r

TABLE

OF

CONTENT

S

Page

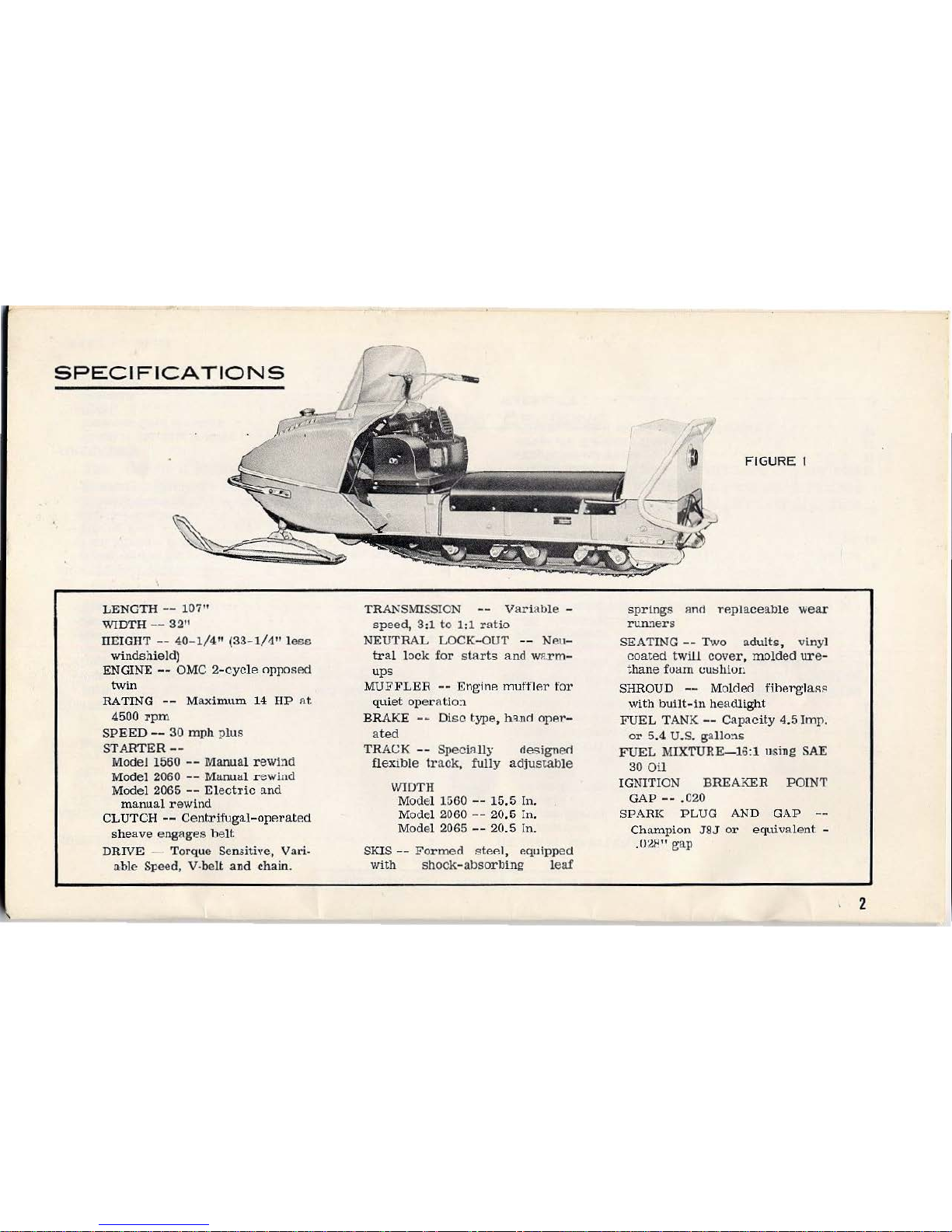

SPEC

IFICATIONS • • • • • • • . . . . • • • • . • • . • 2

ASSEMBLY

INSTRUCTIONS

-W

i

ndsh

i

eld

• • • • • • • • • • . • • • • 3

-Taillight

• • • • • • • • • • • . . • • • 3

-:::>kis

• • • • • • • • • . . • • . • • . • 3

-Tow Ba:r,

Seat

Dack &

Compar

t

mcn

,t : • 3

-Battery.

