Shaft Quantitative Inspection Device (SQUID)

Field Operations Manual

Pile Dynamics, Inc.

Device Nomenclature:

SQUID Main Unit: Hand held data collection device

SQUID Acquisition Unit: Down-hole sensor device

SQUID Transmitter Unit: Wireless communication adapter between the Acquisition Unit and the Main Unit.

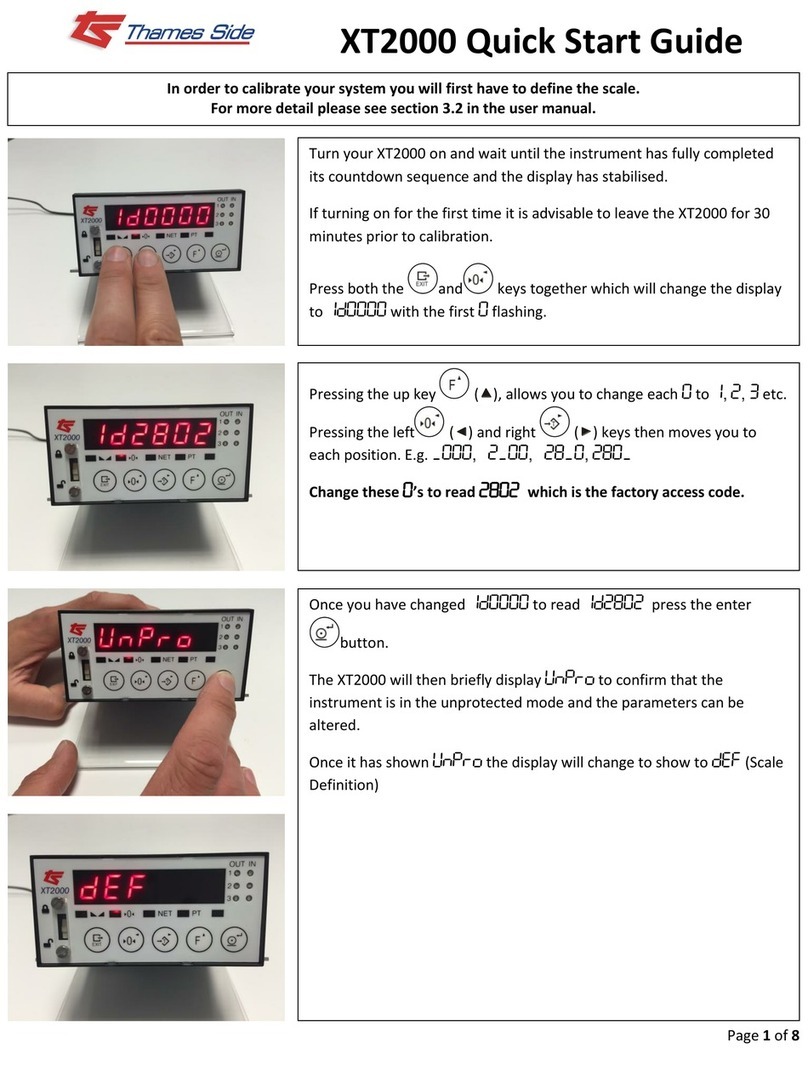

Setup:

1. Place SQUID Acquisition Unit on level ground

2. Attach appropriate Kelly bar adapter

3. Verify that the penetrometers and the guide bars for the displacement plates are not damaged

4. Connect one end of the SQUID cable to the connector on the SQUID Acquisition Unit

5. Connect the other end of the SQUID cable to either the Transmitter Unit or the Main Unit

6. If a Transmitter Unit is used, connect power connector and verify the green light is lit

7. Turn on power to the SQUID Main Unit

8. Using the Main unit, enter the SQUID program located on the Windows 7 Desktop

9. Verify that the drop down box next to the connect button is set to “COM7”

10. Press “Connect”

If wired operation, skip to step 16

11. The “Configure Bluetooth” menu should open in the upper right hand corner

12. Press “Scan” to scan for the Transmitter box

a. The scan command will last for 30 seconds

b. If no Transmitter IDs appear, verify power to the SQUID Transmitter Unit and press “Drop” then

“Reset” then “Scan”

13. Select the appropriate Transmitter ID: SQUID_v_2_3+<Your serial number>

14. Press “Connect”

15. When the connection is valid, the status bar in the lower right hand corner will read “connected”

16. Press “SG Read” to import strain gauge data from the SQUID Acquisition Unit

17. Press “Balance” to balance the gauges – wait 20 seconds for the balance to apply

18. Press “Clear Data” to erase all accumulated data and zero the sensors

19. Move the position sensing plates and observe changes on the graph

20. The SQUID system is now setup and operational