Patrick HPK315NFI User manual

SERVICE MANUAL

Model:

: HPK315NFI

Contents

Specifications ------------------------1

Circuit Diagram-----------------------4

Refrigerant Circuit-------------------6

Replacement of Parts---------------7

Trouble shooting---------------------17

P a g e | 1

PRINTED : JULY’2017 REF NO. COD-002-000062

SERVICE MANUAL Refrigerator

1

Specifications

1-1) Specific parts for specific countries

Item

No.

Model

Destination

Power Source (Voltage-

ac / Hz)

Power Cord

1.

HPK315NFI

Argentina

220-240V 50Hz

Argentina plug

P a g e | 2

PRINTED : JULY’2017 REF NO. COD-002-000062

1-2) Product

Model

HPK315NFI

Classification

2 Doors No Frost

Temperature Control

Mechanic control

Defrost System

Automatic

Drain System

Automatic (Heat by transfer from the Condenser)

Evaporator

Fined Evaporator

Condenser

Pipe Condenser

Insulation

Cabinet

Rigid Polyurethane Foam ( Cyclopentane )

Freezer Door

Rigid Polyurethane Foam ( Cyclopentane )

Refrigerator Door

Rigid Polyurethane Foam ( Cyclopentane )

Refrigerant

R-600A

Refrigerant Charge (g.)

46

Overall Dimension (WxDxH (mm.))

595x 677 x 1650.5

Packing Dimension (WxDxH (mm.))

630x755x1751.5

Net Weight (kg.)

55

Gross Weight (kg.)

61

P a g e | 3

PRINTED : JULY’2017 REF NO. COD-002-000062

1-3) Electrical Parts

Compressor

Model HPK315NFI

ETC95

Electrical data

Input: 220-240V 50Hz

Resistance value

Main :22.04±10%Ω

Aux : 18.36±10% Ω

Overload Protector

Model

BT32-115

Electrical data

Operation Current(25°C): 3.6 A

Operation time: 6~16 S

Reset time: ≥10 S

Operation Temperature: 115±5°C

Reset Temperature: 61±9°C

Min Operation Current(70°C): 0.6~1.0 A

Starting Relay

Model

TY-QZ-003

Electrical data

Normal resistance: 15±20%Ω

Operating time: 0.1~3.5 S

Reset time: ≤150 S

Max Voltage: 350 V,8A

Running Capacitor

Model

CBB65A-2

Electrical data

3µF 50/60HZ 400/450V

Freezer Fan motor

Model

FD-F6110A-5059

Electrical data

Rated Current: 0.048±15%,(AT 25°C)

Input Rated Power: 7.1±15%,(AT 25°C)

Thermal fuse

Model

SF76E

Electrical data

10A 250V

cut-off temperature 77 C

BIMETAL THERMO

Model

S101-DF

Electrical data

Cut off temp: 11±3°C

Cut in temp: 2±4°C

Door switch

Model

D3D-211

Electrical data

250V AC 0.5A T55

Thermostat

Model

WPFE7.5H-L

Electrical data

250VAC, 125 A

Defrost timer

Model

TMDFX05ZH1

Electrical data

Runtime 50Hz: 12.0 hr±6 Min

Defrost 50Hz :6.36± 1.12Min

Lamp

Model

E-14,T20

Electrical data

220V.,10W

P a g e | 4

PRINTED : JULY’2017 REF NO. COD-002-000062

2

Circuit Diagram

Model: 2-1 Circuit Diagram

2-2 Reference wiring diagram

P a g e | 5

PRINTED : JULY’2017

REF NO. COD-002-000062

P a g e | 6

PRINTED : JULY’2017 REF NO. COD-002-000062

3

Refrigerant Circuit

P a g e | 7

PRINTED : JULY’2017 REF NO. COD-002-000062

4

Replacement of Parts

•Unplug the power cord before servicing.

Part Name

Frz Fan Blade.

Operating Procedure

1. Remove Ice Storage Box.

2. Remove Ice Cube Tray Assy.

3. Remove Shelf F.

4. Dig Cover Cap out.

5. Release screws at FF Cover

6.Lift Cover and Fan Cover out.

7. Dig Spring

8. Lift Spring..

9. Pull out Fan Blade from Fan Motor

10. After replacing Fan Blade, reverse the steps above.

P a g e | 8

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Fan Motor.

Operating Procedure

- Follow step 1-10 of replacing Fan Blade.

1. Lift Plate MTG Motor out.

2. Take out socket of Fan Motor.

3. Release screw at Cover A.

4. Pull Cover A from Plate MTG Motor.

5. Pull out Fan Motor from Plate MTG

Motor.

6. After replacing Fan Motor,

reverse the steps above.

P a g e | 9

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Bimetal Thermo.

Operating Procedure

- Follow step 1-10 of replacing Fan Blade.

-Follow step 1-2of replacing Fan Motor.

1. Take out socket of Bimetal Thermo.

2. Cut out Cable Tie from Evaporator

tube.

3. Pull Bimetal Thermo from

Evaporator tube.

