycol percentage that would

prevent freezing at -15F.

Freeze Owner’s Manual 5 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

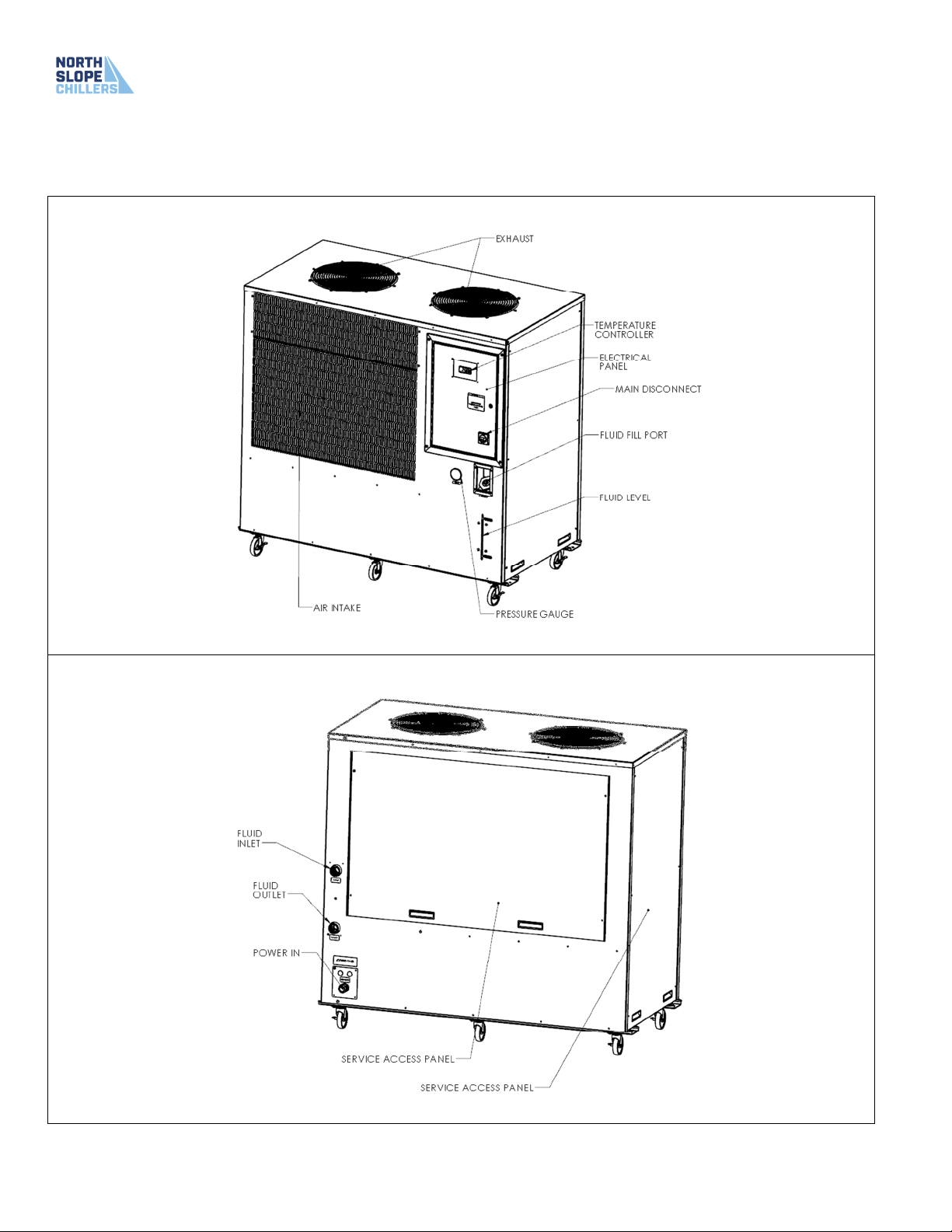

Chiller Component Overview

NSC0500, NSC 000 and NSC2000 Models

FRONT (NSC0500, NSC1000 and NSC2000 models)

BACK (NSC0500, NSC1000 and NSC2000 models)

Freeze Owner’s Manual 6 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

NSC5000 and NSC 0000 Models

FRONT (NSC5000 and NSC10000 models)

BACK (NSC5000 and NSC10000 models)

Freeze Owner’s Manual 7 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Fluid Circuit (NSC5000 and NSC10000 models)

Electrical (NSC5000 and NSC10000 models)

Freeze Owner’s Manual 8 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Installation

1. Position chiller for use

●Place unit on a flat level surface in a well-ventilated area

2. Connect inlet and outlet fluid hoses

●Confirm hoses are connected to proper inlet and outlet ports

. Fill the reservoir

4. Connect to power

●nsure you have the correct power supply before plugging in chiller

5. Turn on chiller and adjust temperature controller

●See page 8 for instructions on how to adjust temperature controller

Freeze Owner’s Manual 9 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

User Interface

Set the Setpoint

1

The display shows the current temperature

2

Press "up/down" to access setpoint.

