3

TABLE OF CONTENTS

Identification

of

Controls & Features .

..

2

Stopping

Instru

ct

ion

s.

Operating Instructions.

Preventive Maintenance.

7

7

8

9

Table

of

Contents

Foreword.

Servicing Procedures

Manual.

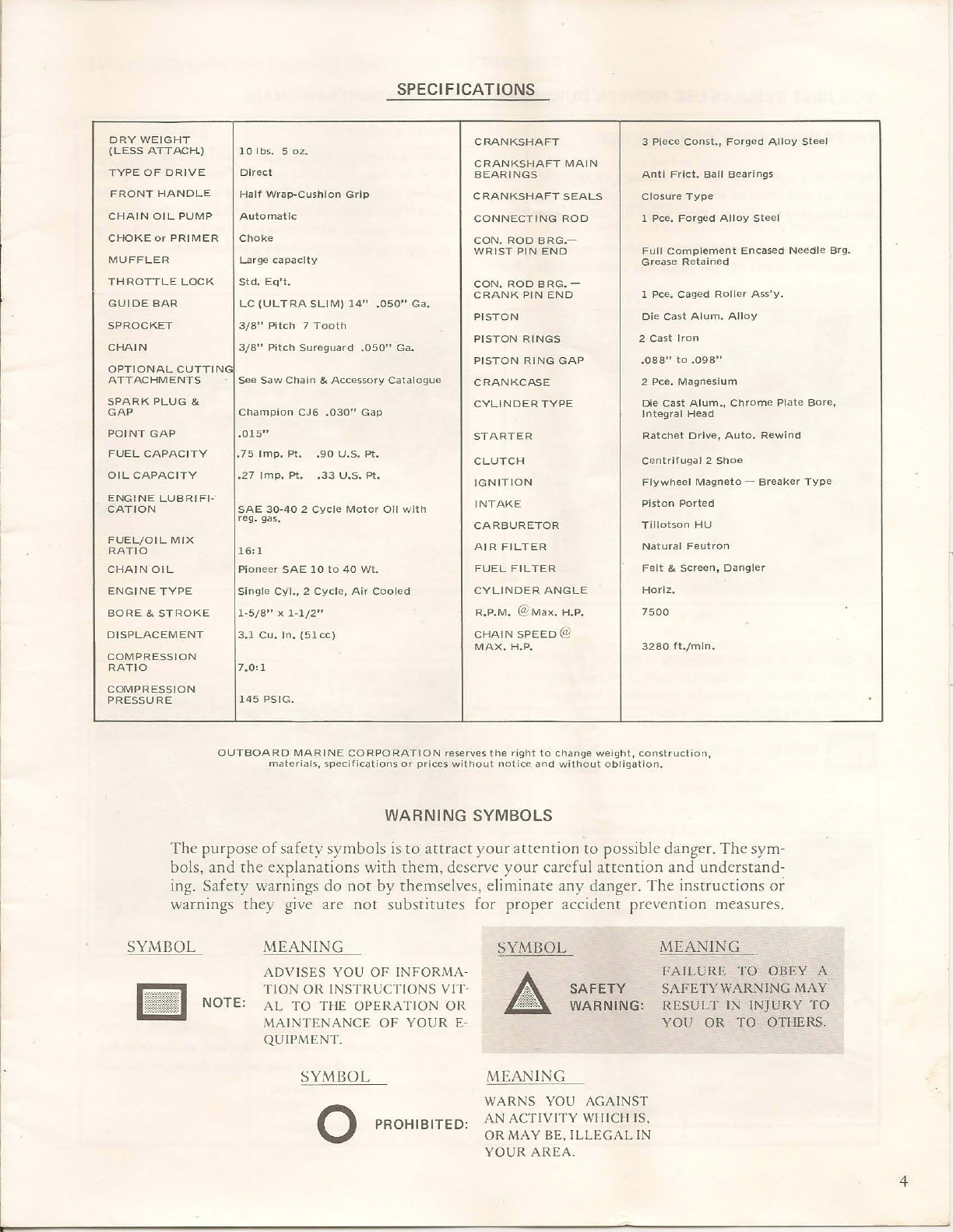

Specifications.

