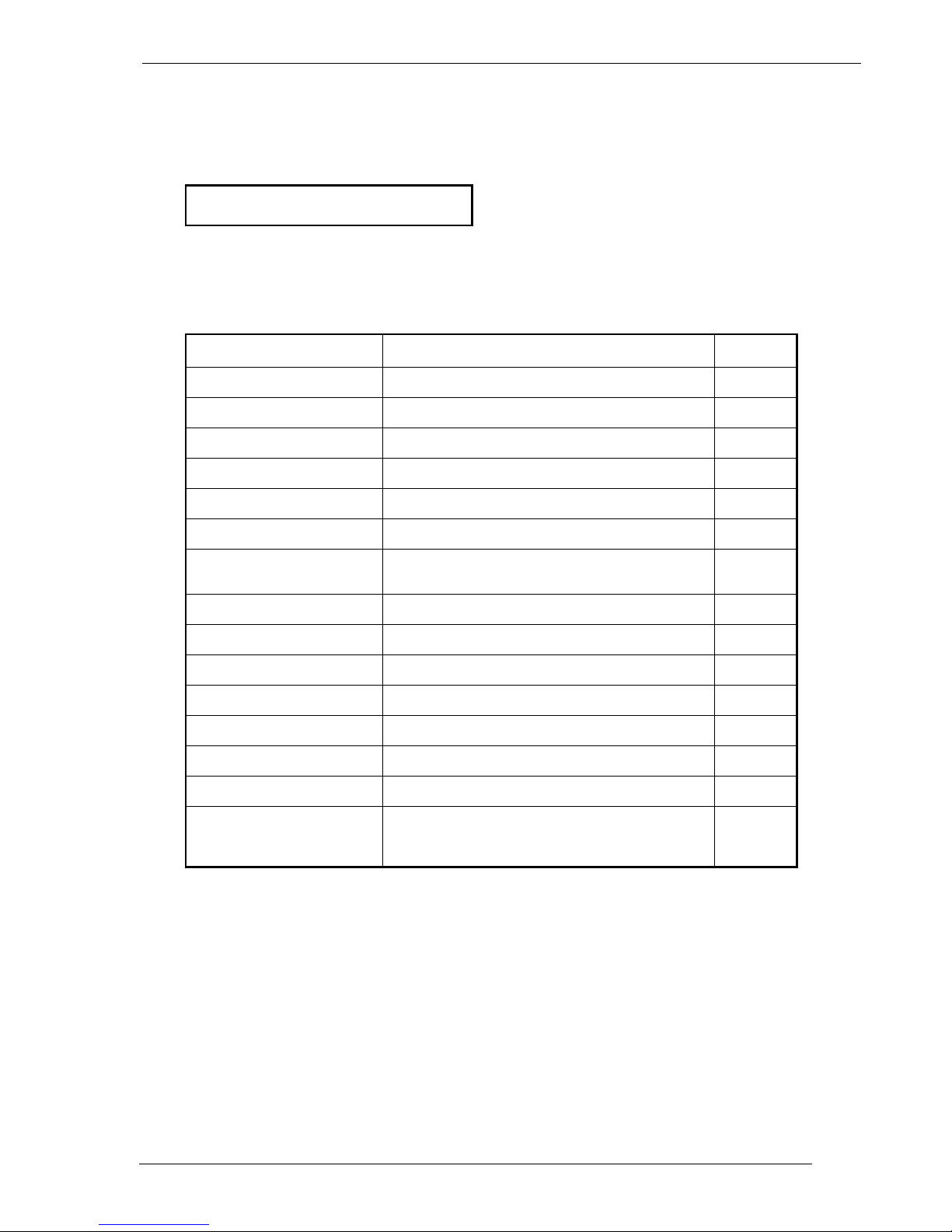

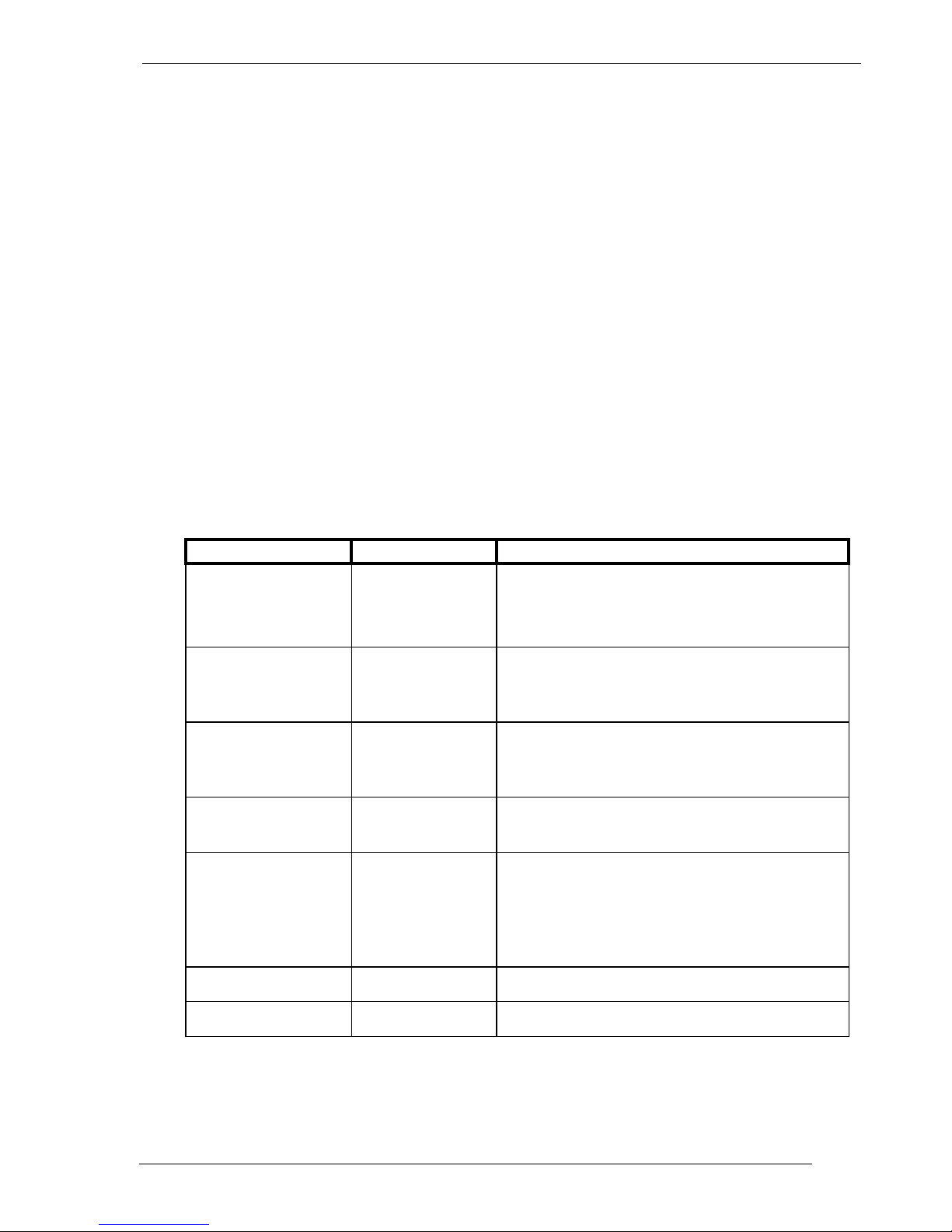

2. Description of the parameters

The parameters shown in bold correspond to the basic factory settings of the control

units.

2.1 Machine type

This setting allows the adjustment of the control system to the different machine sizes.

