Index

1. Package contents ...................................................................................................... 4

1.1. Unpacking the stove ............................................................................................ 4

2. Safety warnings........................................................................................................ 4

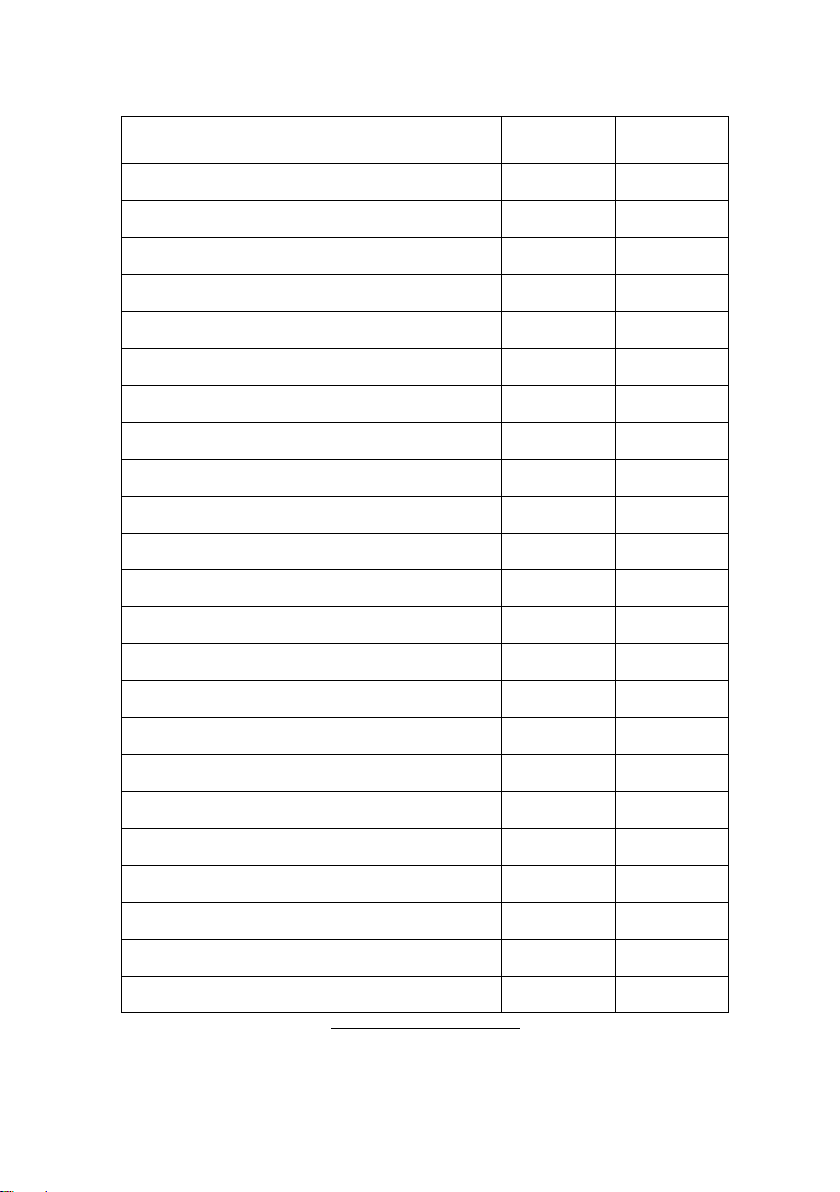

3. Technical specifications* ............................................................................................ 6

