Portland 64497 User manual

!"#$%&'(&)*&+,-./01

2"3$45&#$647'(&7#&)*$6737$%&"(%&

#9':;%&('4&69"(<$=&$>6$84&?9$@$&('4$%A&&

B%%747'(";&?"@(7(<#&6"(&C$&"%%$%&4'&

D9"7(&2"?&2"3$45&E"@(7(<#&'(&8"<$&

.&"34$@&)*&@$F:7@$%&?"@(7(<#&G8@'%:64&

#8$67376&?"@(7(<#&'(&8"#4$C'"@%HA

I7#74&':@&?$C#74$&"4J&9448JKK???A9"@C'@3@$7<94A6'L

ML"7;&':@&4$69(76";&#:88'@4&"4J&8@'%:64#:88'@4N9"@C'@3@$7<94A6'L

Owner’s Manual & Safety Instructions

Save This Manual Keep this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the

back of the manual near the assembly diagram (or month and year of purchase if product has no number).

Keep this manual and the receipt in a safe and dry place for future reference. 20i

When unpacking, make sure that the product is intact

and undamaged. If any parts are missing or broken,

please call 1-888-866-5797 as soon as possible.

Copyright© 2020 by Harbor Freight Tools®. All rights reserved.

No portion of this manual or any artwork contained herein may be reproduced in

any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein.

Tools required for assembly a nd service may not be i ncluded.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Page 2 O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-A Item 64497

2BOMRS TUMVBRWTX YBWXRMXBXDM2MR)U

R"C;$&'3&D'(4$(4#

Safety ......................................................... 2

Specifications ............................................. 8

Setup .......................................................... 8

Operation ................................................... 11

Maintenance .............................................. 16

Parts List and Diagram .............................. 18

Warranty .................................................... 20

EBVXWXZ&2SY!T*2&BX[&[MOWXWRWTX2

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

WYUTVRBXR&2BOMRS&WXOTVYBRWTX

Z$($@";&U'?$@&R'';&2"3$45&E"@(7(<#

V$"%&";;&#"3$45&?"@(7(<#&"(%&";;&7(#4@:647'(#A&&

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

2"\$&";;&?"@(7(<#&"(%&7(#4@:647'(#&3'@&3:4:@$&@$3$@$(6$A

The term ″power tool″ in the warnings refers to your mains-operated (corded) power tool.

E'@]&B@$"&2"3$45

1. ^$$8&?'@]&"@$"&6;$"(&"(%&?$;;&;74A&&

Cluttered or dark areas invite accidents.

2. ['&('4&'8$@"4$&8'?$@&4'';#&7(&$>8;'#7\$&

"4L'#89$@$#=&#:69&"#&7(&49$&8@$#$(6$&'3&

3;"LL"C;$&;7F:7%#=&<"#$#&'@&%:#4A Power tools

create sparks which may ignite the dust or fumes.

3. ^$$8&697;%@$(&"(%&C5#4"(%$@#&

"?"5&?97;$&'8$@"47(<&"&8'?$@&4'';A

Distractions can cause you to lose control.

Page 3O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-AItem 64497

2BOMRSTUMVBRWTXYBWXRMXBXDM 2MR)U

M;$64@76";&2"3$45

1. U'?$@&4'';&8;:<#&L:#4&L"469&49$&':4;$4A&&

X$\$@&L'%735&49$&8;:<&7(&"(5&?"5A&&

['&('4&:#$&"(5&"%"84$@&8;:<#&?749&<@':(%$%&

8'?$@&4'';#A Unmodified plugs and matching

outlets will reduce risk of electric shock.

2. B\'7%&C'%5&6'(4"64&?749&<@':(%$%&#:@3"6$#&

#:69&"#&878$#=&@"%7"4'@#=&@"(<$#&"(%&

@$3@7<$@"4'@#A& There is an increased risk of

electric shock if your body is grounded.

3. ['&('4&$>8'#$&8'?$@&4'';#&4'&@"7(&'@&?$4&

6'(%747'(#A Water entering a power tool

will increase the risk of electric shock.

4. ['&('4&"C:#$&49$&6'@%A&&X$\$@&:#$&49$&6'@%&

3'@&6"@@57(<=&8:;;7(<&'@&:(8;:<<7(<&49$&

8'?$@&4'';A&&^$$8&6'@%&"?"5&3@'L&9$"4=&'7;=&

#9"@8&$%<$#&'@&L'\7(<&8"@4#A&&Damaged or

entangled cords increase the risk of electric shock.

5. E9$(&'8$@"47(<&"&8'?$@&4'';&':4%''@#=&

:#$&"(&$>4$(#7'(&6'@%&#:74"C;$&3'@&

':4%''@&:#$A Use of a cord suitable for outdoor

use reduces the risk of electric shock.

6. W3&'8$@"47(<&"&8'?$@&4'';&7(&"&%"L8&;'6"47'(&

7#&:("\'7%"C;$=&:#$&"&Z@':(%&O":;4&D7@6:74&

W(4$@@:84$@&GZODWH&8@'4$64$%&#:88;5A

Use of a GFCI reduces the risk of electric shock.

