3

G. Unless otherwise specified, tighten all bolts to the

standard torque specifications listed at the end of

the note's section. Do not use an impact wrench to

tighten any of these bolts. They tend to over tighten

smaller bolts and under tighten larger bolts. USE A

TORQUE WRENCH!!!

H. Rancho parts come with a protective coating. Do

not chrome, cadmium, or zinc plate any of the

components in this kit, or alter their original finish

in any way. However, you may add a layer of

Enamel paint over the original coating.

I. Do not weld anything to these components, and do

not weld any of these components to the vehicle. If

any component breaks or bends, contact your local

Rancho dealer or Rancho for replacement parts.

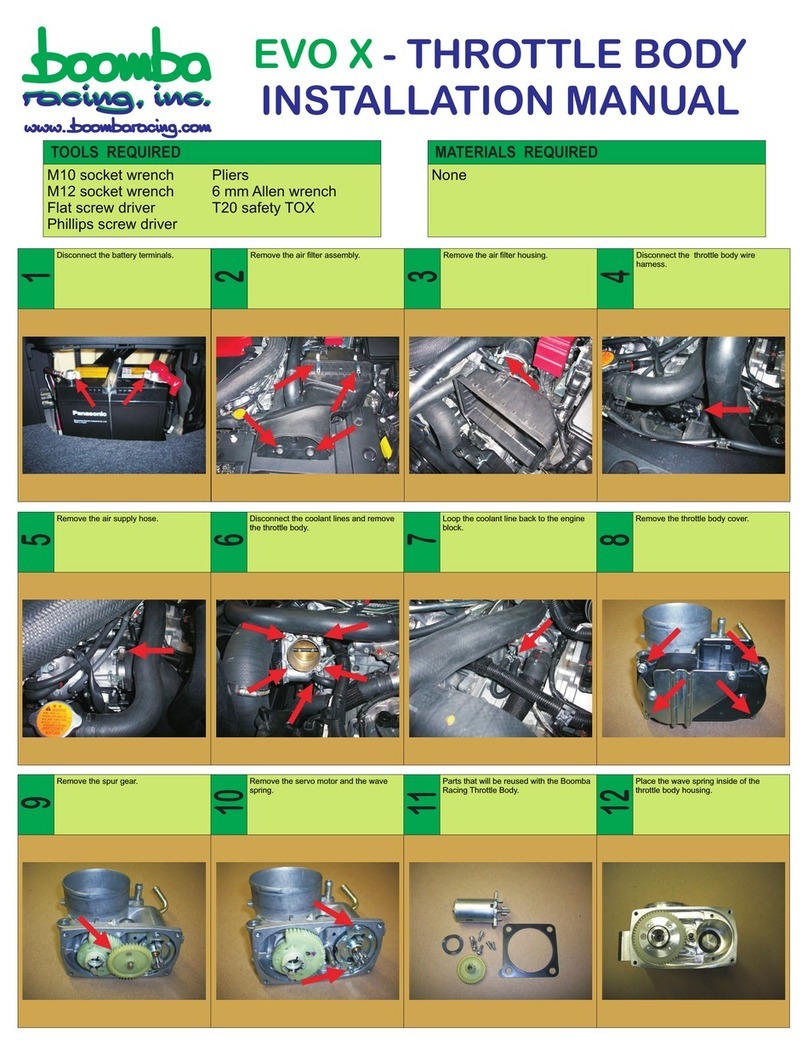

J. Some of the service procedures require the use of

special tools designed for specific procedures.

These special tools should be used when

recommended.

