Northern Industrial Tools 100501 User manual

Thank you verymuch for choosinga NORTHERN TOOL + EQUIPMENT CO., Inc.,Product! For future

reference, please completethe owner's recordbelow:

Model: _______________ PurchaseDate: _______________

Save the receipt,warranty and theseinstructions. It isimportant that youread the entiremanual to

become familiar withthis product beforeyou begin usingit.

This machine isdesigned for certainapplications only.Northern Tool + Equipmentstrongly recommends

that this machineis not modifiedand/or used forany application otherthan that forwhich it wasdesigned.

If you haveany questions relativeto a particularapplication, DO NOTuse the machineuntil you havefirst

contacted Northern Tool + Equipmentto determine ifit can orshould be performedon the product.Before

using this product,please read thefollowing instructions carefully.

For technical questionsand replacement parts,please call 1-800-222-5381.

DESCRIPTION

This reversible airdrill has durablelightweight aluminum housing,a variable speed trigger for precision

and includes aquick release coupler. This productis an ergonomicchoice for drilling,honing and hole

sawing.

TECHNICAL SPECIFICATIONS

Save These Instructions.

This manual hasall the necessarysafety warnings andprecautions. It alsocontains assembly,operating,

and maintenance procedures.Look in theback for theparts list andassembly diagram. Keepthis manual

and invoice ina safe anddry place forfuture reference.

WARNINGS AND SAFETY RULES

WARNING: The warnings, cautions,and instructions inthis owner's manualcannot cover all

possible conditions andsituations that mayoccur. Itmust be understoodby the operatorthat common

sense and cautionare factors thatcannot be builtinto this product,but must besupplied by theoperator.

1.Keep thework area clean.An untidy andcluttered work areaincreases the riskof accidents.

2.Always wearsafety glasses orgoggles. Afacemask should beworn when dustis generated.

3.Wear suitablework clothes. Do not wearloose fitting clothesor jewelry.They can becaught in

moving parts andmay cause injury. For outdoor work, rubber gloves and non-slip footwear are advised.

Wear a protectivehair net tocontain long hair.

4.Takeprecautions with compressedair. Do not disconnect air hoses ortools when theline is under

pressure. Close offair supply andrelease pressure first.Do not pointtools or directcompressed air at

people or animals.

5.Observe workarea environment. Do not expose air tools to rain or wet conditions. Do not use air tools

in close proximityto flammable liquidsor gases. Thework area shouldbe well litand ventilated.

6.Keep pets,untrained operators andchildren away.Children should be kept away fromthe work area.

Do not permitthem to handlethe tool ortool cable.

7.Secure thework pieces. Use clamps or a vice to hold your work. This will freeup both handsto

operate the tool.

8.Do notoverreach when working.Keep a balancedfooting at alltimes. Avoidabnormal stances and

awkward body positioning.

9.Do notoverload or forcetools. Toolsoperate better inthe specified performanceranges. Forcing the

tool may causemotor damage.

10.Check fordamage. Always check theprotection guards carefullyto ensure properoperation and

performance before use.Check for alignmentof moving parts,binding of movingparts, breakage of

parts, mountings, andany other conditionsthat may effectthe tool's operation.In cases ofsevere

impact, a crackor damage mayoccur do notuse a toolif a crackdevelops or ifair is escaping.

11.Useair tools fortheir intended purpose.Do not forcea small toolor accessory todo the jobof a

Heavy-duty tool. Donot exceed therecommended air pressure.

1 OF 4

Item

Chuck Size

No-load Speed

Air Consumption

Air Inlet Diameter

Min. Hose Size

Max. Air Pressure

Description

3/8" (10mm)

2200 RPM

4 CFM @90 PSI

1/4" -18 NPT

3/8" ID

90 PSI

12.When changingtools or accessories.Always closeoff air supplyand release pressure before

attempting to loosenany connection.

13.Beware oftemperature extremes. The expanding air causes the air tools to run very cold. Light

gloves are advisablefor operator comfort.Conversely, thecylinder head and air delivery pipe of the

compressor tank willrun quite hot.Avoid contact.

14.Maintain toolswith care. For efficient andsafe operation, toolsshould be keptclean. Check the

connections and hoses.If damaged theyshould be replaced.

15.Avoid unintentional triggering. Do not carry the tool or connect it with your finger on the trigger.

16.Do notabuse hoses. Do not carry tools by the hose or use the hose to drag the compressor. Protect

hoses from heat,oil, and sharpobjects. Avoiddraping the hose over the compressor cylinder head.

17.Storage. When not inuse, air toolsshould be storedin a dryarea that isnot accessible tochildren.

18.Stay alert.Do not usewhen you aretired or underthe influence ofalcohol and drugs.Use common

sense and payattention to avoidserious injury.

19.Remove keysand spanners. Do not forget to remove any adjustment keys, spanners, or wrenches

before operating thetool.

20.Do notleave unattended. Do not leave the compressor operating while unattended for extended

periods of time.If you havefinished using thecompressor and associatedtools, switch offthe air

supply and removethe plug.

