PREP RING YOUR CH JN S W FOR USE

It will be necessary to assemble the pivot grip, cutter bar and chain to the moto-r

unit and properly adjust the chain tension.

1. Remove the strut assembly and outer and inner guide plates from the motor unit

figure 3).

2. Secure the pivot grip to the motor unit figure 3).

3. Place the inner guide plate and cutter bar on the motor unit engaging them on the

two mounting studs.

4. Assemble the chain to the sprocket and cutter bar making sure that the cutting

teeth direction is correct figure 4).

5. Replace the outer guide plate and strut assembly, but do not tighten permanently.

The chain adjusting pin must engage into the cutter bar slot.

6. Tighten chain, using the adjusting screw figure 4). Then back off until the chain

can be pulled freely around the bar by hand figure 5). CAUTION - Use gloves

or cloth to protect your hands.

7. Secure the two hexagonal nuts attaching the strut assembly and cutter bar to the

motor unit. Lift bar tip slightly to insure correct seating.

FUEL ND LUBRIC TION

Lubrication of internal moving parts of your chain saw motor is solely supplied by oil

which is mixed with gasoline. Therefore it is very important to prepare your fuel

mixture properly. Mix one part of SAE: 40 motor oil to 16 parts of regular gasoline:

or use a ratio of 1 pint of oil to 2 gallons of regular gasoline. MIXING PRO-

CEDURE: Pour into a clean metal container half the amount of gasoline to be mixed,

and add all the required oil. Shake or stir until thoroughly mixed. Then add balance

of gasoline and shake or stir to insure mixing. DO NOT MIX DIRECTLY IN CHAIN

SAW FUEL TANK. Strain fuel mixture through a fine mesh screen when pouring into

fuel tank, to eliminate any water or foreign particles.

CH IN OILER

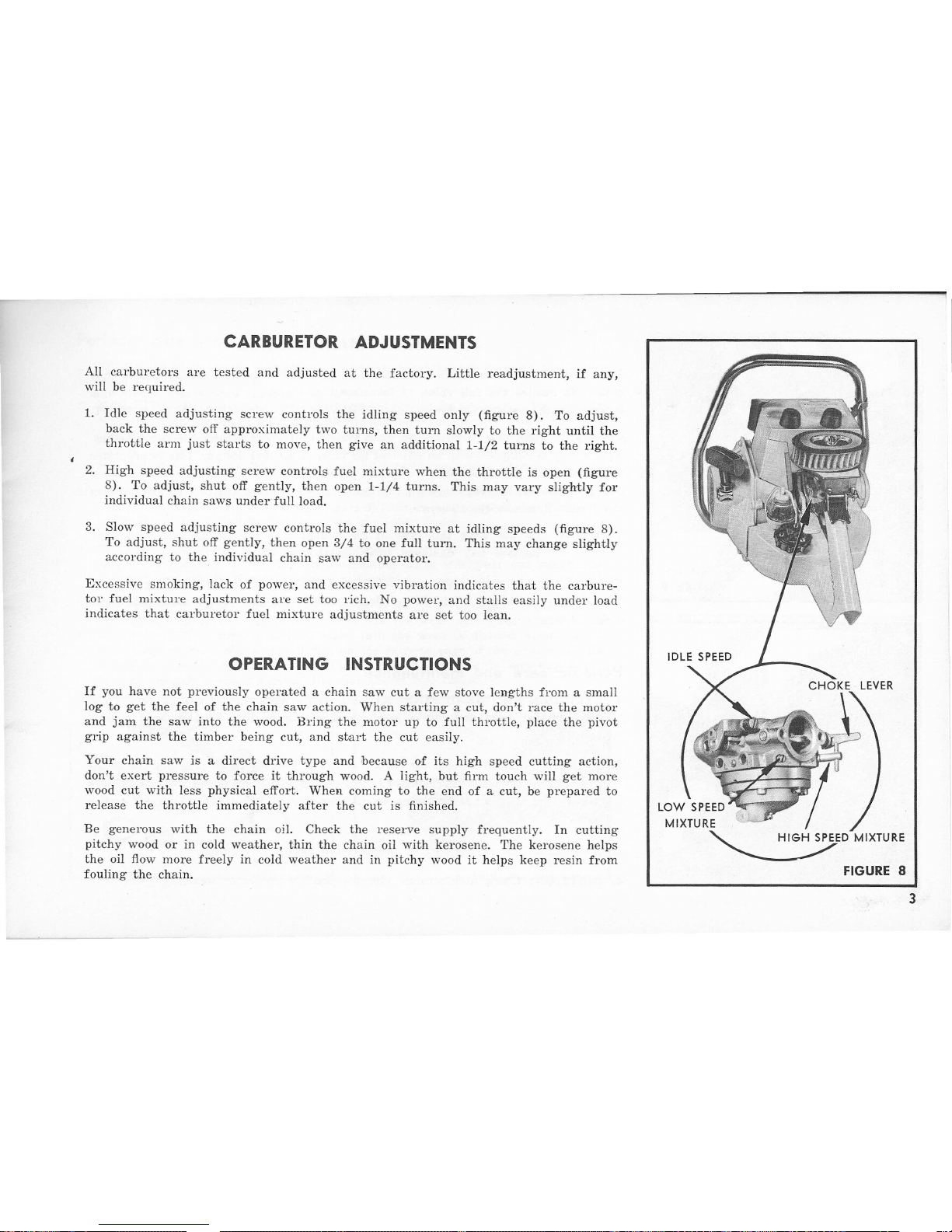

Lubrication of the cutting chain is essential to minimize pitch fouling, wear and fric-

tion power loss. This is done through the chain oiler figure 1) which is manually

controlled, drawing its oil supply from a separate reservoir located at the cutting end

of the motor unit. Good clean oil is a must. SAE 10 or 20 is recommended but

because of locality, season and the timber being cut the weight of oil is variable,

We recommend a penetrating oil with a tacky quality.

INNER GUIDE

PL TE