Northern Industrial Tools 155301 User manual

5-Speed

BENCH DRILL PRESS

with Laser

OWNER'S MANUAL

Item # 155301

WARNING:

Read carefully and understand all INSTRUCTIONS before

operating. Failure to follow the safety rules and other basic

safety precautions may result in serious personal injury.

1

Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC. Product!

For future reference, please complete the owner's record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire

manual to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment cannot be

responsible for issues arising from modification. We strongly recommend this machine is not

modified and/or used for any application other than that for which it was designed. If you

have any questions relative to a particular application, DO NOT use the machine until you

have first contacted Northern Tool + Equipment to determine if it can or should be performed

on the product.

For technical questions please call 1-800-222-5381.

INTENDED USE

This bench drill press is designed for drilling in metal or wooden pieces.

TECHNICAL SPECIFICATIONS

Description Specifications

Motor: 1/2 HP

Volts: 120V

Speed: 570 - 3050 RPM

Chuck Size: 1/2”

Swing: 10"

Stroke: 2 1/3"

Drilling Capacity: 1/2”

Work tabel: 7 15/16" x 7 3/4"

Work base: 13 11/16" x 8 1/4"

Ship Weight:71 lbs

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

WARNING! The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that could occur. It must be understood by the operator

that common sense and caution are factors which cannot be built into this product, but must be

supplied by the operator.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep work area clean, free of clutter and well lit. Cluttered and dark work areas can cause accidents.

• Do not use your tool where there is a risk of causing a fire or an explosion; e.g. in the presence of

flammable liquids, gasses, or dust. Power tools create sparks, which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control, so visitors should remain at a safe distance from the work area.

2

• Be aware of all power lines, electrical circuits, water pipes and other mechanical hazards in your work

area, particularly those hazards below the work surface hidden from the operator's view that may be

unintentionally contacted and may cause personal harm or property damage.

• Be alert of your surroundings. Using power tools in confined work areas may put you dangerously close to

cutting tools and rotating parts.

ELECTRICAL SAFETY

WARNING! Always check to ensure the power supply corresponds to the voltage on the rating plate.

• Do not abuse the cord. Never carry a portable tool by its power cord, or yank tool or extension cords from

the receptacle. Keep power and extension cords away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords may cause a fire and increase the risk of electric shock.

• Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes

and ordinances. Never remove the grounding prong or modify the plug in any way. Do not use any adapter

plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the other). This plug will

fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still doesn't

fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an

increase risk of electric shock if your body is grounded.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.” These cords

are rated for outdoor use and reduce the risk of electric shock.

• Extension Cord Use:

A. Use only 'Listed' extension cords. If used outdoors, they must be marked “For Outdoor Use.” Those

cords having 3-prong grounding type plugs and mating receptacles are to be used with grounded tools.

B. Replace damaged or worn cords immediately.

C. Check the name plate rating of your tool. Use of improper size or gauge of extension cord may cause

unsafe or inefficient operation of your tool. Be sure your extension cord is rated to allow sufficient current

flow to the motor. For the proper wire gauge for your tool, see chart.

CHART FOR MINIMUM WIRE SIZE OF EXTENSION CORD:

If in doubt, use larger cord. Be sure to check voltage requirements of the tool to your incoming power source.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock.

• Do not let your fingers touch the terminals of plug when installing to or removing from the outlet.

• Ground fault circuit interrupters. If work area is not equipped with a permanently installed Ground Fault

Circuit Interrupter outlet (GFCI), use a plug-in GFCI between power tool or extension cord and power receptacle.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of drugs, alcohol or medication. Amoment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts. Air vents often

cover moving parts and should be avoided.

• Use safety apparel and equipment. Use safety goggles or safety glasses with side shields which comply

with current national standards, or when needed, a face shield. Use as dust mask in dusty work conditions.

This applies to all persons in the work area. Also use non-skid safety shoes, hardhat, gloves, dust collection

systems, and hearing protection when appropriate.

3

• Avoid accidental starting. Do not carry the power tool with your finger on the switch. Ensure the switch is in

the off position before plugging tool into power outlet. In the event of a power failure, while a tool is being

used, turn the switch off to prevent surprise starting when power is restored.

• Do not overreach. Keep proper footing and balance at all times.

• Remove adjusting keys or wrenches before connecting to the power supply or turning on the tool. A

wrench or key that is left attached to a rotating part of the tool may result in personal injury.

