GENERAL INFORMATION

Thank you for purchasing a quality Evaporative Cooler, We care about your safety

and would ask you to spend a few minutes reading these simple instructions before

installing or operating this product.

Safety

Read carefully all of these instructions prior to installing and operating the unit.

Read and Save these Instructions .Do not throw these Instructions away

Installations of this cooler in any manner not prescribed by these instructions

could cause a safety issue and WILL void any warranty

Use only with a 220v 50Hz single phase grounded outlet.

Unplug the cooler and turn off the machine when installing, servicing or

cleaning.

Do not operate cooler with Rear filter panel removed.

Do not operate cooler with a damaged cord, plug or other component.

Do not run the power cord under carpet or other floor covering

Do not sue the cooler with an improperly grounded outlet.

Do not alter or modify this cooler.

Do not allow children to install, operate or service this cooler.

WARNING: To reduce the risk of fire or electric shock, do not use this product

with any solid state speed control device.

Use only qualified electricians for replacement or servicing of switches, or

electrical motors.

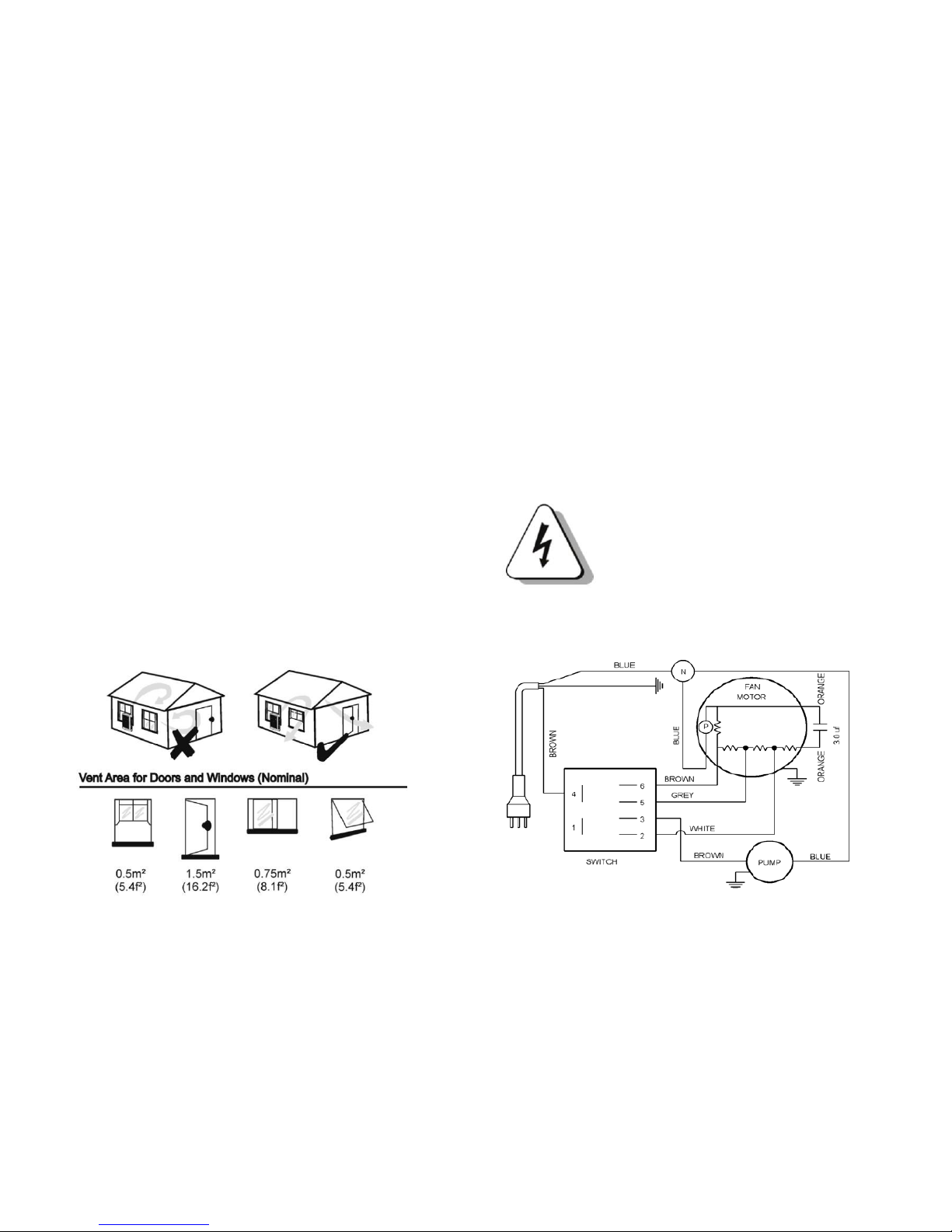

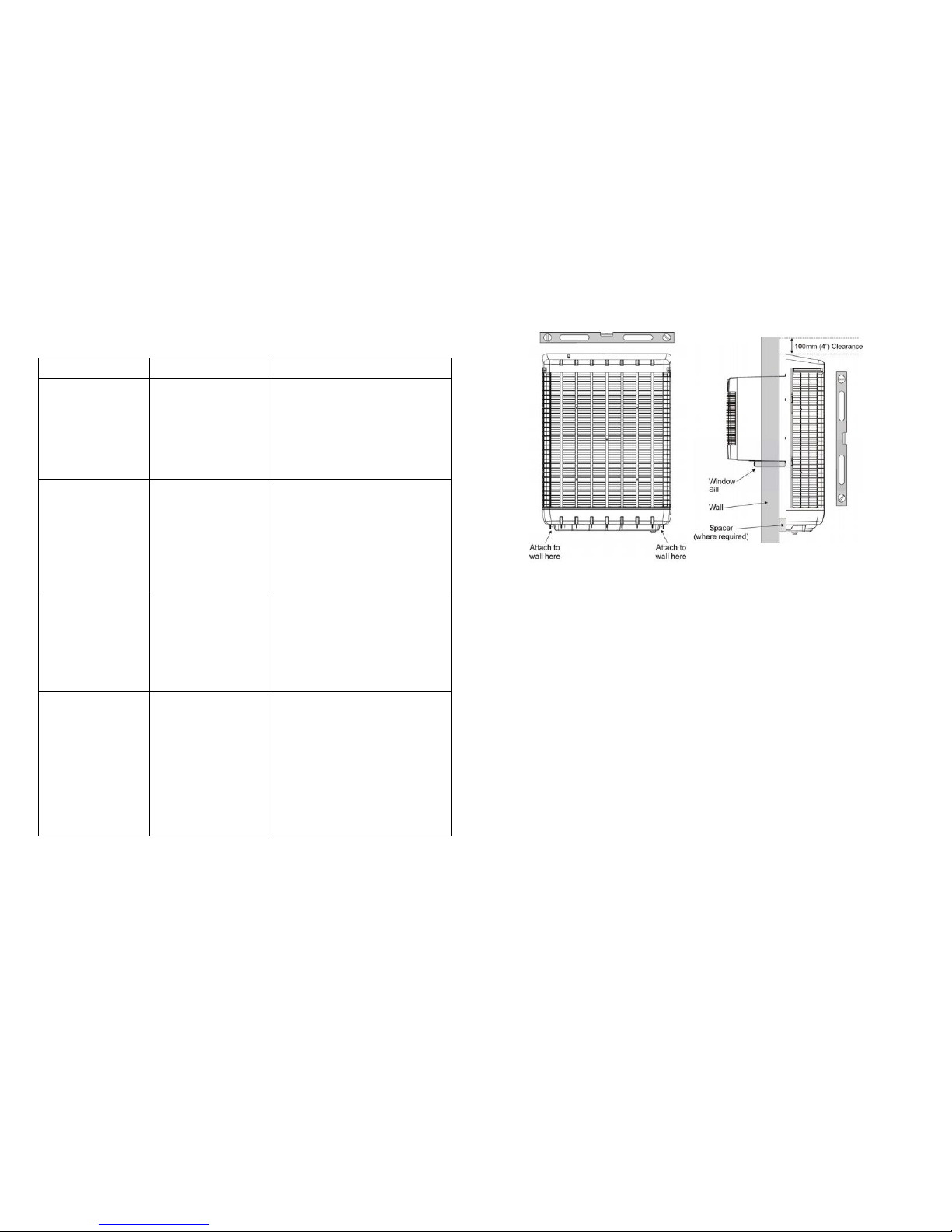

This Window Mounted Cooler is suitable for installation in windows (either sash

hung or sliding) with a minimum opening width of 550 mm and height of 550

mm please ensure that the directions for correct mounting are adhered to for

the SAFE operation of this cooler.

Ensure there is a minimum 100mm clearance above the external cabinet for

maintenance purposes.