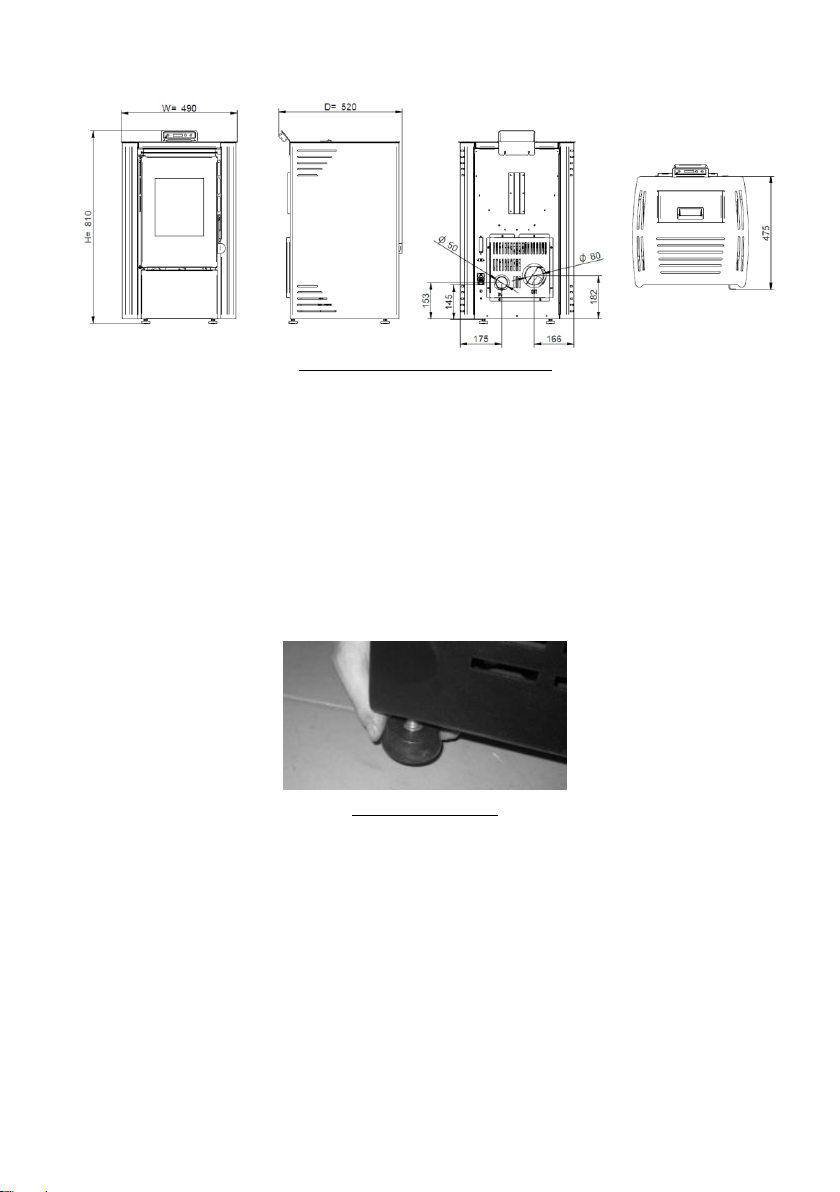

4. Installation of the pellet stove .................................................................................... 7

