PP Systems EGM-4 User manual

EGM-4 Environmental Gas

Monitor For CO2

Operator’s Manual

Version 4.19

For Firmware (EPROM) Version 1.46 and Greater

© 2012 PP Systems. All Rights Reserved

14 February 2013

PP Systems

110 Haverhill Road, Suite 301

Amesbury, MA 01913 U.S.A.

Tel: +1 978.834.0505

Fax: +1 978.834.0545

Email: support@ppsystems.com

Web Site: http://www.ppsystems.com

This page left intentionally blank for printing purposes.

Table of Contents

EGM-4 Operator's Manual – Version 4.19

- 3 -

Table of Contents

Table of Contents...........................................................................................3

Preface............................................................................................................5

System Calibration........................................................................................5

User Registration..........................................................................................5

Warning Notice...............................................................................................6

Condensation Risk........................................................................................6

PP Systems’ Contact Information .................................................................7

Technical Specification.................................................................................8

Introduction....................................................................................................9

Measurement Principle.................................................................................9

Getting Familiar With The EGM-4...............................................................10

Front Panel ................................................................................................................... 10

Environmental Sensor Inputs (I/O Ports) ....................................................12

Analog Output.............................................................................................13

Current Output............................................................................................13

RS232 Port.................................................................................................13

Soda Lime Absorber Column......................................................................13

Soda Lime ........................................................................................................................ 14

Keypad........................................................................................................14

LCD Display................................................................................................14

Gas Ports....................................................................................................14

Battery ........................................................................................................14

Powering The EGM-4 With Internal 12V NiMH Battery...............................14

CHARGING THE INTERNAL 12V NiMH BATTERY........................................................ 15

Charge Cycle and LED Indications for 12V NiMH Battery Charger................................. 15

Charge Socket............................................................................................15

Power Supply/Charger ..................................................................................................... 15

Power Switch..............................................................................................16

Operation......................................................................................................17

Main Menu..................................................................................................19

1REC..........................................................................................................19

Stand Alone CO2Analyzer (Probe Type 0)...................................................................... 20

Measurement Mode Display Structure............................................................................. 21

Changing Plot Number..................................................................................................... 22

Environmental Monitor (Probe Types 1-6 and 10)........................................................... 22

PP Systems Environmental Sensor Conversions:........................................................... 23

Steady State Porometer (Probe Type 7).......................................................................... 23

Closed System Soil Respiration (Probe Type 8).............................................................. 24

Use of our PAR Sensor with SRC-1 Soil Respiration Chamber ...................................... 24

Oxygen (Probe Type 9).................................................................................................... 27

Open System Soil Respiration (Probe Type 11).............................................................. 27

Calculation Of Fluxes For CFX And CPY Chambers....................................................... 29

2SET...........................................................................................................30

1EGM ............................................................................................................................... 30

Probe Types..................................................................................................................... 30

Probe Setting Override..................................................................................................... 31

2Z ..................................................................................................................................... 31

Changing the Zero Type................................................................................................... 31

Table of Contents

EGM-4 Operator's Manual – Version 4.19

- 4 -

Changing the Zero Time................................................................................................... 32

3PMP................................................................................................................................ 32

Static Sampling with the EGM-4....................................................................................... 32

4AV................................................................................................................................... 32

5RECD ............................................................................................................................. 33

6ALM ................................................................................................................................ 33

Setting the Low CO2Alarm Setpoint................................................................................ 33

Setting the High CO2Alarm Setpoint ............................................................................... 34

7VOUT.............................................................................................................................. 34

3CAL...........................................................................................................35

Connecting Calibration Gas To The EGM-4 .................................................................... 35

4DMP..........................................................................................................36

Screen Display ................................................................................................................. 36

Data Dump ....................................................................................................................... 37

Transferring Stored Data Using The Windows®Based Software Program ..................... 37

Logging Data.................................................................................................................... 38

Record Structure .............................................................................................................. 38

Data Structure Based On Probe/Sensors........................................................................ 39

Error Cod.......................................................................................................................... 40

es...................................................................................................................................... 40

EGM Serial Outputs....................................................................................41

5CLR...........................................................................................................41

6CLK...........................................................................................................42

Diagnostics and Initialisation .....................................................................43

Diagnostics .................................................................................................43

Initialisation.................................................................................................43

Maintenance.................................................................................................44

Soda Lime Absorber Column......................................................................44

Soda Lime ........................................................................................................................ 44

MATERIAL SAFETY DATA FOR SODA LIME ................................................................ 45

Servicing The EGM-4..................................................................................46

Fuse.................................................................................................................................. 46

Inside the EGM-4.......................................................................................................... 47

Infrared Source................................................................................................................. 47

Checking EGM-4 Raw A/D Readings .............................................................................. 48

EPROM ............................................................................................................................ 48

