PPM 2240 PROcheck User manual

INSTRUCTION MANUAL

2240 PROcheck

Fumigation Monitor

Revi ion March 2022

Subject to change without notice

All right re erved

No part of thi publication may be reproduced or modified

in any form or by any mean without prior permi ion of

ppm Me technik GmbH

Jahn tra e 12 – 85661 For tinning – Germany

www.ppm-mt.com

Revi ion hi tory

Revision 1. 4 September 2010 Software amendments

concerning USB records-

Error handling e tended

Revision 2 . 0 March 2011 GSM modem option added

Software amendments

Printer option removed

- option obsolete

Revision 2 . 1 March 2022 Updated address

4-20mA additional info

Obsolete details removed

UART-option removed

- option obsolete

Interface details added

TABLE OF CONTENTS

TABLE OF CONTENTS..........................................................................................................3

1. General In truction .............................................................................................................1

1.1 Indications.......................................................................................................................................................1

1.2 Safety Precautions and Important Instructions................................................................................................2

1.3 Transportation / Storage / Unpacking.............................................................................................................2

2. De cription of Ga Monitor..................................................................................................3

2.1 Instrument layout.............................................................................................................................................3

2.1.1 Front view.................................................................................................................................................3

2.1.2 Rear View.................................................................................................................................................4

2.2 Description of function....................................................................................................................................5

2.2.1 Description of sensor function.................................................................................................................5

2.2.2 Description of equipment function...........................................................................................................6

2.3 Manufacturer-based configuration..................................................................................................................8

2.4 Adaptations at customer's facility...................................................................................................................8

2.4.1 Adjustment of local time / date................................................................................................................8

2.5 Technical data..................................................................................................................................................9

3. Mounting and In tallation..................................................................................................10

3.1 Mounting.......................................................................................................................................................10

4. Start-up................................................................................................................................12

5. Operation.............................................................................................................................12

5.1 Self-testing of instrument..............................................................................................................................12

5.2 Warm-up period............................................................................................................................................13

5.3 Zero adjustment.............................................................................................................................................13

5.4 Automatic measurement operation................................................................................................................15

5.5 E ternally controlled measurement operation...............................................................................................16

5.6 Measurement process....................................................................................................................................17

6. Operational Failure ...........................................................................................................20

6.1 Messages on instrument display....................................................................................................................20

6.1.1 Warning messages..................................................................................................................................20

6.1.2 Failure messages.....................................................................................................................................21

6.2 Communication problems between instrument and plant control.................................................................24

6.2.1 Errors caused by plant control................................................................................................................24

6.2.2 Error on interface cable..........................................................................................................................25

6.2.3 Error on Gas Monitor - interface module (MG-IF)................................................................................25

7. Maintenance........................................................................................................................26

7.1 General hints..................................................................................................................................................26

7.2 E change of Activated Carbon filter.............................................................................................................26

7.3 E change of sample gas filters (particle filter).............................................................................................28

7.4 Calibration of Instrument..............................................................................................................................29

8. Option .................................................................................................................................30

8.1 Analog-outputs..............................................................................................................................................30

8.1.1 Options V218 - analog recorder output 4-20mA....................................................................................30

8.1.2 Option V220 - analog recorder output 0-10V........................................................................................31

8.2 Option V252 – Internal Gas Flow Control....................................................................................................31

8.3 Option V253 - E ternal Memory (USB-Stick).............................................................................................32

8.3.1 Storage of average values.......................................................................................................................32

8.3.2 Readout and erasure of USB-Stick.........................................................................................................34

8.4 Option V260 – Internal GSM Modem..........................................................................................................35

8.4.1 Transmitted values and additional services............................................................................................35

8.4.2 Operating frequencies.............................................................................................................................36

8.4.3 International roaming.............................................................................................................................36

8.4.4 Operation................................................................................................................................................36

Annex A: In tallation................................................................................................................1

1. Installation site..................................................................................................................................................1

2. Electric connection............................................................................................................................................1

3. Sample gas connection......................................................................................................................................2

4. Interface Cable..................................................................................................................................................3

A1: Description of Interface 2240 PROcheck - Plant Control..............................................................................4

A2: Pin Assignment of Machine-Interface Connector..........................................................................................6

A3: Standard-Interface-Cable................................................................................................................................7

A4: Pin Assignment of Standard-Interface-Cable.................................................................................................8

A5: Consumables / Spare parts for 2240 PROcheck.............................................................................................9

Annex B: Technical Specification GSM Modem (Option V260).........................................1

1. Safety recommendations...................................................................................................................................1

2. Conformity Assessment Issues..........................................................................................................................1

3. Declaration of Conformity................................................................................................................................2

1. General In truction

1.1 Indication

This manual has to be read carefully before switching on the instrument.

