Installation and servicing manual

Shell & Tube Cooler

8Parker Hannin Corporation

Hydraulics Group

Catalogue HY10-6014-UM/CN

Preventive Maintenance/Procedures

4.4 Before Operation

4.4.1 PIPE INSTALLATION CHECKUP

Ensure that the pipe is installed properly prior to

operating the equipment. Oil and cooling water

may leak when the pipe is not installed properly.

4.4.2 COOLING WATER SUPPLY

Check that the cooling water is being supplied prior to use.

No heat exchanger effect will take place if the cooling water

is not supplied. See PRIOR TO INSTALLATION for cooling

water quality.

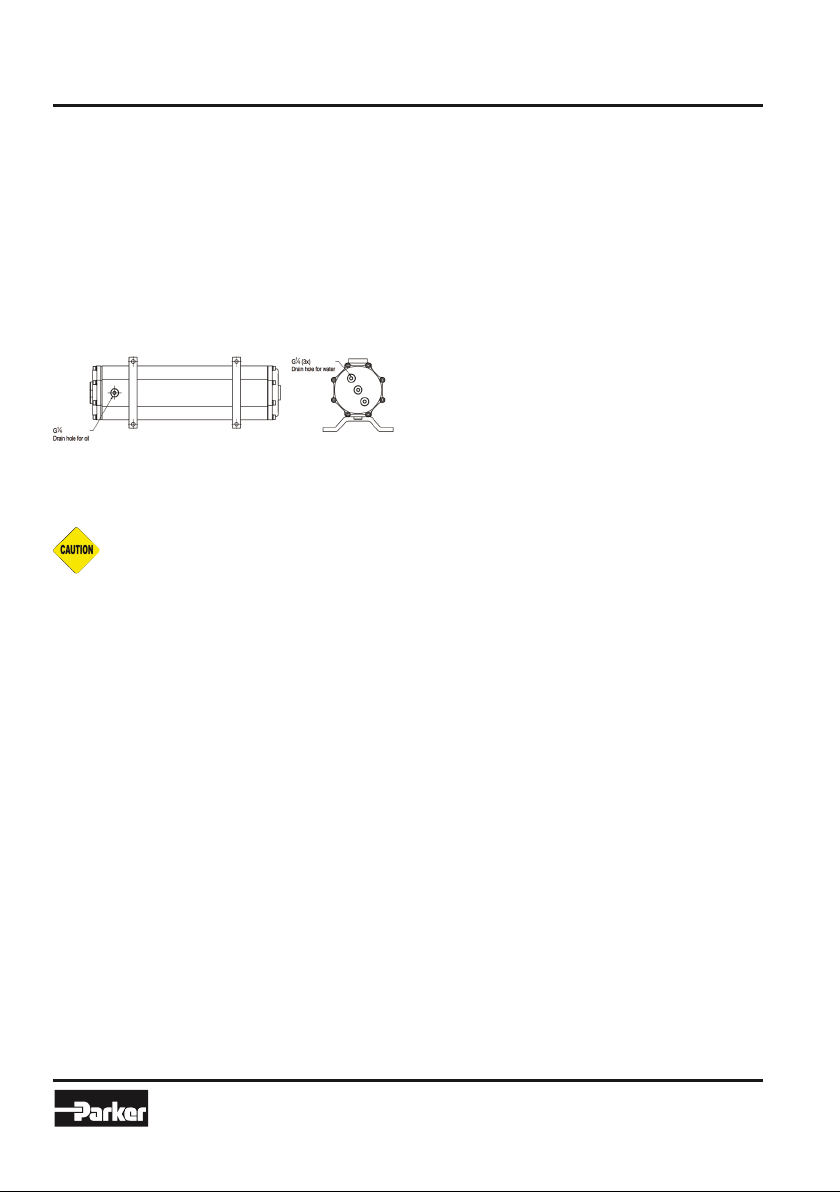

4.4.3 DRAIN PLUG

Ensure that water and oil drain plugs at the bottom are

closed prior to operating.

4.5 Operation

1. Ensure the entire system is clean before starting

operation to prevent clogging of tubes or shell side.

2. Open vent connections before starting up. A

heat exchanger is a pressure vessel designed

for operation at certain specific limits of pressure

and temperature. The cooling or process system,

which includes the heat exchanger, must be

safeguarded with safety valves and controls so

that these heat exchanger design conditions are

not exceeded. All operating personnel should be

made aware of these specific design pressures and

temperatures.

3. Start Operating the system. If in doubt, contact

Parker OLAER Suzhou office for specific instructions.

4. After the system is completely filled with the

operating fluids and all air has been vented, close all

manual vent connections.