ZERO Valve...................................................................................................................... 49

12V Lead Acid Battery...................................................................................................... 49

12V Lead Acid Battery Specification................................................................................ 49

Removing The 12V Lead Acid Battery............................................................................. 49

12V NiMH Battery............................................................................................................. 50

12V NiMH Battery Specification....................................................................................... 50

Removing The 12V NiMH Battery.................................................................................... 50

Air Sampling Pump........................................................................................................... 51

Replacing The Air Sampling Pump .................................................................................. 51

Cleaning The Air Sampling Pump.................................................................................... 51

In-Line Filter Assembly (Hydrophobic)............................................................................. 52

Consumables and Spares for EGM-4.........................................................53

User Notes....................................................................................................54

Preface

EGM-4 Operator's Manual – Version 4.19

- 5 -

Preface

It is extremely important that you take the time to review this operator’s manual prior to

installation and operation of the EGM-4 CO2Gas Analyzer. Otherwise, damage may be

caused which is not covered under our normal warranty policy. This operator’s manual is

relevant to all EGM-4’s running firmware (EPROM) version 1.30 and higher.

System Calibration

•This product is shipped as a factory calibrated system. System calibration is not

required upon receipt from our factory.

•Familiarization with the documentation and calibration procedures is required prior to

future recalibration. See section 3CAL on page 35 of this manual.

•All calibration related questions may be directed directly to PP Systems at:

Telephone: +1 978.834.0505

Fax: +1 978.834.0545

Email: support@ppsystems.com

User Registration

It is very important that ALL new customers register with us to ensure that our user’s list is

kept up to date. If you are a PP Systems’ user, please register yourself electronically on our

web site at http://www.ppsystems.com/user_registration2.htm .

Only REGISTERED users will be allowed access to our protected “Users” section of our web

site. This section will contain important product information including hardware/software

updates, application notes, newsletters, etc.

Thank you in advance for your cooperation.

The warranty excludes all defects in equipment

caused by incorrect installation, operation or

maintenance, misuse, alteration, and/or

accident.

Warning Notice

EGM-4 Operator's Manual – Version 4.19

- 6 -

Warning Notice

This instrument must not be used in situations where its failure could result in injury or

death. For applications where failure of this instrument to function correctly would

lead to consequential damage, the Analyzer must be checked for correct operation and

calibration at intervals appropriate to the criticality of the situation.

This manual is provided to help you install and operate the equipment. Every effort has been

made to ensure that the information contained in this manual is accurate and complete. PP

Systems does not accept any liability for losses or damages resulting from the use of this

information. PP Systems' equipment warranty is limited to replacement of defective

components, and does not cover injury to persons or property or other consequential

damage. This manual, and the information contained in it, is copyright to PP Systems. No

part of the manual may be copied, stored, transmitted or reproduced in any way or by any

means including, but not limited to, photocopying, photography, magnetic or other mechanical

or electrical means, without the prior written consent of PP Systems.

The EGM-4 is covered under warranty for one complete year, parts and labour included.

This, of course, is provided that the equipment is properly installed, operated and maintained

in accordance with written instructions (i.e. Operator's Manual). The warranty excludes all

defects in equipment caused by incorrect installation, operation or maintenance,

misuse, alteration, and/or accident.

If for some reason, a fault is covered under warranty, it is the responsibility of the customer to

return the goods to PP Systems or an authorised agent for repair or replacement of the

defective part(s).

Condensation Risk

If condensation occurs in the analysis sample line, free water may enter the analyzer causing

serious damage which will result in a very expensive repair. Therefore, it is critical that you

periodically inspect the pipeline to be sure that condensed water does not enter the analyzer.

If the EGM-4 is supplied on its own, we do NOT supply any external filters. If the EGM-4

is used in conditions where there is risk of condensation or water in the sample line, (i.e.

when used with the SRC-1, CPY-2, CPY-4 or CPY-3 chambers for measurement of

soil/canopy assimilation, we strongly recommend fitting our hydrophobic filter to the “Gas In”

port as shown below. Our hydrophobic filter assembly (Part No. 10045-1) is supplied with all

SRC-1’s, CPY-2’s, CPY-4’s and CPY-3’s. All EGM-4 customers can purchase this filter from

PP Systems (Part No. 10045-1) at any time if required. In addition, when this filter is used, it

must be checked regularly and replaced as when dirty or wet. Otherwise, blockage can

occur.

Our in-line filter assembly

(Part No. 10045-1)

Warning Notice

EGM-4 Operator's Manual – Version 4.19

- 7 -

For maintenance instructions, see In-Line Filter Assembly (Hydrophobic) on page 52.

Very Important

If there is any risk of of water entering the EGM-4, you must protect the instrument by using

an external 3 µm hydrophobic filter (Part No. 10045-1) or water drop out trap. We strongly

recommend using 3 µm filters as any other size may cause damage to the pump. If a

water drop out trap is used, it should be regularly checked and emptied as required.