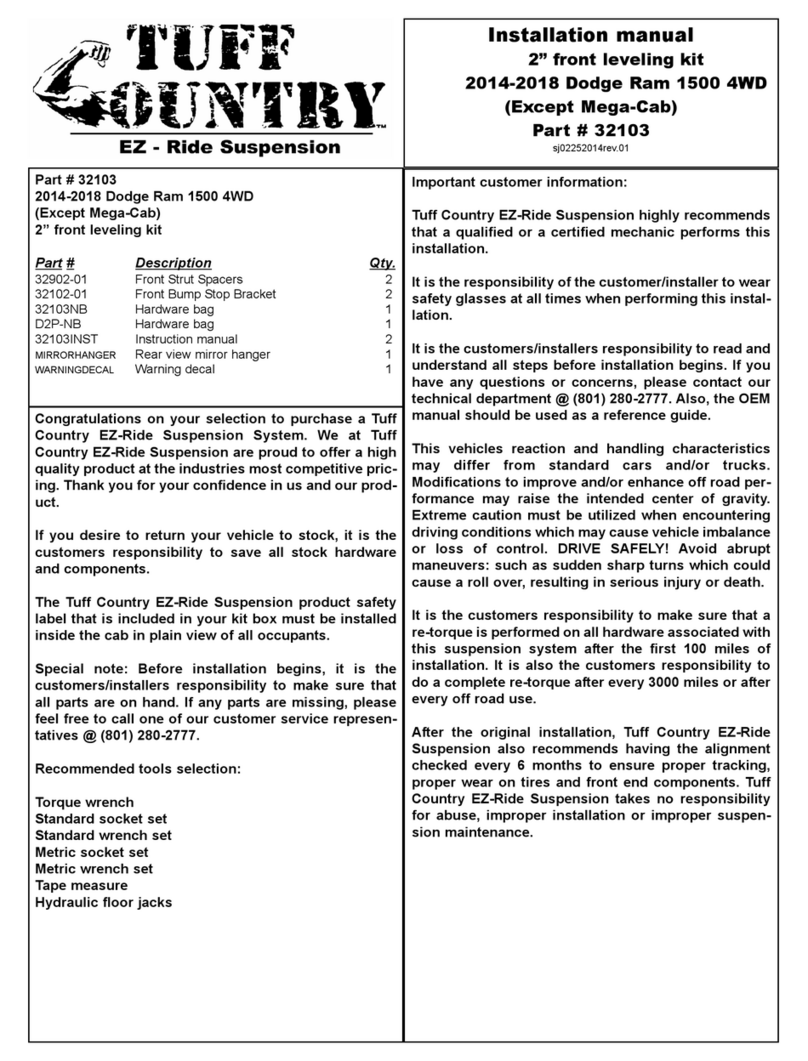

K. The following tools and supplies are recommended

for proper installation of this kit. Ρ

Jeep Service Manual

Spring Compressor

Drill Motor

23/64", 15/32", 13/32" and 9/32" Drills

Torque Wrench (250 FT-LB capacity)

1/2” Drive Ratchet and Sockets

Combination Wrenches

Allen Wrenches

Torx Key Sockets

Heavy Duty Jack stands

Wheel Chocks (Wooden Blocks)