• • • • • . • • • . • • . • . • 3

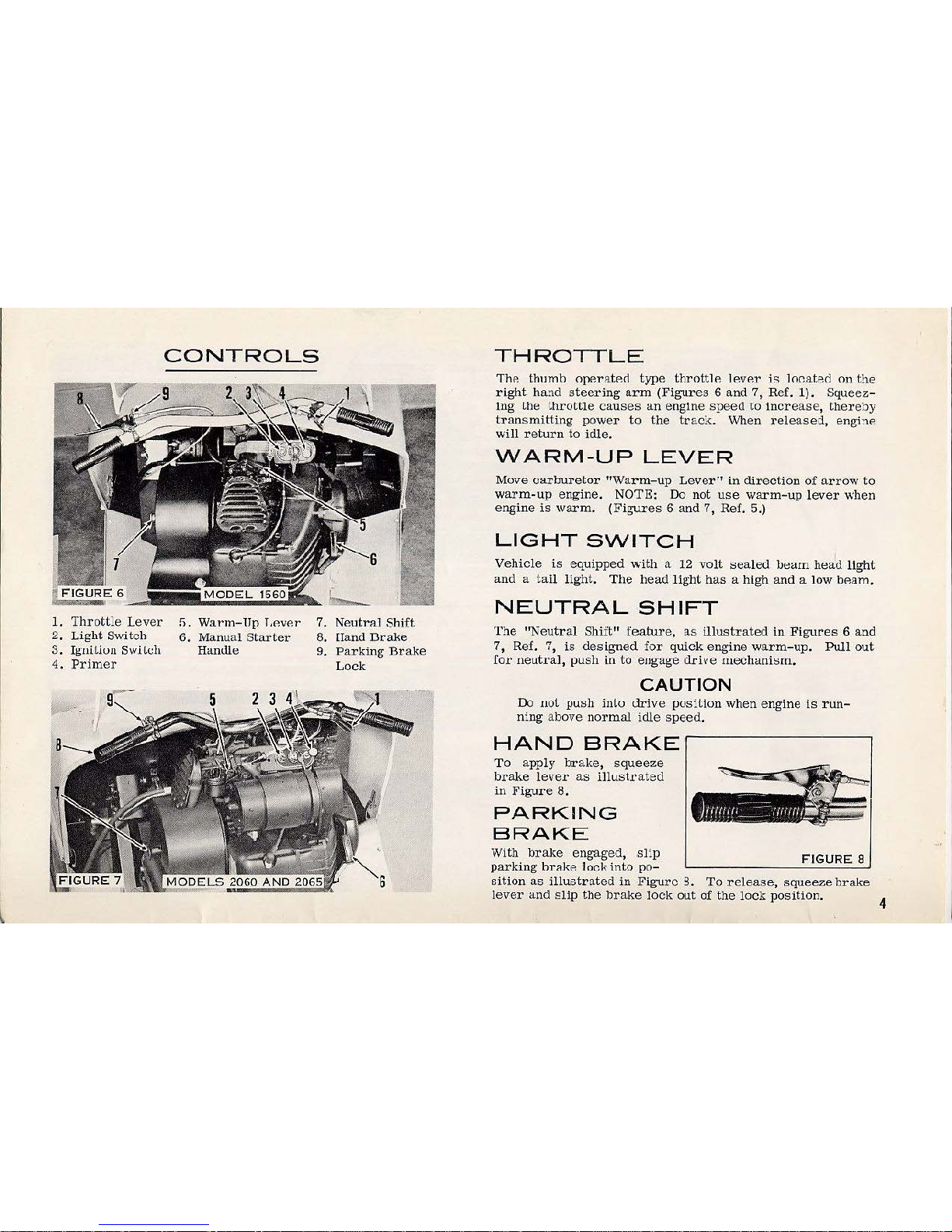

CONTROLS

-Throttle

• • • • • 4

-Warm

-U

p

Lever.

1

-Ligh

t

Swi

t

ch

• • 4

-Neutral

Shift

• • 4

-Hand

Hrake

• • 4

-Po.rking

Brllltc

• 4

-

Transmission

• 5

HOW

TO

GR'T'