If condensation persists, it is then recommended that a PP Systems’ water vapor equilibrator

(Part No. 10049-1) is used (see picture below). This is constructed from a material that is

very permeable to water vapor but impervious to CO2. If this is placed in-line in the analysis

pipe at the sampling point, the water vapor concentration of the analysis air will be brought

close to ambient.

Part No. 10049-1 Water Vapor Equilibrator fitted to top of EGM-4

The problem may also be avoided by putting a suitable water drop out trap or drier in the

same position. Drierite (anhydrous Calcium Sulphate) is suitable. DO NOT use Silica Gel,

which also absorbs CO2.

Please note that any method used to remove excess water from the analysis

sample will render any humidity measurement incorrect.

If you have any questions whatsoever with regards to possible condensation risk,

contact PP Systems (See PP Systems’ Contact Information on page 7).

PP Systems’ Contact Information

PP Systems

110 Haverhill Road, Suite 301

Amesbury, MA 01913 U.S.A.

Tel: +1 978.834.0505 Fax: +1 978.834.0545

Support: support@ppsystems.com

Sales: sales@ppsystems.com

Service: service@ppsystems.com

Technical Specification

EGM-4 Operator's Manual – Version 4.19

- 8 -

Web Site: http://www.ppsystems.com

Technical Specification

Analysis Method

Non-dispersive infrared with microprocessor control and linearisation.

Measurement

Range

(CO2)

0-1,000 ppm (µmol mol-1)

0-2,000 ppm (µmol mol-1)

0-5,000 ppm (µmol mol-1)

0-10,000 ppm (µmol mol-1)

0-20,000 ppm (µmol mol-1)

0-30,000 ppm (µmol mol-1)

0-50,000 ppm (µmol mol-1)

0-100,000 ppm (µmol mol-1)

Measurements are automatically corrected for temperature and pressure.

Accuracy (CO

2

)

< 1% of span concentration over the calibrated range, but limited by the

accuracy of the calibration gas mixture.

Linearity

< 1% throughout the range.

Stability

Automatic Zero at regular intervals. It corrects for sample cell

contamination, source and detector ageing and pre-amplifier gain

changes.

Sample Pump

Integral DC pump operating at a flow rate of approximately 350 ml/min.

Pump can be disabled for static measurements on demand.

Gas Flow Rate

Through Analyzer

Minimum flow rate: 200 ml/min

Maximum flow rate: 400 ml/min

Environmental

Sensor Interface

Two inputs available for use with external sensors (humidity, temperature,

PAR, oxygen, soil respiration, canopy assimilation, etc.).

Air Filter

Filtered sample line (hydrophobic)

Calibration

Default value preset in factory (Built-in Initialization). Automatic

calibration via keypad if required.

CO2Control

High and low set points

Alarm

Audio Alarm

Real Time Clock

Accuracy > 1 minute per month at 25˚C, operating temperature 0-70˚C.

Automatic correction for month end and leap years.

Recording

Manual (by keypress) or automatic at user selected intervals between 1

and 250 minutes.

Keypad

Custom, tactile keypad

Data Storage

512 K Battery backed RAM (1,000 records).

Response Time

Display/analog output: 1.6 seconds

Analog Output

(CO2only)

4-20 mA, 0-1 V, 0-2 V, 0-3 V, 0-4 V, 0-5 V (Linear)

Digital Output

(RS232)

9600 baud/8 data bits, 1 start bit/2stop bits/no parity

ASCII Format

Display

High contrast 2 x 16 character LCD.

Power Supply

12 V, 2.0 Ah Rechargeable Lead Acid Battery providing up to 4 hours

continuous use or 12V NiMH rechargeable battery providing up to 8 hours

continuous use. Longer times available with external 12V battery. Battery

life may be reduced when EGM-4 is used with add-on

sensors/accessories.

Gas Connections

Two barbed fittings (inlet and exhaust) for 1/8” (.125”) ID tubing.

Housing

High impact, aluminum enclosure.

Operating

Environment

-5oC – 50o C, non-condensing. In dirty or high humidity environments,

external air filtration is required.

Dimensions

18 cm (W) x 21.5 cm (H) x 6.3 cm (D)

Weight

1.9 kg

Introduction

EGM-4 Operator's Manual – Version 4.19

- 9 -

PP Systems is continuously updating its products and reserves the right to amend product

specifications without notice.

Introduction

The EGM-4 CO2Analyzer is a portable operated unit that is powered by an internal 12 V, 2.0

Ah lead acid rechargeable battery providing up to 4 hours continuous use or 12V NiMH

rechargeable battery providing up to 8 hours continuous use. For extended operation in the

field, PP Systems can also provide an external power supply cable that will allow you to

connect up to an external 12 V battery. If interested, please contact PP Systems (See PP

Systems’ Contact Information on page 7).