21.Use onlycompressed air.This tool isintended for usewith compressed aironly. Neverattempt to

operate the toolusing compressed bottledoxygen or combustiblegases.

22.Use propersize and typeof air pressureline and fittings.Air hosesrated for amaximum of 150PSI or

Greater must beused with thistool.

OPERATING INSTRUCTIONS

GENERAL

1.Shut offthe air supply, disconnect air hose and releasepressure when changingbits.

2.Only operatethis tool withinthe recommended pressurerange 60 90PSI. Use outsidethis range will

cause poor performance,excessive wear andpossible danger.

3.Safety glassesmust always beworn for eyeprotection. Earplugs arestrongly recommended when

operating for longperiods.

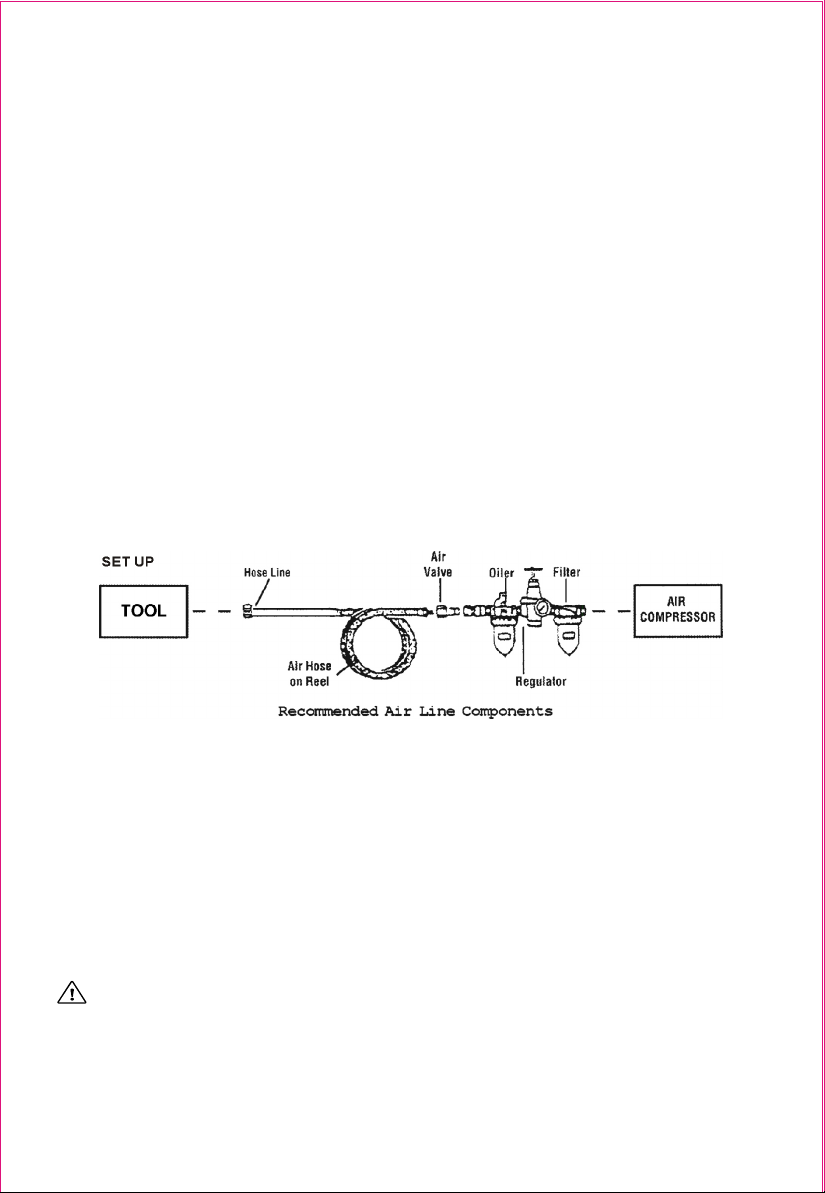

TOOL SET UP

Fig. 1 (Above)shows an optimalset-up that includesan inline filter, regulator and oiler. All of these

components are soldseparately through NorthernTool+ Equipment.

NOTE: If you arenot using anautomatic oiler system,before operation, adda few dropsof Pneumatic

ToolOil to theairline connection.Add a fewdrops more afteran hour ofcontinual use.

1.Prepare the1/4" air nipple(#37) to connectto the airinlet on theair drill. First,wrap the 1/4"air nipple

with pipe threadseal tape (notincluded) before threadingit into theinlet. Connect the3/8" I.D. airhose

(not included) toa quick-disconnect coupler(not included) andthen to theair nipple.

2.Turn on the air pressure on your compressor to 90 PSI. Do not exceed the recommended air pressure of

90 PSI.

3.Check theair connection forleaks.

AIR SUPPLY

WARNING: Ensure the airsupply is cleanand does notexceed 90 PSIwhile operating thetool. Too

much air pressureand unclean airwill shorten theproduct life dueto excessive wear, and may cause

damage and/or personalinjury.

