Table of Contents

WARNING / INFORMATION SYMBOLS .............................................. ........................................... 3

APPLICATION OF THE DEVICE ................................................ .................................................. ............... 3

TECHNICAL DATA ................................................ .................................................. ................................ 4

SAFETY ................................................. .................................................. ................................ 4

GENERAL THOUGHTS ................................................ .................................................. .................................... 4

Regarding noise level ............................................... .................................................. ................. 4

Workplace................................................ .................................................. ..................................... 5

Work safety ................................................ .................................................. ....................... 5

Personal safety ................................................ .................................................. .................. 5

Using the Tool ................................................ .................................................. ...................... 6

Repairs ................................................. .................................................. ........................................... 6

Additional safety instructions ............................................... ................................................ 6

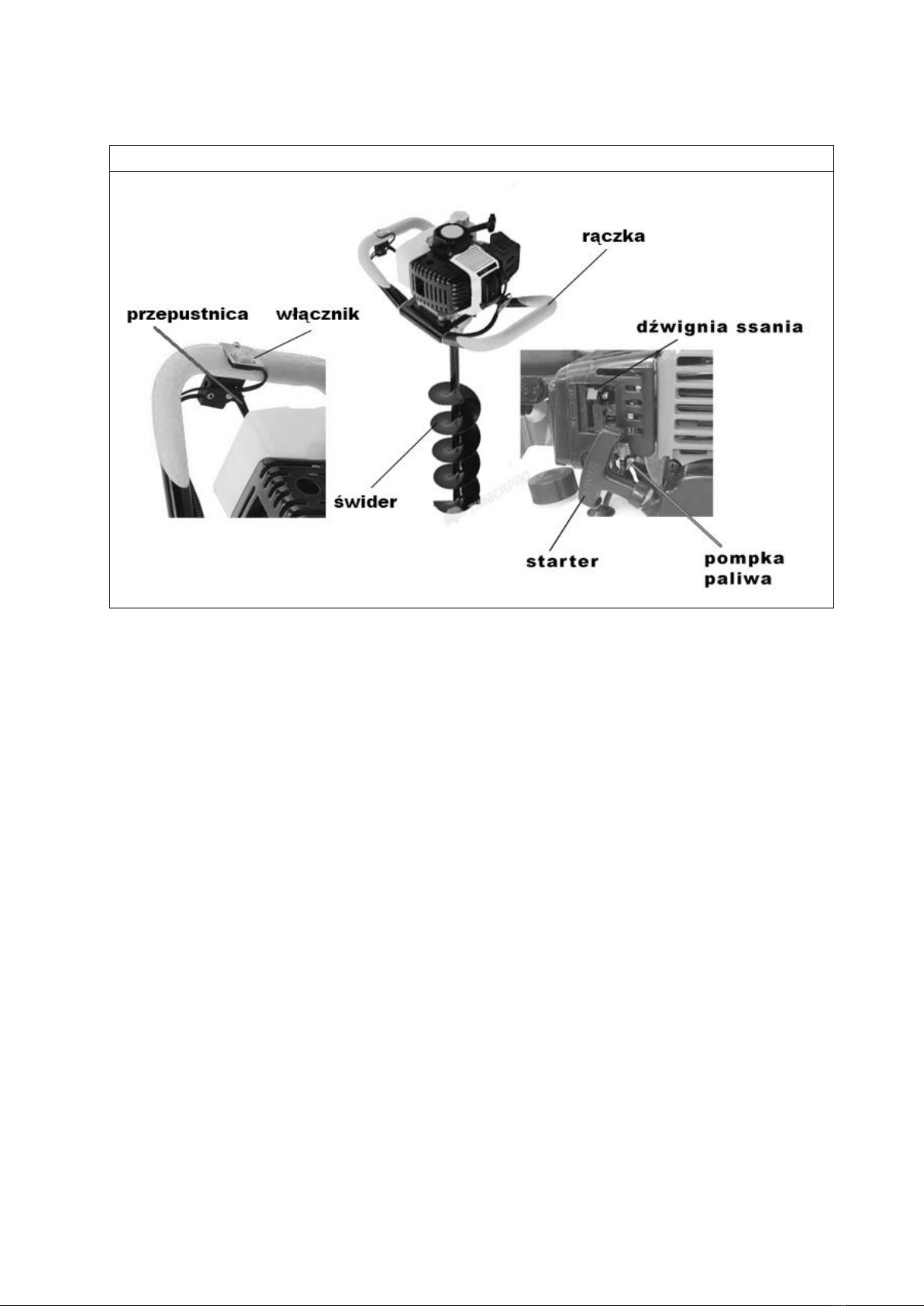

DEVICE DESCRIPTION ................................................ .................................................. ................................. 8

PRELIMINARY STEPS ................................................ .................................................. ........................... 8

Auger assembly ................................................ .................................................. ................................... 8

Fuel ................................................. .................................................. ............................................... 9

HOW TO USE THE DEVICE ................................................ .................................................. ......................... 9

Starting the engine ................................................ .................................................. ....................... 10

Drilling holes................................................ .................................................. ......................... 11

MAINTENANCE AND SERVICE ............................................... .................................................. ...................... 12

Oil change in gearbox .............................................. .................................................. ............. 12

Air filter ................................................ .................................................. ................................. 12

Carburetor adjustment ................................................ .................................................. ............................ 13

Checking the spark plug ............................................... .................................................. ...... 13

Fuel filter................................................ .................................................. ....................................... 13

Maintenance of cylinder ribs ............................................... .................................................. .............. 13

Other maintenance activities ............................................... .................................................. ......... 13

Service ................................................. .................................................. ............................................. 13

Storage................................................. .................................................. ............................. 14

DISPOSAL OF USED DEVICES ............................................... .................................................. ....... 14

MANUFACTURER'S DATA ................................................ .................................................. ............................ 14

DECLARATION OF CONFORMITY................................................ .................................................. ................... 15

2