5. Bolting on all gasket or packed joints should be

retightened after the heat exchanger has reached

operating temperatures to prevent leaks and gasket

failures. Refer to tightening torque table in annex of

this shell and tube cooler manual.

6. Do not operate the heat exchanger under pressure

and temperature conditions in excess of those

specified on the name plate.

7. Drain all fluids when shutting down to eliminate

possible freezing and corrosion.

8. In all installation there should be no pulstation of

fluids since this cause vibration and will result in

reduced operating life.

5. Preventive Maintenance

5.1 Inspection and Cleaning

External and internal inspection and cleaning by

disassembling the shell and tube cooler are required every 6

months if used on application using clean fluid, as per water

quality table in annex of the shell and tube manual, and

equipped with filtration system.

For coolant from other origins, external and internal

inspection and cleaning by disassembling the shell and tube

cooler are required every 4 months.

5.2 Cleaning

During the inspection and cleaning process at the required

time intervals, check the cooler carefully for any sign of wear

or corrosion (internal and external) that could lead to product

malfunctioning or leakage.

Any component presenting any sign of advanced wear should be

analyzed carefully and replaced if necessary, to ensure product

function and reliability.

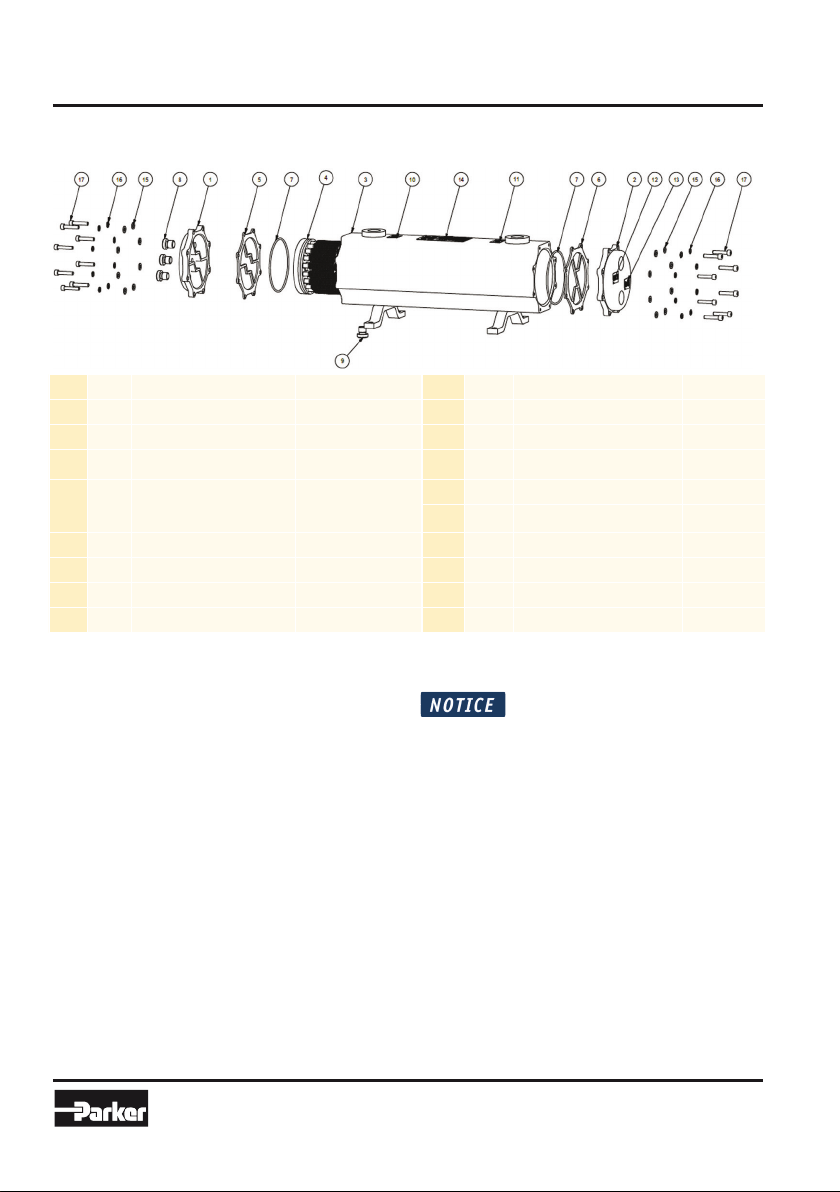

5.3 Replacable Components

Shell and tube cooler components subject to wear and that

potentially need to be replaced during preventive maintenance

process are the following : tube bundle, floating Cover and

stationery cover, O-Ring, Gaskets.

Refer to the product exploded view in annex of this manual,

or to the product technical specifications for components part

number.

