10

TRIM PROCEDURE

SSH

SSH Users Manual

retroaktiv

SQRSAW TRISIN

TRIM PROCEDURE

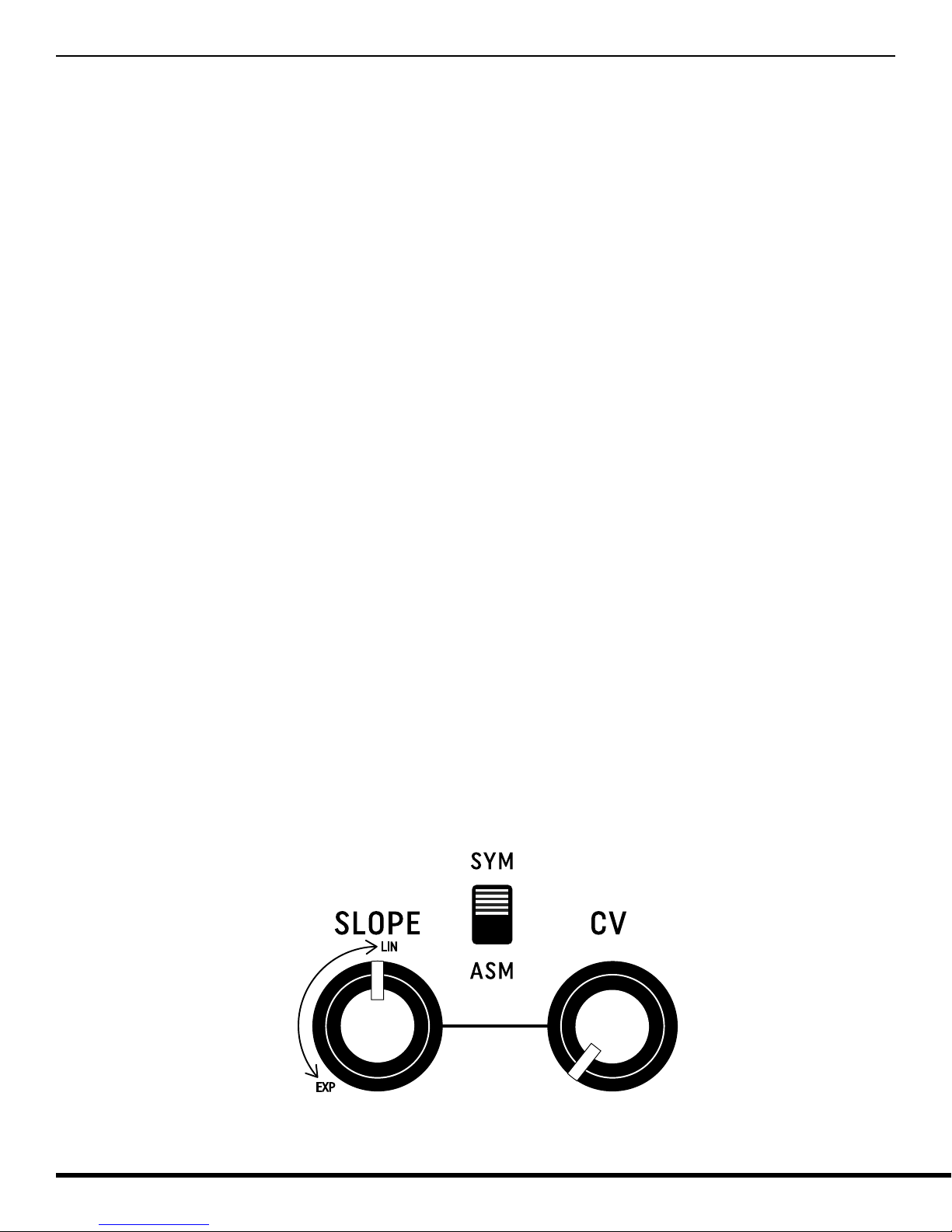

MIN RATE TRIM

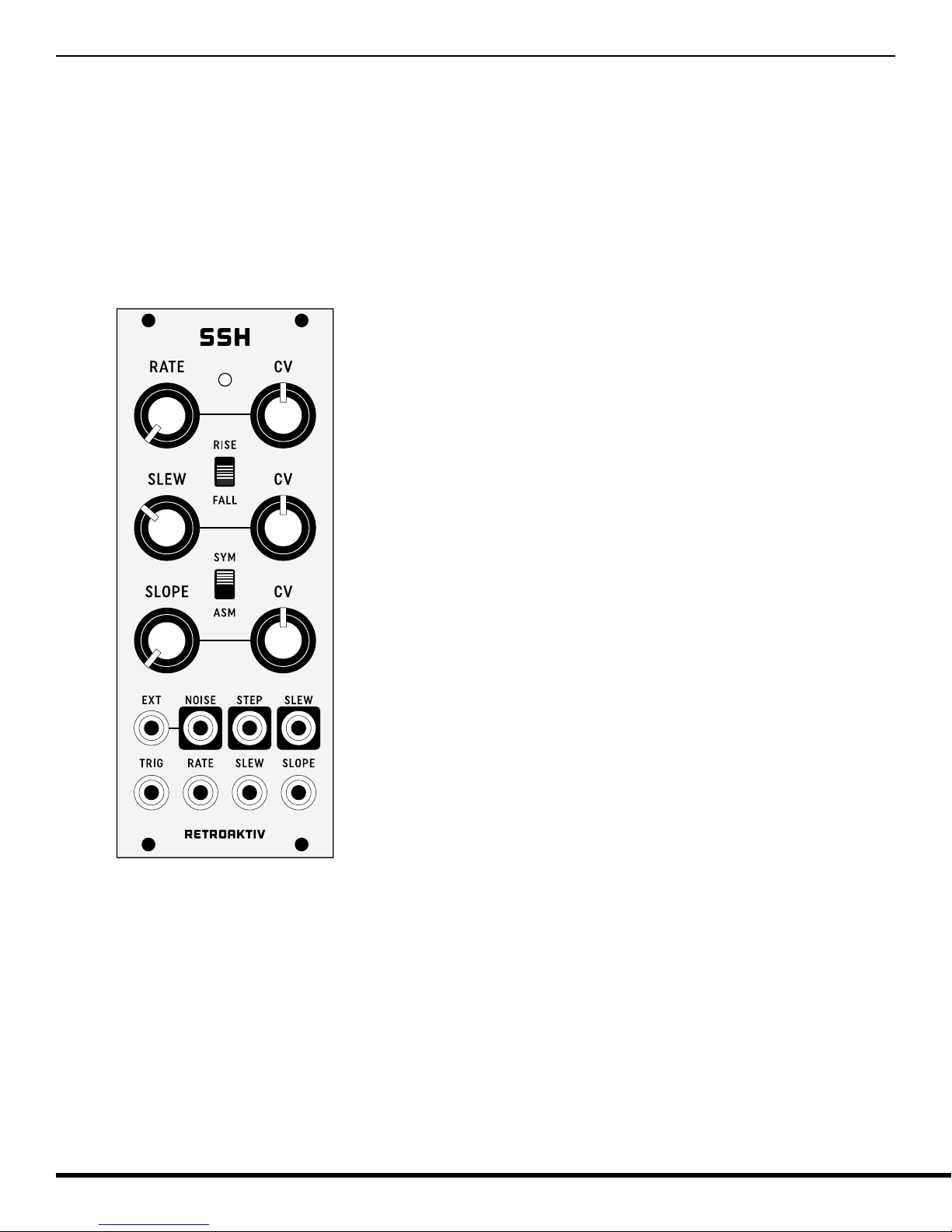

• Set front panel knobs as shown in Fig 11. RATE

should be set at minimum.

• Use the MIN RATE trimmer on the PCB to adjust the

minimum rate of the internal clock. Monitor the

rate using the panel LED indicator. If this trimmer

is set too low, the clock LFO will no longer oscillate.

A recommended minimum rate is .25Hz (period of

about 5 seconds.)

SLOPE CIRCUIT TRIM

• It is recommended that an oscilloscope be used to

monitor the SSH output signals when trimming the

SLOPE circuit. This can be done by ear as well, but

it can take more work.

• Set the front panel knobs as shown in figure 11. Set

RATE knob to center position. Monitor the SLEW

output signal at the SLEW test point at the rear of

the SLEW output jack.

