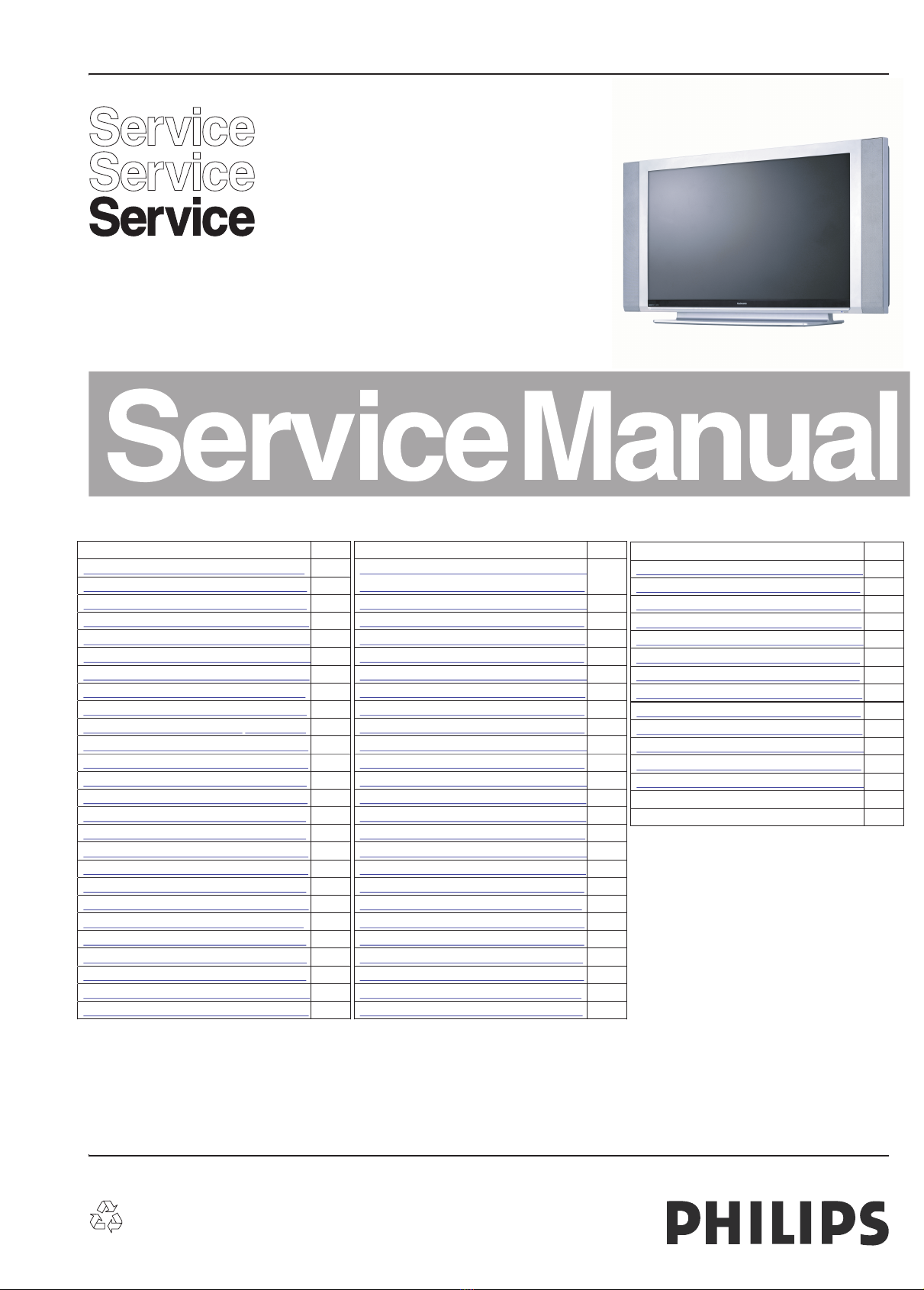

DDeessccrriippttiioonn PPaaggee

Revision List.....................................………. 2

Important Safety Notice................................ 3

Warning/Caution/Notice of PANEL .............. 4

Technical Specification................................. 8

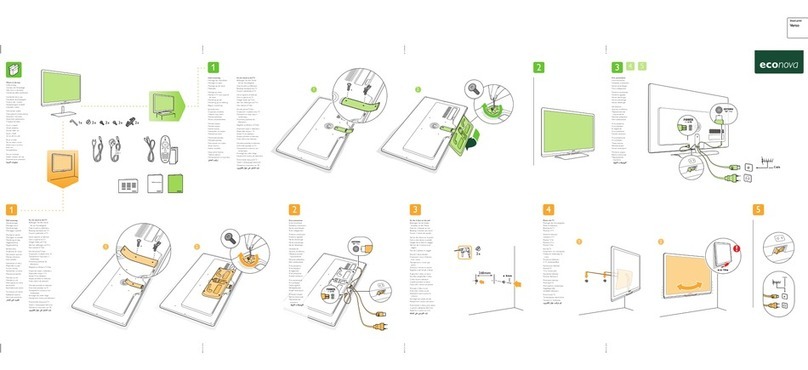

Connecting the PDP...................................... 14

Input interfaces.............................................. 18

Top Key and Remote control ........................