U$@#'(";&2"3$45

1. 24"5&";$@4=&?"469&?9"4&5':&"@$&%'7(<&

"(%&:#$&6'LL'(&#$(#$&?9$(&'8$@"47(<&

"&8'?$@&4'';A&&['&('4&:#$&"&8'?$@&

4'';&?97;$&5':&"@$&47@$%&'@&:(%$@&49$&

7(3;:$(6$&'3&%@:<#=&";6'9';&'@&L$%76"47'(A

A moment of inattention while operating power

tools may result in serious personal injury.

2. )#$&8$@#'(";&8@'4$647\$&$F:78L$(4A&&

B;?"5#&?$"@&$5$&8@'4$647'(A Protective

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

3. U@$\$(4&:(7(4$(47'(";"@47(<A&

M(#:@$&49$&R@7<<$@&7#&7(&49$&'3308'#747'(&C$3'@$&

6'(($647(<&4'&8'?$@&#':@6$=&876]7(<&:8&'@&

6"@@57(<&49$&4'';A

Carrying power tools with your finger on

the Trigger or energizing power tools that

have the Trigger on invites accidents.

4. ['&('4&'\$@@$"69A&&^$$8&8@'8$@&3''47(<&"(%&

C";"(6$&"4&";;&47L$#A This enables better control

of the power tool in unexpected situations.

5. [@$##&8@'8$@;5A&&['&('4&?$"@&;''#$&6;'497(<&'@&

_$?$;@5A&&^$$8&5':@&9"7@=&6;'497(<&"(%&<;'\$#&

"?"5&3@'L&L'\7(<&8"@4#A Loose clothes, jewelry

or long hair can be caught in moving parts.

6. W3&%$\76$#&"@$&8@'\7%$%&3'@&49$&6'(($647'(&'3&

%:#4&$>4@"647'(&"(%&6';;$647'(&3"67;747$#=&$(#:@$&

49$#$&"@$&6'(($64$%&"(%&8@'8$@;5&:#$%A Use of

dust collection can reduce dust-related hazards.

7. T(;5&:#$&#"3$45&$F:78L$(4&49"4&9"#&C$$(&

"88@'\$%&C5&"(&"88@'8@7"4$"(%"@%#&"<$(65A

Unapproved safety equipment may not provide

adequate protection. Eye protection must be

ANSI-approved and breathing protection

must be NIOSH-approved for the

specific hazards in the work area.

U'?$@&R'';&)#$&"(%&D"@$

1. ['&('4&3'@6$&49$&8'?$@&4'';A&&)#$&49$&

6'@@$64&8'?$@&4'';&3'@&5':@&"88;76"47'(A

The correct power tool will do the job better and

safer at the rate for which it was designed.

2. ['&('4&:#$&49$&8'?$@&4'';&73&49$&R@7<<$@&&

%'$#&('4&4:@(&74&'(&"(%&'33A

Any power tool that cannot be controlled with the

Trigger is dangerous and must be repaired.

3. [7#6'(($64&49$&8;:<&3@'L&49$&8'?$@&#':@6$&

C$3'@$&L"]7(<&"(5&"%_:#4L$(4#=&69"(<7(<&

"66$##'@7$#=&'@'@7(<&8'?$@&4'';#A

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

4. 24'@$&7%;$&8'?$@&4'';#&':4&'3&49$&@$"69&'3&

697;%@$(&"(%&%'&('4&";;'?&8$@#'(#&:(3"L7;7"@&

?749&49$&8'?$@&4'';&'@&49$#$&7(#4@:647'(#&

4'&'8$@"4$&49$&8'?$@&4'';A Power tools are

dangerous in the hands of untrained users.

5. Y"7(4"7(&8'?$@&4'';#A&&D9$6]&3'@&L7#";7<(L$(4&

'@&C7(%7(<&'3&L'\7(<&8"@4#=&C@$"]"<$&'3&8"@4#&

"(%&"(5&'49$@&6'(%747'(&49"4&L"5&"33$64&49$&

8'?$@&4'';`#&'8$@"47'(A&&W3&%"L"<$%=&9"\$&49$&

8'?$@&4'';&@$8"7@$%&C$3'@$&:#$A Many accidents

are caused by poorly maintained power tools.

Page 4 O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-A Item 64497

2BOMRS TUMVBRWTX YBWXRMXBXDM2MR)U

6. ^$$8&6:447(<&4'';#	"@8&"(%&6;$"(A Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7. )#$&49$&8'?$@&4'';=&"66$##'@7$#&"(%&4'';&C74#&

$46A&7(&"66'@%"(6$&?749&49$#$&7(#4@:647'(#=&

4"]7(<&7(4'&"66':(4&49$&?'@]7(<&6'(%747'(#&

"(%&49$&?'@]&4'&C$&8$@3'@L$%A Use of the

power tool for operations different from those

intended could result in a hazardous situation.

2$@\76$

a"\$&5':@&8'?$@&4'';&#$@\76$%&C5&"&F:";737$%&@$8"7@&8$@#'(&:#7(<&'(;5&7%$(476";&@$8;"6$L$(4&8"@4#A&

This will ensure that the safety of the power tool is maintained.

D9"7(&2"?&2"3$45&E"@(7(<#

1. ^$$8&";;&8"@4#&'3&49$&C'%5&"?"5&3@'L&49$&

#"?&69"7(&?9$(&49$&69"7(&#"?&7#&'8$@"47(<A&&

!$3'@$&5':"@4&49$&69"7(&#"?=&L"]$&#:@$&

49$&#"?&69"7(&7#&('4&6'(4"647(<&"(5497(<A

A moment of inattention while operating

chain saws may cause entanglement of your

clothing or body with the saw chain.