Hydraulic Floor Jack

Large "C" Clamps and or Bench Vise

Hammer

Molybdenum Grease or Anti Seize Compound

Silicone Spray

Safety Glasses--Wear safety glasses at all times

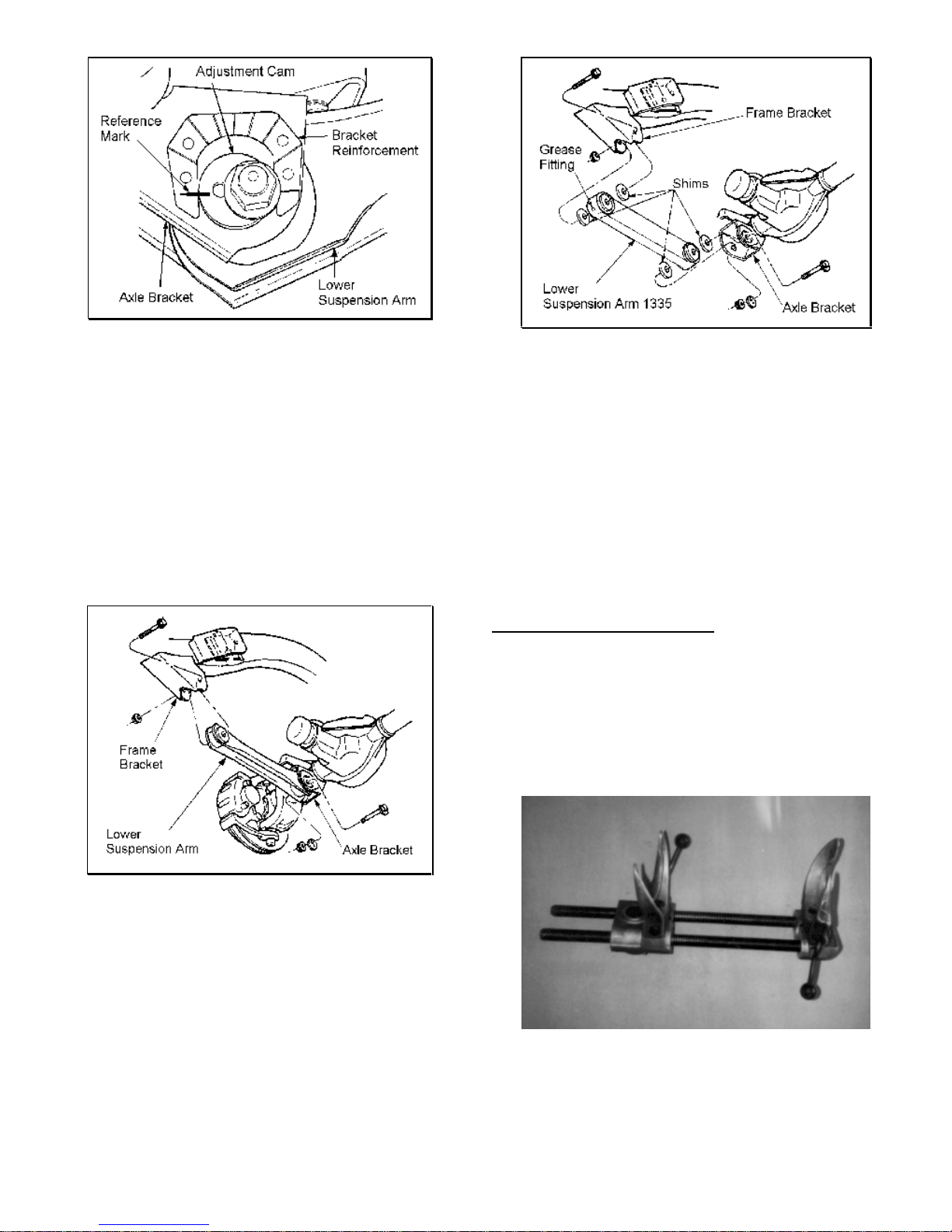

L. It is extremely important to replace torsion bars, CV

flanges, and front drive shaft/pinion relationships as

original. Be sure to mark left/right, front/rear, and

indexing of mating parts before disassembly. A

paint marker or light colored nail polish is handy for

this.