19

OSD Tree .......................................... .......... .. 21

OSD operation ...................... ...................... . 24

Trouble shooting .... ................. ................... 44

Repair flow chart ............ .................. .......... . 46

White-Balance adjustment ............. ............. . 51

Software upgrade ........................................ 53

Function block diagram ............................... 55

Waveform of signals .................................... 60

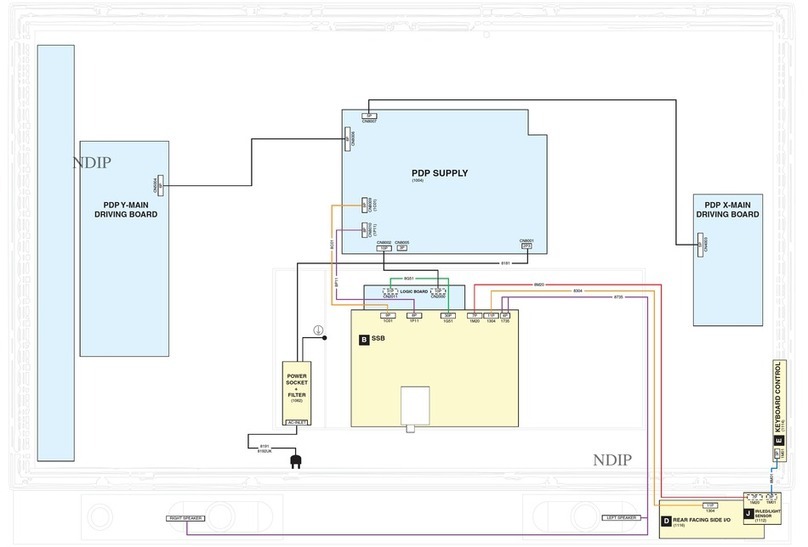

Wiring diagram............................................. 62

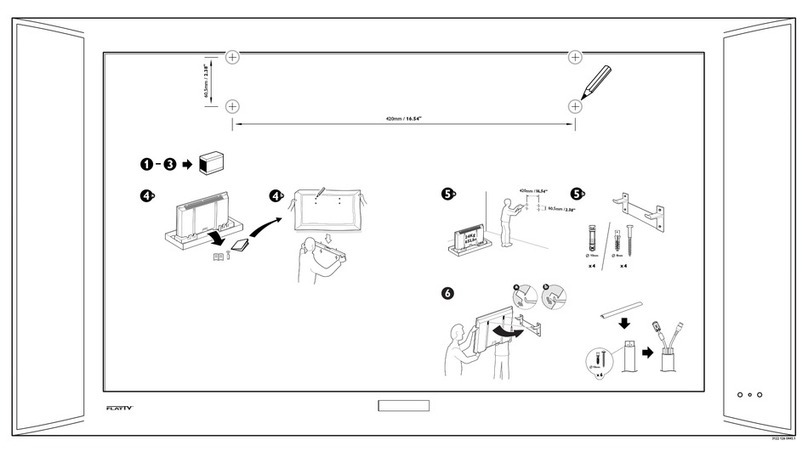

Mechanical Instructions................................ 63

Disassembly and assembly ......................... 68

Definition of pixel defects ............................ 72

Block diagram ............................ ................. 75

UART diagram........................... ................. 81

Analog I/O diagram ................... ................. 82

Audio diagram ........................... ................. 83

Supply+RS232 diagram............. ................. 85

DC/DC diagram........................... ................. 86

Video-DAC diagram...................................... . 87

DDeessccrriippttiioonn PPaaggee

Display interface dia

ram.............................

88

PNX2015 supply diagram............................. . 89

PNX2015 standby&control diagram.............. 90

PNX2015 DDR interface diagram................. . 91

PNX2015 Tunnelbus diagram....................... . 92

PNX2015 DV I/O diagram............................. . 93

PNX2015 Audio/Video dia

ram..................... 94

Miscellaneous diagram.................................

95

EEPROM diagram..... ............ ............ ............ . 96

VIPER supply diagram.................................. . 97

A/V+Tunnelbus dia

ram................................ 98

Main Memory diagram.................................. . 99

Control diagram............................................. 100

HDMI I/O+control diagram............................ 101

