- 4 -

GB

0800_GB-Inhalt_3531

TABLE OF CONTENTS

Attention!

ÈÛìÞëïÞÌÚßÞíò

ÁâçíìâçíáÞ

ìîééåÞæÞçí

ÍÚÛåÞèßÜèçíÞçíì

WARNING SIGNS

CE sign ............................................................................................................................................................................. 5

Meanings of warning signs............................................................................................................................................... 5

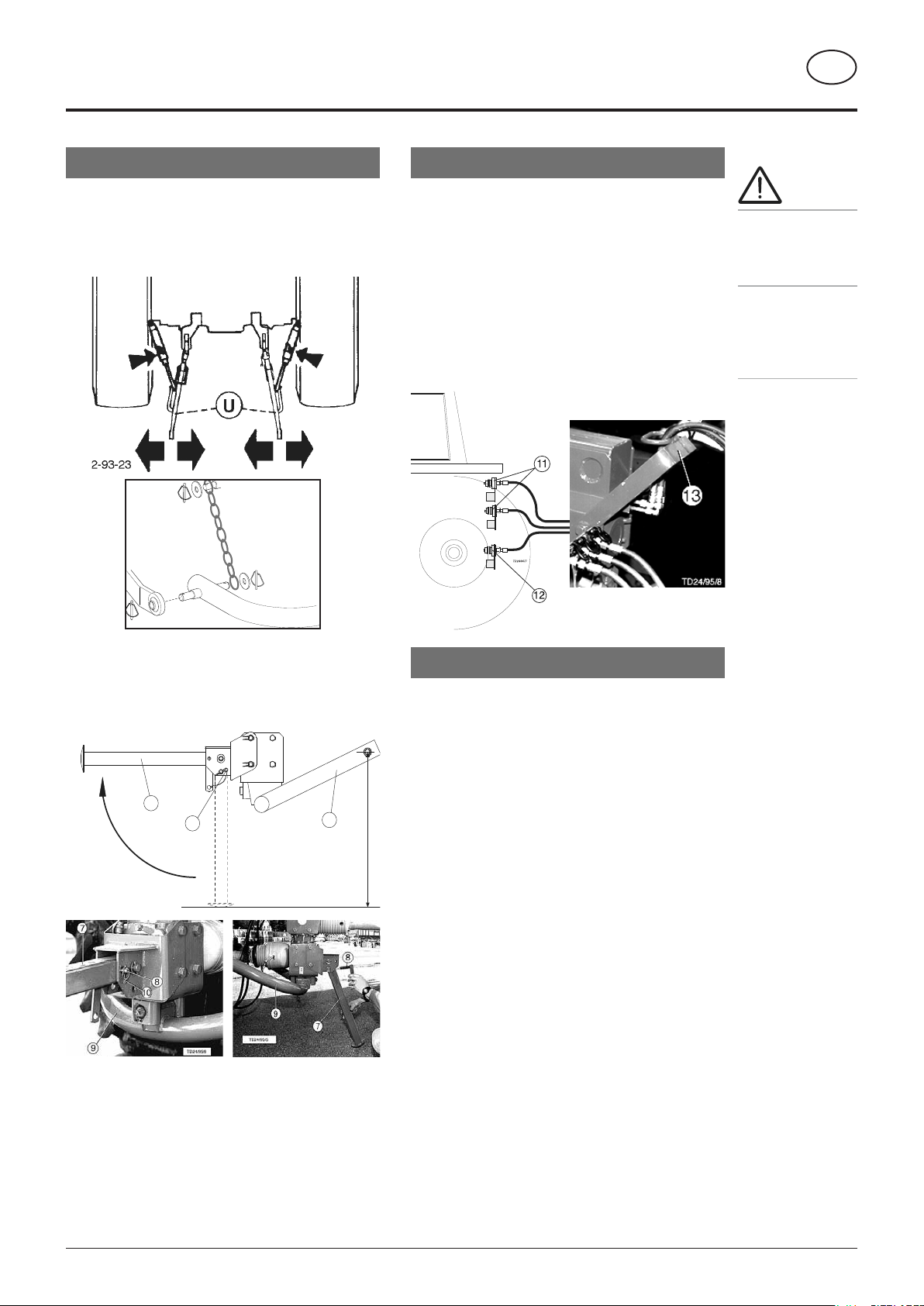

ATTACHMENT

Attaching the machine ..................................................................................................................................................... 6

Connecting the hydraulics................................................................................................................................................ 6

Connecting the electrics................................................................................................................................................... 6

Check driving motor speed ............................................................................................................................................. 7

Correct drive shaft............................................................................................................................................................ 7

Drive shaft length ............................................................................................................................................................. 7