The instructions must be strictly adhered to.

Non-ob ervance of the e in truction may lead to the lo of right to

claim for damage or warranty!

Meaning of signs used in this instruction manual:

: Warning

: Indication of particular importance

: Avoid actions marked with this sign

CATCHWORDS appear in italics on the right hand margin

1

1.2 Safety Precaution and Important In truction

The 2240 PROcheck-Analyzer is designed for monitoring, displaying,

and logging the levels of a certain compound (gas).

The analyzer is not intended to be a safety monitor. The 2240

PROcheck-analyzer is not designed for use in potentially e plosive

environments. Never place and operate the instrument in areas with a

potentially e plosive atmosphere!

The analyzer should be used only for its intended field of application and

should be operated only by qualified personnel.

1.3 Tran portation / Storage / Unpacking

During transportation please make sure that the instrument is being pro-

tected against violent shocks or impacts. Transportation of instrument

should as a matter of principle only be made in original cardboard bo

containing shock absorbing elements. When storing the instrument for a

longer period of time, it should be wrapped in a plastic hood together

with a silica gel bag for protection against humidity. During storage or

transportation e posure of the instrument to temperatures below -10° or

higher than +60° C must be avoided.

TRANS-

PORTATION

DAMAGES?

Immediately after unpacking the instrument should be visually inspected

for e ternal damage which might have been caused to it during transpor-

tation. In the event of such damage, the supplier has to be informed im-

mediately and the instrument must not be switched on by any means.

2

2. De cription of Ga Monitor

2.1 In trument layout

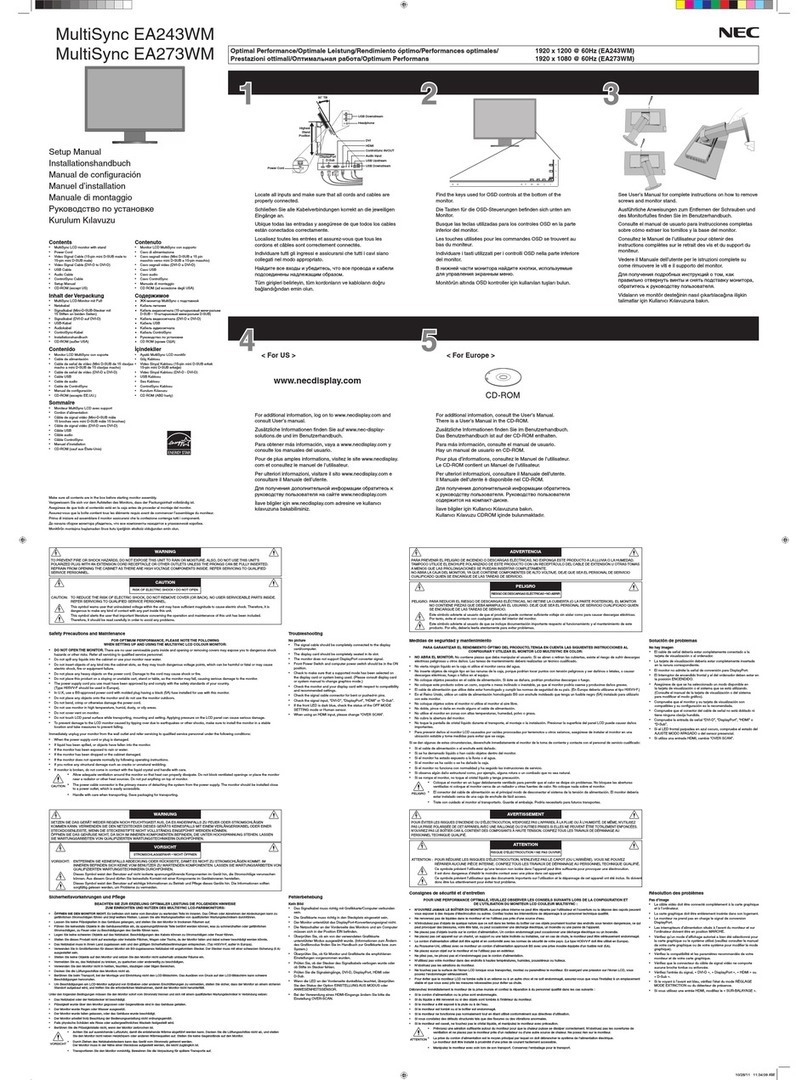

2.1.1 Front view

1 2 3 4 5 6 7 8

Fig. 1 Front View

1 mains switch

2 cover of activated carbon filter

3 device status display

4 LC-Display

5 measurement channel status display

6 push buttons (behind front panel) for instrument setup

7 interface USB-Stick (optional)

