17

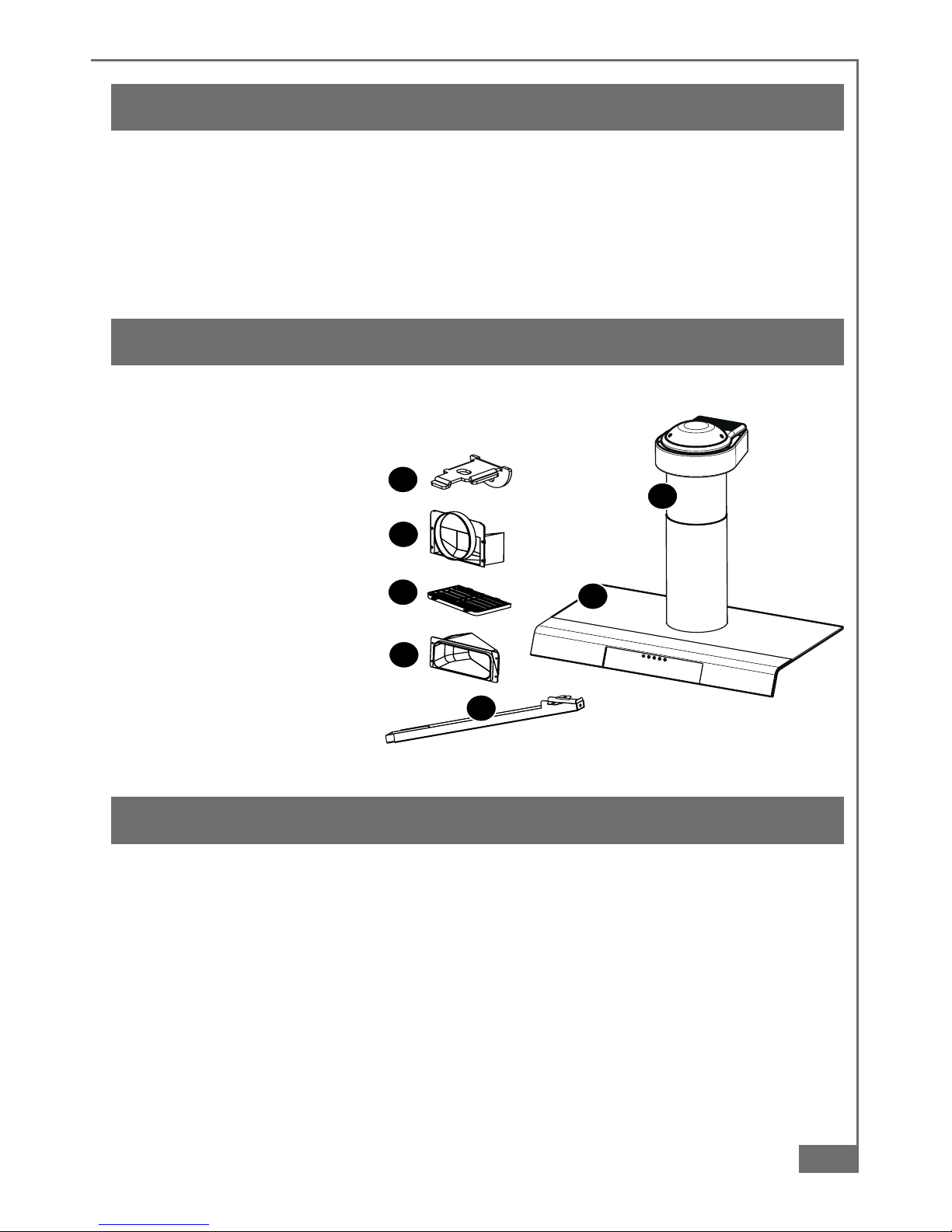

Part 1 - INSTALLATION INSTRUCTIONS

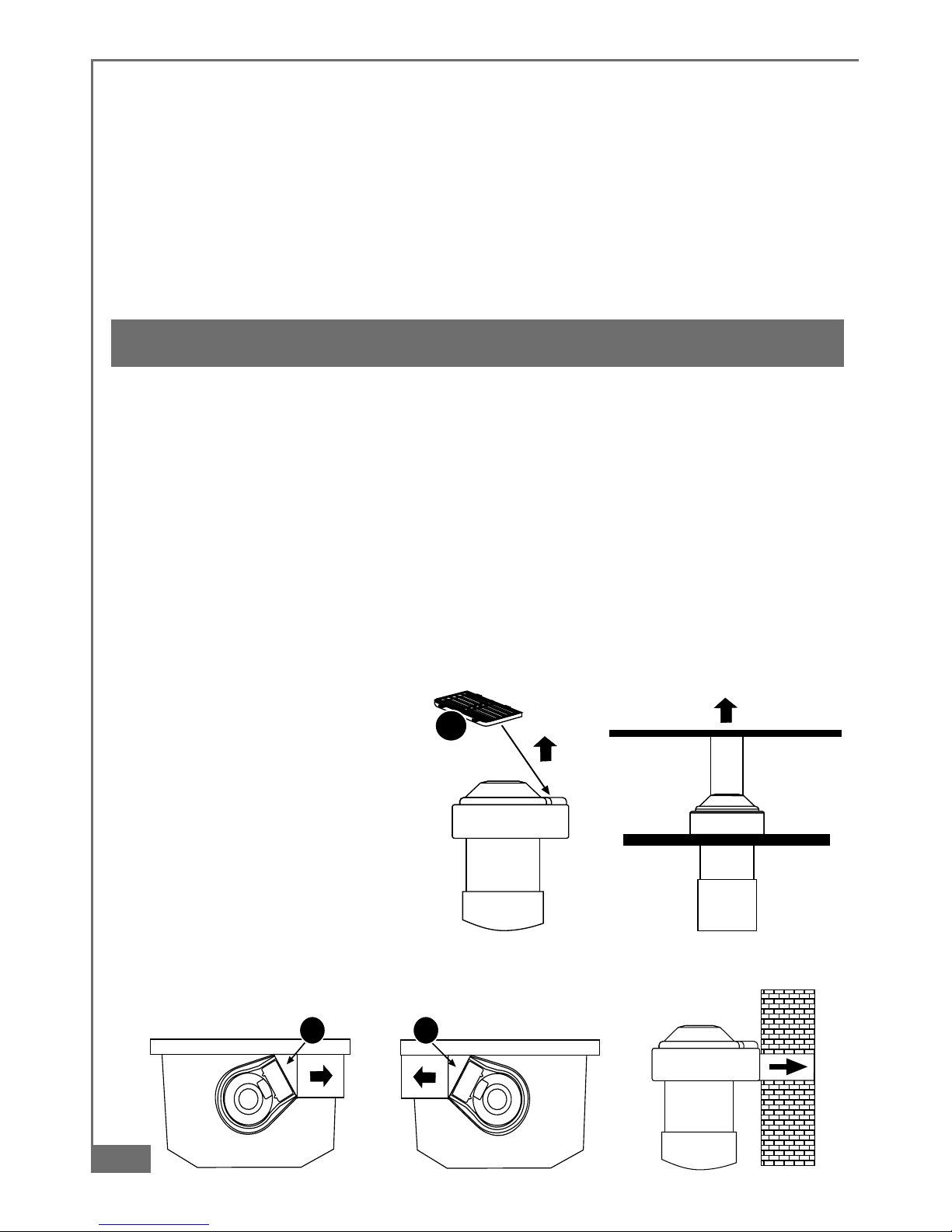

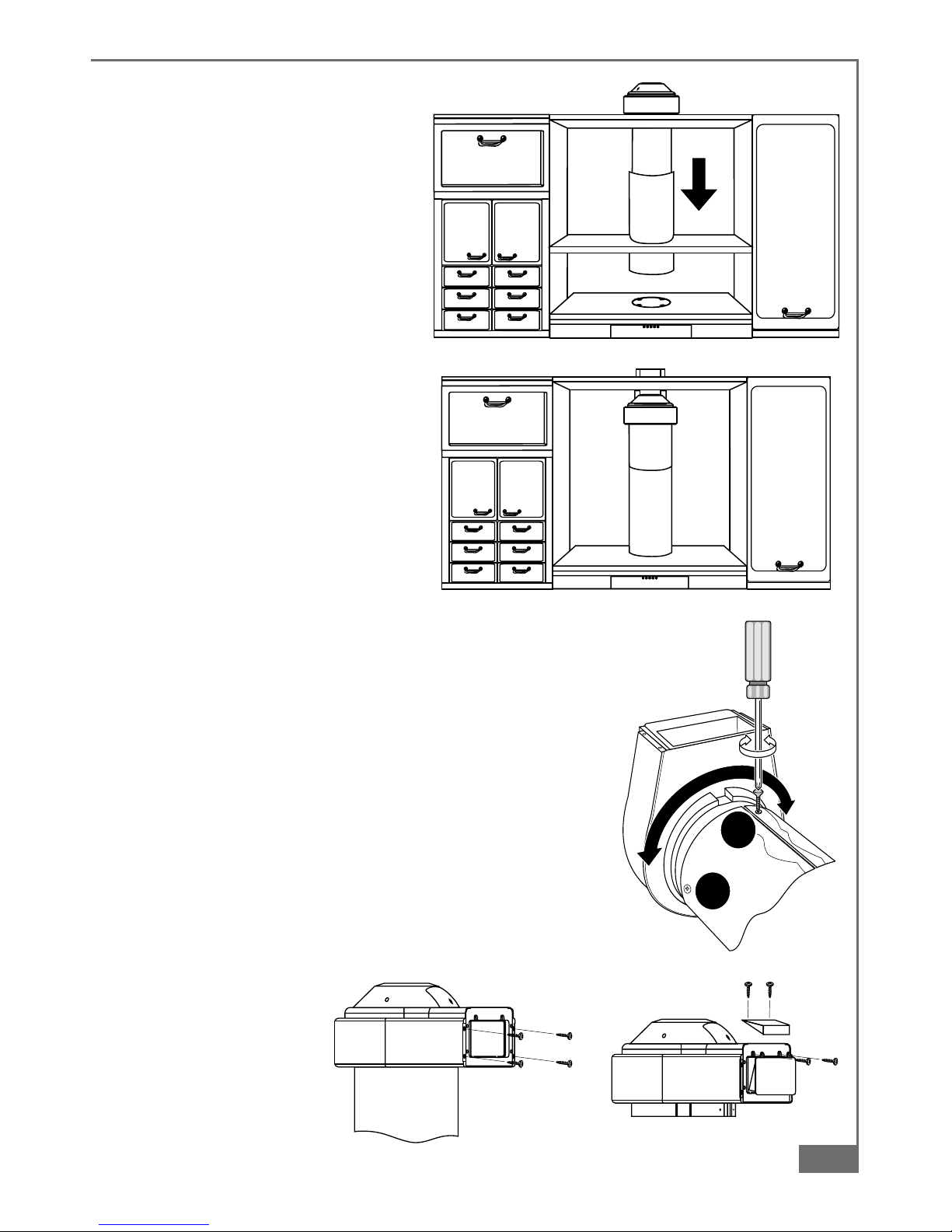

