Dear Customer,

We congratulate you on your purchase of an OilQuick quick coupler system.

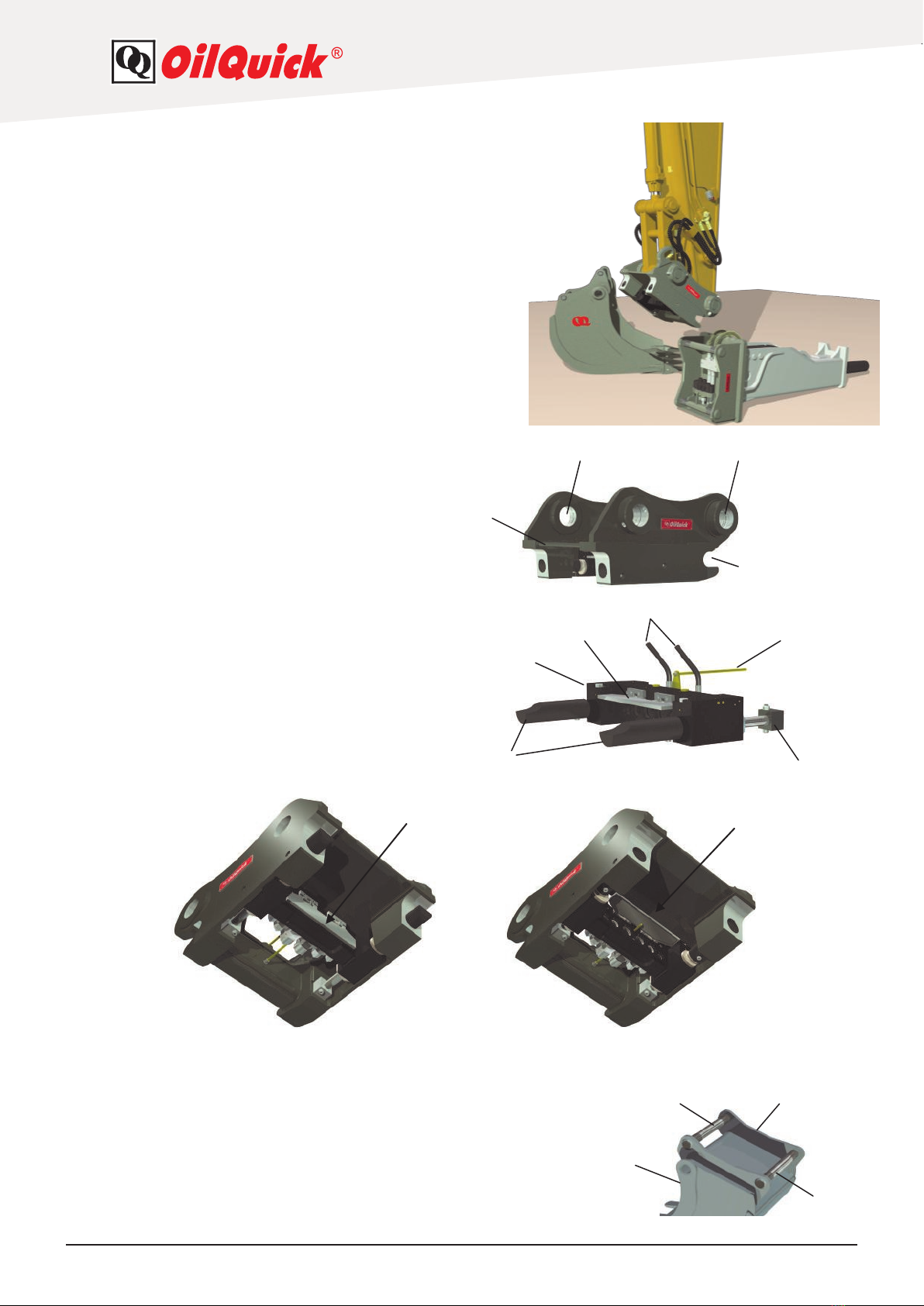

OilQuick is the most advanced quick coupler system for excavators and can be supplied in various models for

machines from 1 to 120 tons.

The modular OilQuick system is available as a standard hydraulic hitch or also with OilQuick function, which

allows hydraulic attachments to be connected or disconnected automatically from inside the cab.

Hydraulic attachments that can be used include Grab John buckets, tiltrotators, compactors, sorting grapples

and hydraulic hammers.

The OQ 70/55 model is suitable for excavators from 18 to 28 tons operating weight.

The OQ 80 model is suitable for excavators from 25 to 45 tons operating weight.

OilQuick products bear the CE marking and comply with all the applicable safety regulations.

When installing, using and repairing OilQuick quick coupler systems, please ensure that you meet all the

requirements.

Changes may only be made to OilQuick quick coupler systems with the approval of OilQuick AB.

Any unauthorized changes will void the warranty and CE-marking.

Please send us the completed warranty card as soon as possible.

We hope you enjoy the benefits and wish you every success with your new OilQuick quick coupler system.

Introduction

These instructions apply to models OQ 70/55 and OQ 80.

Components are also described in the instructions that are optional accessories, which you may not have

ordered with your new quick coupler system. Please observe all the safety regulations and ensure that your

equipment is properly maintained. This will minimize the risk of damage and injury.

Subject to change without notice. Errors and omissions excepted.

This is a translation of the original manual.

Copyright © OilQuick AB.

Please read the instructions carefully before mounting and using the quick coupler system.

Information in boxes as illustrated below are

warnings that you should read particularly

carefully and understand.

Ignoring such warnings may result in personal

injury or damage to property.

Example

Information in boxes as illustrated below

contains important notes that you should read

carefully and understand.

Example