..8 GSM-Antenna connector (optional)

3

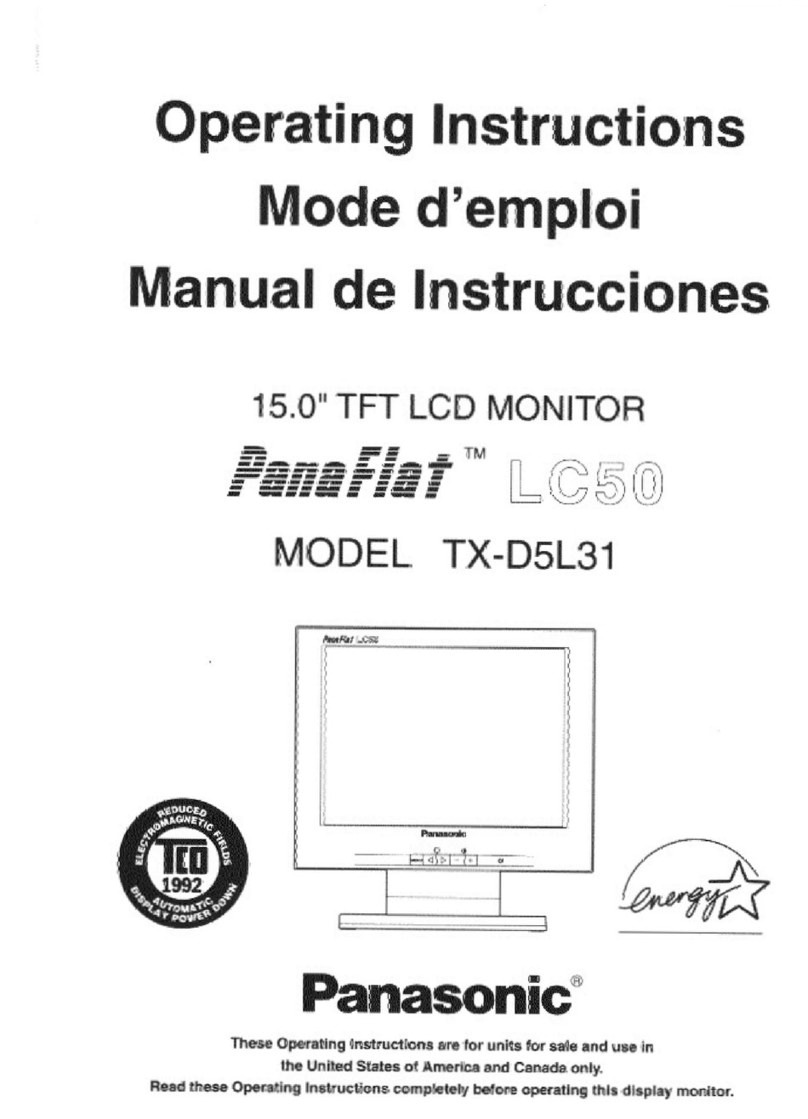

2.1.2 Rear View

9 5 10 11 12 13

1 2 3 4 5 6 7 8

Fig. 2 Rear View

1 CPU-Module 8 Power supply module

2 Analog output (optional) 9 Service interface connector

3 Reset-Button 10 Gas outlet

4 Sensor-Module 11 Gas inlets (1...3)

5 Hose S/I – Sensor 12 SUB-D connector control interface

6 Sampling / Interface module (S/I) 13 Mains power connector

7 Hose S/I – activated carbon filter

4

2.2 De cription of function

2.2.1 De cription of en or function

In Gas Monitors 2240 PROcheck a sensor is being used which

operates on the principle of

Infrared - NDIR.

By means of which the physical quality of many gases to react to

electromagnetic waves (for instance infrared rays) is being e ploited

as they respond to a single (or to several) wave length(s) specific to

every kind of gas as well as absorb such energy.

PRINCIPLE

An infrared radiation source emits IR-radiation of a wide range and of

different wave lengths. An optical filter permits the passage of defined

wave lengths of small band width from the radiation source's

spectrum. This defined bandwidth is characteristic for the gas

component to be determined.

