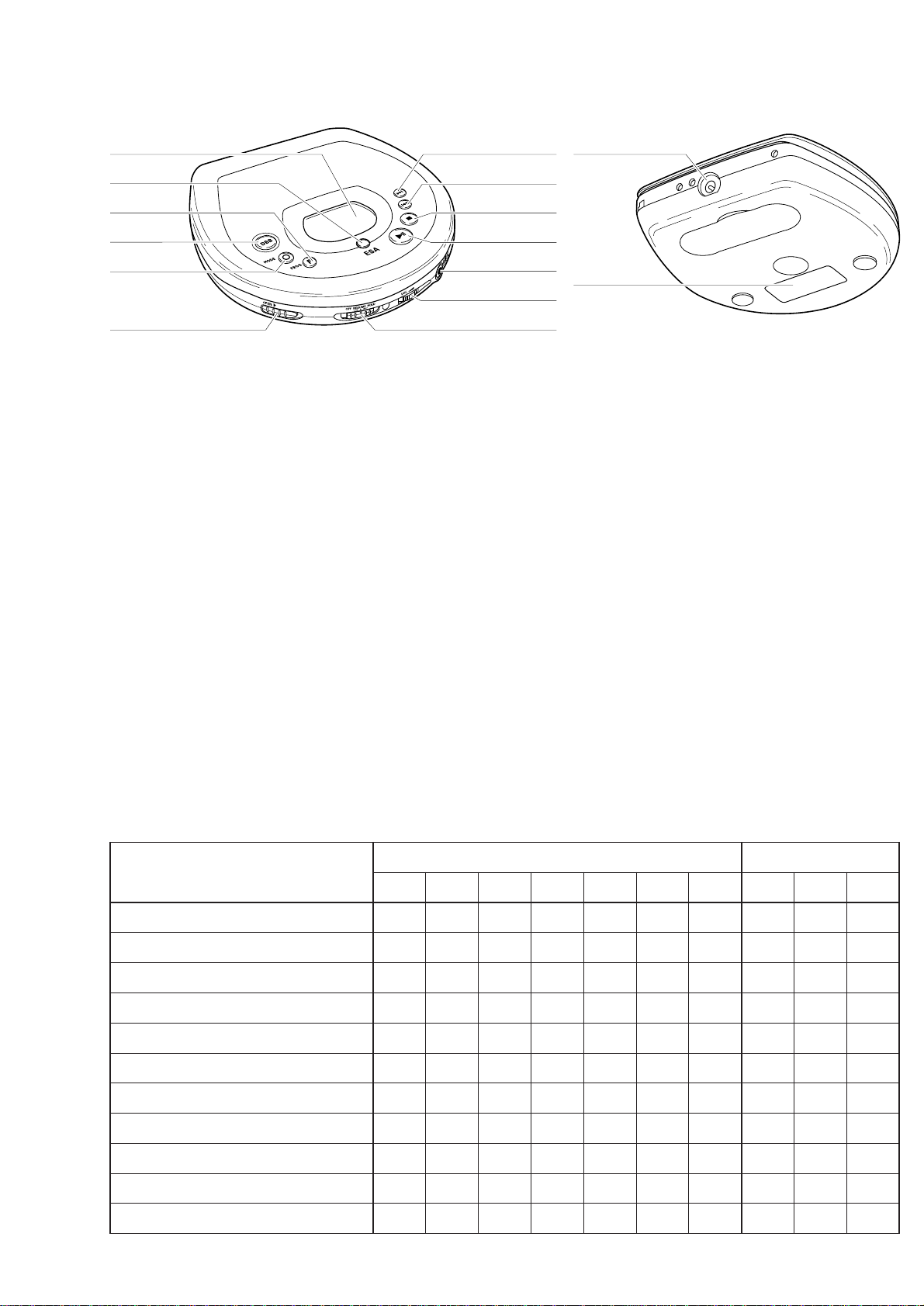

SERVICE TEST PROGRAM

1. PRELIMINARY SETUP

•To enter the service test program hold the keys “MODE” and

“STOP” depressed while turning POWER ON (i.e. connecting

the AC/DC adaptor or inserting batteries).

•The display shows the software version of the built-in

microprocessor (i.e. “S-19”). Versions are counted from “00”

onwards; that means the higher the number the newer the

software.

•The program is now in the main menu – various tests can be

entered by pressing the corresponding buttons (see flow chart

on next page or detailed description of test programs below).

•To exit the service test program disconnect the set from the

power source.