The EGM-4 is a high precision instrument for use in CO2monitoring applications such as

greenhouses, environment control rooms, nurseries and laboratories. Long term stability and

accuracy is ensured as a result of our unique “Auto-Zero” technology. The EGM-4 also

features inputs for additional sensors for measurement of humidity, temperature, PAR, O2,

soil respiration, soil temperature and canopy assimilation.

Measurement Principle

The EGM-4 CO2is a non-dispersive, infrared gas analyzer that features an “Auto-Zero”

facility. Using infra-red gas analysis techniques, we can readily determine CO2(Carbon

Dioxide) concentrations to within a few ppm and instantaneous measurements are possible.

Gases with di-atomic molecules such as CO2strongly absorbs photons in the infra-red range.

For CO2 , one region of strong absorption is 4.26 microns. A source emitting strongly at this

wavelength is a light bulb. If this is positioned at one end of a tube and at the other end is

placed a sensor that is sensitive to photons at 4.26 microns, we have a simple infra-red gas

Analyzer. As carbon dioxide is passed down the sample cell, it absorbs some of the infra-red

and the sensor reading decreases. The “Auto-Zero” feature, which occurs at regular

intervals, allows for fast warm-up, adaptation to changing ambient conditions and excellent

stability of the CO2signal. The action of auto-zeroing minimizes the effects on span (gas

sensitivity) of sample cell contamination, source aging, changes in detector sensitivity and

changes in pre-amplifier gain.

The entire optical bench assembly (i.e. sample cell) is filtered and should never require

replacement.

To ensure proper operation, the EGM-4 MUST always

be operated in a vertical, upright position.

The EGM-4 can be supplied with two different optical benches. One bench is optimized for

measurement of CO2in the ranges of 0-1,000 ppm up to 0-30,000 ppm. The other optical

bench is optimized for 0-50,000 ppm and 0-100,000 ppm. All instruments are checked and

calibrated at the concentration specified at time of order to ensure that the readings are < 1%

of that value. When an instrument is reset to its default values (i.e. when the system is

initialised, see Initialisation on page 43), it returns to this setting.

It is important to note that the information contained in this documentation normally

refers to the latest firmware (EPROM) which can change over time. We recommend

that all users keep in contact with us from time to time to ensure that they are running

the most up to date system firmware.