STARTED

-B1·eak-In Pel'iod . . . . • . . . , • G

-

Fuel

Mixture

& Recommendations

!'i

-Mix

i

ng

Fuel

• . . • 5

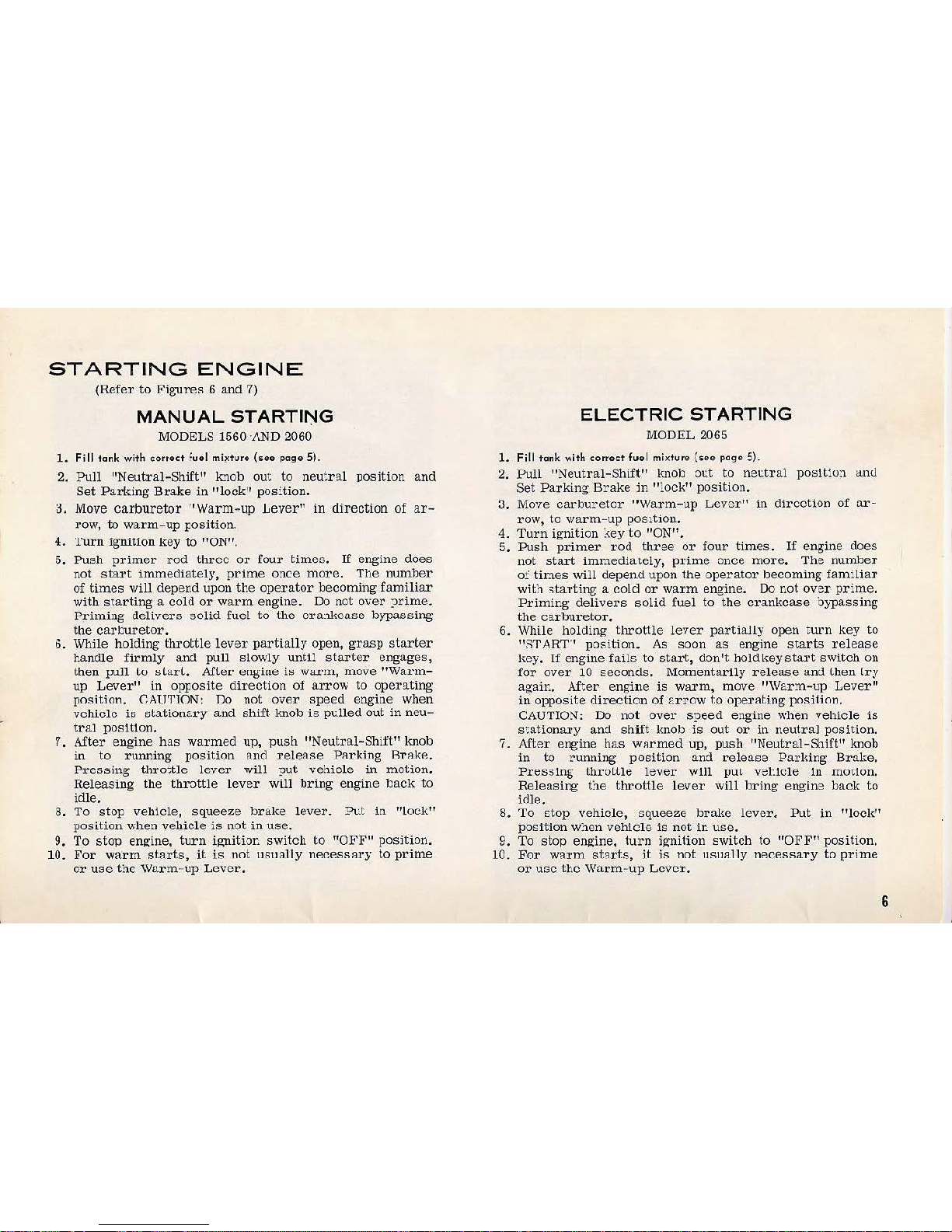

-Start

ing

Engine

. . 6

-Electric

SL<u·

C

ing

7

-Emergency

St

arting

7

OP

ERAT

I

ON

- E

lectric

Starting

Models 7

-Extreme

Cold

Weather

7

-Uph!ll

• • . . • • • 7

-Downhill

. • • . • • 7

-Glare

Ice

. • . . . 7

-Safety

Precautions

8

PART

No.

404278

GENE

R

AL

MAINTENANCE

-Ca

.

rhuretor

-

Engine

Shroud

••

•••

.

-

Battery

.•.....

..

. .

-Chain

&

Transmissio

n

Guard

-Gas

Tank

.......•

-Dl'ive

Cha

in

Adjustment

•

-

Install

i

ng

Drive

Chain

.

-Brake

Adj

us

tment

-T

rack

Tension

-Traek

AligrunenL

D

RIVE

BELT

REPLACEMENT

••••.

•

••••

-Procedure

for

Installing

the

Transmission

Belt

-::>tarter Motor Drive Belt • •

-Ski

Alignment

• • • • • • • •

-Off

Season

Storage

• • • . .

-After

Storing

-

Before

Using

TROTJRT.F.

CH

ECK

L

IST

SERVIC

E DIAGNOSIS • •

MAINTENANCE

AND

LUBRIC

AT

IOK

ITEMS

OF

SPECIAL

INTEREST

-Repair

Service

•••••••

-Replacement

Parts

. . . . .

-Owner':;

Warranty

Certificate

•

-Where

to

Find

Model

&

Serial

Ntunber

WARRAN

TY

...••.•.•

• . •

.•

••

Page

8

9

9

9

9

9

10

10

11

11

12

13

13

11

14

14

14

15-16

16

17

17

17

17

...

..

~ 18