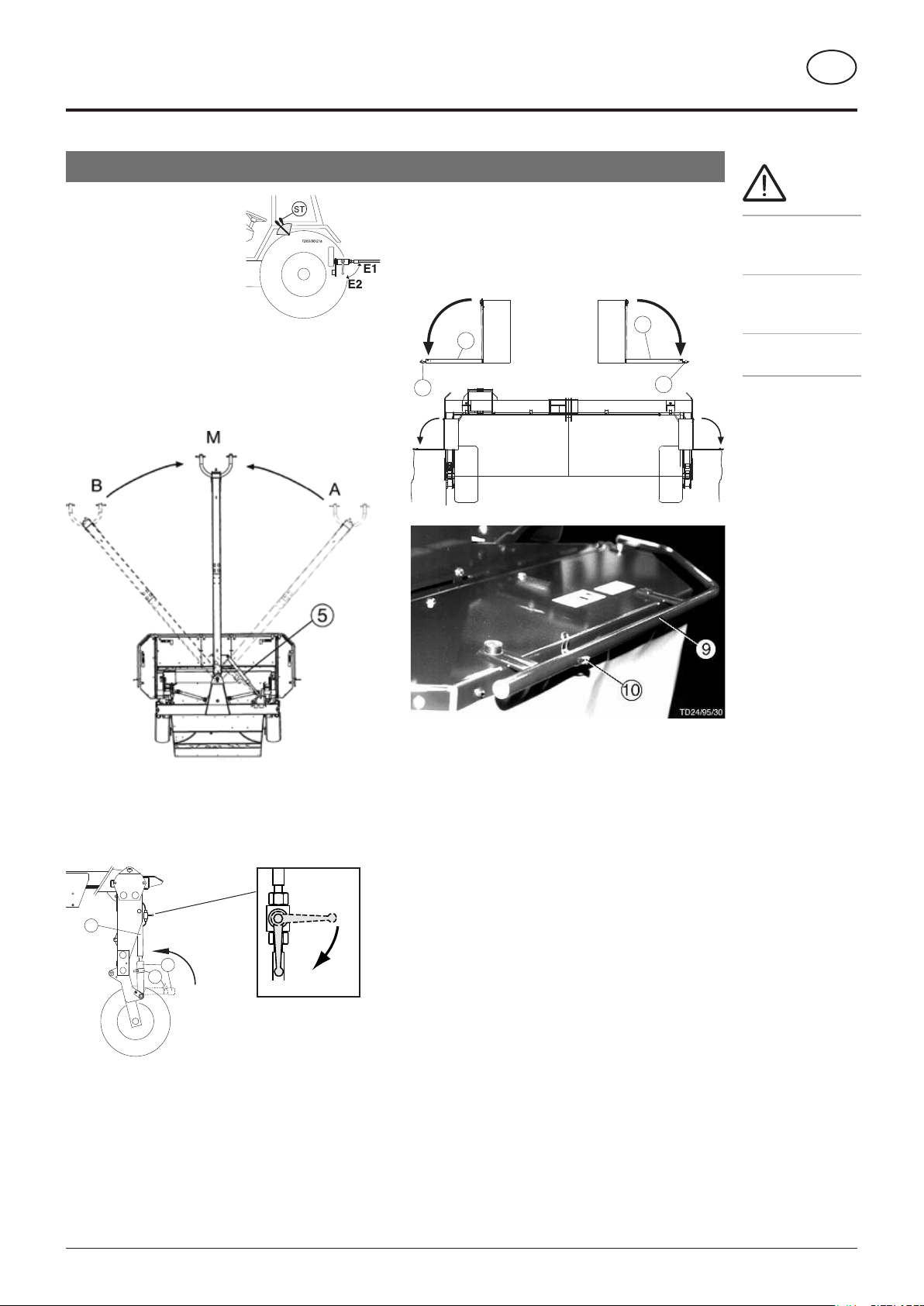

TRANSPORT AND WORKING POSITION

Conversion from transport to working position................................................................................................................ 8

Changing from work to transport position ....................................................................................................................... 9

Transporting on public roads............................................................................................................................................ 9