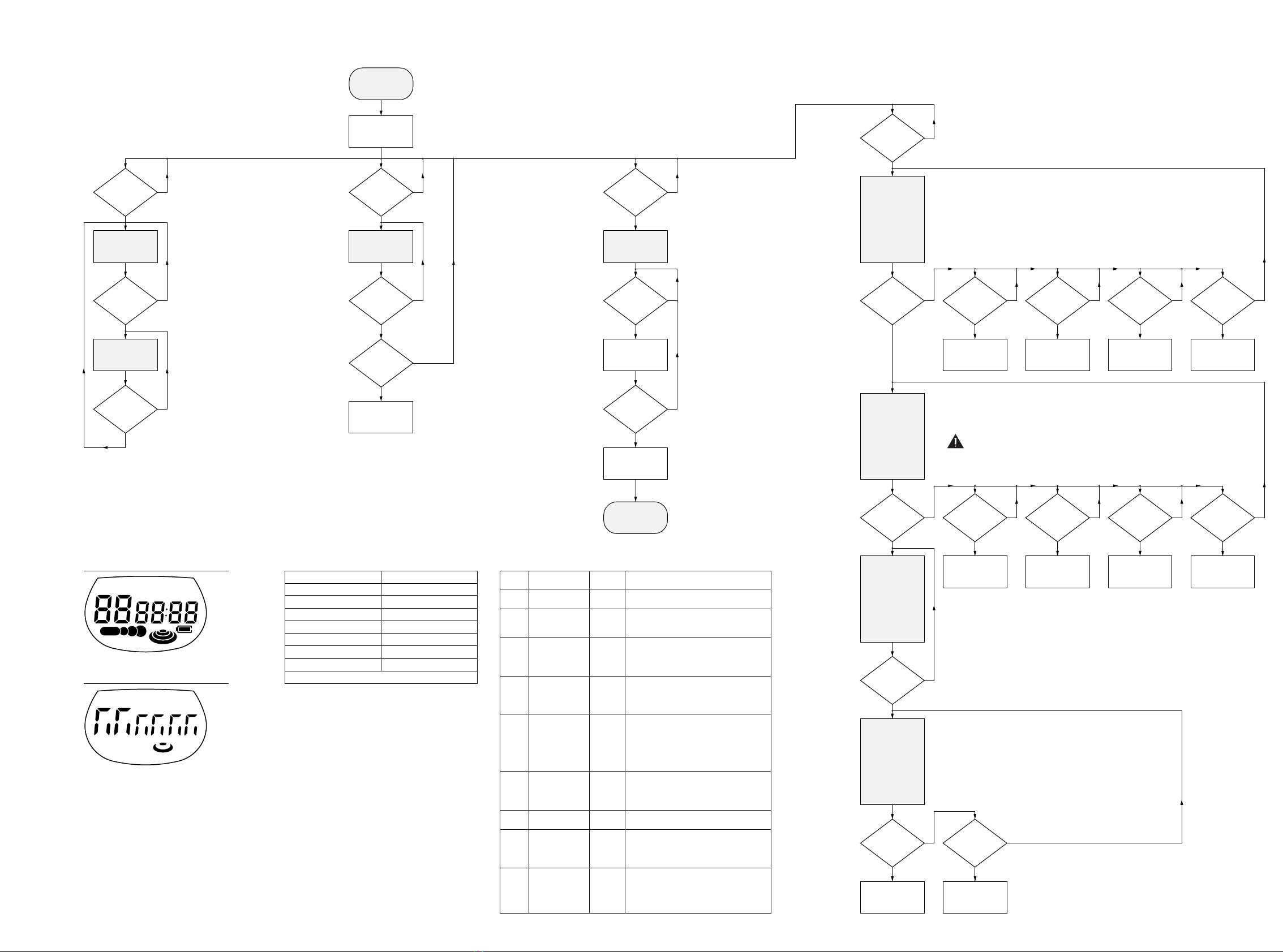

2. DISPLAY TEST

Purpose: Check functionality of display and display driver.

•To enter the display test start service test program and press

the “NEXT” button.

•The display shows test pattern1. All segments are activated for

finding open circuits (see flow chart on next page).

•To jump to the next pattern press the “NEXT” button.

•The display shows test pattern2. All alternate pins (2, 4, ...) are

activated for finding short circuits (see flow chart on next page).

•To jump back to test pattern1 press the “NEXT” button, to exit

the display test and return to the main menu press the “STOP”

button.