2. B;?"5#&9';%&49$&69"7(&#"?&?749&5':@&@7<94&

9"(%&'(&49$&@$"@&9"(%;$&"(%&5':@&;$34&9"(%&'(&

49$&3@'(4&9"(%;$A Holding the chain saw with a

reversed hand configuration increases the risk

of personal injury and should never be done.

3. a';%&49$&8'?$@&4'';&C5&7(#:;"4$%&<@7887(<&

#:@3"6$#&'(;5=&C$6":#$&49$&#"?&69"7(&L"5&

6'(4"64&97%%$(&?7@7(<&'@&74#&'?(&6'@%A

Saw chains contacting a “live” wire may make

exposed metal parts of the power tool “live” and

could give the operator an electric shock.

4. E$"@&#"3$45&<;"##$#&"(%&9$"@7(<&8@'4$647'(A&

O:@49$@&8@'4$647\$&$F:78L$(4&3'@&9$"%=&

9"(%#=&;$<#&"(%&3$$4&7#&@$6'LL$(%$%A

Adequate protective clothing will reduce

personal injury by flying debris or

accidental contact with the saw chain.

5. ['&('4&'8$@"4$&"&69"7(&#"?&7(&"&4@$$A

Operation of a chain saw while up in a

tree may result in personal injury.

6. B;?"5#&]$$8&8@'8$@&3''47(<&"(%&'8$@"4$&

49$&69"7(&#"?&'(;5&?9$("(%7(<&'(&37>$%=&

#$6:@$&"(%&;$\$;&#:@3"6$A Slippery or unstable

surfaces such as ladders may cause a loss

of balance or control of the chain saw.

7. E9$(&6:447(<&"&;7LC&49"4&7#&:(%$@&4$(#7'(&

C$&";$@4&3'@@7(<&C"6]A When the tension

in the wood fibres is released the spring

loaded limb may strike the operator and/

or throw the chain saw out of control.

8. )#$&$>4@$L$&6":47'(&?9$(&6:447(<&

C@:#9&"(%&#"8;7(<#A The slender material

may catch the saw chain and be whipped

toward you or pull you off balance.

9. D"@@5&49$&69"7(&#"?&C5&49$&3@'(4&9"(%;$&?749&

49$&69"7(&#"?&#?7469$%&'33&"(%&"?"5&3@'L&5':@&

C'%5A&E9$(&4@"(#8'@47(<&'@'@7(<&49$&69"7(&

#"?&";?"5#&374&49$&<:7%$&C"@&6'\$@A Proper

handling of the chain saw will reduce the likelihood

of accidental contact with the moving saw chain.

10. O';;'?&7(#4@:647'(#&3'@&;:C@76"47(<=&69"7(&

4$(#7'(7(<&"(%&69"(<7(<&"66$##'@7$#A

Improperly tensioned or lubricated chain may

either break or increase the chance for kickback.

11. ^$$8&9"(%;$#&%@5=&6;$"(=&"(%&3@$$&3@'L&

'7;&"(%&<@$"#$A Greasy, oily handles

are slippery causing loss of control.

12. D:4&?''%&'(;5A&['&('4&:#$&69"7(&#"?&3'@&

8:@8'#$#&('4&7(4$(%$%A&&

O'@&$>"L8;$J&%'&('4&:#$&69"7(&#"?&3'@&6:447(<&

8;"#476=&L"#'(@5&'@&('(0?''%&C:7;%7(<&L"4$@7";#A

Use of the chain saw for operations different than

intended could result in a hazardous situation.

13. D":#$#&"(%&'8$@"4'@&8@$\$(47'(&'3&]76]C"6]J

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause

a sudden reverse reaction, kicking the

guide bar up and back towards the operator.

Pinching the saw chain along the

top of the guide bar may push the guide

bar rapidly back towards the operator.

Page 5O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-AItem 64497

2BOMRSTUMVBRWTXYBWXRMXBXDM 2MR)U

Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury. Do not rely exclusively upon the

safety devices built into your saw. As a chain saw

user, you should take several steps to keep

your cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below:

a. Y"7(4"7(&"&37@L&<@78=&?749&49:LC#&"(%&

37(<$@#&$(67@6;7(<&49$&69"7(&#"?&9"(%;$#=&

?749&C'49&9"(%#&'(&49$&#"?&"(%&8'#747'(&

5':@&C'%5&"(%&"@L&4'&";;'?&5':&4'&@$#7#4&

]76]C"6]&3'@6$#A Kickback forces can be

controlled by the operator, if proper precautions

are taken. Do not let go of the chain saw.

)#$&497#&<@78&

49:LC&C$;'?&

9"(%;$

O7<:@$&BJ&&a';%7(<&49$&D9"7(&2"?

b. ['&('4&'\$@@$"69&"(%&%'&('4&6:4&"C'\$&

#9':;%$@&9$7<94A This helps prevent

unintended tip contact and enables better control

of the chain saw in unexpected situations.

c. T(;5&:#$&@$8;"6$L$(4&C"@#&"(%&

69"7(#$6737$%&C5&49$&L"(:3"64:@$@A

Incorrect replacement bars and chains may

cause chain breakage and/or kickback.

d. O';;'?&49$&L"(:3"64:@$@`#	"@8$(7(<&"(%&

L"7(4$("(6$&7(#4@:647'(#&3'@&49$&#"?&69"7(A

Decreasing the depth gauge height

can lead to increased kickback.