At this wave length the gas component will absorb IR-radiation. This

effect is converted into electric signals by a measuring transducer.

The concentration of the gas component is being calculated via

calibration functions filed in the Gas Monitor's configuration library.

5

2.2.2 De cription of equipment function

The devices of the type 2240 PROcheck are primarily intended for

measurement of gas concentrations in fumigation processes. They are

equipped with 3 measuring gas connections, which can be selected

either by the instrument software automatically or by an e ternal

controller (Plant- or machine-control). Two limits per channel can be

adjusted to suit your requirements independently.

For measuring the gas concentration of the currently selected

measurement channel, the gas to be analysed is drawn by the device

internal diaphragm pump through a particulate filter and the sample

gas line in the sensor (active sampling). During the measuring

operation a large number of individual measured values is integrated.

The result is continuously displayed and compared with the limiting

values valid for the current measurement channel.

A comparison of the set limits versus measured value will be e ecuted

only after a predetermined time (set by device software) to avoid

mispricing by short-term fluctuations in concentration. The formation

of mean values for the storage (USB / GSM) begins just after this time

has elapsed.

The “traffic light” indicator on the front panel visually inform about

the status of the measuring channel with respect to the set limits.

For the behavior of the alarm contacts are three settings available:

NO (normally open)

NC (normally closed)

Alarm window

The following tables describe the status of the LED lights and the

signal contacts with different alarm settings.

6

Setting NO:

In this setting, the contacts of the pre- and main-alarm are clo ed in

case of e ceeded thresholds.

Mea ured LED- Contact Contact

concentration level Light MOK(1..3)V MOK(1..3)H

Value < Pre-alarm and

Value < Main-alarm open open

Value > Pre-alarm close open

Value > Main-alarm close close

Setting NC:

In this setting, the contacts of the pre- and main-alarm are opened in

case of e ceeded thresholds.

Mea ured LED- Contact Contact

concentration level Light MOK(1..3)V MOK(1..3)H

Value < Pre-alarm and

Value < Main-alarm close close

Value > Pre-alarm open close

Value > Main-alarm open open

Setting Alarm window:

This setting is useful when an area between pre-alarm and main alarm

threshold must be met.

Mea ured LED- Contact Contact

concentration level Light MOK(1..3)V MOK(1..3)H

Value > Pre-alarm and

Value < Main-alarm open open

Value < Pre-alarm closed open

Value > Main-alarm open closed

7

2.3 Manufacturer-ba ed configuration

For best possible adaptation of instrument to the envisaged task many

parameters of the configuration may be determined by the customer for

their integration at the factory or by authorized service personnel, for

e ample:

Alarm thresholds (in ppm)

Operating mode (e ternally controlled or automatic

measuring operation)

Cyclic zero value measuring (activated, not activated, time in-

tervals)

Reference temp. and -pressure Standard: 0 °C and 1013 mbar

Time for measuring cycle Standard: 20 seconds

The changing of operating mode and/or of cycle time requires access to

the internal settings of the instrument. For this purpose a special

configuration software for authorized service personnel is available.

2.4 Adaptation at cu tomer' facility

2.4.1 Adju tment of local time / date

At the right-hand side of the display two switches are to be found

behind two small bores in the front plate. These switches may be

activated with a simple slim screwdriver or with a similar tool (Fig. 1,

item 6) in order to set for instance e act local time and calendar date.

The setting of time and date is achieved by following steps:

Switch off instrument

Keep upper switch in pressed down position and switch on instru-

ment. The input mask will appear. Now release switch. The cursor

is blinking at “day”.

With the upper switch any full hour between "00 and 23 "may be

selected and set

Confirm the hour setting by briefly pressing the lower switch

The cursor jumps to the ne t position (“month”). Proceed in the

way described above.

8

After input of date is finished, the cursor jumps to the time input.

Proceed similar to date adjustment

After confirmation of the minutes field, the device continues with

normal start-up procedure

If there are any mi take in the adju tment of date/time, plea e

repeat from the beginning. In that ca e witch off device fir t.