3. KEY TEST

Purpose: Check operation of keys.

•To enter the key test start service test program and press the

“MODE” button.

•The display shows “--”.

•Hold key depressed and check corresponding key code on the

display. Key codes can be found in table1 (see flow chart on

next page).

•To exit the key test and return to the main menu press the

“STOP” button.

4. PLAYBACK TEST WITH ERROR ANALYSIS

Purpose: Analyse errors that occur during playback and search

for intermittent failures.

•To enter the playback test start service test program and press

the “DBB” button. Note that the playback test can only be

entered if the CD-door is closed.

•The set now reads the TOC and switches to stand-by.

•Press the “PLAY” button to start the error analysis.

As long as the playback is free of errors the display shows track

and time information like in normal play-mode.

In case of an error a corresponding error code will be displayed.

The meaning of this error code can be found in table2 (see flow

chart on next page).

Note: Errors can either be

“fatal”

or

“non fatal”

. Fatal errors

always stop the playback, non fatal errors only cause a

short interruption of the music. Fatal errors are displayed

as long as the set is connected to the power source, non

fatal errors are displayed until a new error occurs or a

button is pressed.

•To stop the playback test disconnect the set from the power

source.

5. SERVO TEST

Purpose: Check door switch and inner switch, movement of

slide and acceleration of discmotor.

•To enter the servo test start service test program and press the

“PLAY” button.

•The display shows “S

xy

”.

“

x

” indicates state of door switch;

“

y

” indicates state of inner switch.

x,y

= “0” means switch is closed; “1” means switch is open.

•To move slide outside hold the “NEXT” button depressed.

•To move slide inside hold the “PREV” button depressed.

•To accelerate the discmotor clockwise hold the “MODE” button

depressed.

•To accelerate the discmotor counter-clockwise hold the

“PROG” button depressed.

•To enter the focus test press the “PLAY” button, to exit the

servo test and return to the main menu press the “STOP”

button.

6. FOCUS TEST

Purpose: Check movement of lens and operation of focus servo.

•The focus servo loop is switched on and the set starts

searching the focus (“focus ramping”). As soon as the focus

has been found the focus servo loop is closed and the state of

the focus is monitored continuously.

If the focus is OK the display shows “ F”, else “-F”.

•When the disc is turned manually “focus noise” is audible.

•To move slide outside hold the “NEXT” button depressed.

•To move slide inside hold the “PREV” button depressed.

•To accelerate the discmotor clockwise hold the “MODE” button

depressed.

•To accelerate the discmotor counter-clockwise hold the

“PROG” button depressed.

•In case the focus is OK the discmotor test can be entered by

pressing the “PLAY” button, to exit the focus test and return to

the main menu press the “STOP” button.

7. DISCMOTOR TEST

Purpose: Check speed regulation of discmotor.

•The speed regulation is switched on and the discmotor starts

rotating. If the speed reaches 75% of the nom. speed the

display shows “ d”, else “-d”.

•In parallel also the state of the focus is monitored continuously

(display “ F” or “-F”).

•In case the disc speed is OK and the focus is OK the radial test

can be entered by pressing the “PLAY” button, to exit the

discmotor test and return to the main menu press the “STOP”

button.

8. RADIAL TEST

Purpose: Check if radial loop locks and an audio signal is

audible at the headphone output.

•The radial servo loop is switched on, mute is released and the

audio signal is audible. If the system is on track the display

shows “ r”, else “-r”.

•In parallel also the disc speed (display “ d” or “-d”) and the

state of the focus (display “ F” or “-F”) are monitored

continuously.

Note: In case of radial errors the audio output is muted and

muting is not released automatically when the systems

recovers from the error. “-r” remains on the display.

To open mute again press the “NEXT” or “PREV” button.

•To jump 10 tracks outside press the “NEXT” button.

•To jump 10 tracks inside press the “PREV” button.

•To exit the radial test and return to the main menu press the

“STOP” button, to exit the service test program disconnect the

set from the power source.

Important remark:

In radial test mode data to the DRAM is written at 1.2 times the

nominal speed, and read from the DRAM at nominal speed.

Because writing is done faster than reading the DRAM gets full

after a certain time.

In normal play mode the system would now wait until the DRAM

is partly emptied again, jump backwards and resume filling at the

last written position. However, in radial test mode the jumps

would disturb measurements on the radial servo loop.

Therefore this function has been disabled and filling restarts

immediately from the current position of the pick-up unit. As a

result “jumps” are audible during playback.

3-1

CS 46 517