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 10 -

Getting Familiar With The EGM-4

Front Panel

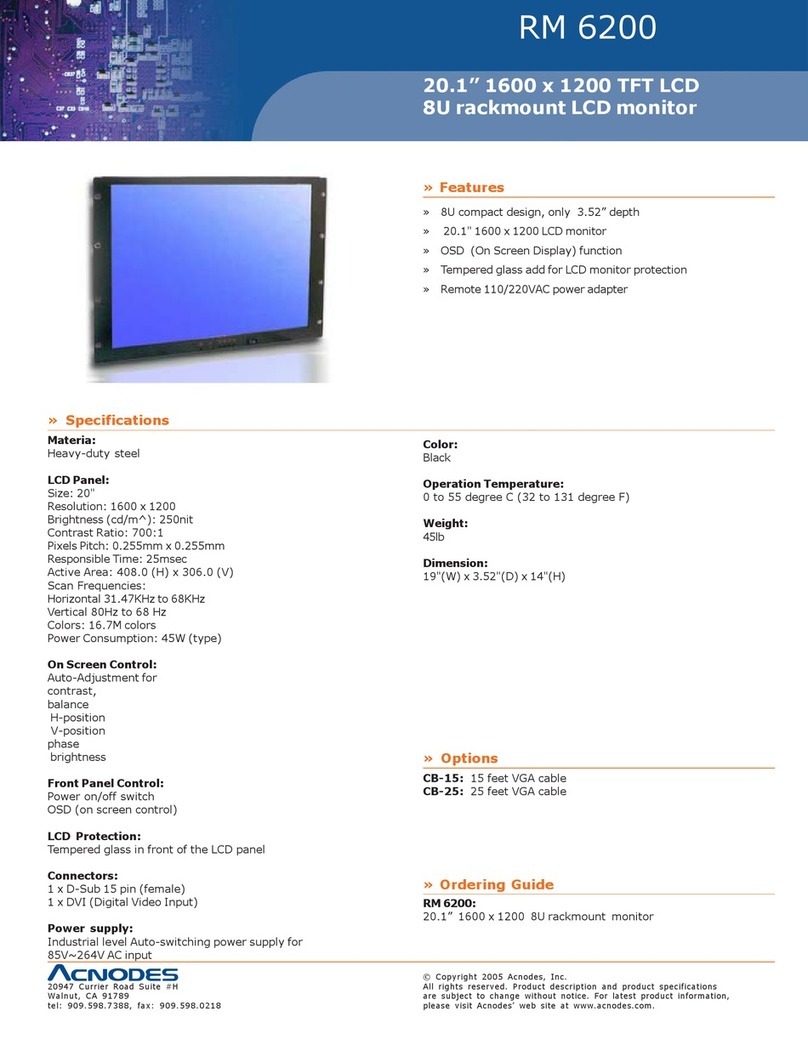

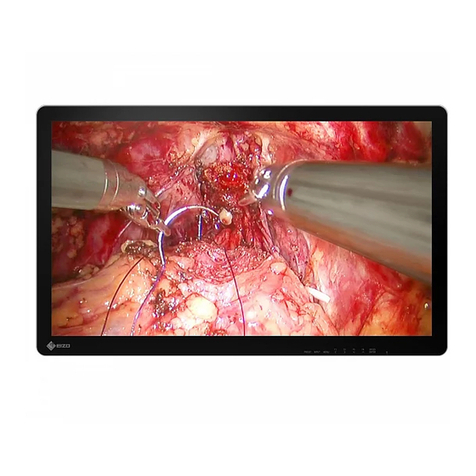

Figure 1 EGM-4 Display (Front Panel)

LCD Display

(2 x 16)

Character

Custom,

tactile

keypad

Sensor I/O

Connectors

RS232

Connector

Gas In Port

Gas Out Port

4-20 mA

Access Hole

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 11 -

Top of EGM-4

Back Panel of EGM-4 fitted with 12V Lead Acid Battery

Back panel of EGM-4 fitted with 12V NiMH Battery

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 12 -

Environmental Sensor Inputs (I/O Ports)

The EGM-4 has 2 environmental sensor inputs (I/O) to allow external sensors (i.e. soil

respiration chamber, CPY-2/CPY-3/CPY-4 Canopy Assimilation Chambers, TRP-1

Temperature/PAR Probe, PAR-1 Probe, etc.) to be used simultaneously. All sensor inputs

lines require 0-1V input. Note, the sensor inputs are displayed in mV (i.e. 0-1,000 mV)

instead of Volts.

If one of our environmental sensors is used with the EGM-4, it must be plugged into the

instrument prior to turning it on. The EGM-4 automatically detects the sensor connected as a

result of code resistors which are fitted to the 15 pin D Connector between pins 1 and 6. The

code resistors for our environmental sensors are as follows:

Probe Type

PP Systems Sensor

Code Resistor

0

The EGM-4 is being used as a stand

alone IRGA (no external sensors

connected)

Not applicable. This is

determined by keypad

selection.

1

STP-1 Soil Temperature Probe

100 KΩ

2

Not Applicable. Used to be used with

older sensors.

56 KΩ

3

TRP-1/TRP-2 Temperature/PAR Probe

36 KΩ

4

PAR-1/PAR Sensor

27 KΩ

5

Not Applicable. Used to be used with

older sensors.

20 KΩ

6

Not Applicable. Used to be used with

older sensors.

15 KΩ

7

Steady State Porometer (PMR-5)

Not applicable. This is

determined by keypad

selection.

8

SRC-1 Soil Respiration Chamber or CPY-

2/CPY-

4 Canopy Assmiliation Chamber

(Closed System operation)

9.1 KΩ

9

OP-1/OP-2 O2 Sensor

20 KΩ

10

Not Applicable. Used to be used with

older sensors.

5.6 KΩ

11

CFX-1 Open System Soil Respiration

Chamber or CPY-3 Canopy Chamber.

4.3 KΩ

12

CPY-4 Canopy Assimilation Chamber

(Closed System Operation)

9.1 KΩ

Note. When the EGM-4 is supplied with a PP Systems accessory (i.e. SRC-1, CPY-4, etc.),

the probe type will be set at the factory based on the accessory supplied. Therefore, it may

be necessary to change the probe type if required. The probe type can be changed from the

2SET menu on page 30. if required. See Analog Output on page 13 for analog output pin-

outs and location for code resistor placement (Pin 1).

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 13 -

Analog Output

The EGM-4 has two 15 pin I/O connectors with a 0-5V analog output. The default output is

set at 0-5V. However, this can be changed by the user (if required) to any value in between

(i.e. 0-1V, 0-2V, 0-3V, 0-4V). (See 7VOUT on page 34). The pin-outs for the two I/O

connectors are as follows:

DB15 I/O

Connector

Description

1

Code Resistor (connect to pin 6)

2

PAR

3

RH

4

Aux. Analog Input

5

Temp

6

+5V

7

Alarm 1 (Buffered)

8

Digital Ground

9

RS232 Output

10

Data Request /CO2 Control

11

RS232 Input

12

+12V

13

Aux. Digital I/O

14

CO2Analog Out

15

Analog Ground

Current Output

If required, current output (4-20 mA) is available and can be accessed through the top of the

EGM-4. Inside the EGM-4, there is a 2 pin connector labelled CN7 on the PC075-1 circuit

board. The EGM-4 contains a 4-20 mA current transmitter that is powered from an internal

12V supply. To utilize the current output, simply connect the Iout pins directly to a 4-20 mA

meter or digitizer. No power supply or other connections are required to get a 4-20 mA output

from the EGM-4. Applying voltage to the Iout pins higher than 12 V will damage the internal

circuitry.

