6 7

FOR SAFE OPERATION

FOR SAFE OPERATION

GLOVES

Gloves should be worn where appropriate.

HEARING PROTECTION

Hearing protection should be worn to prevent

damage to your ears. Ensure your hearing

protection provides adequate noise reduction.

EYE PROTECTION

Approved eye protection should be worn at all

times during operation.

BOOTS

Wear sturdy, non-slip boots.

CLOTHING

Appropriate clothing should be worn during

operation. Ensure clothing is made of strong

fabric and is not baggy or loose.

IMPORTANT

• Never operate a chain saw when you are fatigued, ill, or upset, or

under the influence of medication that may make you drowsy, or if

you are under the influence of alcohol or drugs - risk of accident!

• Use safety footwear, snug fitting clothing and eye, hearing and head

protection during use.

• Keep the saw chain sharp and the saw, including the AV system,

well maintained. A dull chain will increase cutting time, and pressing

a dull chain through wood will increase the vibrations transmitted

to your hands. A saw with loose components or with damaged or

worn AV buers will also tend to have higher vibration levels.

• Always use caution when handling fuel. Wipe up all spills and then

move the chainsaw at least 3m from the fuelling point before

starting the engine - risk of fire!

• Eliminate all sources of sparks or flame (i.e. smoking, open flames,

or work that can cause sparks) in the areas where fuel is mixed,

poured, or stored - risk of fire!

• Do not smoke while handling fuel or while operating the chain saw

- risk of fire!

• Do not allow other persons to be near the chain saw when starting

or cutting. Keep bystanders and animals out of the work area.

Children, pets and bystanders should be a minimum of 10m away

when you start or operate the chainsaw - risk of accident!

i• Never start cutting until you have a clear work area, secure

footing, and a planned retreat path from the falling tree - risk of

accident!

• Always hold the chain saw firmly with both hands when the

engine is running. Use a firm grip with thumb and fingers

encircling the chain saw handles.

• Keep all parts of your body away from the saw chain when the

engine is running - risk of accident!

• Before you start the engine, make sure the saw chain is not

contacting anything - risk of accident!

• Always carry the chain saw with the engine stopped, the guide

bar and saw chain to the rear, and the muler away from your

body. Always inspect the chain saw before each use for worn,

loose, or damaged parts. Never operate a chain saw that is

damaged, improperly adjusted, or is not completely and secure-

ly assembled. Be sure that the saw chain stops moving when

the throttle control trigger is released. All chain saw service,

other than the items listed in the Owner’s Manual, should be

performed by competent chain saw service personnel. (e.g if

improper tools are used to remove the flywheel, or if an improper

tool is used to hold the flywheel in order to remove the clutch,

structural damage to the flywheel could occur which could sub-

sequently cause the flywheel to disintegrate.)