5.4 Record

Maintenance tasks performed on the shell and tube cooler shall

be recorded and available at any time.

Product maintenance record should be provided in case of faulty

product or warranty claim.

6. Maintenance Procedures

6.1 Remove O-Ring or Gasket

Ensure to remove all the pressure in the shell and

tube heat exchanger before disconnecting any bolt,

connection, plug or cover.

6.1.1 WHEN TO REMOVE

• O-Ring or gasket may be needed to be replaced when a

leak occurs arround them.

• Replace O-Ring and gasket during periodic pipe cleaning.

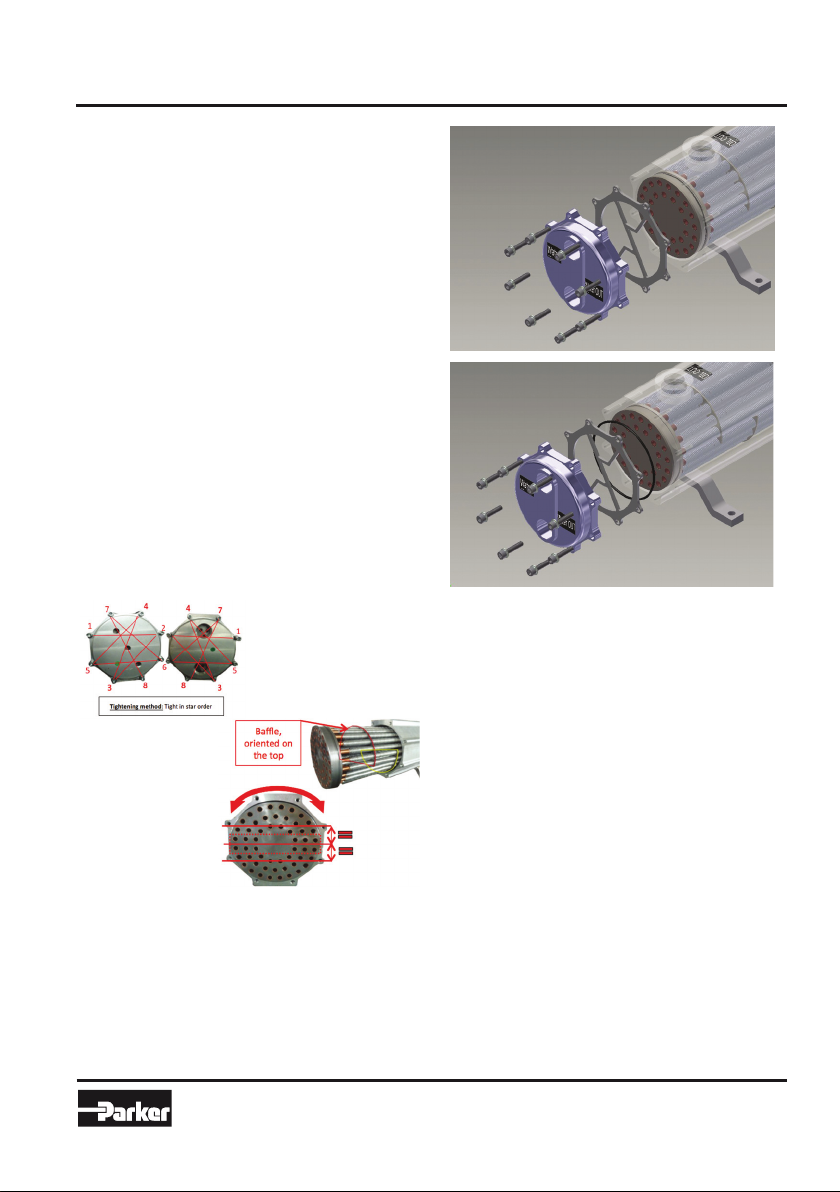

6.1.2 HOW TO REMOVE

For the name of the components, please refer to “3. Product

Parts Name”.

1. Unscrew the bolts, the spring washers and washers.

2. Remove the bolts, the spring washers and washers.

3. Remove the covers.

4. Remove the gaskets (if you only need to change the

gaskets, change them and repeat the above steps

reversely, 4 to 1).

5. Beat with a rubber hammer on the tube sheet on one

side until the other side is out of the shell. DO NOT USE A

HARD TOOL. This will result in tube damage and result in

cooler leakage.

6. Remove the first O-Ring.

7. Beat on the other side (on the tube sheet) until tube

bundle is out of the shell.

8. Remove the second O-Ring.

9. Change them and repeat the above steps reversely, 8 to 1

steps reversely (in order of 1, 2,3 and 4) to

complete assembling.