RS232 Port

The EGM-4 has one 9 pin RS232 connector used for transferring stored data to a PC or

laptop computer. To transfer stored data from the EGM-4 to an external PC, connect the data

transfer cable (supplied by PP Systems) between the RS232 connector on the EGM-4 and

the 9 pin serial connector on the PC. Data transfer software (supplied by PP Systems) steps

you through the data transfer process. See Data Dump on page 37 for more information on

data transfer. If required, a data transfer cable can easily be made up by the user. See table

below:

9 PIN D Socket on

EGM-4

9 Pin D Socket on PC

Pin 2

Pin 2

Pin 5

Pin 5

Soda Lime Absorber Column

The absorber column is labelled “Soda Lime” on the rear panel. It contains a CO2scrubbing

desiccant known as Soda Lime. When air passes through this column, it removes all of the

CO2from the air stream. The “Auto-Zero” facility built into the EGM-4 periodically switches

the flow of gas from the Analyzer through this column to check the Analyzer zero. This

routine ensures long term stability and accuracy of the CO2Analyzer. It automatically

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 14 -

corrects for such things as sample cell contamination, source aging, detector sensitivity and

changes in electronics.

Soda Lime

Soda lime is used to remove CO2from air entering the EGM-4. It is supplied as self-

indicating granules (1-2.5mm) that turn from green to brown as it becomes exhausted. The

contents of the absorber column should be replaced when it is 2/3rds exhausted (brown).

Soda Lime cannot be regenerated and should be discarded when exhausted. For accurate

measurements and calibration, it is absolutely critical that the EGM-4 absorber column is not

exhausted. If the soda lime is becoming exhausted, it will cause the ZERO to be performed

on non-ZERO air causing an error in the calibration.

When exhausted, the Soda Lime Cap should be removed along with the foam filter pad (with

the EGM-4 facing upwards) and the contents discarded. When replacing the soda lime, we

recommend using a funnel to ensure that the desiccant fills the absorber column. Leave

approximately 1” from the end of the column to allow the foam pad and cap to be refitted.

! CAUTION !

WASH YOUR HANDS AFTER HANDLING SODA LIME

Keypad

The custom, tactile keypad consists of 12 keys. There are ten keys that are labelled 0-9.

Also, there are a few keys that have additional functions. The Y/R (Yes/Record) key is used

to accept settings and to record measurements. In addition, the Y/R key is pressed to

advance from one display to the next. The Nkey is normally used to return to the Main Menu

from Measurement Mode, reject settings or to step back through the menus. The 8/X key is

used to toggle from one display to another in Measurement Mode.

LCD Display

The EGM-4 features a 2x16 character, backlit LCD display.

Gas Ports

There are two barb fittings located on the top of the EGM-4. Each barb fitting is designed for

use with 1/8” (.125”) ID tubing. One barb fitting is labelled “Gas In” and the other “Gas Out”.

The sampling line should be fitted to the “Gas In” port using 1/8” tubing. The “Gas Out” line

should be left open to atmosphere to allow the sample air to exhaust without restriction. Note,

for closed system measurements with our SRC-1 Soil Respiration Chamber or CPY-2 Canopy

Asssimilaton Chamber, one gas line is connected to the “Gas In” port and the other to the

“Gas Out” port.

Battery

The EGM-4 can be powered by an internal 12V 2.0 Ah lead acid rechargeable battery

providing up to 4 hours continuous use or a 12V NiMH rechargeable battery providing up to 8

hours continuous use.

Powering The EGM-4 With Internal 12V NiMH Battery

There are two ways to power the EGM-4 :-

1. Using the internal 12V NiMH battery:

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 15 -

A. Set the slide switch on the rear panel of the EGM-4 to the 'BATTERY'

position.

B. Switch the instrument on using the 'POWER' toggle switch.

Note, the internal battery CANNOT be used to power the EGM-4 while it is being

charged, but the external power supply can be used simultaneously instead.

2. Using the external power supply

A. Set the slide switch on the rear panel of the EGM-4 to the 'CHARGE' position.

B. Plug the EGM-4 External Power Supply into the '-ve/+ve' socket.

C. Switch the instrument on using the 'POWER' toggle switch.

CHARGING THE INTERNAL 12V NiMH BATTERY

1. Set the slide switch on the rear panel of the EGM-4 to the 'CHARGE' position.

2. Plug the EGM-4 NiMH Battery Charger into the 'CHARGE SKT'. To do this, line up

the three socket pins with the plug, and screw on the plug sleeve (do not overtighten).