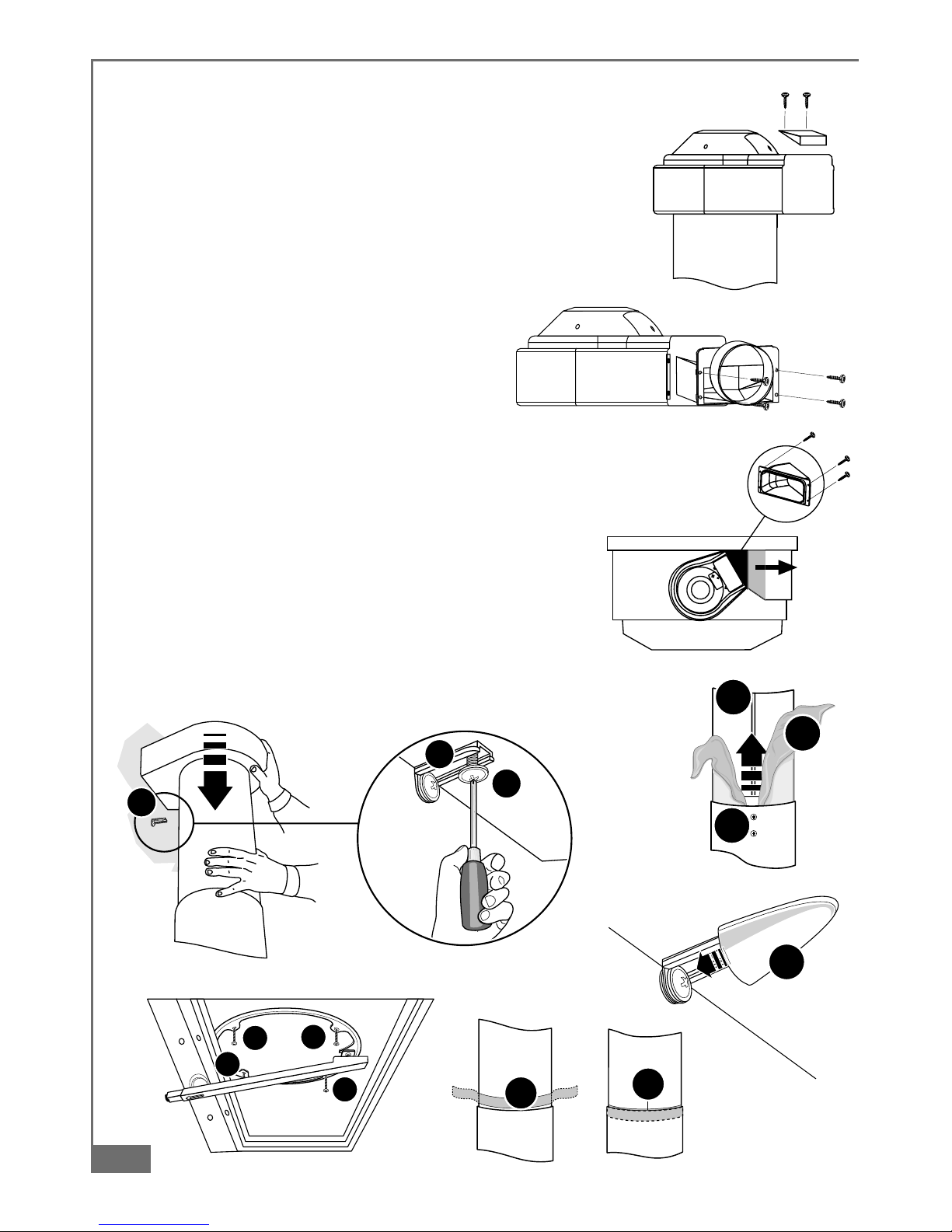

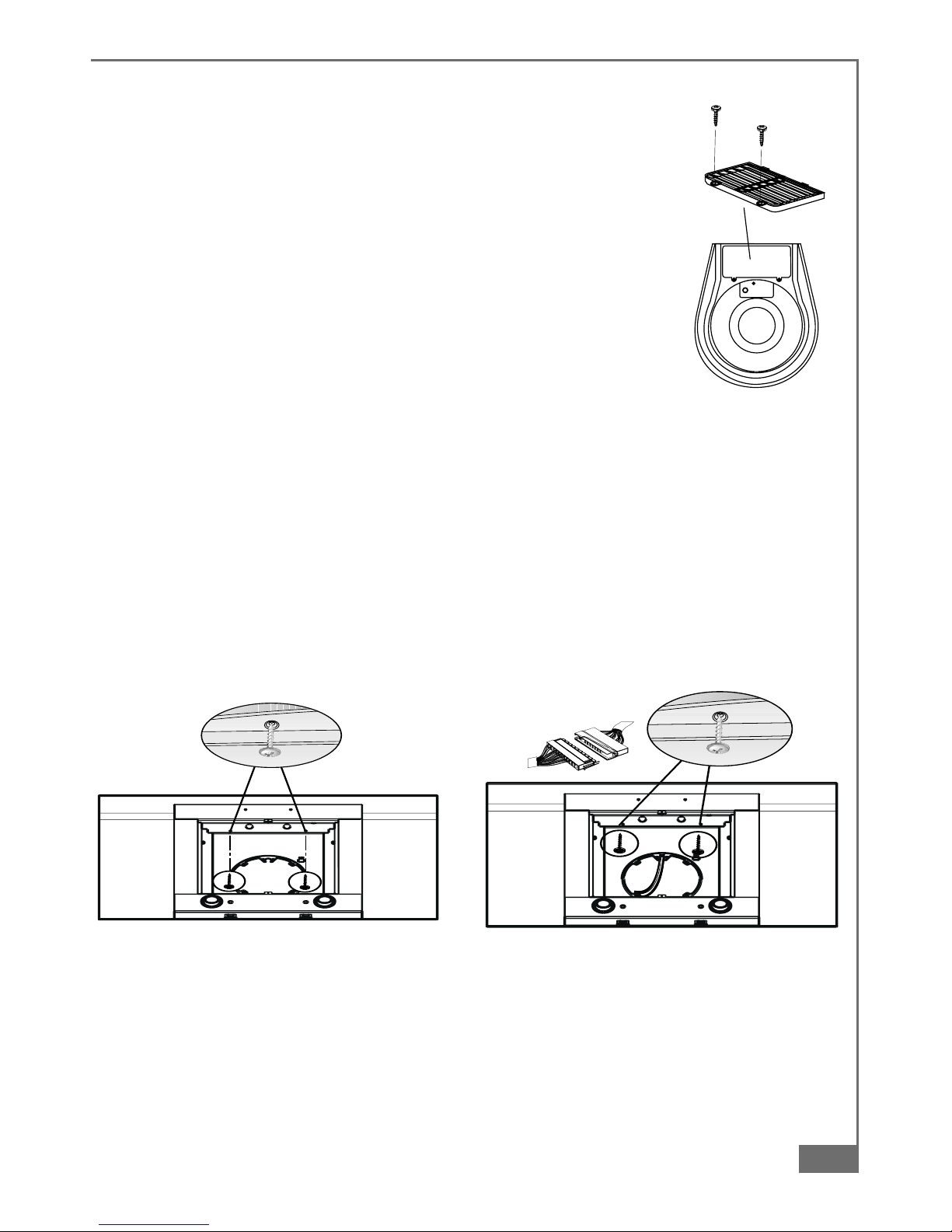

1 - Drilling the shel es:

a) Using the cardboard template

pro ided, and taking hole “B” as

a point of reference, drill the

shel es along the central axis to

allow the passage of the chimney.

The chimney must be inserted into

the shel es before it is fixed to the

hood canopy C (fig. 12).

b)When installing the ducting

ersion with the air outlet directed

upwards, if the ducting fan unit is

positioned below the line of

shel es it will be necessary to drill

a suitable hole in the top shelf only,

to allow the air ducting pipe to pass

through (fig. 13).