4. After replacing Bimetal Thermo, reverse the steps above.

Part Name

Thermal Fuse.

Operating Procedure

- Follow step 1-10 of replacing Fan Blade.

-Follow step 1-2of replacing Fan Motor.

1. Take out socket of Thermal Fuse.

2. Cut out Cable Tie from Evaporator

tube.

3. Pull Thermal Fuse from

Evaporator tube.

4. After replacing Thermal Fuse, reverse the steps above.

P a g e | 10

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Glass Tube Heater.

Operating Procedure

- Follow step 1-10 of replacing Fan Blade.

- Follow step 1-2of replacing Fan Motor.

1. Take out socket of Glass Tube Heater.

2. Take out socket of Glass Tube

Heater.

3. Remove aluminium tape that

cover electrical wire.

4. Hold and lift Evaporator up.

5. Hold Glass Tube Heater at the

rubber connector.

6. After replacing Glass Tube

Heater, reverse the steps above.

P a g e | 11

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

LAMP.

Operating Procedure

1. Pull out Chiller.

2. Remove all Glass Shelf.

3. Remove Lamp Cover .

4. Remove lamp.

5. After replacing lamp, reverse the steps above.

P a g e | 12

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Thermostat.

Operating Procedure

-Follow step 1-5 of replacing Lamp.

1. Release screws at Multi Duct Ass’y.

2. Turn Thermo Knob R to “left

” position.

3. Pull out Thermo Knob R from Multi

Duct Ass’y.

4. Pull out Multi Duct Ass’y.

5. Take out socket of Thermostat.

6.Pull out Multi Duct Insulallon from

each other.

6. Pull Thermostat from Thermo Case.

7. Pull Thermostat from Multi Duct.

8. Hold Recept Terminal then pull out

electrical wires from Thermostat.

9. After replacing Thermostat, reverse the steps above.

P a g e | 13

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Lamp Socket.

Operating Procedure

-Follow step 1-5 of replacing Lamp.

-Follow step 1-6 of replacing Thermostat.

1. Take out socket of Thermostat.

2. Press R Lamp Socket to remove lock.

3. Lift out R Lamp Socket.

4. After replacing R Lamp Socket, reverse the steps above.

P a g e | 14

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Starting Relay (PTC)

Operating Procedure

- Follow step 1-4 of replacing Elec. Component Ass’y.

1. Release screws that hold Relay

Cover.

2. Remove Relay Cover.

3. Lever Starting Relay by flatton

screw driver.

4. Remove Starting Relay.

5. Hold Recept Terminal then pull out

electrical wires from Starting Relay.

6. After Replacing Starting Relay,

reverse the steps above.

P a g e | 15

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Overload Protector.

Operating Procedure

-Follow step 1-5 of replacing Starting Relay.

1. Remove Overload Protecto

2. Hold Recept Terminal then pull out

electrical wires from Overload Protector.

3. After Replacing Overload

Protector, reverse the steps

above.

Part Name

Running Capacitor

Operating Procedure

- Follow step 1 of replacing compressor cover.

1. Release nut that Running Capacitor

2. .Remove Running Capacitor

3.Pull out socket.

4. After replacing Running Capacitor.reverse the steps above.

P a g e | 16

PRINTED : JULY’2017 REF NO. COD-002-000062

Part Name

Timer.

Operating Procedure

1. Release screws that hold Electric Box

Ass’y.

2. Pull out Electric Box Ass’y

3. Release screws that hold Cover

Case Elec.

4. Separate Electric Box Ass’y from

each other.

5. Release screws that hold Electric

Box.

6. Pull out Timer.

7. Take out socket of Timer.

8. After Replacing Timer, reverse the steps above.

P a g e | 17

PRINTED : JULY’2017 REF NO. COD-002-000062

5

Trouble shooting

Before calling for service, please read the following troubleshooting table first. This can save both your time and money. The

table contains common problems except those caused by defects in workmanship or material of the refrigerator.

Problem

Cause

Solution

Refrigerator Operation

The

compressor

does not work

The refrigerator is in the

defrosting cycle.

The refrigerator is not plugged into a

power outlet.

This is normal for an automatic

defrosting refrigerator.

Verify the plug is plugged in the socket

firmly.

The refrigerator

runs frequently

or runs for too

long period

The indoor or outdoor

temperature is high.

The refrigerator has been powered

off for a period of time.

The door is opened too frequently or

for long period.

The door of the fridge/freezer storage

compartment is not tightly closed.

The temperature setting is too low.

The door gasket of the

fridge/freezer storage compartment

is dirty, worn, cracked or

mismatched.

In this case, it is normal for the refrigerator

to run longer.

Normally, it takes 8 to 12 hours for the

refrigerator to totally cool down.

Warm air enters the refrigerator and causes

it to start frequently. Please do not open the

door too frequently.

Ensure the refrigerator is

located on a level ground and there is no

food or container jarring the door. See

“door/drawer opening/closing”in section

“Problem”

Set the temperature higher until a

satisfactory refrigerator temperature is

obtained. It takes 24 hours for the

refrigerator temperature to become stable.