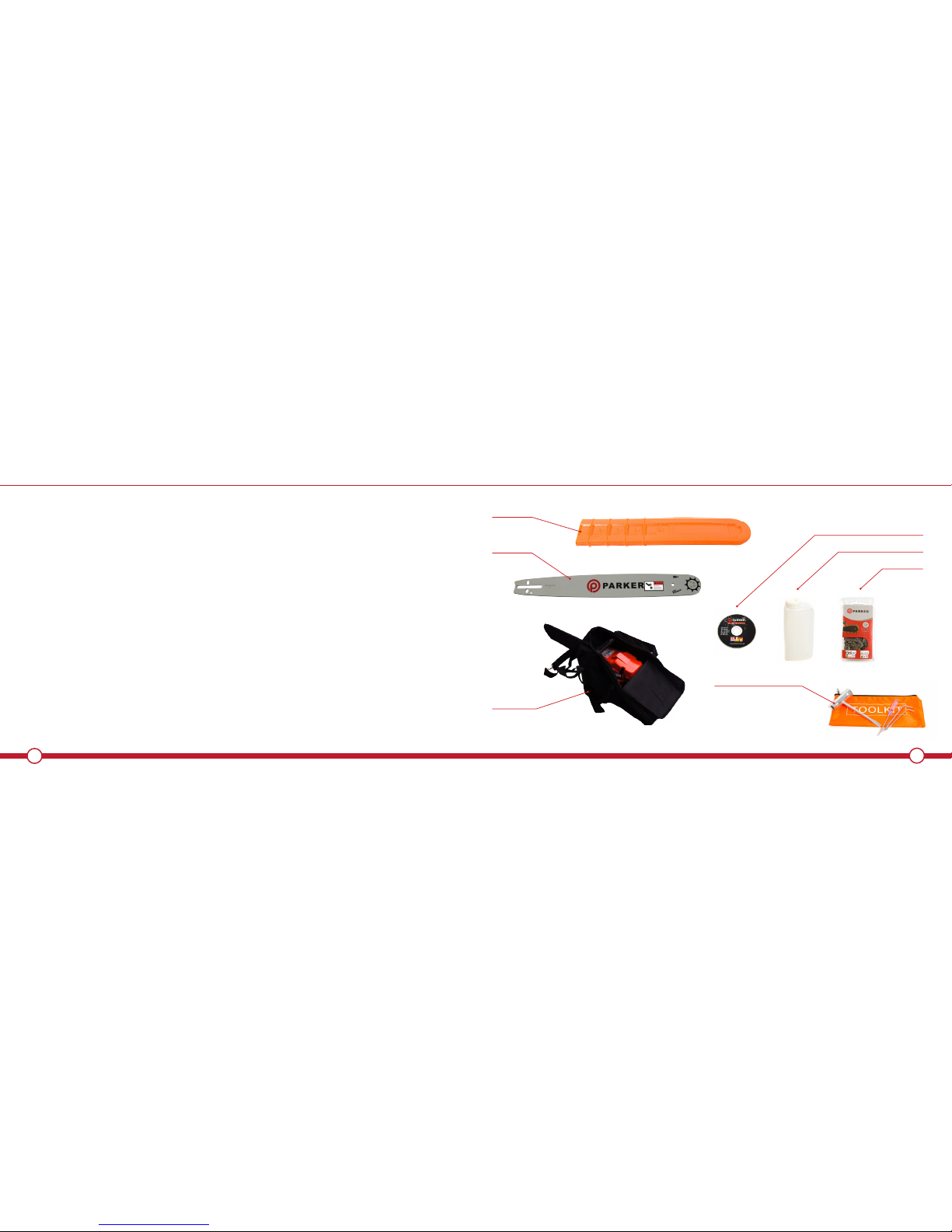

• When transporting your chain saw, make sure the appropriate guide

bar scabbard is in place.

• Always shut o the engine before setting it down.

• Use extreme caution when cutting small size brush and sap-

lings because slender material may catch the saw chain and be

whipped toward you or pull you o balance - risk of accident!

• When cutting a limb that is under tension, be alert for spring-

back so that you will not be struck when the tension in the wood

fibers is released.

• Never cut in high wind, bad weather, when visibility is poor or in

very high or low temperatures. Always check the tree for dead

branches which could fall during the felling operation. Keep the

handles dry, clean and free of oil or fuel mixture.

• Operate the chain saw only in well ventilated areas. Never start

or run the engine inside a closed room or building and potential-

ly explosive atmosphere. Exhaust fumes contain dangerous car-

bon monoxide - risk of fatal injury from breathing toxic fumes!

• Do not operate the chain saw in a tree unless specially trained to.

• Guard against kickback. Kickback is the upward motion of the guide

bar which occurs when the saw chain at the nose of the guide bar

contacts an object. Kickback can lead to dangerous loss of control

of the chain saw.

• Sawdust, fumes, smoke and lubrication oil mist may be produced

while using the machine may be hazardous to health. If dust is gen-

erated, wear a dust mask.