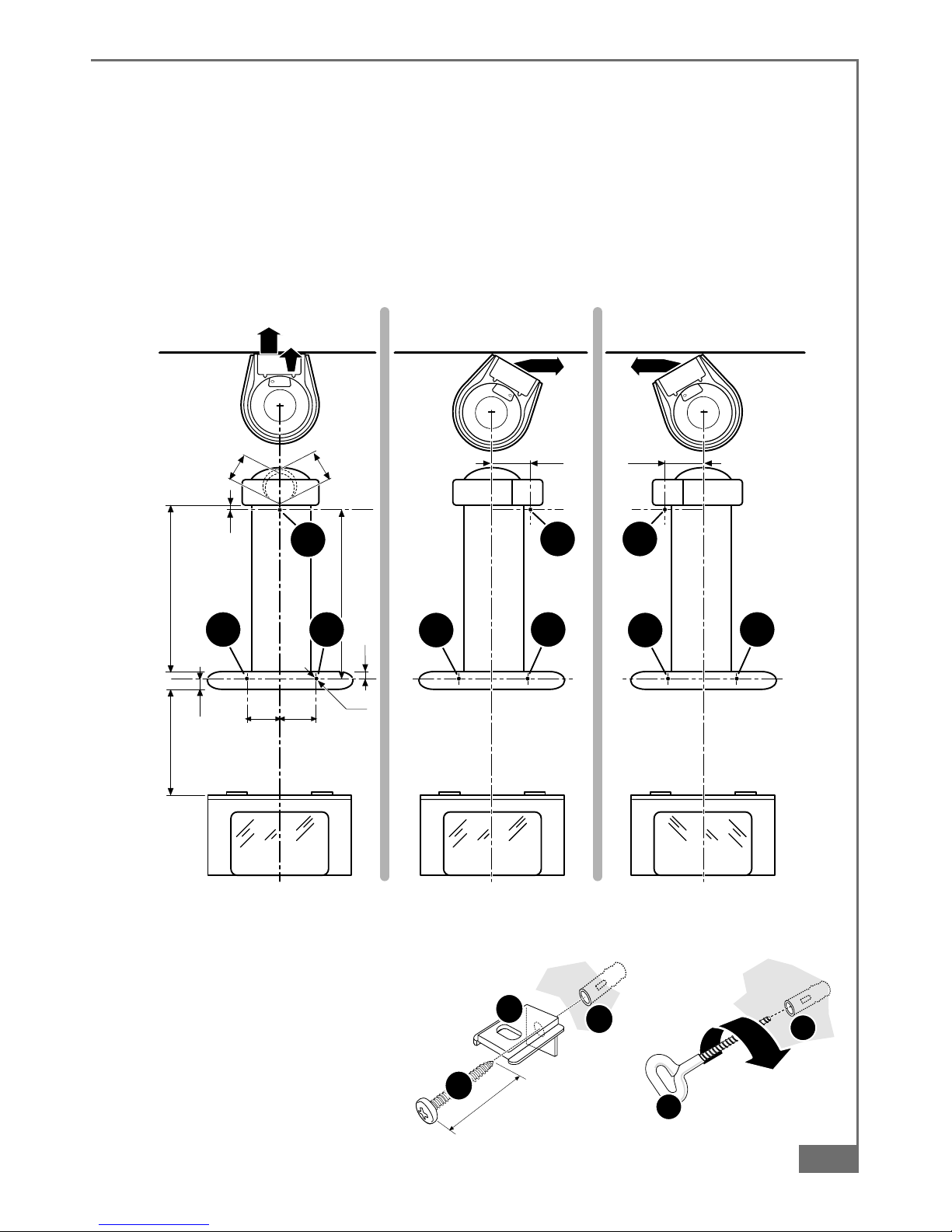

2 - Direction and position of the

ducting fan unit

a) The hood is normally supplied with

the air outlet directed towards the

wall (fig. 3), if it is to be installed with the air outlet directed

to the right or left (fig. 4a-b), it will be necessary to change

the direction of the ducting fan unit, proceeding as follows:

- Unscrew the screws U (fig. 14);

- Turn the ducting fan unit 60° to the right or left;

- Replace the screws U.

