US-3

HEZ230F/HEZ260F

U

S

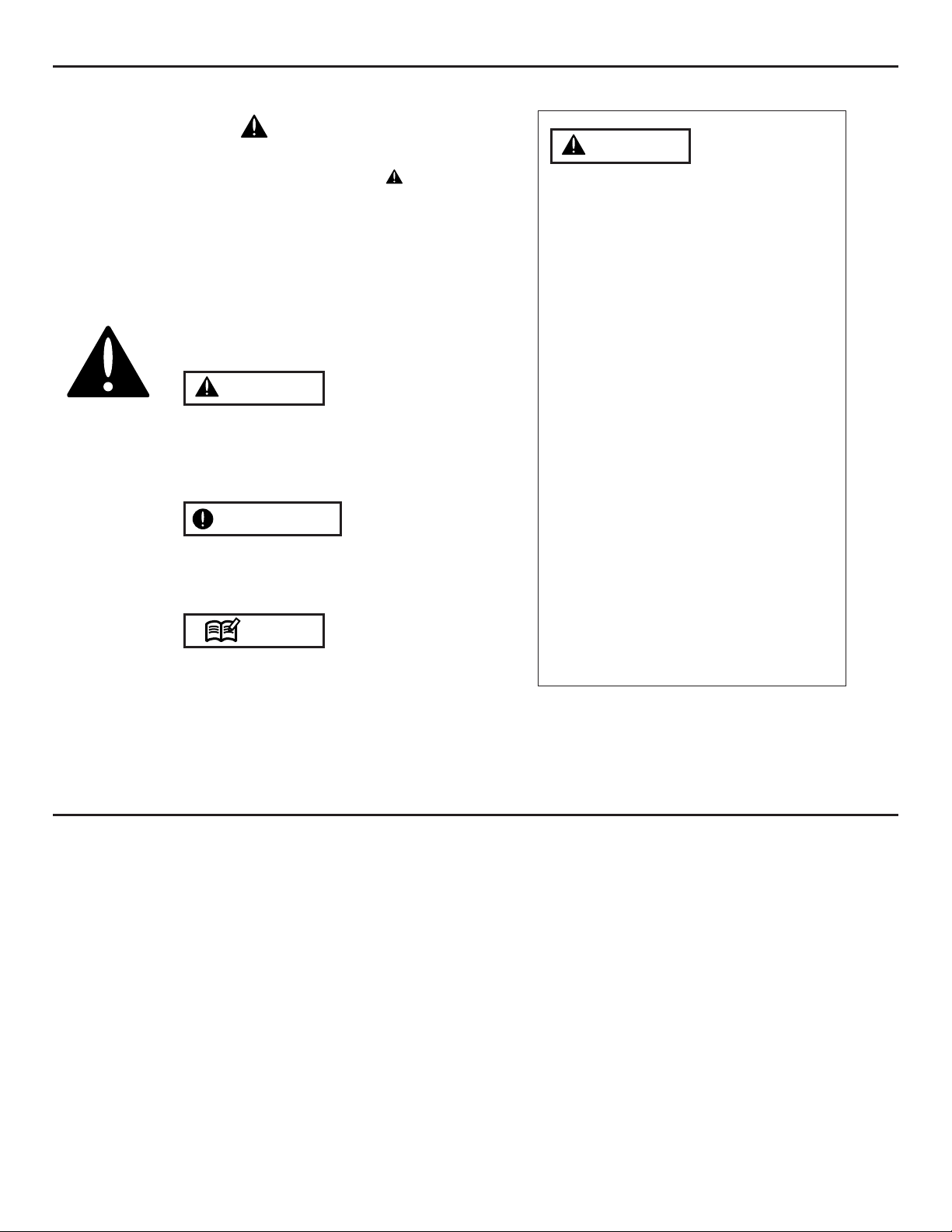

1. Parts location

1. Loop handle

2. Stop switch

3. Throttle cable

4. Throttle lever

5. Blade guard

6. Grease filler cap

7. Wheel

8. Spark arrester

9. Starter knob

10. Fuel tank

11. Air purge

12. Choke lever

13. Air cleaner cover

14. Locking nut

15. Support flange

16. Blade

17. Drive disk

18. Combination spanner

19. Locking pin

20. Operator's manual

2. Specifications

■HEZ260F

Overall size(LxWxH) ··············································································· 69.0 (1752)x11.1 (283)x11.4 (290) in (mm)

Dry weight w/o acc. ······················································································································ 14.6 (6.63) lbs (kg)

Engine Type·················································································································· Air-cooled 2-stroke gasoline

Model ················································································································································· GZ26S

Displacement ················································································································· 1.6 cu-in (25.4 cm3)

Max. output ························································································ 1.27 Hp (0.95 kW) at 7500/min-1(rpm)

Idle speed····················································································································3000 ± 200/min-1(rpm)

Fuel ·················································································································· Mixture (Gasoline 50 : Oil 1)

··················································································································(when using RedMax genuine oil)

Carburetor ··············································································································· Walbro Diaphragm type

Spark plug ······························································································································NGK BPMR8Y

Fuel tank capacity···························································································································22.3 fl.oz (0.66 )

Transmission···································································································· Centrifugal clutch, Flexible driveshaft

Reduction ratio····················································································································································· 1.25

Cutting head rotating direction··················································································· Clockwise (Vew against blade)

Durability period··············································································································································300 hrs.

Blade length ···································································································································7.87 (200) in (mm)

Use for ·················································································································································· Lawn edging

Specifications are subject to change without notice.

■HEZ230F

Overall size(LxWxH) ··············································································· 68.9 (1749)x11.1 (282)x11.4 (289) in (mm)

Dry weight w/o acc. ························································································································· 14 (6.35) lbs (kg)

Engine Type·················································································································· Air-cooled 2-stroke gasoline

Model ················································································································································· GZ22S

Displacement ················································································································· 1.4 cu-in (22.5 cm3)

Max. output ·························································································· 1.0 Hp (0.75 kW) at 8000/min-1(rpm)

Idle speed····················································································································3000 ± 200/min-1(rpm)

Fuel ·················································································································· Mixture (Gasoline 50 : Oil 1)

··················································································································(when using RedMax genuine oil)

Carburetor ··············································································································· Walbro Diaphragm type

Spark plug ······························································································································NGK BPMR8Y

Fuel tank capacity···························································································································21.6 fl.oz (0.64 )

Transmission···································································································· Centrifugal clutch, Flexible driveshaft

Reduction ratio····················································································································································· 1.25

Cutting head rotating direction··················································································· Clockwise (Vew against blade)

Durability period··············································································································································300 hrs.

Blade length ···································································································································7.87 (200) in (mm)

Use for ·················································································································································· Lawn edging

Specifications are subject to change without notice.