2.5 Technical data

Dimensions: Height appro .: 150 mm = 5.91 in

Width (standard unit) appro .: 235 mm = 9.25 in

Depth appro .: 270 mm = 10.63 in

Weight: appro . 4.5 kg

Electrical mains: Wide range input

90 – 264 Volts AC

47 – 63 Hz

Power consumption: ma . 65 Watt

Temperature range: storage: -10°C to +60°C

(+14°F to +140°F)

operation: +10°C to +40°C

(+50°F to +104°F)

Air moisture range: 0 to 95%, non condensing relative humidity

Digital display: 4-line, 20-character-LCD-display, monochrome

Measuring principle: physical, infrared spectroscopy, NDIR sensor

Compound: SO2F2, Profume®, Vikane®

Measuring range: 1 – 150 g/m³

Accuracy: 1% of measured value plus ± 0.5 g/m³

9

3. Mounting and In tallation

3.1 Mounting

MOUNTING

SITE

In order to a ure trouble-free functioning of the in trument,

mounting it a free of vibration a po ible i of e ence. The

in trument hould be kept at a afety di tance of at lea t 5 cm away

from all urrounding wall to en ure free airflow for cooling of the

equipment ( ee al o chapter 3.2.2 for reference).

The instrument has been specified for an ambient temperature range from

+10°C (+50°F) up to +40°C (+104°F). Condensation of air moisture

inside the instrument has to be avoided.

FILTERS

For protection of valve and mea uring chamber again t pollution all

mea uring point have to be provided with appropriate filter . The

filter hould be in talled clo e t to the ampling point to avoid

contamination of the ampling ho e.

Suitable filters are of such quality that they will neither adsorb molecules

of the gas components to be measured in the filter housing nor in the fil-

ter element itself. Moreover will they permit filtration of particles the

size of 5 micrometers.

10

ELECTRIC

CONNECTION

Electric connection

The electric mains for 2240 PROcheck must meet the following

requirements:

Nominal voltage: 90 - 264 Volts AC

Frequency: 47 to 63 Hz

Power consumption: ma . 65 Watts

Before connecting in trument to electric main verify if upply

voltage meet tho e requirement and if it ha been expertly fu e

protected. Incorrect voltage may cau e the fu e of the in trument

to blow or damage the in trument it elf.

WARNING! HIGH VOLTAGE!

Prior to opening up of in trument for any rea on, it main power

upply cable mu t be unplugged!

Non-ob ervance of the e in truction can re ult

in per onal injury or death.

SAMPLE GAS

CONNECTIONS

Sample ga connection

The sample gas inlet and outlet of 2240 PROcheck are shown in

Chapter 2.1.2, fig. 2, item 10 and 11.

The sample gas inlets can be equipped with gas tubes of length up to

100 meters without disturbance of the instruments function. On the

sample gas outlet also tubes of length up to 100 meters can be

connected.

Additional detailed information concerning sample gas hoses, instal-

lation of dust filter and about sampling of measuring gas is given in

Annex A. Periodical changing of filters is described in Chapter 7,

Maintenance.

In tallation of fal e filter and undue exten ion of maintenance

interval will inevitably lead to malfunction or to damage on the

mea uring in trument!

In order to avoid clogging of valve or contamination of

mea uring chamber, the in trument hould only be operated with

appropriate filter in talled right behind the mea urement point!

11

4. Start-up

Before connecting the instrument to the mains, make sure that supply

voltage strictly corresponds to the requirements detailed in Chapter 3.2.2

Before tarting-up the in trument, remove du t eal from the

mea uring ga inlet and outlet . Al o check the exi tence of the

zero ga filter.

Now you may start the instrument by activating the mains switch on the

instrument front panel.

5. Operation

As soon as the instrument has been connected to the mains and switched-on,

it will automatically run through the following routines before starting the

actual measuring operation:

Self-Te ting

Warm-up period

Auto-zero adju tment

During the startup-process the green power-light is flashing.

5.1 Self-te ting of in trument

Immediately after the instrument is switched on, a self-test is performed.

All optic and acoustic displays are powered for a brief moment. The

compound to measure, its over-all measuring range and the software

release is shown in the LC-display.

During the warm-up period and also while in normal operation (e cept

while in Stand-By-Mode) the instrument will carry out automatic self-

testing at intervals of appro . 20 seconds as a check on important instru-

ment functions. In the event of any malfunction, the warm-up period or

the actual measurement cycle will be interrupted with the most probable

fault appearing on the display (see Chapter 6, - Malfunctions).

Simultaneously an acoustic as well as an optical alarm (flashing of

display and of fault indicator) will appear, which can be stopped either by

pressing the alarm-quit-button (if realized at the connected

machine/plant) or will stop automatically after 1 minute. In case of a

malfunction of the instrument, a restart of the instrument becomes

necessary.

