English --- 9

115391326 Rev. 3 1/31/11

GENERAL SAFETY PRECAUTIONS

Personal protective equipment

SApproved protective helmet

SHearing protection

SProtective goggles or a visor

SGloves with saw protection

STrousers with saw protection

SBoots with saw protection, steel toe--cap and

non--slip sole

SAlways have a first aid kit nearby.

SFire Extinguisher and Shovel

Generally clothes should be close--fitting

without restricting your freedom of move-

ment.

Machine’s safety equipment

In this section the machine’s safety fea-

tures and their function are explained.

For inspection and maintenance see

instructions under the heading Checking,

maintaining and servicing chain saw safety

equipment. See instructions under the

heading, What is what?, to find where

these parts are located on your machine.

The life span of the machine can be reduced

and the risk of accidents can increase if

machine maintenance is not carried out

correctly and if service and/or repairs are

not carried out professionally. If you need

further information please contact your

nearest servicing dealer.

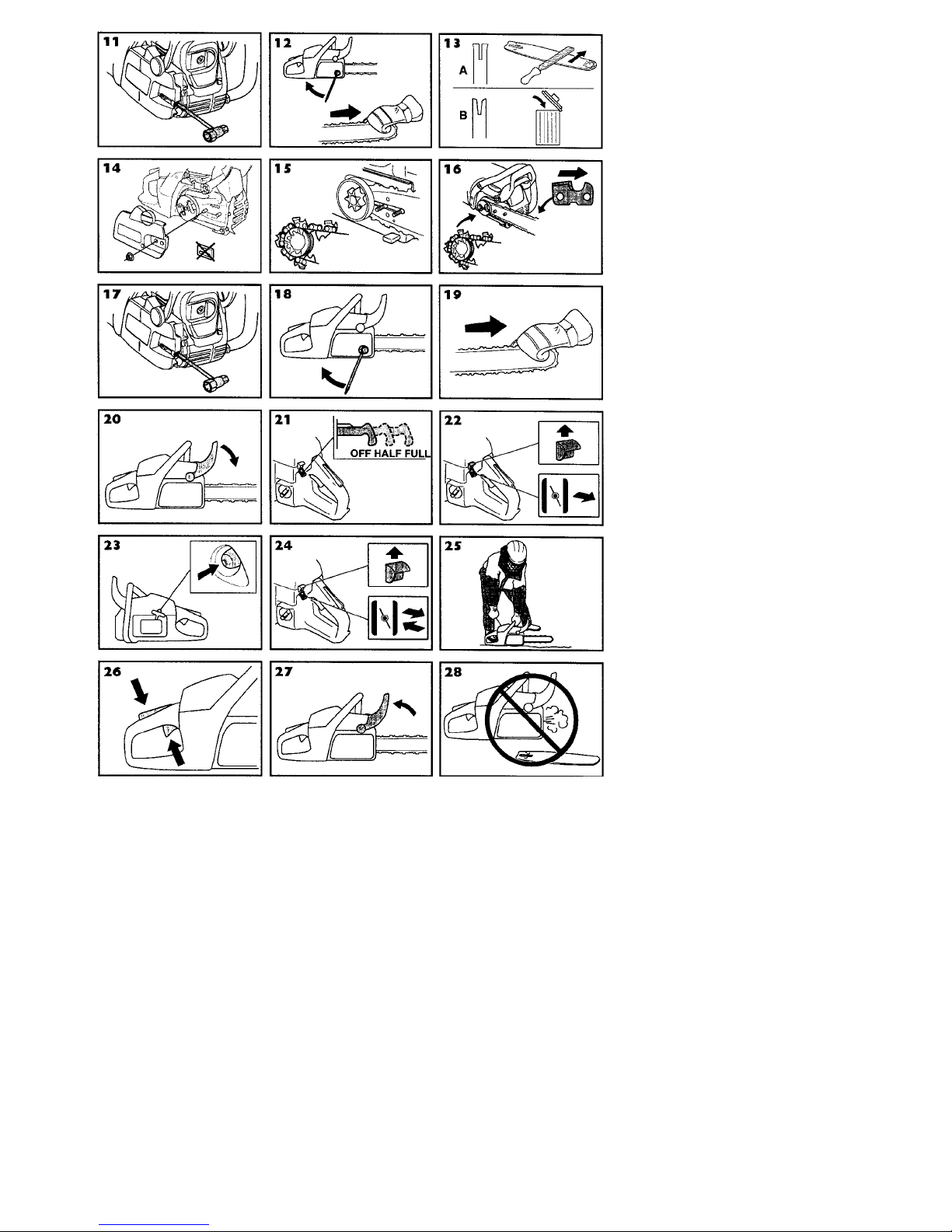

Chain brake and front hand guard

Your chain saw is equipped with a chain

brake that is designed to stop the chain if

you get a kickback. The chain brake re-

duces the risk of accidents, but only you

can prevent them.

Take care when using your saw and make

sure the kickback zone of the bar never

touches any object.

SThe chain brake (A) can either beactivated

manually (by your left hand) or automati-

cally by the inertia release mechanism. (3)

SThe brake is applied when the front hand

guard (B) is pushed forward. (3)

SThis movement activates a spring--loaded

mechanism that tightens the brake band

(C) around the engine drive system (D)

(clutch drum). (4)

SThe front hand guard is not designedsolely

to activate the chain brake. Another impor-

tant feature is that it reduces the risk of your

left hand hitting the chain if you lose grip of

the front handle.

SThe chain brake must be engaged when the

chain saw is started to prevent the saw chain

from rotating.

SUsethechainbrakeasa“parkingbrake”

when starting and when moving over short

distances, to reduce the risk of moving chain

accidentally hitting your leg or anyone or any-

thing close by.

WARNING: Most chain saw acci-

dents happen when the chain

touches the operator. You must use

approved personal protective

equipment whenever you use the

machine. Personal protective

equipment cannot eliminate the risk

of injury but it will reduce the de-

gree of injury if an accident does

happen. Ask your dealer for help in

choosing the right equipment.

WARNING: Faulty cutting equip-

ment or the wrong combination of

bar and saw chain increases the

risk of kickback! Only use the bar/

saw chain combinations we

recommend, and follow the filing

instructions. See instructions un-

der the heading Technical data.

Always use common sense (2)

It is not possible to cover every conceivable

situationyoucanfacewhenusingachain

saw. Always exercise care and use your

common sense. Avoid all situations which

you consider to be beyond your capability. If

you still feel uncertain about operating proce-

dures after reading these instructions, you

should consult an expert before continuing.

Do not hesitate to contact your dealer or us if

you have any questions about the use of the

chain saw. We will willingly be of service and

provide you with advice as well as help you

to use your chain saw both efficiently and

safely. Attend a training course in chain saw

usage if possible. Your dealer, forestry school

or your library can provide information about

which training materials and courses are

available. Work is constantly in progress to

improve the design and technology -- im-

provements that increase your safety and

efficiency. Visit your dealer regularly to see

whether you can benefit from new features

that have been introduced.

IMPORTANT! Sparks can come from the

muffler, the bar and chain or other sources.

Always have fire extinguishing tools avail-

able if you should need them. Help prevent

forest fires.

WARNING: Never use a machine

with defective safety components.

Safety equipment must be in-

spected and maintained. See in-

structions under the heading

Checking, maintaining and servic-

ing chain saw safety equipment. If

your machine does not pass all the

checks, take the saw to a servicing

dealer for repair.