• Never place your fingers in a position where they could contact the drill or other cutting tool if the

workpiece should unexpectedly shift or your hand should slip.

• Whenever possible, position the WORKPIECE to contact the left side of the column if it is too short or

the table is tilted, clamp solidly to the table. Use table slots or clamping ledge around the outside edge of

the table.

• When using a drill press VISE, always fasten it to a table.

• Never climb on or allow others to climb on the drill press table; it could break or pull the entire drill

press down.

• Turn the motor Switch OFF and put away the Switch Key when leaving the drill press.

• To avoid injury from thrown work or tool contact, do NOT perform layout, assembly, or setup work on

the table while the cutting tool is rotating.

TOOL USE AND CARE

• Do not force the tool. Tools do a better and safer job when used in the manner for which they are designed.

Plan your work, and use the correct tool for the job.

• Never use a tool with a malfunctioning switch. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired by an authorized service representative before using.

• Disconnect power from tool and place the switch in the locked or off position before servicing, adjusting,

installing accessories or attachments, or storing. Such preventive safety measures reduce the risk of starting

the power tool accidentally.

• Secure work with clamps or a vise instead of your hand to hold work when practical. This safety precaution

allows for proper tool operation using both hands.

• Store idle tools. When tools are not is use, store them in a dry, secure place out of the reach of children.

Inspect tools for good working condition prior to storage and before re-use.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that may be

suitable for one tool may create a risk of injury when used on another tool.

• Keep guards in place and in working order.

For your own safety, do not try to use your drill press or plug it in until it is completely assembled and installed

according to the instructions, read and understood this Instruction manual:

• Your drill press must be bolted securely to a workbench. In addition, if there is any tendency for your drill

press to move during certain operations, bolt the workbench to the floor

• This drill press is intended for use in dry conditions, indoor use only.

• Always keep hands out of the path of a drill bit. Avoid awkward hand positions where a sudden slip could

cause your hand to move into the drill bit.

• Do not install or use any drill bit that exceeds 175 mm (7") in length or extends 150 mm (6") below the chuck

jaws. They can suddenly bend outward or break.

• Do not use wire wheels, router bits, shaper cutters, circle (fly) cutters, or rotary planers on this drill press.

• When cutting a large piece of material make sure it is fully supported at the table height.

• Do not perform any operation freehand. Always hold the workpiece firmIy against the table so it will not rock

or twist. Use clamps or a vice for unstable workpieces.

• Make sure there are no nails or foreign objects in the part of the workpiece to be drilled.

• Do not touch the bit or chips. Drill bits and cuttings are hot immediately offer drilling.

• Never reach around or under the working head, or grab the chuck key to stop the drill press.

• Make sure the drill press speed is appropriate for both the type of material and bit size you are using.

4

• Clamp workpiece or brace against the left side of the column to prevent rotation. If it is too short or the table

is tilted, clamp solidIy to the table and use the fence provided.

• If the workpiece overhangs the table such that it will fall or tip if not held, clamp it to the table. Provide

auxiliary support.

• Make sure all clamps and locks are firmly tightened before drilling.

• Securely lock the head and table support to the column, and the table to the table support before operating

the drill press.

• Never turn your drill press on before clearing the table of all objects. (tools, scraps of wood, etc.)

• Before starting the operation, jog the motor switch to make sure the drill bit does not wobble or vibrate.

• Let the spindle reach full speed before starting to drill. If your drill press makes an unfamiliar noise or if it

vibrates excessively, stop immediately, turn the drill press off and unplug. Do not restart until the problem

is corrected.

• Do not perform layout assembly or set up work on the table while the drill press is in operation.

• Make sure the spindle has come to a complete stop before touching the workpiece.

• To avoid injury from accidental starting, always turn the switch "OFF" and unplug the drill press before

installing or removing any accessory or attachment or making any adjustment.

• Keep guards in place and in working order.

• Use onIy self-ejecting type chuck key as provided with the drill press.

• Do not try to drill material too small to be securely held.

• Use the drill press in a well-lit area and on a level surface clean and smooth enough to reduce the risk of

trips, slips, or falls. Use it where neither the operator nor a casual observer is forced to stand in line with a

potential kickback.

• Never leave tool running unattended.