3

Press "up/down" to a

djust setpoint. After 30 seconds, the display automatically reverts to showing the

current temperature. Or Press 2 x "Back"

Modifying Parameters

Display Unit

Default Unit: Fahrenheit (°F). Adjust display unit first before changing other parameters.

1

Pr

ess "up/down" and hold 5 seconds to access the menu.

2

Press "up/down" to find

3

Press “OK”

4

Press "up/down" to find

5

Press “OK”

6

Press "up/down" to change parameter

7

Press “OK”

Thermostat Differential

Default differential: 3°F

1

Press "up/down" and hold 5 seconds to access the menu.

2

Press "up/down" to find

Freeze Owner’s Manual 10 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

3

Press “OK”

4

Press "up/down" to find

5

Press “OK”

6

Press "up/down" to change parameter

7

Press “OK”

Upper and Lower limit of Thermostat Set Point

Default Limits: Upper = 65°F, Lower = 25°F

1

Press "up and down" and hold 5 seconds to access the menu.

2

Press "up/down" to find

3

Press “OK”

4

Press "up/down" to find (Upper limit of thermostat set point)

5

Press “OK”

6

Press

"up/down" to change parameter

7

Press “OK”

8

Press "up/down" to find (Lower limit of thermostat set point)

9

Press “OK”

10

Press "up/down" to change parameter

11

Press “OK”

Freeze Owner’s Manual 11 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

Troubleshooting

Symptoms

Possible Cause(s)

Compressor does

not start. The temperature rises but

the pump runs fine.

1.

Compressor is not being powered

2. Flow switch is not activated

Compressor hums but doesn’t start

1.

Low line voltage

2. Incorrect wiring

3. Internal compressor damage

Compressor does not run or try to start

( doesn’t hum)

1.

Open circuit due to blown fuse or open disconnects

2. Shorted motor windings

3. Compressor motor protector open

4. Open thermostat

5. Loss of refrigerant

6. Refrigerant solenoid valve not working

Compressor starts but trips on overload protector

1.

Suction

or discharge pressure is too high

2. Low line voltage

3. Broken overload protector

4. Mechanical damage to compressor

5. Shorted motor windings

Chiller short cycles

1.

Insufficient refrigerant

2. Leaking refrigerant solenoid valve

3. Leaking discharge valve

4. Malfunctioning expansion valve

High refrigerant pressure fault

1.

xcessive refrigerant

2. Clogged condenser

3. Condenser fan malfunction

4. Air entering condenser is too hot

Low refrigerant pressure fault

1.

Refrigerant leak

2. Coolant not flowing through heat exchanger

3. Liquid line solenoid valve stuck closed

4. Stuck expansion valve or bulb well not charged

5. Low ambient air temperatures

Lube protector fault

1.

Low compressor oil level due to:

●Oil trapped in system

●Compressor short cycling

●Not enough oil in system

Freeze Owner’s Manual 12 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

●

Suction pressure too low

2. xcessive refrigerant

3. Broke oil pump

Fluid temperature too cold

1.

Set point temperature is too low

2. Malfunctioning temperature controller

3. Malfunctioning temperature sensor

4. Leaking refrigerant solenoid valve

Fluid flow fault

1.

Fluid pump not working

2. Insufficient refrigerant

3. Air trapped inside system

4. Malfunctioning flow switch

Freeze Owner’s Manual 1 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

STANDARD PRODUCT WARRANTY

. LIMITED WARRANTY

Manufacturer warrants North Slope Chillers Products sold as “new” to be free from defects in material and

workmanship for a period of one (1) year from the date of purchase by a retail customer when used, stored,

inspected and serviced as specified in any operating instructions provided with the North Slope Chillers

Product. Exclusions from warranty consideration include, but are not limited to: normal wear and tear; abuse,

misuse, or non-standard application; act of nature; lack of proper maintenance; improper care or storage

(blankets should be folded and not rolled up); unauthorized repair; unauthorized modification; or attachment to

another product, use with any attachment or as integrated into another product. Neither Manufacturer, nor its

representatives, assumes any responsibility for any other products used with the North Slope Chillers Product

or for results of or damages caused to persons or property by the use of the North Slope Chillers Product. Only

the Manufacturer is authorized to make any warranty or representation and the customer may not rely on any

other warranty or representation. All implied warranties are hereby disclaimed.