Selection: ; Spirit 55: 5.5 kg- MFH; Spirit 65: 6.5 kg shared dwelling

- Washing and spin speeds

- Motor / drum transmission ratio

- Parameters for load measurement

- Water levels, water quantities

- Monitoring times for heating period, water intake and water drainage

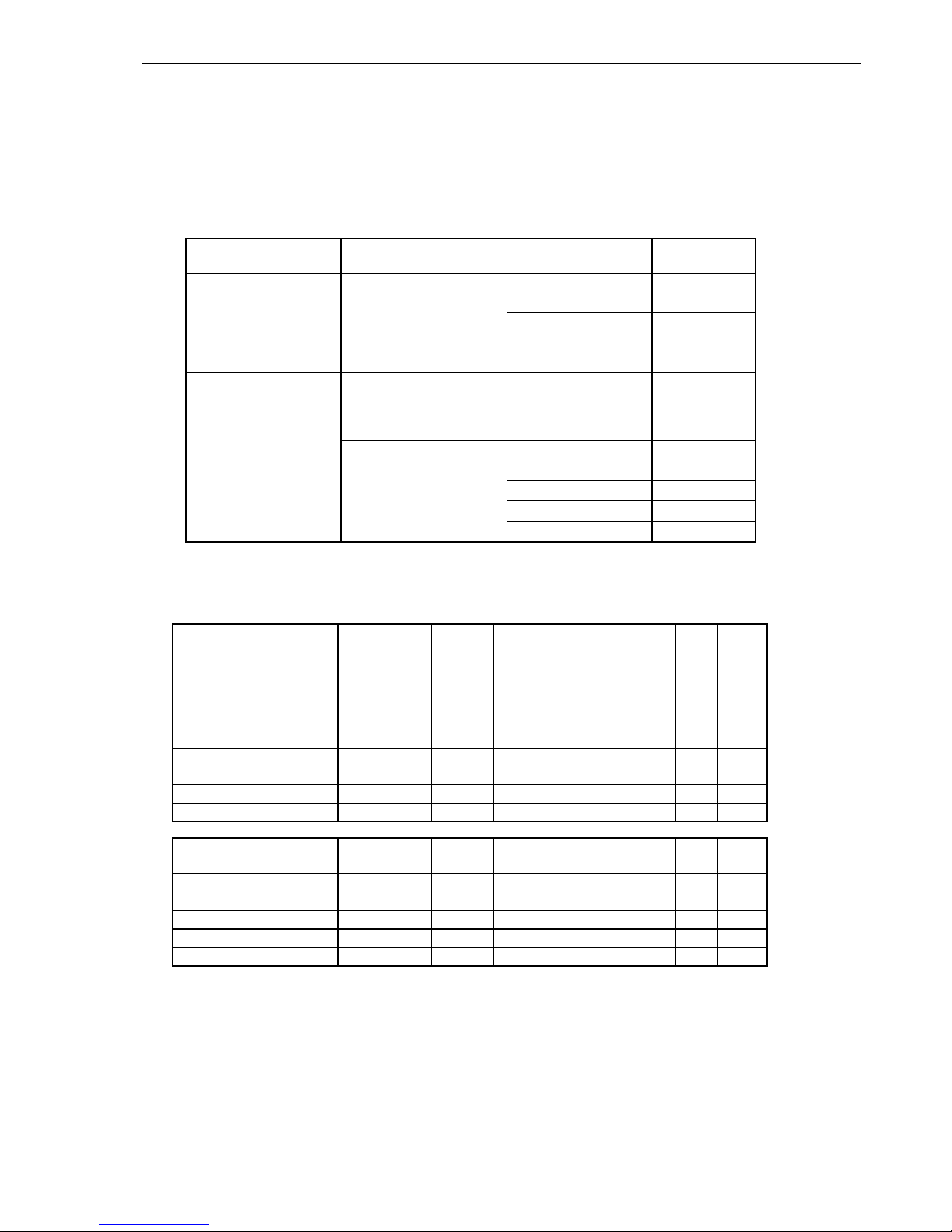

2.2 Operating concept

This setting allows the adjustment of the control system to the various user screens.

The interface variants are numbered from “UI-TAB-00 ÷ 09”. The screen variants for

the

different machine types are shown on Page ... .

The setting of the operating variant also defines the available wash programmes and

the maximum spin speeds.

For the Topline Export machines, only the UI-TAB-08 and UI-TAB-09 variants are

compatible with the user screens.

2.3 Welcome text

The chosen text with the company logo appears when the washing machine is

switched on at the mains.

Selection: SCHULTHESS; MERKER; FUST; NEUTRAL (off)

2.4 Soaking / hygiene function

This setting enables the user to access these functions with the extended basic set-

tings (see p. 4).

Selection: NONE; SOAKING; HYGIENE FUNCTION; SOAKING + HYGIENE FUNCT.

The hygiene function is not described for the export machines.

2.5 Temperature limit

This setting limits the washing temperature to 87°C , regardless of the programmed

Temperature (machines in higher locations with lower boiling temperatures).

The display of the temperature deselection is not affected by this setting. (95 ⇒80)

Selection: NONE; ON

2.6 Specify spin speed

This setting determines the maximum spin speed of the machine. In addition to this

setting, the maximum spin speed is determined by the setting of the operating concept

(see Section 2.2).

Selection: 800 ; 900 ÷1400