WARNING! For your own safety, do not attemp to operate your drill press until it is completely assembled

and installed according to the instructions and until your have read and understand the following:

1. General Safety Instructions for Power Tools

2. Getting to Know Your Drill Press

3. Basic Drill Press Operation

4. Adjustments

5. Maintenance

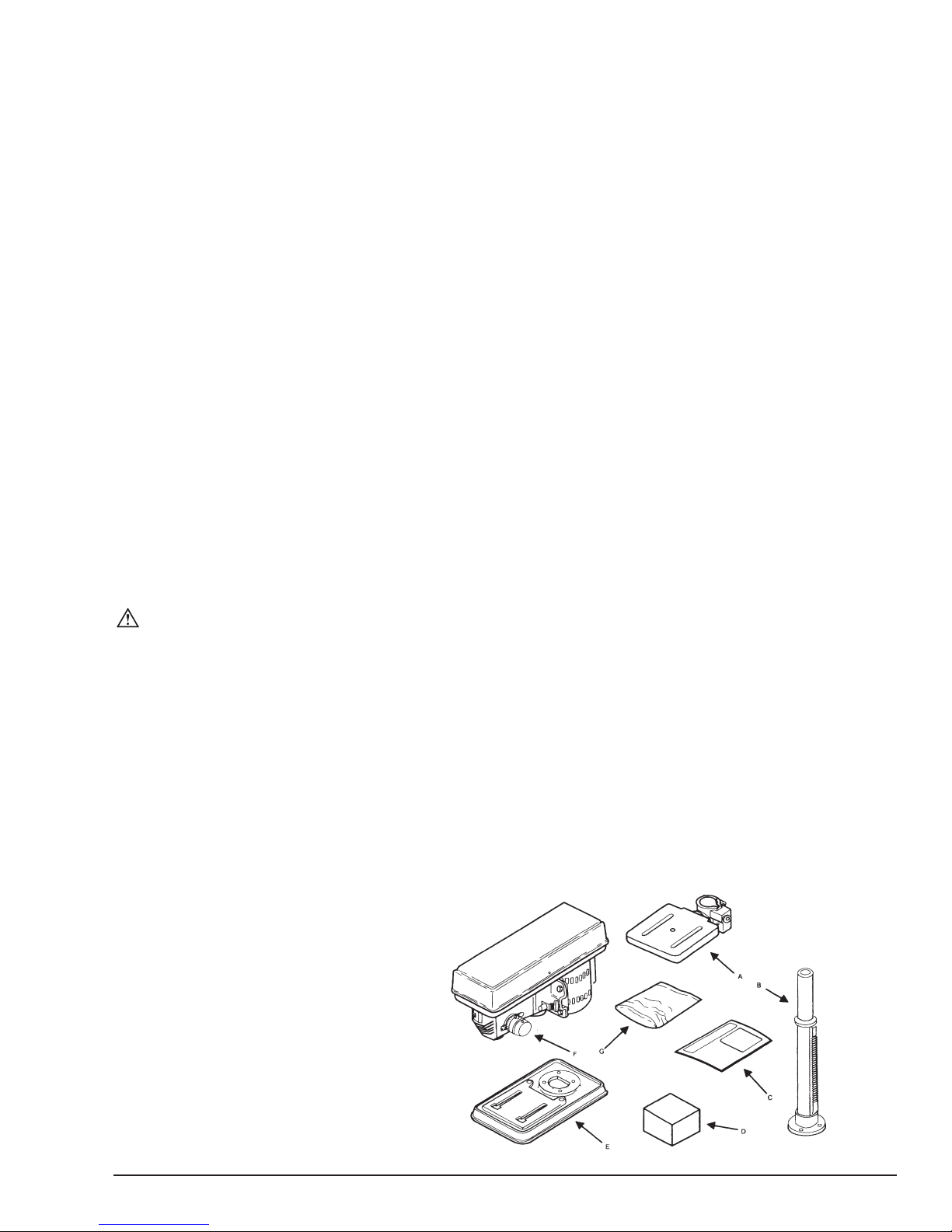

UNPACKING

On receipt, carefully unpack the components ensuring that no damage was suffered in transit, and that all

following parts are accounted for.

A. Table Support Asm

B. Column Support Asm

C. Manual

D. Box of Loose Parts

E. Base

F. Head Asm

G. Bag of Loose Parts

5

Check the parts againts the above

list and refer to the diagrams.