14. Maintain labels and nameplates on the tool.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

15. Avoid unintentional starting.

Prepare to begin work before turning on the tool.

16. Do not leave the tool unattended when it is plugged

into an electrical outlet. Turn off the tool, and

unplug it from its electrical outlet before leaving.

17. This product is not a toy.

Keep it out of reach of children.

18. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with Trigger locked on.

• Properly maintain and inspect to avoid

electrical shock.

• Properly ground power cord. Ground Fault Circuit

Interrupter (GFCI) should also be implemented

– it prevents sustained electrical shock.

19. The warnings, precautions, and instructions

discussed in this instruction manual cannot cover all

possible conditions and situations that may occur.

It must be understood by the operator that

common sense and caution are factors

which cannot be built into this product,

but must be supplied by the operator.

&2BIM&RaM2M&WX2RV)DRWTX2A

Page 6 O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-A Item 64497

2BOMRS TUMVBRWTX YBWXRMXBXDM2MR)U

Z@':(%7(<

RT&UVMIMXR&M*MDRVWD&2aTD^&BX[&[MBRa&OVTY&

WXDTVVMDR&ZVT)X[WXZ&EWVM&DTXXMDRWTXJ&

D9$6]&?749&"&F:";737$%&$;$64@767"(&73&5':&"@$&7(&%':C4&"#&4'&?9$49$@&49$&':4;$4&7#&8@'8$@;5&

<@':(%$%A&&['&('4&L'%735&49$&8'?$@&6'@%&8;:<&8@'\7%$%&?749&49$&4'';A&&X$\$@&@$L'\$&49$&

<@':(%7(<&8@'(<&3@'L&49$&8;:<A&&['&('4&:#$&49$&4'';&73&49$&8'?$@&6'@%&'@&8;:<&7#&%"L"<$%A&&W3&%"L"<$%=&9"\$&

74&@$8"7@$%&C5&"&#$@\76$&3"67;745&C$3'@$&:#$A&&W3&49$&8;:<&?7;;&('4&374&49$&':4;$4=&9"\$&"&8@'8$@&':4;$4&7(#4";;$%&C5&

"&F:";737$%&$;$64@767"(A

Z@':(%$%&R'';#J&R'';#&?749&R9@$$&U@'(<&U;:<#

b0U@'(<&U;:<&"(%&T:4;$4

1. Tools marked with “Grounding Required” have

a three wire cord and three prong grounding

plug. The plug must be connected to a properly

grounded outlet. If the tool should electrically

malfunction or break down, grounding provides

a low resistance path to carry electricity away

from the user, reducing the risk of electric shock.

G2$$&b0U@'(<&U;:<&"(%&T:4;$4AH

2. The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire

in the cord must be the only wire connected to

the tool’s grounding system and must never

be attached to an electrically “live” terminal.

G2$$&b0U@'(<&U;:<&"(%&T:4;$4AH

3. The tool must be plugged into an appropriate outlet,

properly installed and grounded in accordance

with all codes and ordinances. The plug and outlet

should look like those in the preceding illustration.

G2$$&b0U@'(<&U;:<&"(%&T:4;$4AH

[':C;$&W(#:;"4$%&R'';#J&R'';#&?749&R?'&U@'(<&U;:<#

T:4;$4#&3'@&c0U@'(<&U;:<

1. Tools marked “Double Insulated” do not

require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with

the applicable standards of Underwriters

Laboratories, Inc., the Canadian Standard

Association, and the National Electrical Code.

2. Double insulated tools may be used in either of the

120 volt outlets shown in the preceding illustration.&&&

G2$$&T:4;$4#&3'@&c0U@'(<&U;:<AH

Page 7O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-AItem 64497

2BOMRSTUMVBRWTXYBWXRMXBXDM 2MR)U

M>4$(#7'(&D'@%#

1. Grounded tools require a three wire extension cord.

Double Insulated tools can use either

a two or three wire extension cord.

2. As the distance from the supply outlet increases,

you must use a heavier gauge extension cord.

Using extension cords with inadequately sized wire

causes a serious drop in voltage, resulting in loss of

power and possible tool damage. G2$$&R"C;$&BAH

3. The smaller the gauge number of the wire, the

greater the capacity of the cord. For example,

a 14 gauge cord can carry a higher current

than a 16 gauge cord. G2$$&R"C;$&BAH

4. When using more than one extension cord

to make up the total length, make sure

each cord contains at least the minimum

wire size required. G2$$&R"C;$&BAH

5. If you are using one extension cord for more

than one tool, add the nameplate&eres

and use the sum to determine the required

minimum cord size. G2$$&R"C;$&BAH

6. If you are using an extension cord outdoors, make

sure it is marked with the suffix “W-A” (“W” in

Canada) to indicate it is acceptable for outdoor use.

7. Make sure the extension cord is properly wired

and in good electrical condition. Always replace

a damaged extension cord or have it repaired

by a qualified electrician before using it.