Warning Symbols

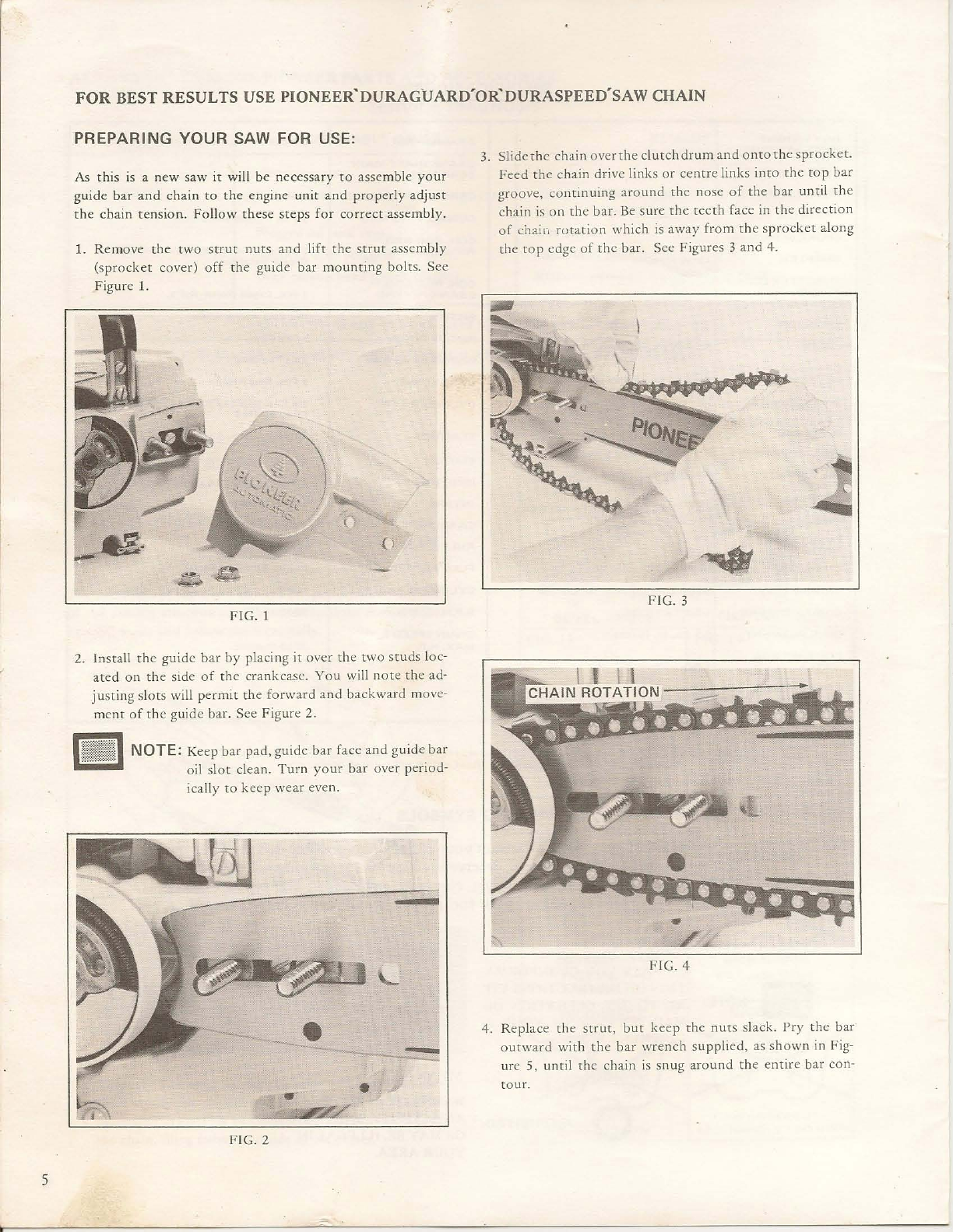

Preparing

Your

Saw

Fo

r

Use

Fuel & Lubrication

Chain

Lubrication.

