TERMITRAB complete

107820_en_00 PHOENIX CONTACT 5 / 8

5Versions

Combine various circuits and features according to the

relevant requirements.

5.1 Pluggability and testing

Pluggable and testable products are indicated with the letter

“P” in the order key.

Surge protection products are designed for use over a long

period of time. When used as intended within the specified

parameter ranges, the service life of the products can run

into many years. During this time, the surge protection

processes a large number of transient overvoltages. The

end device is protected effectively.

However, in the event of intensive overload the quality of

protection may decrease. By testing, you can determine

whether protection is sufficiently effective, or whether

protective devices are already impaired. These tests and

their documentation are a mandatory requirement in some

areas of industry.

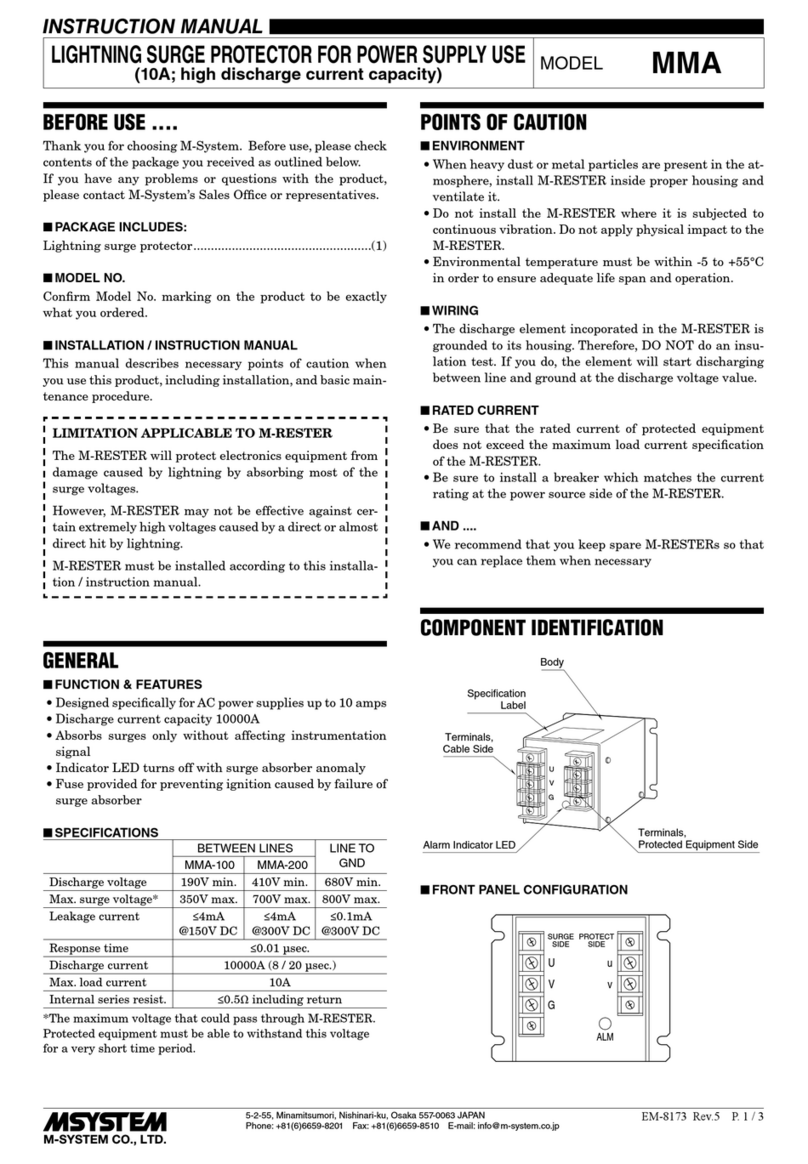

TERMITRABcomplete offers two-piece, pluggable

protective devices. They enable protective plugs to be easily

removed from the base element.

The plug can be tested with the CHECKMASTER2 from

Phoenix Contact. To this end, a barcode is printed on the

plug. The scanner on the CHECKMASTER2 automatically

identifies the corresponding product when the data is read

in. The corresponding template is loaded so that the

CHECKMASTER2 can compare the target and actual

parameter ranges of the protective elements.

If the tested plug is no longer within the intended range,

replacement is recommended. Replacement plugs are

available from Phoenix Contact for such a case.

The order number on the base element is valid for the

complete item comprising the base element and plug. The

order number for the plug is intended for reordering

replacement items.

When plugged in, a snap-in lever prevents the plug from

moving even in the event of strong vibrations. A mechanical

coding system ensures that only matching plugs and base

elements can be connected together.

Insertion and removal is impedance-neutral, which means

that signals are not interrupted during maintenance work

and testing. The cables connected to the base element

remain fixed in the installation.

Figure 1 TERMITRABcomplete, pluggable

5.2 Indirect grounding (floating)

Products with indirect grounding are indicated with the letter

“F” in the order key.

In scenarios where direct grounding of the third terminal

level (terminal blocks 3 - 6) is not desirable, versions with an

additional gas discharge tube for the DIN rail are used.

Example: a common reference potential (common return

conductor) is led via the third terminal level, however this

must not have a ground connection to the surge protection.

An additional gas discharge tube is useful in such a case

Figure 2 Indirect grounding

5.3 Knife disconnection

Products with knife disconnection are indicated with the

letter “M” in the order key.

Disconnect terminal blocks are frequently used in sensor/

actuator cabling. These disconnect terminal blocks are

installed between the modules for measurement and control

technology and the cables led into the field. The disconnect

terminal blocks can be used to interrupt signal circuits in

order to conduct measurements in the field.

The disconnection option can be used on the top two

terminal levels. Isolator1 opens and closes the signal on the

field side directly at terminal point1. Isolator2 opens and

closes accordingly directly at terminal point2.

For example, insulation measurements can be carried out

on the cables without the surge protection components

distorting the test results.

The dielectric strength of the knife disconnection is 2.5kV

(1.2/50µs).