8. Protect the extension cords from sharp objects,

excessive heat, and damp or wet areas.

RB!*M&BJ&&VMDTYYMX[M[&YWXWY)Y&EWVM&

ZB)ZM&OTV&MdRMX2WTX&DTV[2e&G1c,Kc.,&IT*RH

XBYMU*BRM

BYUMVM2

G"4&3:;;&;'"%H

MdRMX2WTX&DTV[&

*MXZRa

c/f /,f -/f 1,,f 1/,f

0 – 2.0 18 18 18 18 16

2.1 – 3.4 18 18 18 16 14

3.5 – 5.0 18 18 16 14 12

5.1 – 7.0 18 16 14 12 12

7.1 – 12.0 18 14 12 10 -

12.1 – 16.0 14 12 10 - -

16.1 – 20.0 12 10 - - -

e&!"#$%&'(&;7L747(<&49$&;7($&\';4"<$&%@'8&4'&37\$&\';4#&"4&

1/,g&'3&49$&@"4$%&"L8$@$#A

25LC';'<5

Double Insulated

Intertek Testing Services NA, Inc.

IVolts

hAlternating Current

BAmperes

n0 xxxx/min. No Load Revolutions per Minute (RPM)

WARNING marking concerning Risk

of Eye Injury. Wear ANSI-approved

safety goggles with side shields.

Read the manual before

set-up and/or use.

WARNING marking

concerning Risk of Fire.

Do not cover ventilation ducts.

Keep flammable objects away.

WARNING marking concerning

Risk of Electric Shock.

Properly connect power cord

to appropriate outlet.

Page 8 O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-A Item 64497

2BOMRS TUMVBRWTX YBWXRMXBXDM2MR)U

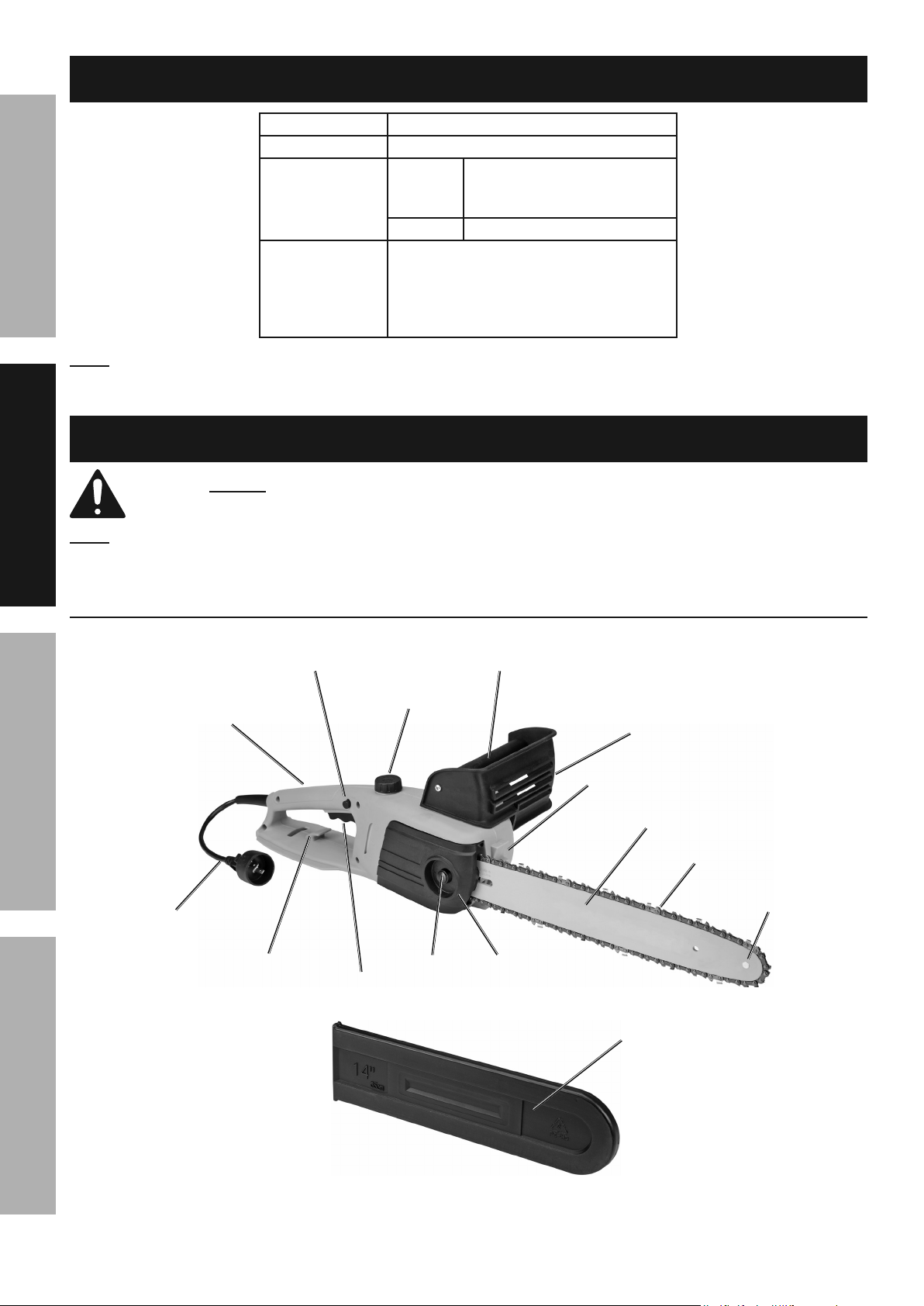

28$67376"47'(#

Electrical Rating 120 VAC / 60 Hz / 9 A

Motor Speed 5,600 RPM (No Load)