Clean or replace the door gasket. A

leakage gap of door gasket can cause a

longer running time of the refrigerator in

order to maintain desired temperature.

TROUBLE-

P a g e | 18

PRINTED : JULY’2017 REF NO. COD-002-000062

Too High Temperature

Too high

temperature in

the fridge /freezer

storage

compartment

The door is opened too frequently

or for too long each time.

Temperature is set too high.

The door is not closed tightly.

Warm air will enter the refrigerator

whenever the

door is opened. Try to open the door as

less frequently as possible.

Reset the temperature.

See “Door/drawer opening/closing in

section “Problem”.

The temperature in

the freezer is too high

while the

temperature in the

fridge storage

compartment is OK

The freezer temperature is set too

high.

Set the freezer temperature lower. It

takes 24 hours for the temperature of the

refrigerator to become stable.

Water/moisture/frost on outside surface of the refrigerator

Moisture accumulates

on the refrigerator's

outside surface or

between two doors

Damp climate.

The refrigerator door is not

closed tightly. This causes

condensation of the cold air in

the refrigerator and the warm

air outside it.

This is normal in damp

climate. The moisture will decrease when

the humidity drops.

See “Door/drawer opening/closing”in

section “Problem”.

Bad odors in the refrigerator

The inside of the

refrigerator is dirty

The inside of the refrigerator

needs cleaning

Food of strong odor is stored in

the refrigerator

Clean the internal of the refrigerator.

Wrap the food tightly.

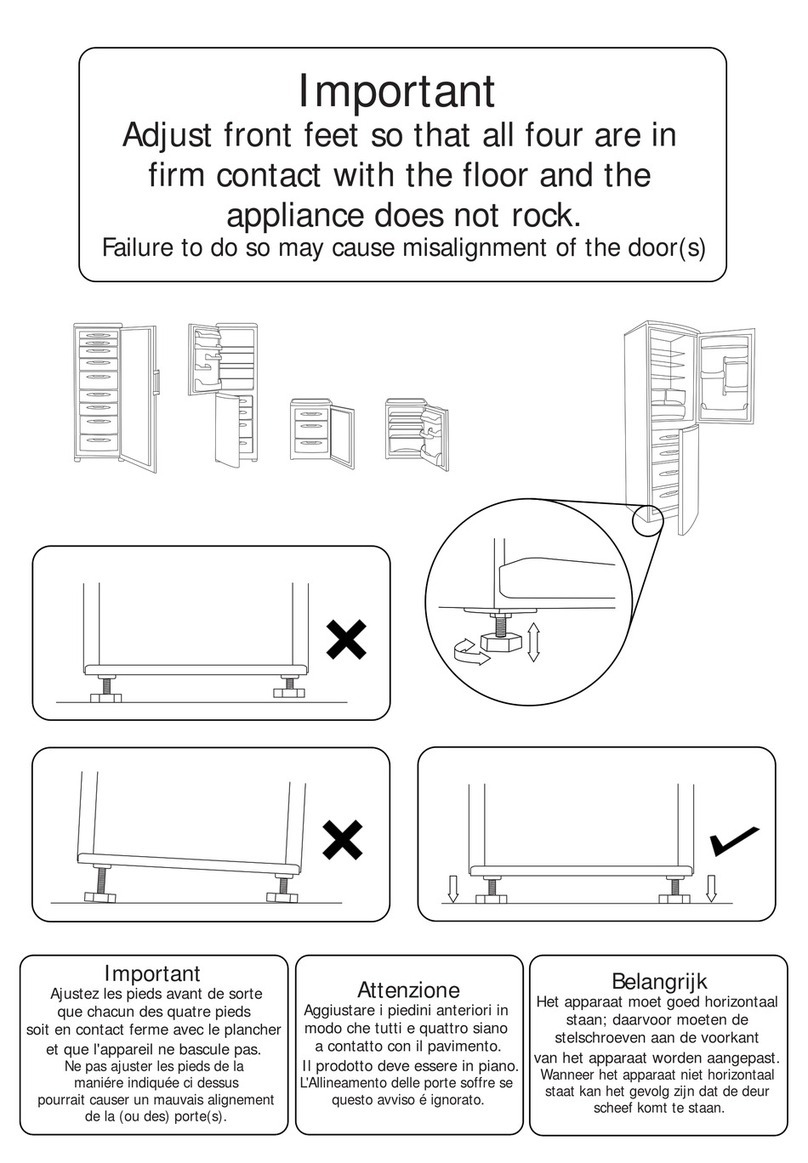

If you hear

Abnormal sound

The refrigerator is not located on

a level place.

The refrigerator touches

some object around it.

Adjust the feet to level the refrigerator.

Remove objects around it.

Slight sound similar

to that of flowing

water

Thid is the sound of the

refrigerating system

Normal

Heating of cabinet

The de-condensation system is

working refrigerating system.

This prevents condensation and is normal.

Table of contents