5 / 182020-06-04 | Document No.: AN149

Precautions and storage

For storage and dispatch, the reels or trays are packed in vacuum-sealed dry

bags together with desiccants. It is generally recommended to leave reels in their

original packaging until they are assembled, and to store components under

ambient conditions of ≤ 10 % RH during processing. Drying cabinets with dry

nitrogen (N2) or dry air are suitable for this type of storage. The product complies

with moisture-sensitive Level 2 (MSL 2) according to JEDEC J-STD- 020E. For

more information please refer to the application note “Dry pack information”.

As is the case for all LEDs from OSRAM Opto Semiconductors, the product also

fulfills the current RoHS guidelines (European Union and China) and therefore

contains no lead or other defined hazardous substances.

Since the OSRAM OSTAR®Projection Power is generally supplied on tape or on

a tray with a dry pack, it should be factory-sealed when stored. The hermetically

sealed package should only be opened immediately before mounting and

processing, after which the remaining LEDs should be repacked in accordance

with the moisture level specified in the data sheet (see JEDEC J-STD-033 —

Moisture Sensitivity Levels).

A suitable storage system should be implemented in order to ensure that

assembled LED boards are not stacked on top of each other (Figure 2). To avoid

the risk of damage to the assembled LEDs, make sure that they are not exposed

to compression forces of any kind. Furthermore, the LED of the assemblies must

also not be touched directly.

Figure 2: Correct storage

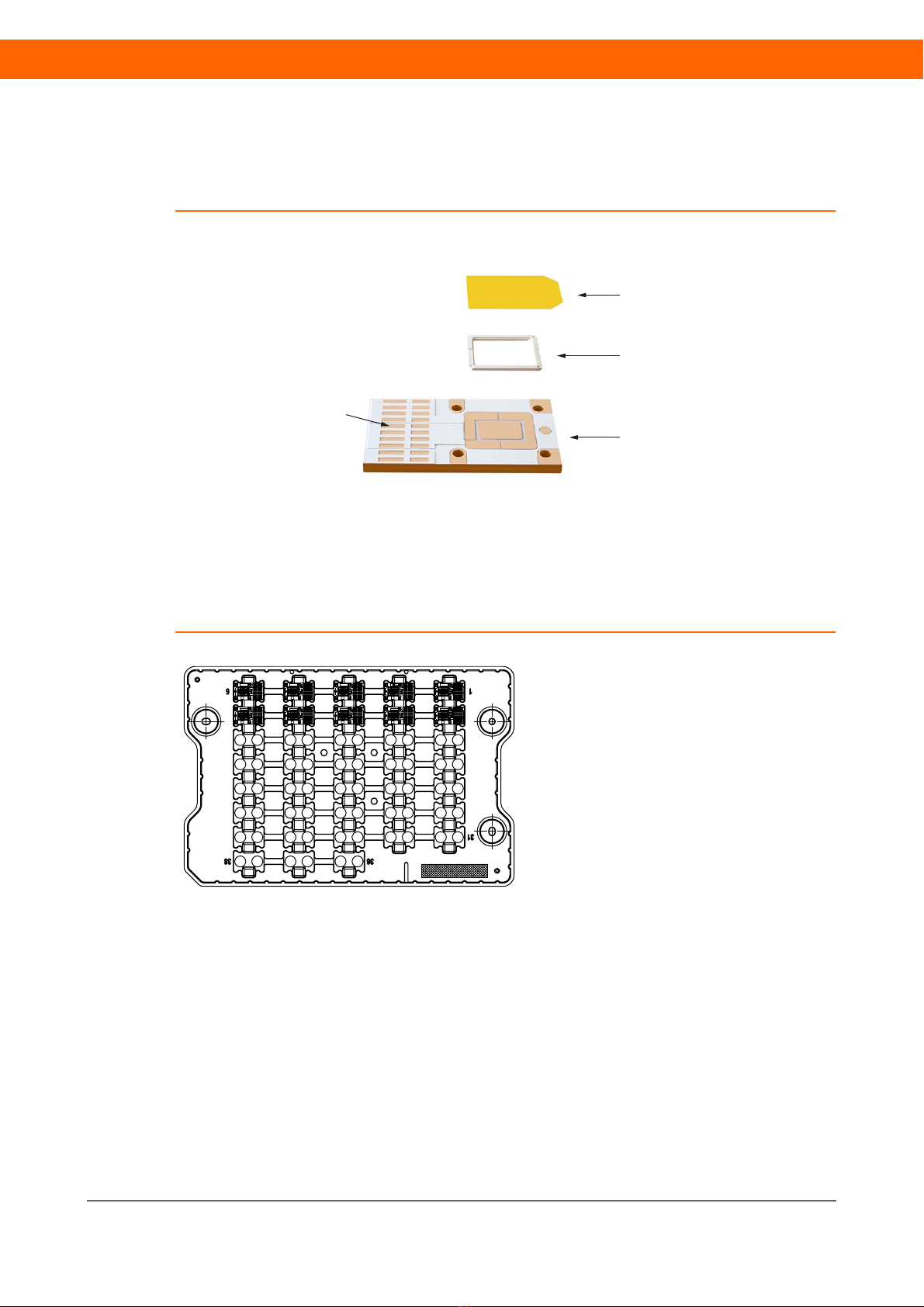

C. OSRAM OSTAR®Projection Power with connecting board

The OSRAM OSTAR®Projection Power devices on a connecting board are

available in three different colors:

• Deep Blue / Blue

•Amber

• Converted Green

Figure 3 shows an overview of the standard OSRAM OSTAR®Projection Power

devices witha connecting board. Amber and (deep) blue devices are covered

with a glass window, the converted green LED is cast in silicone.