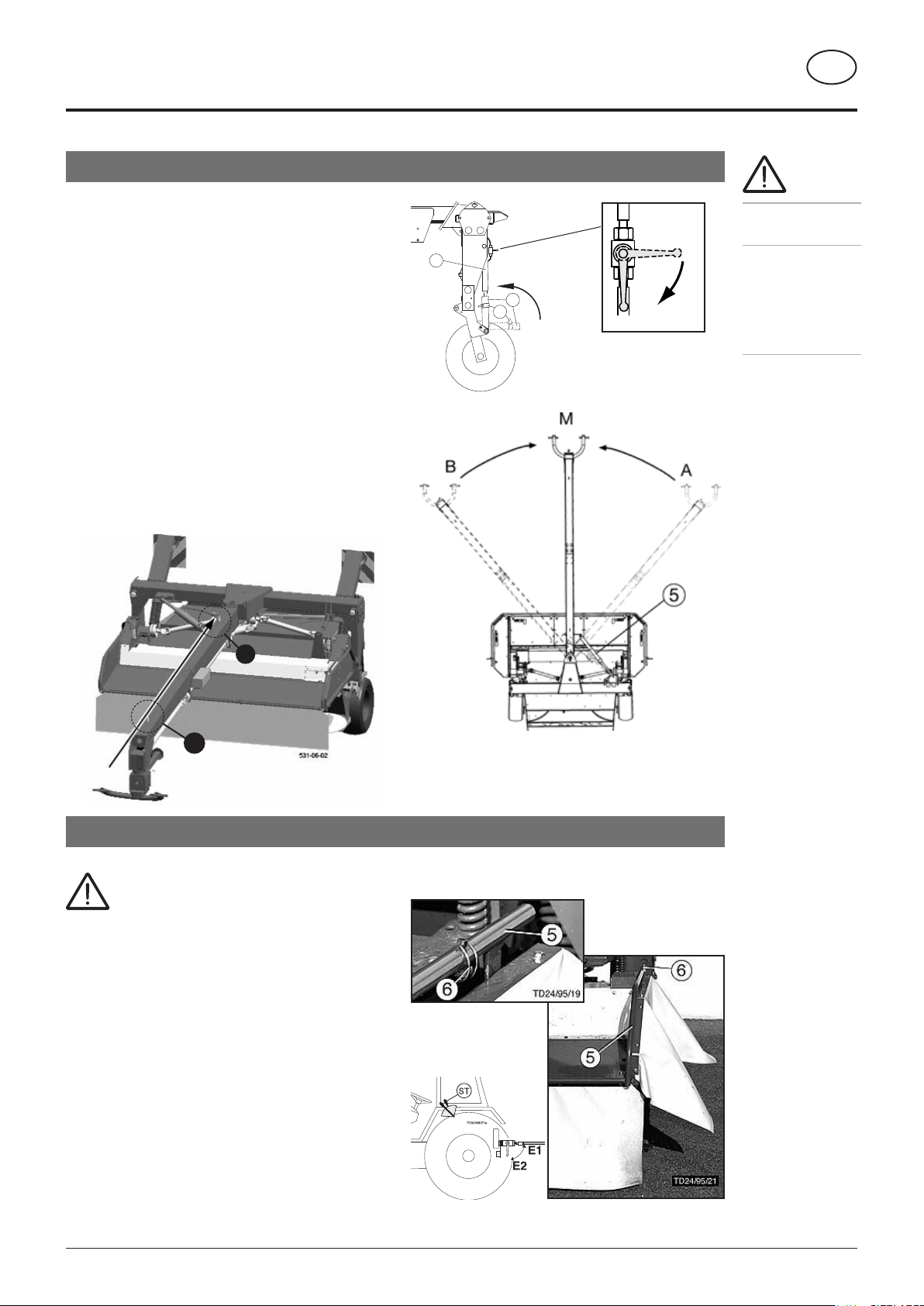

OPERATION

Important points before starting work............................................................................................................................ 10

Adjustbearing pressure .................................................................................................................................................. 11

Adjusting cutting height.................................................................................................................................................. 12

Altering rotor rpm ........................................................................................................................................................... 12

Adjust cutting height with runner .................................................................................................................................. 12

Adjusting processor angle.............................................................................................................................................. 12

Adjusting swath width .................................................................................................................................................... 13

Long swath board .......................................................................................................................................................... 13

Swath formation to the side ........................................................................................................................................... 14

Electrohydraulic operation.............................................................................................................................................. 14

Variation "Extra dry" system........................................................................................................................................... 15

Dismounting the machine............................................................................................................................................... 16

CROSS CONVEYOR

Description ..................................................................................................................................................................... 17

Road transport ............................................................................................................................................................... 17

Settings .......................................................................................................................................................................... 17

Additional cross belt....................................................................................................................................................... 18

Road transport ............................................................................................................................................................... 18

Cleaning the Rollers ....................................................................................................................................................... 18

Adjusting the conveyor belt............................................................................................................................................ 18

MAINTENANCE

Safety point .................................................................................................................................................................... 19

General maintenance hints............................................................................................................................................. 19

Cleaning of machine parts ............................................................................................................................................. 19

Parking in the ope .......................................................................................................................................................... 19

Winter storage ................................................................................................................................................................ 19

Drive shafts..................................................................................................................................................................... 19

Hydraulic unit ................................................................................................................................................................. 19

After the first hours of operation .................................................................................................................................... 20

Roller-type conditioner ................................................................................................................................................... 20

Every 50 hours of operation ........................................................................................................................................... 21

Cutter bar-oil change...................................................................................................................................................... 21

Gearing........................................................................................................................................................................... 22

Starting transmission...................................................................................................................................................... 22

Garaging......................................................................................................................................................................... 23

Installing cutters ............................................................................................................................................................. 23

Lubrication chart ............................................................................................................................................................ 26

TECHNICAL DATA

Technical data ................................................................................................................................................................ 29

Position of Vehicle Identification Plate ........................................................................................................................... 29

Defined use of the mower .............................................................................................................................................. 29

SUPPLEMENT

Recommendations for work safety ............................................................................................................................... 32

Driveshaft ....................................................................................................................................................................... 33

Lubricants....................................................................................................................................................................... 35

Air pressure ................................................................................................................................................................... 37

Taper bushes installation instructions ............................................................................................................................ 38

Turn gearing round ......................................................................................................................................................... 39

Power supply.................................................................................................................................................................. 41

Installation of control panel ............................................................................................................................................ 41