Chain Oil Type

SAE #30 motor oil –

Below 30° F use SAE #10 oil

Above 75° F use SAE #40 oil

Capacity 3.4 oz (100 ml)

Cutting

Attachment

14" Sprocket Nose Chain Guide Bar

Low-Kickback Full Skip Chain

Pitch: 3/8"

Gauge: 0.050"

# of links: 52

X'4$J This electric chain saw is for cutting small logs and for lighter weight trimming jobs.

A more powerful chain saw may be needed for heavy duty use.

2$4:8&0&!$3'@$&)#$J

&V$"%&49$&MXRWVM&WYUTVRBXR&2BOMRS&WXOTVYBRWTX&#$647'(&"4&49$&C$<7((7(<&'3&497#&

L"(:";&7(6;:%7(<&";;&4$>4&:(%$@&#:C9$"%7(<#&49$@$7(&C$3'@$&#$4&:8&'@&:#$&'3&497#&8@'%:64A

X'4$J For additional information regarding the parts listed in the

following pages, refer to Parts List and Diagram on page 18.

O:(647'(#

D9"7(&Z:7%$&

!"@&29$"49

2?7469&*'6]':4

R@7<<$@

U'?$@&D'@%

U'?$@&

D'@%&D;78

T7;&R"(]&D"8

Z:7%$&!"@&

X'#$

D9"7(&Z:7%$&!"@

287]$%&!:L8$@

2"?&D9"7(

O@'(4&a"(%;$&

Z:"@%

O@'(4&a"(%;$

V$"@&

a"(%;$

[@7\$&

D'\$@

X:4&

D'\$@

Page 9O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-AItem 64497

2BOMRSTUMVBRWTXYBWXRMXBXDM 2MR)U

2"3$45&[$\76$&M>8;"("47'(

1. Front Handle Guard – A guard that protects your

hand on the Front Handle from the Saw Chain.

2. Switch Lockout – A movable stop that

prevents the unintentional operation of

the Trigger until manually activated.

3. Low-Kickback Chain – A Chain that complies

with the kickback performance requirements

of ANSI B175.1-1991 when tested on a

representative sample of chain saws.

Z:7%$&!"@&"(%&2"?&D9"7(&W(#4";;"47'(&"(%&B%_:#4L$(4

RT&UVMIMXR&2MVWT)2&WXi)VS&OVTY&BDDW[MXRB*&TUMVBRWTXJ&

Y"]$&#:@$&49"4&49$&R@7<<$@&7#&7(&49$&'3308'#747'(&"(%&:(8;:<&49$&4'';&3@'L&74#&

$;$64@76";&':4;$4&C$3'@$&8$@3'@L7(<&"(5&8@'6$%:@$&7(&497#&#$647'(A

The Chain Saw is supplied with the Chain Guide Bar and Saw Chain pre-installed and no assembly

is required. Before first use and before each use thereafter, check the Saw Chain tension.

X'4$J New Saw Chains often need to be tensioned several times during first use.

Check a new Saw Chain’s tension often when first using.

Follow the directions in the following sections for checking and adjusting Saw

Chain tension and for replacing the Saw Chain when necessary.