Should there be any deficiencies or

damage, you should contact

Northern Tool + Equipment.

GETTING TO KNOW YOUR DRILL PRESS

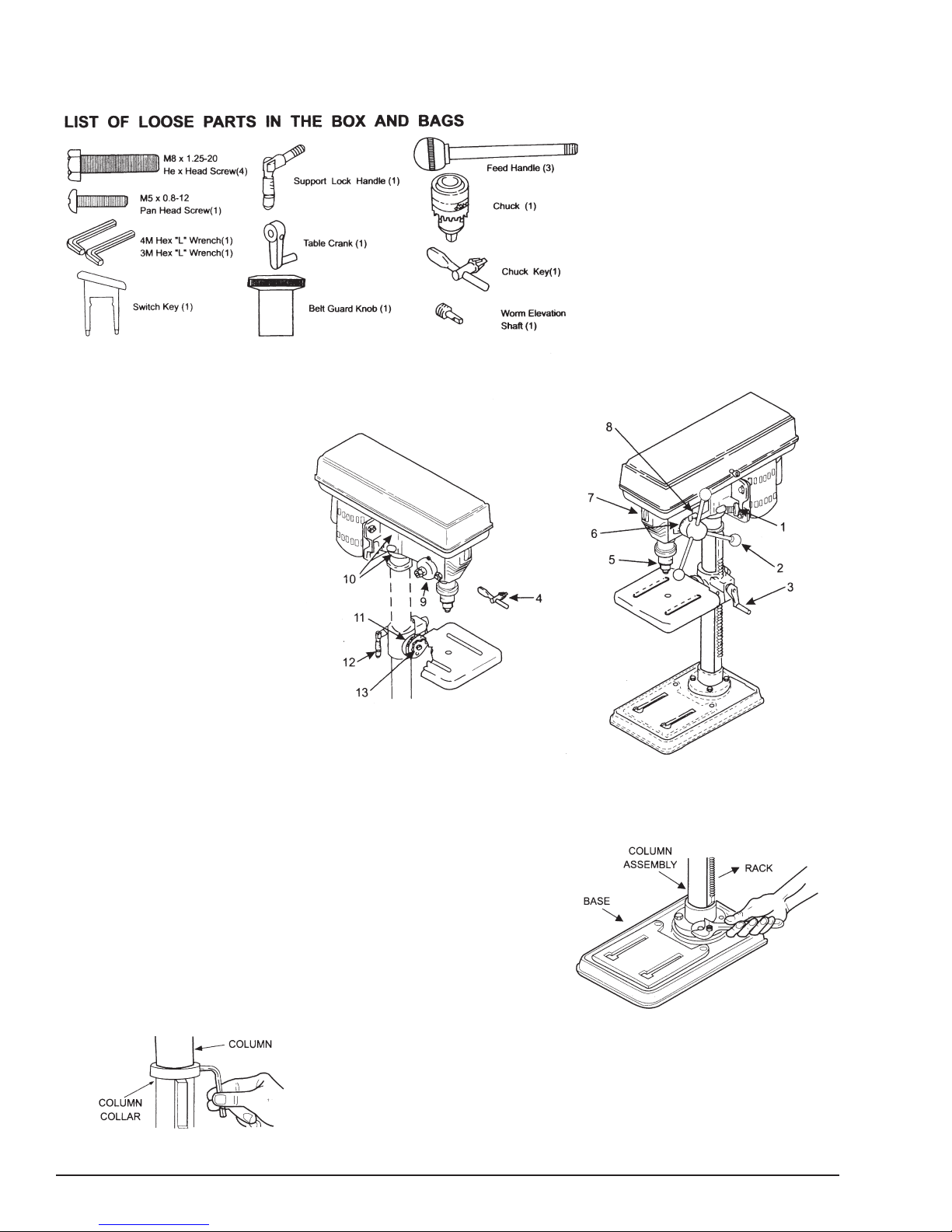

ASSEMBLY

1. Position base on workbench.

2. Remove protective sleeve from column tube and discard. Place

column assembly on base, and align holes in column support with

holes in base.

3. Locate four (4) 5/16” Dia. x 3/4” long bolts among loose parts bag.

4. Install a bolt in each hole through column support and base and

tighten with adjustable wrench.

5. Loosen set screw in cloumn collar with 3mm HEX “L” wrench and

remove collar and rack from column.