1.Make surethat the airvalve (or trigger)is in the"off" position beforeconnecting to the air supply.

2.An airpressure of 90psiis required.

3.Drain theair tank daily. Water in the airline can damage the tool.

4.Clean theair inlet filterweekly.

2 OF 4

Fig. 1

5.Line pressureshould be increasedto compensate forlonger air hoses(over 26 feetor 8 meters).The

hose diameter shouldbe 3/8" I.D.

6.Keep thehose away fromheat, oil andsharp edges. Checkthe hose forwear and makecertain that all

connections are secure.

LUBRICATION

NOTE: It is importantthat the toolis properly lubricatedat all timesto ensure efficientoperation and to

avoid premature componentwearing. Use onlyrecommended lubricants, speciallymade for pneumatic

applications. Substitutes mayharm the rubbercomponents, e.g. O-ringsand other rubberparts.

1.Always lubricatethe tool byintroducing a fewdrops of airlinelubricating oil intothe air inletof the tool

before use.An automatic in-linefilter-regulator-lubricator is recommendedin cases wherethe tool is

used regularly asit increases toollife and enablessustained operations.

2.In the eventthat it becomesnecessary to storethe tool foran extended periodof time, ensureit is

thoroughly lubricated beforeuse. The toolshould be run for approximately 30 seconds to ensure oil is

Evenly distributed throughout.

APPROPRIATE USAGE

1.Run thecompressor and adjustthe compressor regulatorto the correctoperating range of6090 PSI.

2.Open theoutlet tap ofthe compressor tothe drill connection.

3.Select thedirection of rotationand press thetrigger to operate.

WARNING: When changing bits,shut off theair supply to the tool, disconnect drill from air hose

and release thepressure first, toavoid accidental operation.

OPERATIONAL HINTS

1.Always ensurethat the workpiece is firmlyclamped, so thatyou can use2 hands toguide and control

the drill.

2.When drillingwood, to preventsplintering on thereverse face whenthe drill breaksthrough, clamp a

scrap piece ofwood beneath thepoint where youare drilling.

3.When drillingmetals, mark thepoint to bedrilled using acentre punch toassist in startingthe hole in

the correct place.

4.To prevent damage to the drill, apply coolant to the bit if necessary, but do not wetthe tool itself.

5.When drillingwood, plastic, hardrubber, orcast iron nolubricant is needed.Use light mineraloil for

Brass or bronze.Use kerosene foraluminum. Use solubleoil for steeland other metals.

MAINTENANCE

WARNING! Disconnect the toolfrom the airsupply before changingaccessories, servicing or

performing maintenance. Replaceor repair anydamaged parts immediately. Use genuine parts only.

1.Lubricate theair tool dailywith a fewdrops of airtool oil drippedinto the airinlet.

2.Clean thetool after use.DO NOT usea worn, or damaged chuck.

3.Loss ofpower or erraticaction may bedue to thefollowing:

· Excessive drain onthe airline. Moistureor restriction inthe air lineexists. Incorrect sizeor type ofhose

connectors being used.Toremedy, checkthe air supply.

· Grit or debrisdeposits in thetool may alsoreduce performance.

4.When notin use, disconnectthe tool fromthe air supply. Clean thetool and storeit in asafe, dry,

Childproof location.

3 OF 4

DIAGRAM

PARTS LIST #34-39 not shown

For replacement partsand technical questions,please call 1-800-222-5381.

WARRANTY

One-Year Limited Warranty

4 OF 4

Part No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Description

Housing

O-Ring

O-Ring

Valve Stem

O-Ring

Bushing

Trigger Spring

Trigger

Trigger Screw

Pin

Muffler Cover

Screw

Air Inlet

Bearing

End Plate

Rotor

Rotor Blade

Cylinder

Pin

Front Plate

Qty.

1

1

1

1

3

1

1

1

1

1

1

2

1

2

1

1

5

1

1

1

Part No.

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Description

Washer

Gear

Gear

Pin

Gear Plate

Gear

Work Spindle

Tread Ring Gear

Bearing

Clamp Nut

Washer

Chuck

Chuck Screw

Drill Bits 1.5-6mm

Screwdriver Bits

Bit Holder

Nipple

Oil Pot

Key

Qty.

1

1

6

6

1

1

1

2

2

1

1

1

1

10

6

1

1

1

1

WARNING

Some dust createdby power sanding, sawing, grinding, drilling, and other construction

activities contains chemicalsknown to the State of California to cause cancer, birth defects

or other reproductiveharm. Some examples of these chemicals are:

Lead from lead-basedpaints

Crystalline silica frombricks and cement and other masonry products, and arsenicand

chromium from chemically-treatedlumber.

Your risk from theseexposures varies, depending on how often you do thistype of work. To

reduce your exposureto these chemicals: work in a well ventilated area,and work with

approved safety equipment,such as those dust masks that are specially designedto filter

out microscopic particles.

·

·

Table of contents

Other Northern Industrial Tools Drill manuals