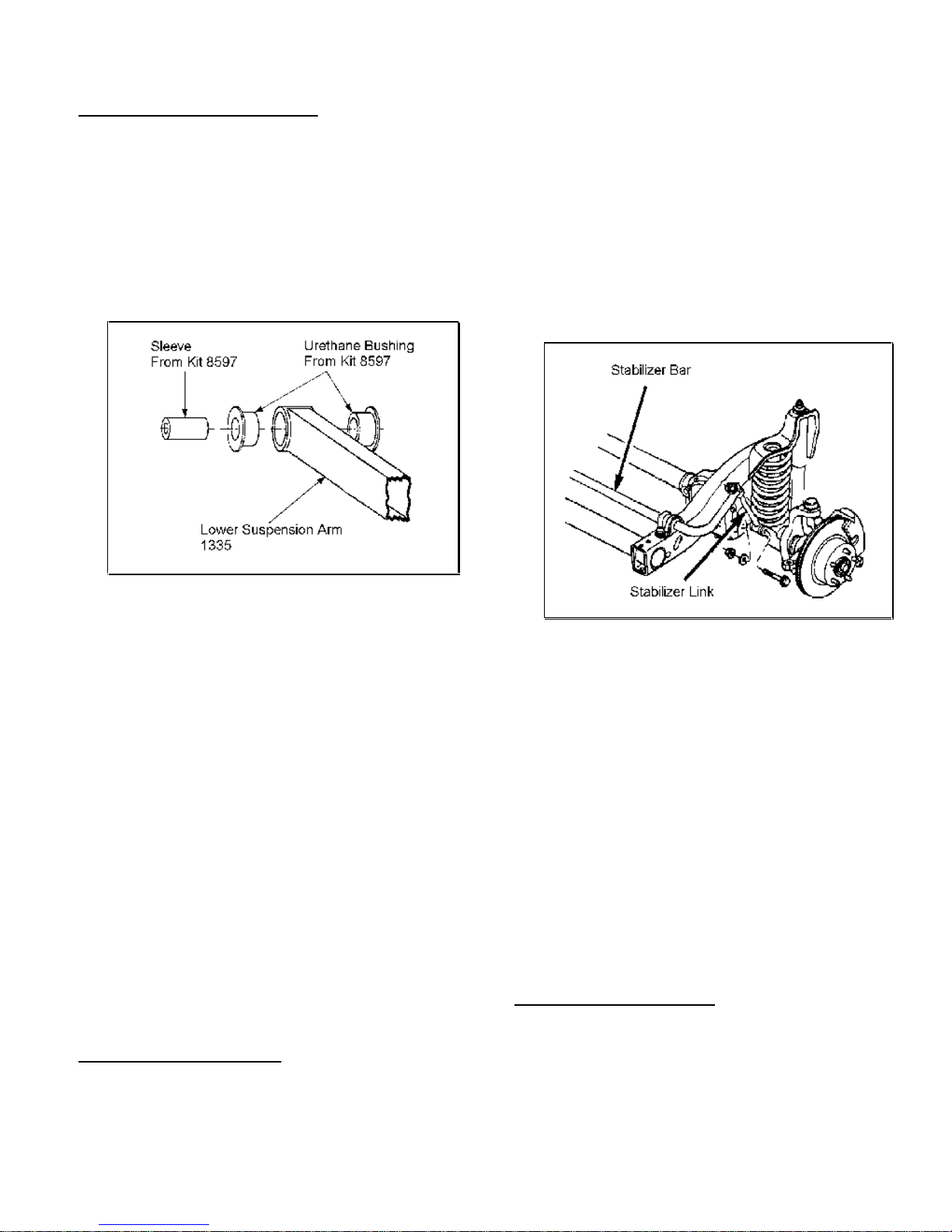

M.Suspension components that use rubber or urethane

bushings should be tightened with the vehicle at

normal ride height. This will prevent premature

failure of the bushing and maintain ride comfort.

N. The required installation time for this system is

approximately 8 hours. Check off the box ( Ρ) at

the beginning of each step when you finish it. Then

when you stop during the installation, it will be

easier to find where you need to continue from.

O. Important information for the end user is contained

in the consumer information pack. If you are

installing this system for someone else, display the

information pack by hanging it from the rear view

mirror.

P. Thank you for purchasing the best suspension

system available. For the best installed system,

follow these instructions. If you do not have the

tools or are unsure of your abilities, have this

system installed by a certified technician.

RANCHO IS NOT RESPONSIBLE FOR

DAMAGE OR FAILURE RESULTING FROM

IMPROPER INSTALLATION OF THIS

SUSPENSION SYSTEM.