MANUFACTURER MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND, EXPRESSED

OR IMPLIED, IN FACT OR IN LAW, INCLUDING WITHOUT LIMITATION ANY

WARRANTY OF MERCHANTABILITY, NONINFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE

OR USE OTHER THAN THE LIMITED WARRANTY SET FORTH ABOVE.

2. LIMITATION OF LIABILITY

MANUFACTURER’S SOLE LIABILITY SHALL BE AS SET FORTH HEREIN, AND SHALL EXTEND ONLY TO

INSPECTION, REPLACEMENT OR REPAIR OF THE NORTH SLOPE CHILLERS PRODUCT, AT THE

DISCRETION OF MANUFACTURER, WITHIN THE TIME PERIOD AND ON THE TERMS SET FORTH

HEREIN. MANUFACTURER HAS NO LIABILITY FOR ANY OTHER PRODUCTS USED WITH, ATTACHED

TO OR WITH WHICH THE NORTH SLOPE CHILLERS PRODUCT MAY BE INTEGRATED INTO, OR FROM

THE RESULTS OF SUCH USE, ATTACHMENT OR INTEGRATION. IN NO EVENT WILL MANUFACTURER

BE LIABLE FOR SPECIAL, INCIDENTAL, INDIRECT, PUNITIVE OR CONSEQUENTIAL DAMAGES. IN NO

EVENT SHALL MANUFACTURER’S LIABILITY EXCEED THE PAYMENTS RECEIVED BY

MANUFACTURER FOR THE NORTH SLOPE CHILLERS PRODUCT.

3. RETURNS

a. When any North Slope Chillers Product has been authorized to return for any inspection, or replacement, it

must be returned as specified in the Return Merchandise Authorization Form.

b. A Manufacturer-issued Returned Material Authorization (RMA) number authorizing a product return must be

acquired prior to sending any return. In addition, documentation of model, product serial number, dealer

invoice number, dated proof of resale, and description of failure shall accompany all returns.

c. All returns must come freight prepaid and in their original containers, or in a manner conducive to proper

shipping and handling procedures. Product(s) replaced, or shipped in accordance with the Return Merchandise

Authorization Form will be returned freight prepaid.

d. Manufacturer reserves the right to postpone, delay, or refuse warranty claim consideration for either

unauthorized returns or returns made by dealers or distributors whose open and active accounts are past due

Freeze Owner’s Manual 14 | Page

www.northslopechillers.com | (866) 826-299 | 1 0 S 10 0 W, Suite 1 | Salt Lake City, UT 84119

Revised: 12/18/2020

or delinquent. The dealer or distributor agrees that no warranties or other guarantees on any products shall be

made in excess of those made by Manufacturer. This agreement excludes Manufacturer or its representatives

from all liability not covered in this Warranty.

4. INDEMNIFICATION

Customer acknowledges that North Slope Chillers has no control over, and is not responsible for the manner in

which the Customer uses the Product(s). The Customer hereby agrees to indemnify, defend and hold

harmless (collectively, “indemnify” or “indemnification”) Customer, its affiliates, and their respective officers,

directors, employees, agents, representatives, successors and assigns from and against any and all suits,

proceedings, demands, judgments (including applicable pre-judgment and post-judgment interest, if any),

awards, losses, damages, costs, penalties, expenses, claims and liabilities, including reasonable attorneys’

fees, witness fees and court costs, and any other losses and liabilities of any kind or nature whatsoever

(“Damages”) of, or awarded to or settled with third parties in third party claims or actions, and the reasonable

costs of North Slope Chillers in successfully enforcing this indemnification obligation, in each case arising out

of one or more of the following: (a) the use, operation or modification of any Product, provided however, that

Customer shall have no indemnification obligation to the extent that the claim arises solely out of any negligent

acts or omissions by North Slope Chillers; (b) negligent acts or omissions or willful or intentional misconduct of

Customer (including its employees, agents, representatives, successors and assigns); and (c) failure to

comply with any relevant federal, state or local laws, regulations, rules or ordinances (including but not limited

to those related to hazardous waste and materials).

This manual suits for next models

9

Table of contents