Guidelines & Information (fs RS_st) Annex Page 2

• Insure that Age Appropriate and Hard Surface Warning/Playworld Systems

identification labels are properly affixed to the play equipment. Labels are to be

plainly visible according to current playground equipment guidelines.

• IMPORTANT! Because accidental falls around your playground equipment

can occur, Playworld Systems recommends that the area under and around the

structure be covered with a resilient material such as sand, bark mulch, or wood

chips. If loose fill surfacing materials are used, Playworld Systems recommends

a depth of 12 in. (305 mm). An approved rubber safety matting can also be

used. Many protective surfacing materials can become compacted due

to weather and use, which reduces their shock absorbency. It is strongly

recommended that the surfacing be checked weekly and material added

or replaced as necessary. Hard surfaces, such as asphalt, concrete and

packed earth are not acceptable for use under playground equipment.

• The entire area, under and around the playground equipment, must be

covered with protective surfacing material. The impact attenuation of the

protective surfacing under and around playground equipment should be rated to

have a critical height value of at least the height of the highest accessible part

of the equipment. The critical height for surfacing is to be rated in accordance

with A.S.T.M. standard, designated F1292, A Standard Specification for Impact

Attenuation of Surface Systems Under and Around Playground Equipment.

Contact the manufacturer of unitary surfacing materials (rubber matting) for the

critical height rating for their products.

Tools Required: Playworld Systemssupplies aservice kitthatcontains commonly

used hex key wrenches required to assemble your equipment. You may also

need:shovel, digging iron, post hole digger, steel rake,wheelbarrow,gardenhoe,

water hose, tape measure, level, alignment tool, 3/8" ratchet with 9/16" socket,

and 9/16" combination wrench.

Maintenance

• Inadequate maintenance of equipment has resulted in injuries on the

playground. Becausethe safetyof playgroundequipment andits stabilitydepends

ongood inspection andmaintenance, a comprehensive maintenance program

must be developed for each playground and strictly followed. All equipment

must be inspected frequently for any potential hazards. Special attention must

to be given to moving parts and other components that can be expected to wear.

Inspections must to be carried out in a systematic manner by trained personnel.

Any damaged or worn parts, or any other hazards identified during inspections

must be repaired or replaced immediately. Complete documentation of all

maintenance inspections and repairs must be retained.

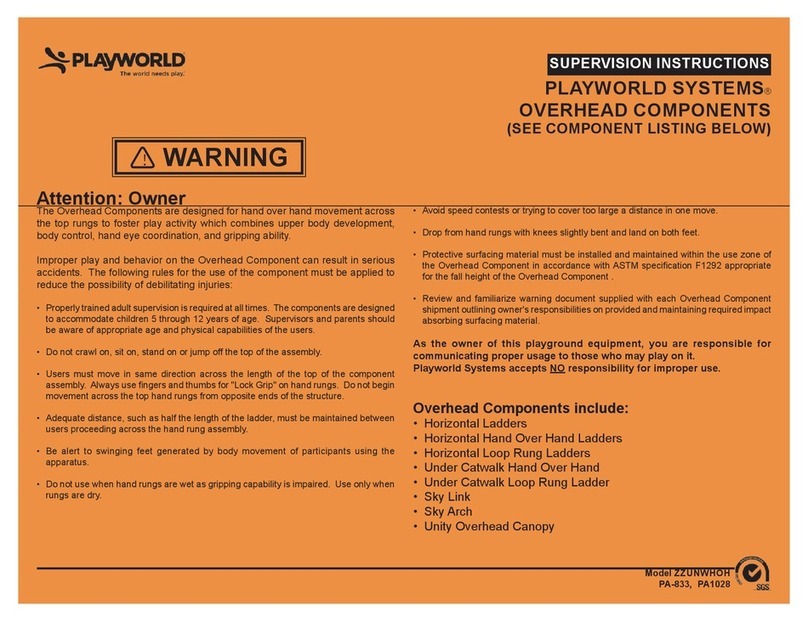

Supervision Guidelines

• PlayworldSystems strongly recommendsclose supervision ofthe children as

theyplay aswell as intensiveclassroom and home instruction aboutsafe behavior

on playground equipment.

• Playgroundsupervisors should be aware that not allplayground equipment is

appropriate for all children who may use the playground. Signs should be posted

near the equipment indicating the recommended age of the users. Supervisors

should direct children to equipment appropriate for their age.

• It is important that playground supervisors recognize that preschool-age

children require more attentive supervision on playgrounds than older children.

• Do not permit the use of wet playground equipment. Wet equipment will

inhibit necessary traction and gripping capabilities. Slips or falls could occur.

• Do not permit too many children on the same piece of equipment at the same

time. It is suggested that children take turns.

• Constantly observe play patterns to discover possible hazardous play and

suggest changes in equipment use or play patterns.