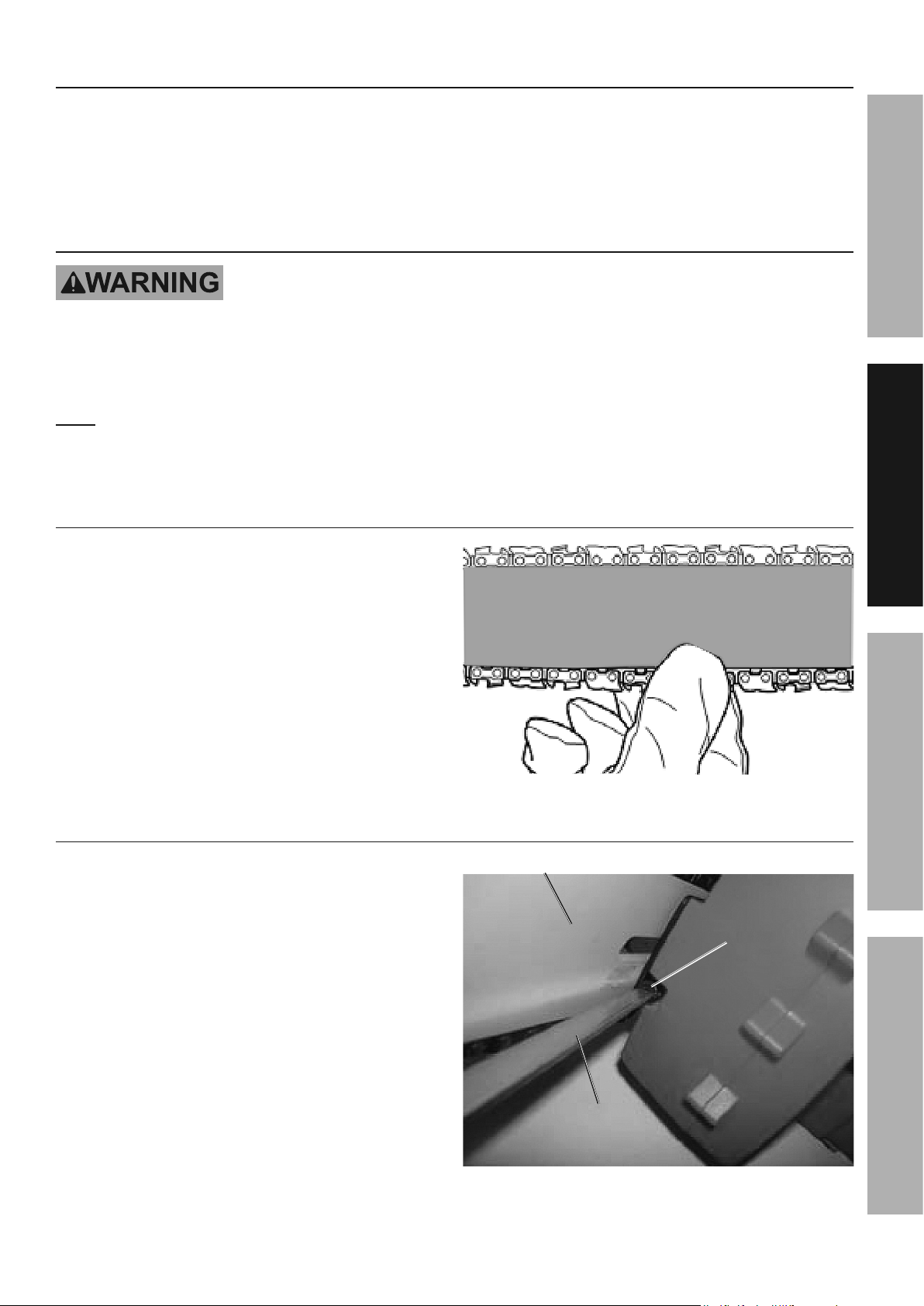

D9$6]7(<&2"?&D9"7(&R$(#7'(

1. Before using, check the Saw Chain tension.

2. While wearing heavy-duty gloves, use your index

finger and thumb to carefully grab the Saw Chain

in the middle section under the Chain Guide Bar.

3. Pull the Saw Chain away from the Guide Bar.

4. The Saw Chain should snap back against

the Guide Bar. The Chain should fit snugly

in the groove of the Chain Guide Bar, yet

you should still be able to slide the chain

along the Chain Guide Bar by hand.

5. There should be no sagging between the Guide Bar

and Saw Chain on the underside of the Guide Bar. O7<:@$&!J&&D9$6]7(<&2"?&D9"7(&R$(#7'(