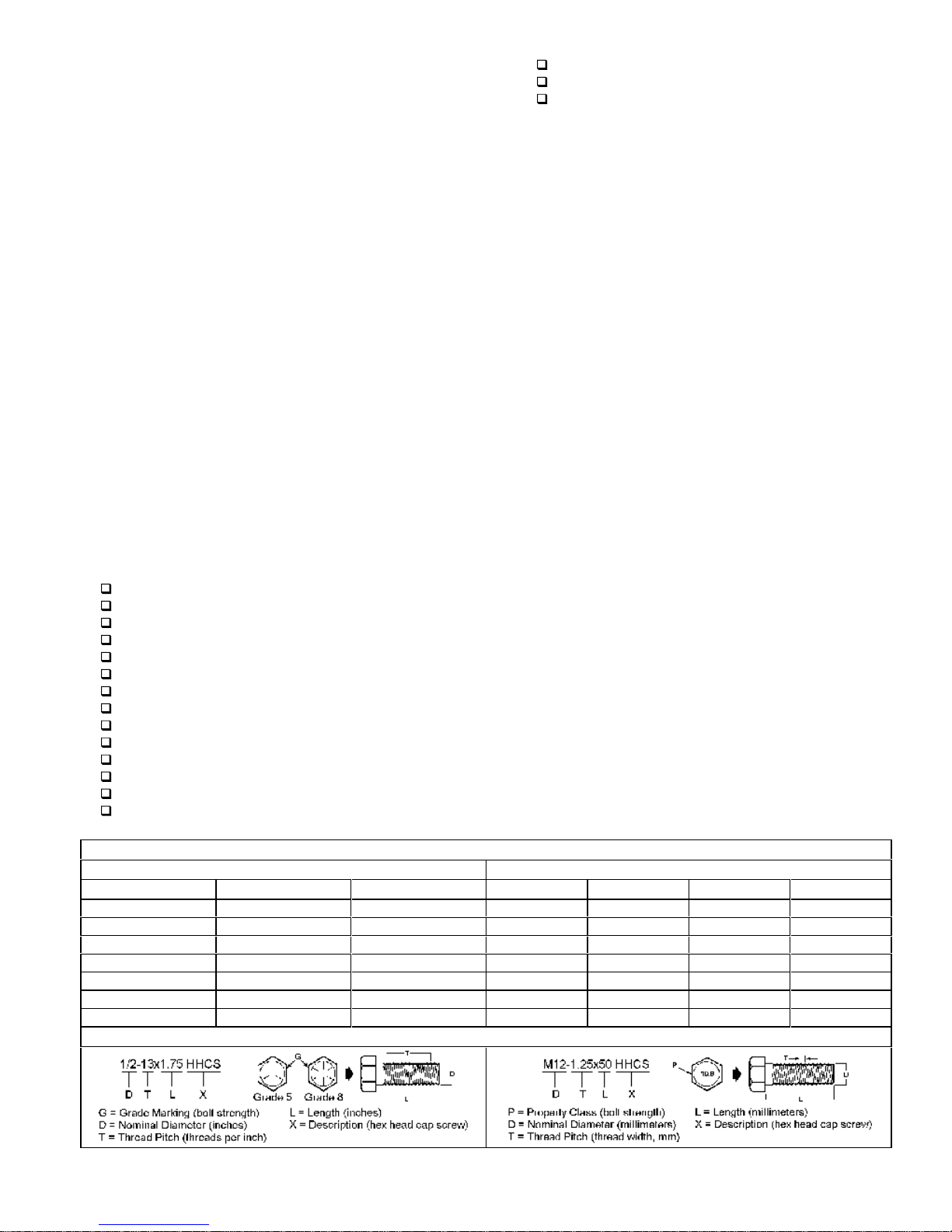

STANDARD BOLT TORQUE SPECIFICATIONS

INCH SYSTEM METRIC SYSTEM

Bolt Size Grade 5 Grade 8 Bolt Size Class 9.8 Class 10.9 Class 12.9

5/16 15 FT-LB 20 FT-LB M6 5 FT-LB 9 FT-LB 12 FT-LB

3/8 30 FT-LB 35 FT-LB M8 18 FT-LB 23 FT-LB 27 FT-LB

7/16 45 FT-LB 60 FT-LB M10 32 FT-LB 45 FT-LB 50 FT-LB

1/2 65 FT-LB 90 FT-LB M12 55 FT-LB 75 FT-LB 90 FT-LB

9/16 95 FT-LB 130 FT-LB M14 85 FT-LB 120 FT-LB 145 FT-LB

5/8 135 FT-LB 175 FT-LB M16 130 FT-LB 165FT-LB 210 FT-LB

3/4 185 FT-LB 280 FT-LB M18 170 FT-LB 240FT-LB 290 FT-LB

BOLT IDENTIFICATION