1. Belt Tension Lock Handles

2. Feed Handle

3. Table Crank

4. Chuck Key

5. Chuck

6. Depth Scale

7. Drill “ON-OFF” Switch

8. Depth Scale Lock

9. Spring Cap

10. Head Locks

11. Bevel Scale

12. Support Lock Handle

13. Table Bevel Lock

6

6. Find elevation worm gear shaft in the loose parts bag. Insert the

elevation shaft into the table support and extend the shaft through the

opening as far as possible. The crank is to be installed on the elevation

worm gear shaft, the set screw is to be aligned with the flat portion of

the shaft. The crank is to be positioned as close to the arm support as

possible, then tighten set screw. (see illustration)

7. With long smooth end of rack pointing upward, slide rack down through

large round opening in table support. Engage rack in gear mechanism

found inside opening of table support.

8. While holding rack and table support in

an engaged position slide both down

over column. Slide rack down column

until rack is positioned against lower

column support.

9. Replace column collar and position it bevel side down over rack. Tighten set

screw in collar with 7/64” HEX “L” wrench. To let the rack slide when the

table is swing to the left or right around the column, the collar must sit

loosely over rack and should not be angled on the column. Only tighten set

screw enough to keep collar in place, otherwise the collar may break due to

excess pressure.

10. Check column collar for proper adjustment. Collar should not be angled on

the column and it should be positioned so rack will slide freely in collars

when table is rotated 360º around column tube. If re-adjusted, only tighten

set screw enough to keep collar in place.

Note: To avoid column or collar damage, do not over-tighten set screw.

11. Locate support lock handle in loose parts bag and tighten by hand.

12. To minimize crank backlash; tighten the support lock and rotate

elevation worm shaft clockwise with the crank. Loosen the set screw in

the crank and reposition the crank as close to the table support as

possible. Tighten the set screw in the crank.

13. Using a 4mm HEX “L” wrench tighten the head lock set screws on the right

side of the head.

7

Laser attachment Introduction

Safety rules for laser lights

The laser light/laser radiation used in the LightSabre system is Class 2 with maximum 1mW and 640 - 660nm

wavelengths. These lasers do not normally present an optical hazard, although staring at the beam may cause

flash blindness.

WARNING! Do not stare directly at the laser beam! A hazard may exist if you deliberately stare into the

beam. Please observe all safety rules as follows:

• The laser should be used and maintained in accordance with the manufacturer's instructions.

• Never aim the beam at any person or an object other than the workpiece.

• The laser beam should never be deliberately aimed at personnel and should be prevented from being

directed toward anyone's eyes.

• Always ensure the laser beam is aimed at a sturdy workpiece without reflective surfaces. (e.g., wood or

pieces with rough-coated surfaces). Bright shiny reflective sheet steel or the like is not suitable for laser use

as the reflective surface could direct the beam back at the operator.

