Quick Reference Guide for CO Analyzer

READ ENTIRE MANUAL BEFORE USE

1. To switch on, hold the On/Off button until the display powers up.

2. To turn off, hold the On/Off button until the display goes blank.

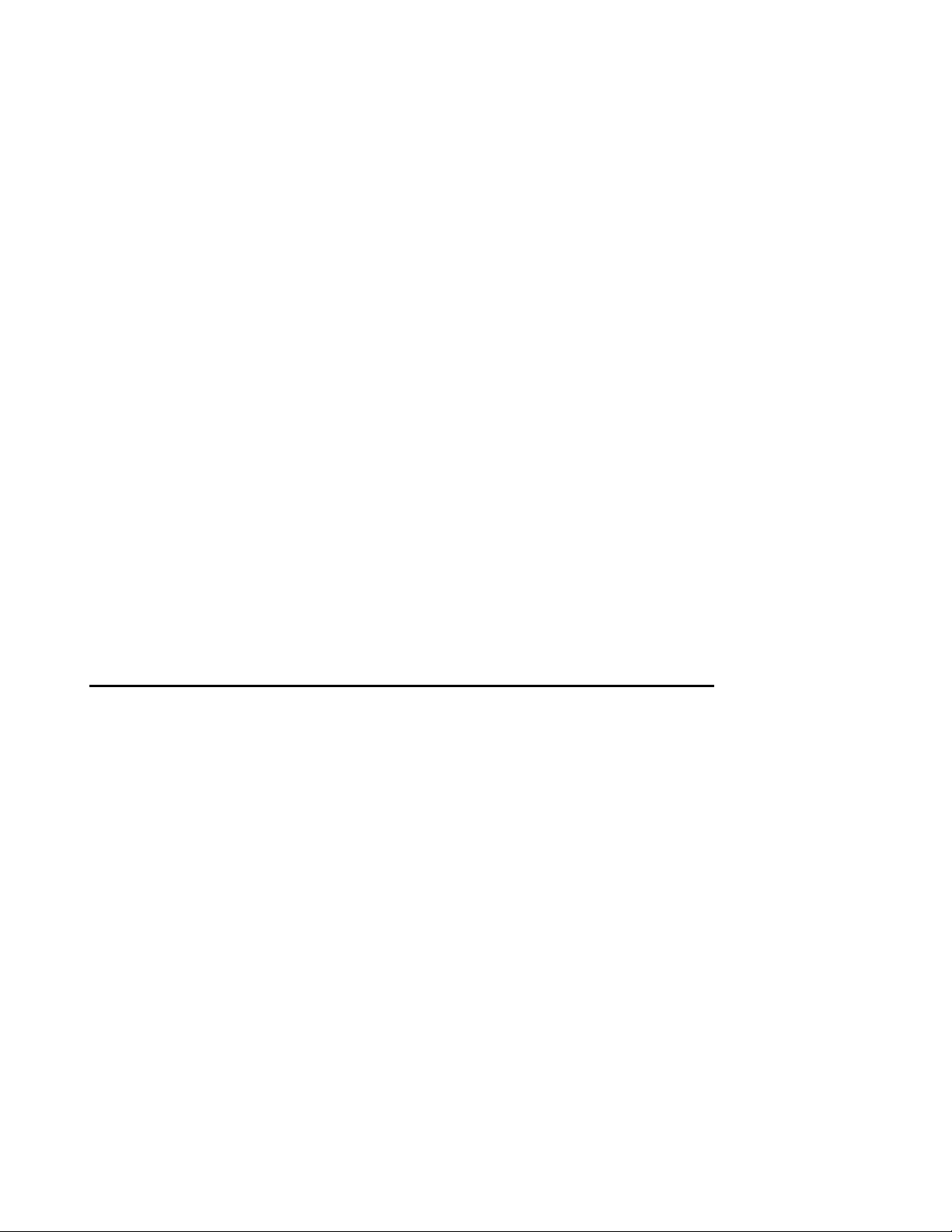

3. Gas flow to the analyzer should be regulated to .5-5 L/min with no pressure on the

sensor. Pressurizing the sensor will lead to inaccurate readings and could damage it.

4. If using a Nuvair 9517.6 flow reducer for sample flow, the incoming pressure should be

75-100 psi.