HDMI + supply diagram................................ 102

Main Tuner diagram...................................... 103

Channel decoder diagram............................

104

Audio amplifier diagram................................

105

Audio Source Selection diagram.................. 106

IF + SAW filter diagram................................ 107

MPIF main supply diagram........ .................. 108

Video source selection diagram .................. 109

PDC diagram............................. .................. 110

Audio output diagram................................... 111

Side AV diagram.......................................... 112

Key control diagram..................................... 113

DDeessccrriippttiioonnPPaaggee

IR diagr am.. .... .. .. .. .. .. .. .. ... .... .. .. .. .. .. . .. ... .... .. .. . 114

OFPC diagra m.... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ... .... .. .. . 115

AC filter diag ram.. ..... .. .. .. .... .. .. .. .. .. .. .. ... .... .. .. .. 116

US B filter dia gram... .. .. .. .. .... .. .. .. .. .. .. .. ... .... .. .. .. 117

Image b oard PC B... .. .. .. ... ... .. .. .. .. .. .. .. ... .... .. .. .. 118

Power bo ard PC B... .. .. .. ... ... .. .. .. .. .. .. .. ... .... .. .. .. 120

OFPC PC B .. ... .. .. .. .. .. .. .. ... .... .. .. .. .. .. .. .. ... .... .. .. . 121

AC filter bo ard PC B... .. .. .. ... .. .. .. .. .. .. .. ... .... .. .. ..

122

US B board P C B.... .. .. .. .. ... .... .. .. .. .. .. .. .. ... .... .. .. 123

Side AV bo ard PC B... .. .. .. ... .. .. .. .. .. .. .. ... .... .. .. ..

124

Audio output board /Key board PC B. .. .. ... .. .. .. 125

IR bo ard PC B... .. .. .. .. .. ... .. ... .. . .. .. .. .. .. ... .... .. .. .. . 126

Recommend ed par ts lis t..... .. .. . .. .. .. .. ... .... .. .. .

127

Complete p arts list …… ………………………

Different par t lis t.... .. .. .. .. .. .... .. .. .. .. .. .. .. ... .... .. .. . TBD

Published by JH 667 TV Service Printed in the Netherlands Subject to modification EN 3122 785 16590

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Colour Television Chassis