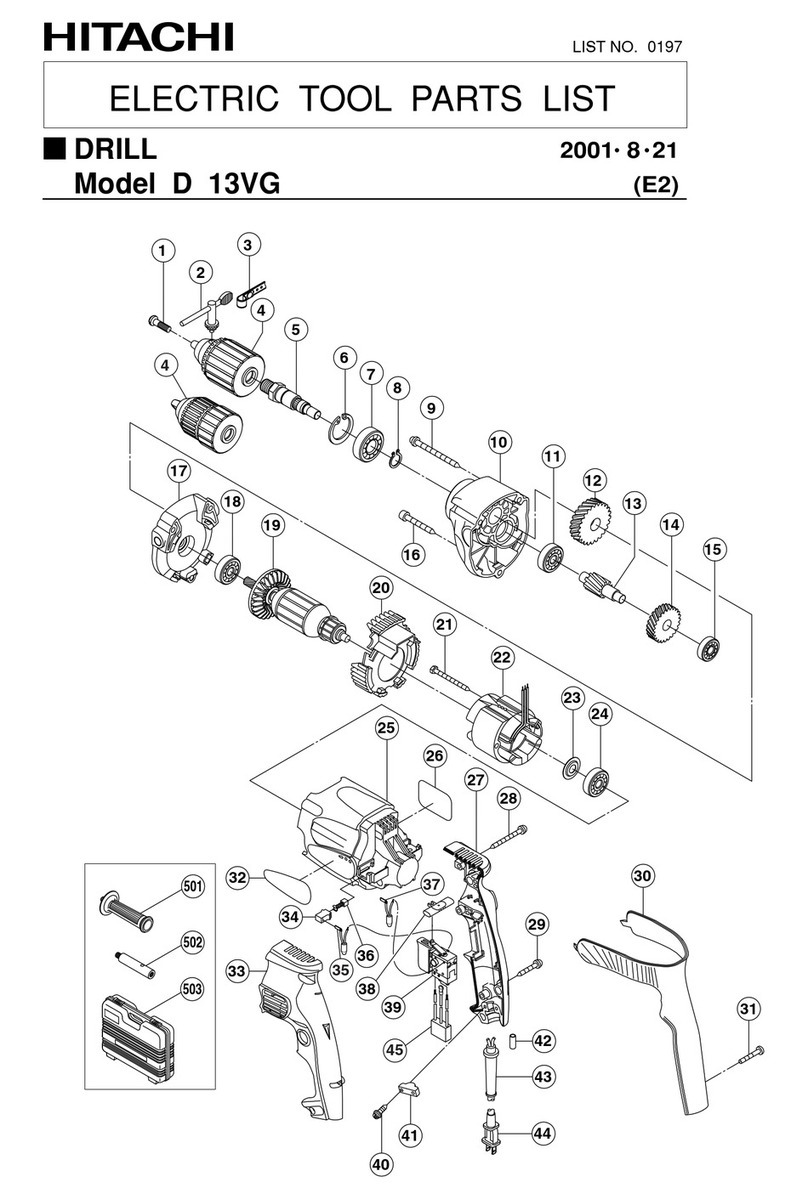

Exploded view & Part list

L0: Head Stock

L1: Battery Box

L2: HEX.HD Screw M4x8

L3: Battery

L4: HEX.Soc.Screw M6x8

L5: Battery Box Cover

L6: Laser switch

L7: Laser Light

Resetting the laser beams

If the intersection of the beams is not precisely at the spot where the drill bit meets the workpiece, the laser light

line generator assembly can be moved. Slacken the fixing screws slightly on the tube holder, and adjust the

tubes until the two beams intersect at the point where the drill bit touches the workpiece; retighten the screws.

See Fig 1, Fig 2, Fig 3

Changing the batteries

1. Unclip the battery cover to gain access to the batteries.

2. Replace both AA batteries, taking care to insert the new batteries with the correct polarity.

3. Replace the laser light battery cover.

See Fig 4, Fig 5, Fig 6

Fig 1 Fig 2 Fig 3

L0

L1

L2

L3

L4

L5

L6

L7

CAUTION! Remove the laser light batteries when the tool is to be stored without use for a few days or

more. If left in position, the batteries might leak and damage the laser light assembly. Damage due to

leaking batteries is not covered under warranty.