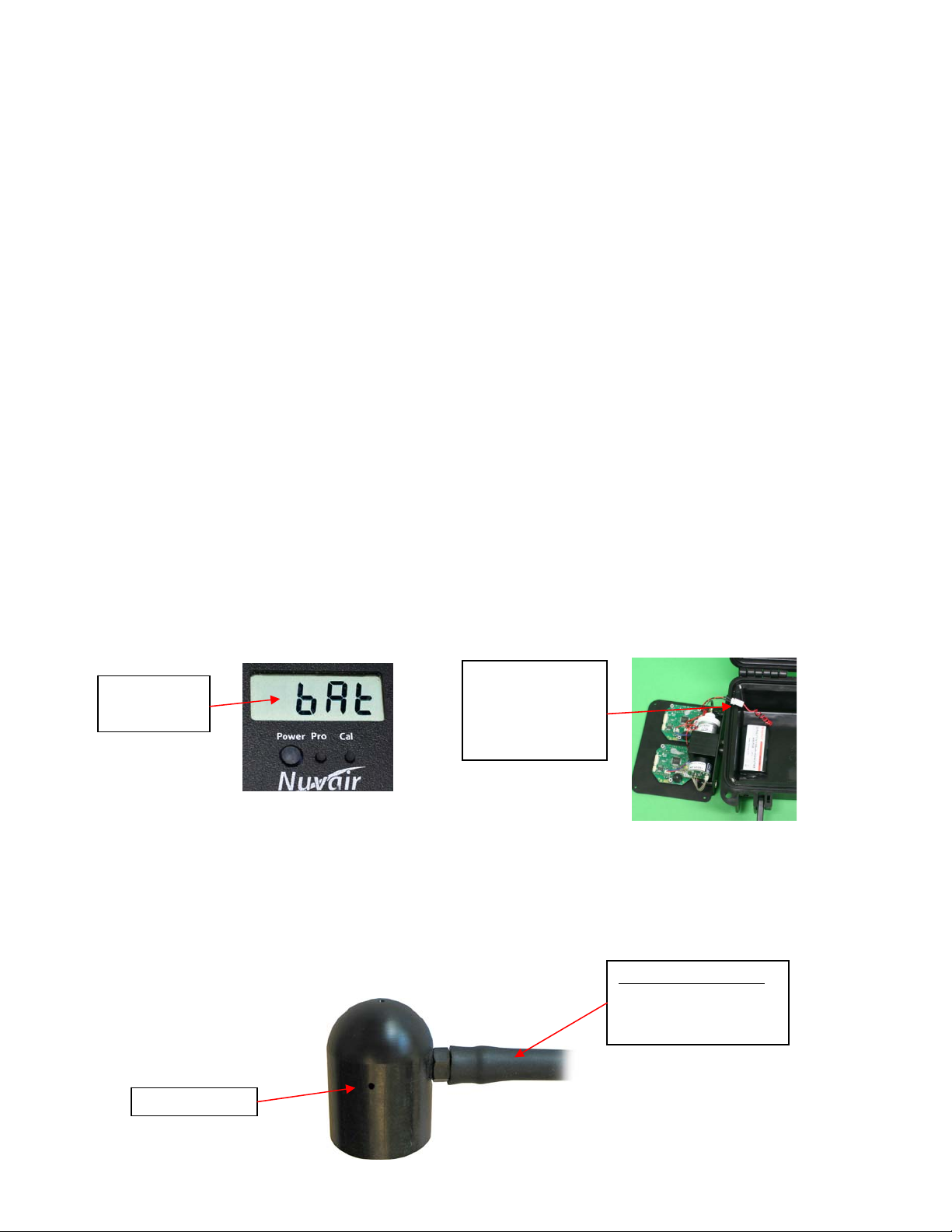

5. Press and hold the Adjust button to view the battery voltage and current ambient

temperature in Celsius.

a. Conversion formula to Fahrenheit: (°C x 1.8)+32=°F

6. Press and hold the Prog button to access the programming pages for:

a. Alarm 1 (AL1) sets the low level alarm (setting to 300 turns this off).

b. Alarm 2 (AL2) sets the high level alarm (setting to 300 turns this off).

c. Full Scale Value (FSC) sets the mA value for the optional output.

d. Conversion Value (nA) is only to be set when a new sensor is installed.

e. Gain Factor (Fct) is only to be set when a new sensor is installed.

f. Calibration value (CAL) is to be adjusted to the CO content of the certified

calibration test gas being used.

g. End is displayed after the last programming page. The display will then return to

the current gas reading value.

7. Press the On/Off button to cycle through the programming screens, the Prog button to

change the value of the blinking digit, and the Adjust button to select which digit to

program.

8. To calibrate the Analyzer Span:

a. Turn on the analyzer and program the CAL value to the CO content of the

calibration gas to be used.

b. Connect the sensor to calibration gas and allow to flow for 2-3 minutes. Flow

should be regulated to 1 L/min with no pressure on the sensor.

c. When the reading is stable, press the On/Off and Adjust buttons

simultaneously and hold until the display flashes “Cal”.

d. The unit is calibrated once the screen returns to the gas reading display. If the

reading drifts after calibration, allow the unit to sit while turned on for a few

minutes so the sensor temperature can stabilize, then repeat steps a-c.

9. To calibrate the Analyzer Zero:

a. Turn on the analyzer.

b. Attach a flow of certified 0 PPM CO, 100% Nitrogen test gas regulated to .5-3

L/min.

c. Press the On/Off and Prog buttons simultaneously and hold until the display

flashes “Cal”.

d. When the display returns to reading 000, the zero has been set.

10. If equipped with a lithium battery, read and understand all instructions included with

the battery charger.

11. Any wind or breeze present while using the analyzer can affect readings.