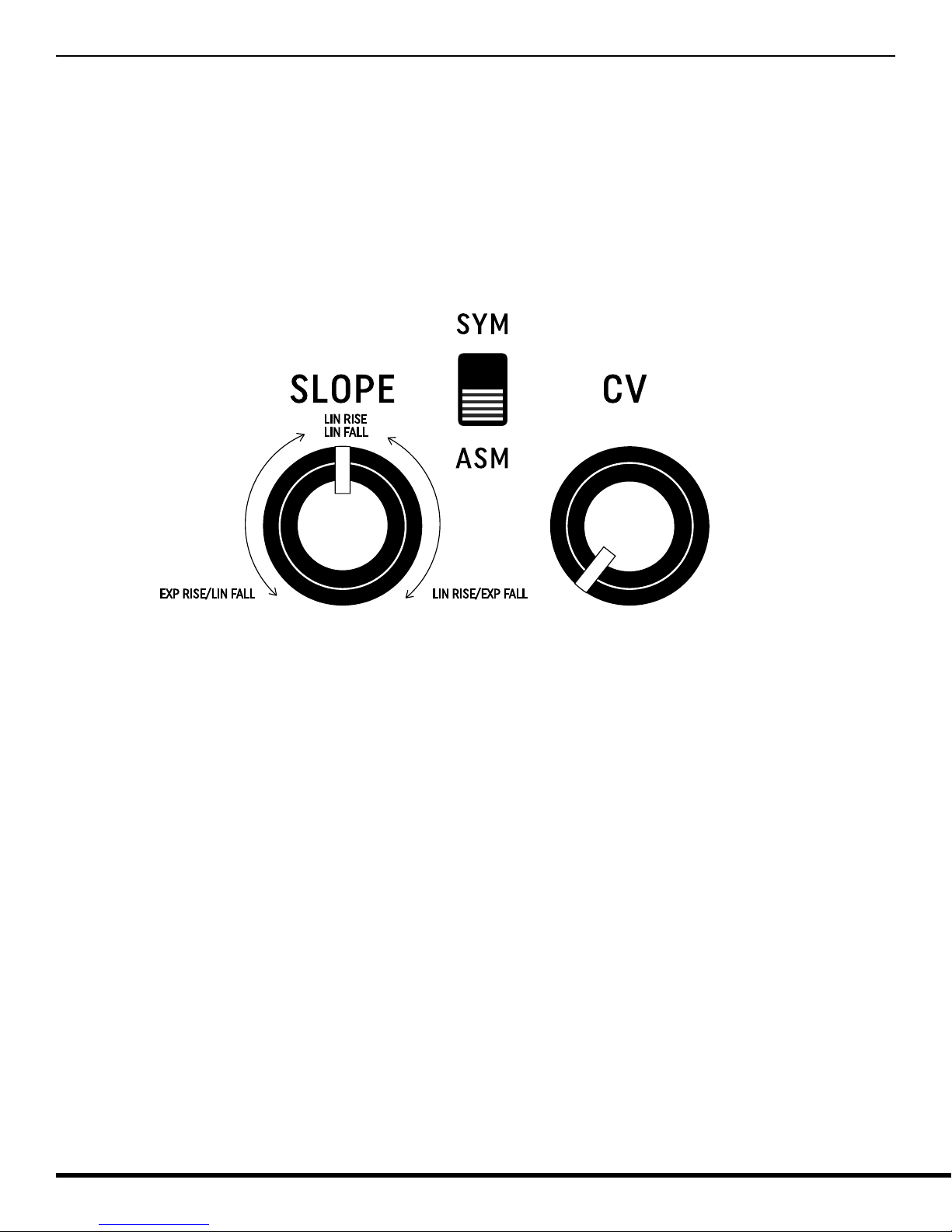

• Use the SHAPE trimmer on the PCB to dial in an

exponential waveform, then sweep the SLOPE knob

to center position. Slewing should morph from EXP

to LIN as the SLOPE knob is swept from fully count-

er-clockwise to mid-position. If the trimmer is set

too high, the slew will not be EXP when SLOPE is set

to its minumum. If the trimmer is set too low, the

slew effect will become extreme.

• When satisfied with the range of the slope knob, set

the SYM/ASM switch to ASM position. Turn SLOPE

knob fully clockwise. Monitor the SLEW output and

use the INV trimmer to trim the falling poions of

the SLEW waveform such that they match the EXP

curve set in the previous step.

• Seing SHAPE and INV can be done by ear if the

SLEW output is connected to the pitch CV input of a

VCO. Monitor the pitch and adjust the shape by ear.

Figure 11 - Panel settings for trimming