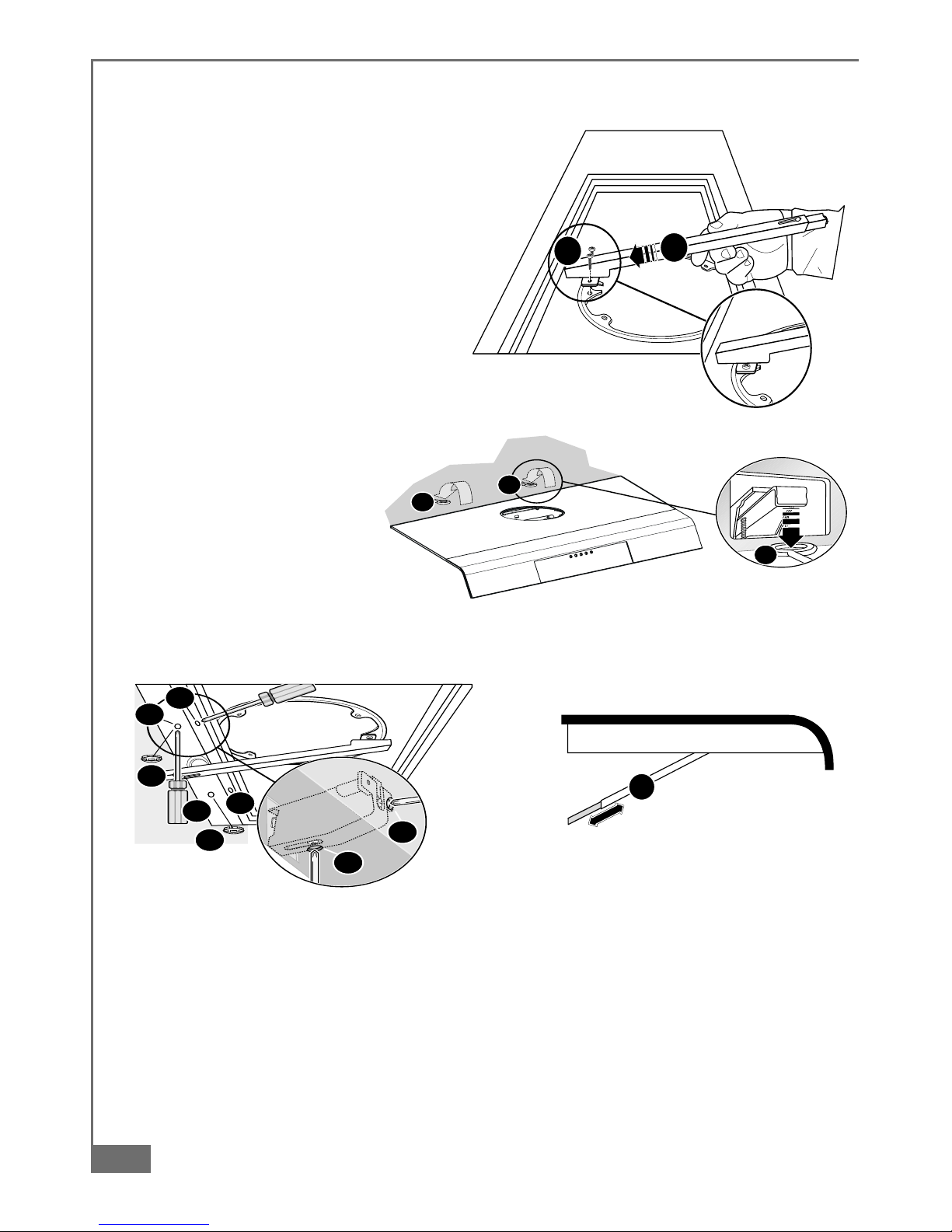

b) The ducting fan unit air outlets must be arranged

according to the type of installation to be carried out.

· Air outlet directed upwards (fig. 2a-b).

- Remo e the plastic plug from the upper part of the enting

grill and replace it on the rear part (fig. 15).

· Air outlet directed towards the wall (fig. 3).

- Remo e the plastic frame from the air outlet (fig. 16).