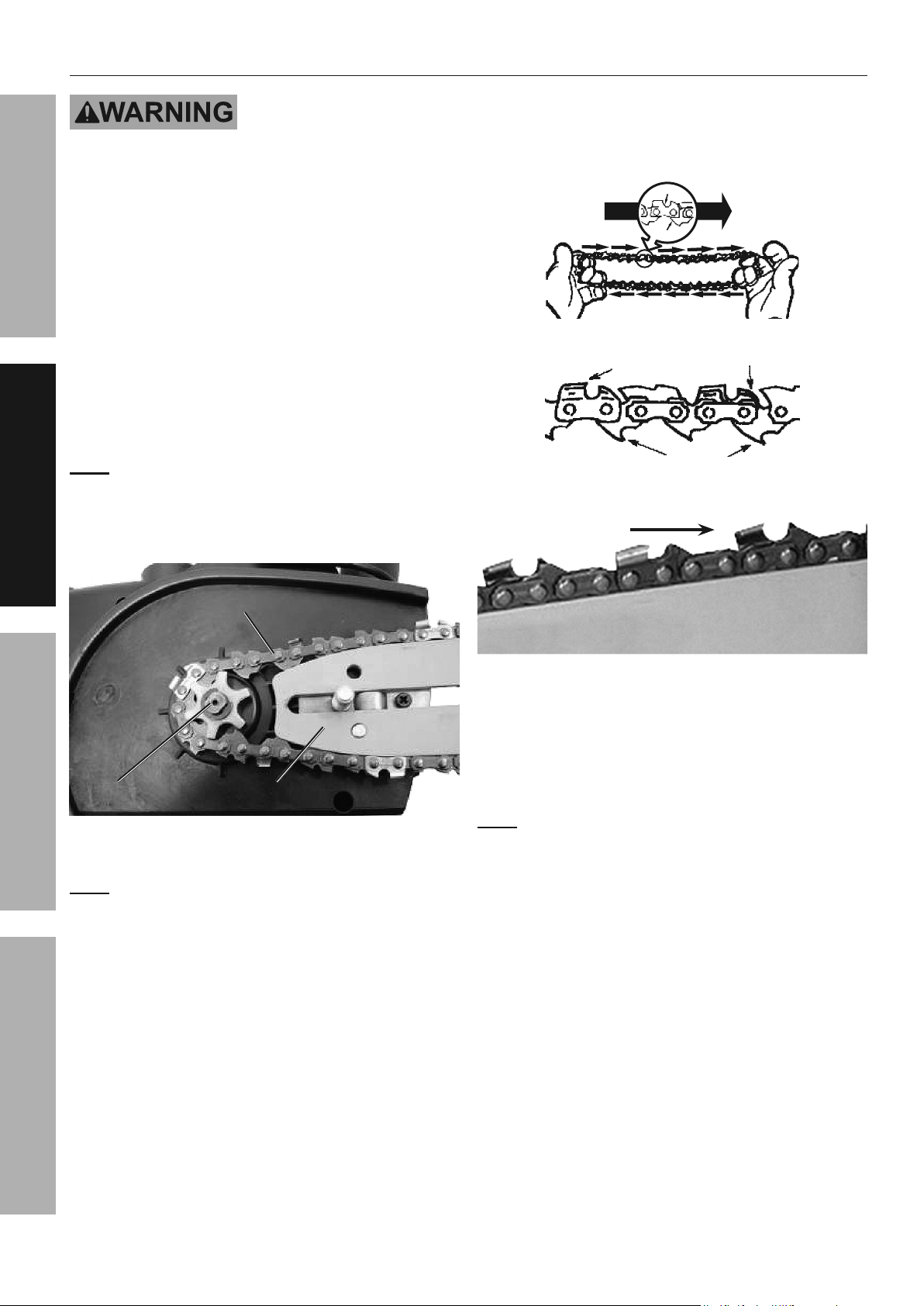

B%_:#47(<&2"?&D9"7(&R$(#7'(

1. Remove the Nut Cover (46) and loosen

the Nut (28) on the Drive Cover (26).

2. Pull up on the Guide Bar Nose and hold it

up while making the tension adjustment.

3. Turn the Tension Screw (31) clockwise,

until the Saw Chain makes contact along

the bottom of the Chain Guide Bar.

Turn the Tension Screw 1/4 turn more.

4. Continue to hold the Guide Bar Nose

up while tightening the Nut.

5. Check the Saw Chain tension again following

steps 2 through 5 under Checking Saw Chain

Tension above. If needed, repeat the adjusting

steps to achieve the correct tension.

6. When adjustment is complete replace the Nut Cover.

R$(#7'(&

26@$?&Gb1H

D9"7(&Z:7%$&!"@&GcQH

26@$?%@7\$@

O7<:@$&DJ&&B%_:#47(<&2"?&D9"7(&R$(#7'(

Page 10 O'@&4$69(76";&F:$#47'(#=&8;$"#$&6";;&10PPP0P++0/-Q-A Item 64497

2BOMRS TUMVBRWTX YBWXRMXBXDM2MR)U

V$8;"67(<&49$&2"?&D9"7(

['&('4&7(#4";;&"&2"?&D9"7(&'@&D9"7(&Z:7%$&!"@&'49$@&49"(&49$j$&"(%&458$&

8@'\7%$%&"(%&;7#4$%&7(&49$&28$67376"47'(#&D9"@4&'(&8"<$&PA

1. Soak the new Saw Chain overnight in

Bar and Chain Oil (sold separately).

2. Remove the Nut Cover (46) and loosen the

Nut (28) on the Drive Cover (26), then loosen

the Tension Screw (31) counter-clockwise

until the Saw Chain (30) is loose.

3. Unthread the Nut and remove the Drive Cover.

4. Push the Chain Guide Bar (29) towards the

Sprocket (37) to further loosen the Saw Chain.

5. Remove the Saw Chain from

the Sprocket, then the Guide Bar.

X'4$J&Check the condition of the Sprocket when

replacing the chain. The Sprocket should be

replaced if it shows signs of wear or is damaged.

If needed, have the Sprocket replaced and the

bearings greased by a qualified technician.

28@'6]$4 Z:7%$&!"@

D9"7(

O7<:@$&[J&&28@'6]$4&;'6"47'(&?749&Z:7%$&

!"@&"(%&2"?&D9"7(&7(&8;"6$

X'4$J Check the condition of the Chain Guide Bar

when replacing the chain. Refer to Chain Guide Bar

Care on page 16.

6. Flip the Chain Guide Bar over before mounting

the new Saw Chain. This will ensure that the

Chain Guide Bar wears evenly over time.

D)RRMV2&Y)2R&OBDM&WX&

[WVMDRWTX&TO&VTRBRWTX

R78&'3&

!"@

D:44$@

[@7\$;7(]

D:44$@# [$849&Z":<$

[@7\$&*7(]#

[7@$647'(&'3&2"?&

D9"7(&D:44$@#

2"?

Z:7%$&!"@&

X'#$

7. Place the new Saw Chain around the Sprocket

and over the Guide Bar. Make sure the Cutters

of the Saw Chain are facing away from the Chain

Saw along the top edge of the Guide Bar. Fit

the Chain in the groove around the Guide Bar.

8. Replace the Drive Cover.

X'4$J For proper placement the pin on the bottom

of the Drive Cover must fit into its hole on the Right

Housing (22) prior to securing the Nut. Do not force.

9. Finger tighten the Nut, then tension the

Saw Chain following the steps in Adjusting

Saw Chain Tension on page 9.

Other manuals for 64497

1

Table of contents

Other Portland Chainsaw manuals