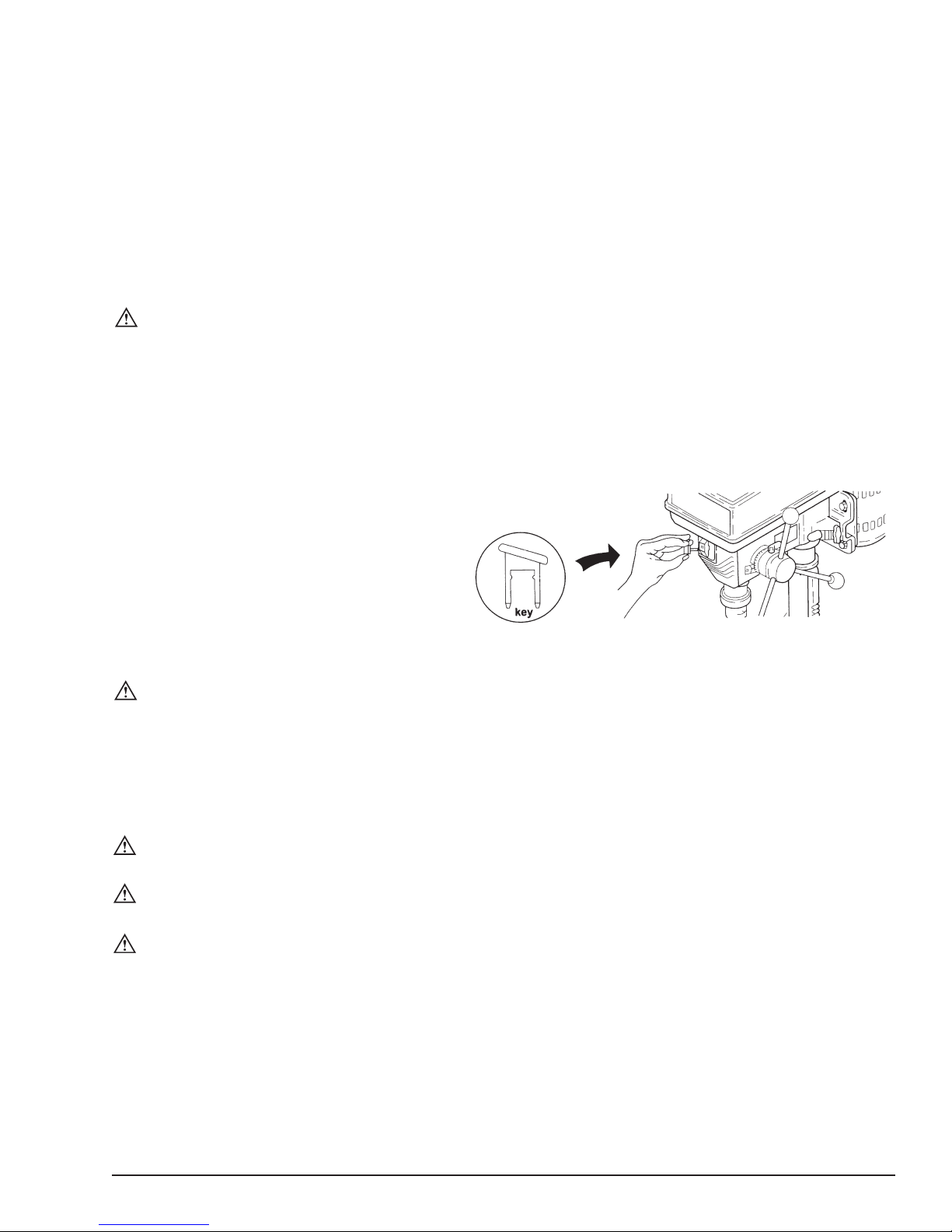

OPERATION

Drill “ON-OFF” switch

This feature is intended to help prevent unauthorized and possible hazardous use by children and others.

Insert KEY into switch.

Note: Key is made of yellow plastic.

To turn drill ON:

Insert finger under switch lever and pull.

To turn drill OFF:

Push lever in.

In an emergency: If the drill bit BINDS... STALLS...STOPS... or tends to tear the workpiece loose... you can

quickly turn the drill OFF by hitting the switch with the palm of your hand.

WARNING! For your own safety, always push the switch “OFF” when drill press is not in use; Remove key

and keep it in a safe place. In the event of a power fallure (all of your lights go out) or blown fuse or tripped

circult breaker, turn switch off, lock it and remove the key. This will prevent the drill press from starting up

again when the power comes back on.

MAINTENANCE

WARNING! For your own safety, turn switch “off” and remove plug from power source outlet before

maintaining or lubricating your drill press.

WARNING! To avoid shock or fire hazard, if the power cord is worn or cut, or damaged in any way, have

it replaced.

WARNING! Make sure this tool is disconnected from its power source before attempting any maintenance,

cleaning, or inspection.

• Maintain your tools. It is recommended that the general condition of any tool be examined before it is used.

Keep your tools in good repair by adopting a program of conscientious repair and maintenance in accordance

with the recommended procedures found in this manual. If any abnormal vibrations or noise occurs, turn the

tool off immediately and have the problem corrected before further use. Have necessary repairs made by

qualified service personnel.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control. Keep handles dry, clean, and free from oil and grease.

• Cleaning. Use only soap and a damp cloth to clean your tools. Many household cleaners are harmful to

plastics and other insulation. Never let liquid get inside a tool.

Fig 4 Fig 5 Fig 6

8

9

WARRANTY

One-Year Limited Warranty

For warranty questions, call 1-800-222-5381

DIAGRAM & PARTS LIST

10

Northern Tool + Equipment Co.,

2800 Southcross Drive West

P.O. Box 1499 Burnsville, MN 55337-0499

Made in China

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm. Some examples of

these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

Table of contents

Other Northern Industrial Tools Drill manuals