Charge Cycle and LED Indications for 12V NiMH Battery Charger

LED

Mode

Orange

Battery not connected

Orange

Battery initialization & analysis

Red

Fast charge

Green with intermittent orange flash

Top-off charge

Green

Trickle charge

Alternating red-green

Error

Check to make sure that the “charge indicator light" (red LED) on the charger is a steady state

red after connection. If the LED does not come on, or it fluctuates, then there may be a bad

connection.

WARNING

THE EGM-4 IS FITTED WITH A SLIDE SWITCH (CHARGE BATTERY).

DO NOT OPERATE THE SLIDE SWITCH WHEN THE EGM-4 IS

CONNECTED TO ANY EXTERNAL POWER SUPPLY OR BATTERY

CHARGER.

Charge Socket

The charge socket is labelled “12V DC” on the rear panel of the EGM-4. The AC

Adapter/charger supplied by PP Systems plugs into this socket to charge the internal 12V 2.0

Ah lead acid battery.

Power Supply/Charger

All systems are supplied complete with an AC Adapter/Charger designed specifically for use

with the EGM-4 for charging the internal 12 V 2.0 Ah lead acid battery and for continuous

operation in the lab. This unit has the following technical specification:

Input

100-240 V ~ 50-60 Hz

Getting Familiar With The EGM-4

EGM-4 Operator's Manual – Version 4.19

- 16 -

Output

15 V @ 2.7 A

Power Indicator

Green LED

Dimensions

10.5 cm x 6.5 cm x 4.5 cm

Weight

0.3 kg

!!! WARNING !!!

USE OF POWER SUPPLIES AND BATTERY CHARGERS OTHER THAN

THOSE SUPPLIED BY PP SYSTEMS FOR THE EGM-4 WILL INVALIDATE

THE WARRANTY.

Please note. EGM-4’s can also be powered by an internal, rechargeable 12V NiMH battery

for extended operation in the field. For more information on this option, refer to Powering The

EGM-4 With Internal 12V NiMH Battery on page 14.

Power Switch

To power up the EGM-4, the On/Off Switch should be toggled to the “On” position. To turn

the instrument off, the switch should be toggled to the “Off” position.

Operation

EGM-4 Operator's Manual – Version 4.19

- 17 -

Operation

The EGM-4 is a menu driven instrument. Note. If any external sensors/probes are to be

used with the EGM-4, they MUST be electrically connected to one (or both) of the I/O

ports prior to turning the instrument on. When the instrument is first powered up, it will go

through its normal warm-up period that takes approximately 5 minutes. Immediately after

powering up the system, the following is displayed:

Whereas:

EGML

Or

EGMH

Or

PMR

Refers to an EGM-4 with a measurement range up to 30,000

ppm.

Refers to an EGM-4 with a measurement range of 50,000 or

99,999 ppm.

Refers to PMR-5 Steady State Poromter.

0456

Refers to the serial number of the EGM-4

V1.30

Refers to the firmware (EPROM).

During warm-up, there is a delay of approximately 45 seconds to allow for calibration of the

electronics and then the instrument proceeds to warm-up until the Analyzer temperature

reaches 50 ˚C. A final Zero check is then performed before proceeding to the Main Menu.

Also during warm-up, several system checks are performed. The “Checksum” message is set

to a factory default value of 123456. If this is incorrect as when a new version of firmware is

first installed, a “CHECKSUM ERROR SEE MANUAL” message is displayed. If this occurs,

simply press any key to proceed to the Main Menu. From the Main Menu, press key 0 to re-

initialise the system (See Initialisation on page 43).

The next display will be dependent on whether or not any external sensors are being used

with the EGM-4.

If the EGM-4 is being used on its own, the following will be displayed:

Where:

C2000

Corresponds to the last calibration gas concentration. After DEFAULT, it is the

original range specified by the end user.

1V=2000

Range of the voltage signal corresponding to the CO2concentration.

R150

Number of records stored in memory.

If the EGM-4 is being used with an external sensor (i.e. SRC-1 Soil Respiration Chamber),

the following will be displayed:

PP SYSTEMS C2002

EGML 0456 V1.30

C2000 1V=2000

mV INPUTS R150

C2000 5V=2000

PROBETYPE 8 R150

Operation

EGM-4 Operator's Manual – Version 4.19

- 18 -

Where:

C2000

Corresponds to the last calibration gas concentration. After DEFAULT, it is

the original range specified by the end user.

5V=2000

Range of the voltage signal corresponding to the CO2concentration.