4.1. Installation requirements ..................................................................................... 8

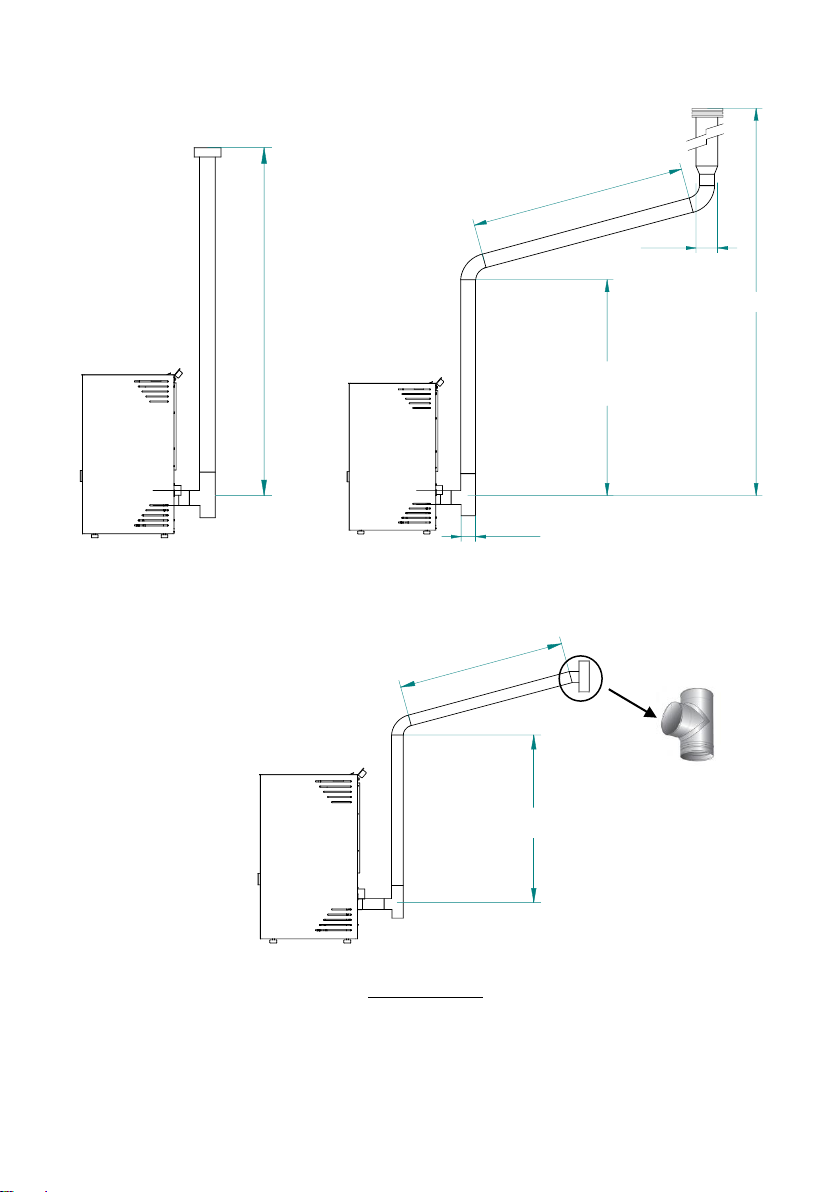

4.2. Installation of ducts and smoke exhaust systems .................................................... 8

4.3. Installation without chimney ................................................................................. 9

4.4. Installation with chimney ................................................................................... 12

5. Fuel ...................................................................................................................... 13

6. Use of pellet stove .................................................................................................. 14

7. Remote Control ...................................................................................................... 15

7.1. Infrared Remote Control..................................................................................... 15

7.2. Control and Display Panel................................................................................... 16

7.3. Display Information Summary............................................................................. 17

7.3.1. Selecting the Manual or Automatic Mode ................................................... 17

7.3.2. ECO Mode ............................................................................................. 18

7.3.3. Pellet Recipe.......................................................................................... 19

7.3.4. Pellet Loading ........................................................................................ 19

7.3.5. Cleaning ............................................................................................... 20

7.3.6. Thermostat ........................................................................................... 20

7.3.7. Combustion Air Offset............................................................................. 20

7.3.8. Mass Air Flow Sensor (not applicable to First units) .................................... 21

7.3.9. Pellet Level Sensor (not applicable to First Model units) .............................. 21

7.3.10. Date/Time............................................................................................. 21

7.3.11. Timer ................................................................................................... 23

7.3.12. Language .............................................................................................. 25

7.3.13. Infrared Remote Control ......................................................................... 25

7.3.14. Technical Menu ...................................................................................... 25

7.3.15. User Info .............................................................................................. 26

8. Alarm / Failure / Recommendation List .............................................................. 28

9. Columbus Electronics .............................................................................................. 30

9.1. Remote Control ................................................................................................. 30

9.2. Client Menu ...................................................................................................... 33

9.3. Submenu ......................................................................................................... 38

10. List alarms / faults / recommendations –Columbus Electronics .................................... 43

11. Start-up................................................................................................................. 45