12

5.2 Warm-up period

The measuring chamber of the sensor is being heated up until 50°C

(122°F) have been reached. This will take appro imately 3 minutes at an

ambient temperature of 20°C (68°F). The actually prevailing temperature

inside the measuring chamber will be displayed in °C. A progress bar

shows the percentage of completion.

After 50°C (122°F) have been reached, warming up is being continued a

certain time period (‘stabilizing’) in order to make sure that the whole

unit has adopted the desired operating temperature.

As soon as the unit finished heating, zero adjustment starts.

5.3 Zero adju tment

Repetitive zero adjustment will compensate possible changes in the sen-

sor equipment (e.g. aging of infrared source) and this way eliminate zero

drift. Ambient air is being drawn in through the installed activated carbon

filter (fig. 1, item 2) or as may be the case through an e ternal zero gas

inlet (see below) and measured in the sensor. Since in a properly serviced

zero filter the activated carbon will adsorb the measurable substance(s),

the concentration of substance(s) in the sensor equals zero.

To provide error-free zero adju tment, the activated carbon filter

mu t be changed regularly. Spent activated carbon filter will lead to

incorrect te t re ult or to error indication

13

INTERNAL

MEASURING

RANGES

Only under the condition that at least 4 con ecutive zero adju tment

cycle are within a specified tolerance, the zero value will be accepted. In

case a measuring value e ceeds the specified tolerance (caused e.g. by a

contaminated measuring chamber or by leaks etc.) the number of

previous measured values will be reset to zero. 2240 PROcheck will

then renew its effort for zero adjustment. If after 50 attempts no

consecutive values prove to be correct, the instrument will stop zero

adjustment and indicate a failure (see Chapter 6).

DURATION OF

ZERO

ADJUSTMENT

Duration of zero adjustment is appro . 1 minutes in a favorable case. In

the most unfavorable case this operation may take up to 15 minutes if e.g.

the gas path or the measuring chamber is contaminated. If no correct zero

adjustment is being achieved within this time frame, then a failure

indication will be given (see Chapter 6).

DISPLAY

During the zero adjustment the display will show the measuring range

actually under test and additionally the progress of zero adjustment:

RNG indicates the actual measuring range, The value after the “A”

shows the number of attempts and the value after the “S” shows the

number of results lying within the specified tolerance bracket.

After successful zero adjustment the instrument normally switches to

"Stand-By-Mode"

Depending on the configuration of the instrument this stand-by mode will

either be maintained or it will automatically switch over to measuring at

a pre-configured channel.

AUTOMATIC

ZERO

ADJUSTMENT

2240 PROcheck automatically carries out a zero adjustment procedure

after every activation of the mains switch.

14

MANUAL ZERO

ADJUSTMENT

In those cases where 2240 PROcheck has been in operation over a

period of several days without interruption a manual zero adjustment is

recommended. The user may trigger such manual zero adjustment by

pressing the push- button ”Reset” on the rear front plate of the CPU-

Module (see fig. 2, item 3).

The instrument will then initiate the power-up-cycle described in this

chapter. This sequence includes carrying out a zero adjustment.

CYCLIC ZERO

ADJUSTMENT

In cases where the instruments are intended to serve in continuous op-

eration, it is recommendable for the user to opt for activation of the pro-

gram function "cyclic zero adjustment" at the manufacturer's side or by

authorized service personnel, rather than selecting the repetitive manual

triggered zero adjustment.

As an interval for cyclic zero adjustment any full hour within a time

frame between 1 and 35 hours may be set up to the program. The interval

to be set should reflect the intensity of operation as well as other local

influencing factors e.g. change of shift etc.

After every lapse of the programmed time interval counting from the

tart-up moment, the measuring operation will be interrupted to be fol-

lowed by a zero point adjustment. Thereafter the measuring operation

will be resumed.

5.4 Automatic mea urement operation

When programmed for automatic measuring operation, 2240 PROcheck

will directly change over to measurement operation after successful zero

adjustment (see Chapter 5.6, Measuring process).

15

5.5 Externally controlled mea urement operation

When programmed for e ternally controlled measurement operation, the

instrument will fall into the passive mode ”Stand-By” after successful

zero adjustment.

No measuring is made.

In this mode 2240 PROcheck is e pecting a request for measurement to

be made. By means of the standard machine interface that request will be

sent to the instrument by the e ternal control using the signal MRQ(1..3),

(for reference see Annex A, fig. A1, A2).

16

Table of contents