PROBETYPE 8

Refers to the probe/sensor connected to the EGM-4. For a list of probe

types, see Environmental Sensor Inputs (I/O Ports) on page 12.

R150

Number of records stored in memory.

If the EGM-4 is being used as a porometer (i.e. PMR-5), the following will be displayed:

Where:

C2000

Corresponds to the last calibration gas concentration. After DEFAULT, it is

the original range specified by the end user.

5V=2000

Range of the voltage signal corresponding to the CO2concentration.

POROMETER

Refers to the PMR-5.

R150

Number of records stored in memory.

After all system checks have been performed and the system achieves warm-up, the EGM-4

Main Menu is displayed as follows:

Note. If the instrument was just powered up, the display will show “WARM UP DELAY

TEMPERATURE = XX” until the instrument achieves its warm up temperature of 50 ˚C prior

to the Main Menu.

While in Measurement Mode, the following key presses can be performed:

Key

To:

Z/0

Perform a manual Zero.

Y/R

Record a measurement and place it in memory.

8/X

Changes to a different display (See section 1REC).

N

Return to the Main Menu.

Refer to the following sections for more information on menus and displays.

1REC 2SET 3CAL

4DMP 5CLR 6CLK

C2000 5V=2000

POROMETER R150

Operation

EGM-4 Operator's Manual – Version 4.19

- 19 -

Main Menu

There are 6 options available to the user when the Main Menu is displayed as follows:

Where:

Press

Key

To

1

Go Into Measurement Mode. See 1REC on page 19.

2

Change system settings (i.e. zero type and time interval, recording type, alarm

settings, etc.). See 2SET on page 30.

3

To calibrate the Analyzer. See 3CAL on page 35.

4

To dump stored data to a PC or to view data on the LCD display. See 4DMP on

page 36.

5

Clear system memory. See 5CLR on page 41.

6

Set/check the system clock (date and time). See 6CLK on page 42.

Each option is discussed in further detail below.

1REC

To begin recording, press key 1. Please note, the EGM-4 display is dependent upon which

probe type is connected to it. The following table illustrates the Probe Types:

If the EGM-4 is used as a:

Then The

Probe Type is

set to:

Stand Alone CO

2

Analyzer (including optional humidity sensor

is fitted). See Stand Alone CO2 Analyzer (Probe Type 0) on

page 20.

0

Environmental Monitor

(With one of our Environmental Sensors such as %RH,

temperature, PAR, O2, etc.). See

Environmental Monitor

(Probe Types 1-6 and 10) on page 22.

1-5

Steady State Porometer. See Steady State Porometer (Probe

Type 7) on page 23.

7

Closed System Soil Respiration

(i.e. SRC-1 Soil Respiration Chamber). See Closed System

Soil Respiration (Probe Type 8) on page 24.

8

O2 probe

9

RH and Temperature

10

Open System Measurement

(i.e. CFX-1 Soil Respiration Chamber, CPY-3 Chamber). See

Open System Soil Respiration (Probe Type 11) on page 27.

11

Closed System operation with the CPY-4. See Closed System

Soil Respiration (Probe Type 8) on page 24.

12

Important Note. Most instruments are supplied with the probe type already set if a sensor is

supplied with the EGM-4. If an existing EGM-4 user purchases an environmental sensor from

us, it may be necessary to set the probe type (see 1EGM on page 30).

In the followng sections, some displays will vary slightly to what is discussed

depending on firmware and sensors connected to the EGM-4.

1REC 2SET 3CAL

4DMP 5CLR 6CLK

Operation

EGM-4 Operator's Manual – Version 4.19

- 20 -

Stand Alone CO2Analyzer (Probe Type 0)

To begin recording, press key 1. Immediately after pressing key 1, the instrument will

automatically perform a zero check. Once completed and assuming no problems with the

zero, the instrument will proceed to “Measurement Mode” where the CO2value (plus

additional values if optional humidity sensor is present) being measured by the instrument is

displayed as follows:

Where:

C

CO2concentration (ppm)

H

Humidity (mb). Only if optional %RH/Temp sensor is present.

A

Absolute pressure in sample cell (mb).

P

Refers to probe type. See 1REC on page 19.

To return to the Main Menu while in Measurement Mode, simply press the N key.

Note. If the instrument was just powered up, the display will show “WARM UP DELAY

TEMPERATURE = XX” until the instrument achieves its warm up temperature of 50 oC prior

to entering into Measurement Mode.

Additional information (i.e. external sensors, etc.) may be viewed on the LCD display if

required. While in Measurement Mode with the CO2concentration displayed, subsequent

presses of the 8 key will show additional displays as follows:

C 545

A1011 P00

C 545 H11.2

A1011 P00

Display 1A (without optional %RH

Sensor)

Display 1B (with optional humidity

Sensor)

Table of contents