Starting Instructions

3

3

3

4

4

5

&6

6

6

7

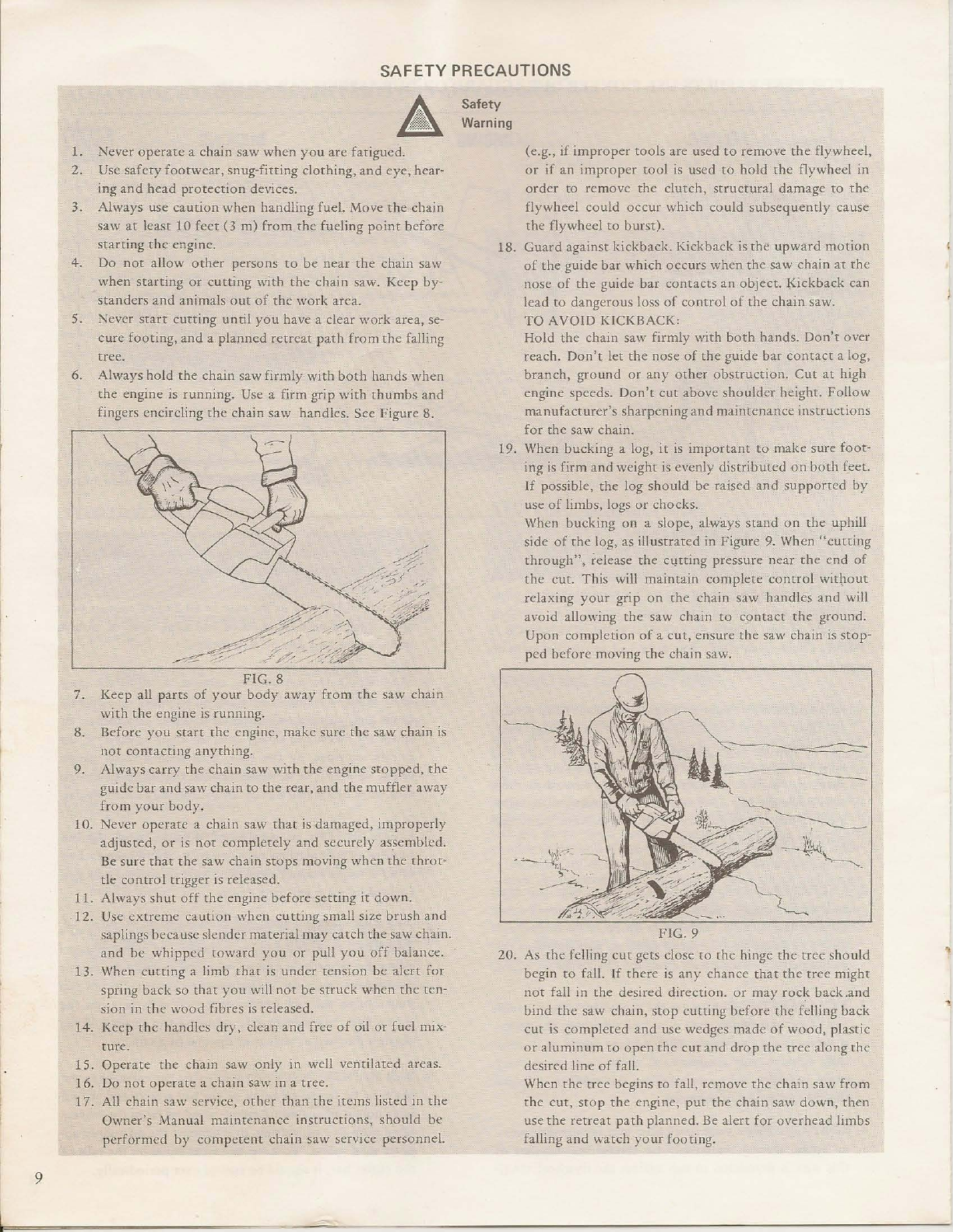

Safety

Precautions.

Service Diagnosis.

Filing Instructions

Sharpening

Cutters.

Chain Diagnosis. . . . . . . . .

Common

Problems

Found

With

10&11

11

11&12

..

12

Cutters &

Links.

..

.....

13

Warranty.

. . . . . . . .

..

(Back

Cover)

FOREWORD

This operators manual has been prepared

to

assist

you

in

the

proper

operation

and mainte

nance

of

your

n

ew

Pioneer Chain Saw.

It

coinains

information

that

you

should

know

in

order

to

realize

peak performance. Please read this e

ntir

e

book

carefully, and keep it

handy

for

iuture

reference.

For

service, always

contact

your

local

authorized

Pioneer dealers. Specify

your

complete model

numb

e

r.

SERVICING PROCEDURES

MANUAL

'A

se

rvicing procedures manual

is

written primarily for the service technician with prior chain saw

training and who

is

equipped with the proper tools. Although limited

in

use to the average individ-

ual, this publication

is

available for purchase. If

you

wish to purchase a pr9cedures manual, please

send cheque

or

money

order

for 50 cents to

Outboard

Marine

Corporation,

739

Monaghan' Road,

Peterborough, Ontario, Canada. In

the

U.S.

A.

order from PioneerChain Saws,

900

North

21 Street,

Lincoln, Nebraska. Sorry NO C.O.D. shipments will be made.

To

assure receiving the correct man-

ual, state full model

number

and

quote

part

no.

430141.

All repairs should be carried

out

by

your

authorized

Pioneer Dealer during

your

warranty period.