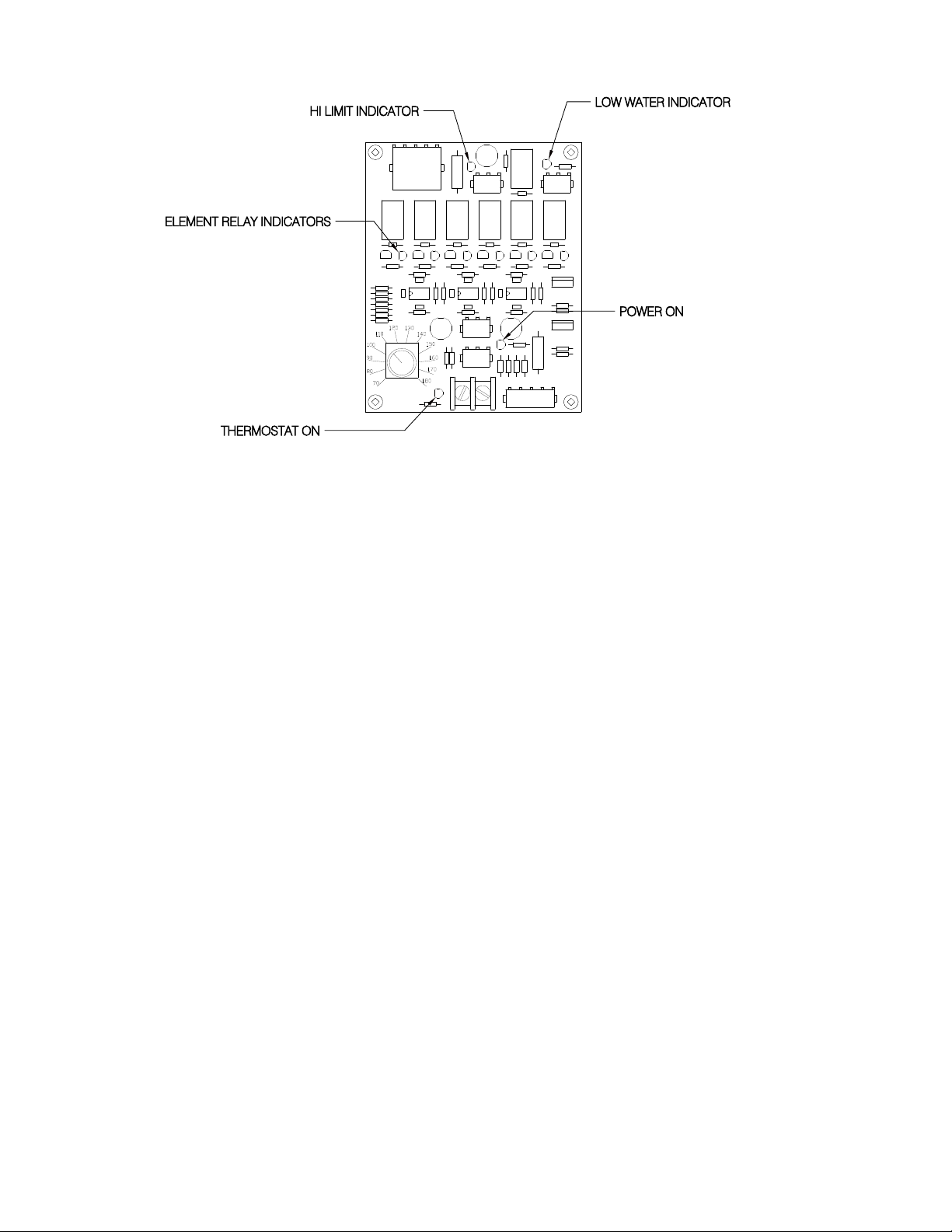

emperature Control Setting (Aquastat)

The boiler has a temperature control knob know as an aquastat on the lower left corner

of the control board. This sets the maximum temperature that the boiler will operate

at. The internal control system monitors the water temperature in the tank and

modulates the heating elements to maintain the water temperature. Note that the

setting on the knob only sets the maximum temperature, it is normal for the boiler to

operate at lower temperatures than this setting at times, this is especially true in the

spring and fall when it is not so cold outside. The actual temperature setting you need

The actual temperature setting you needThe actual temperature setting you need

The actual temperature setting you need

to set it to will be determined by the type of heating system the boiler is installed in.

to set it to will be determined by the type of heating system the boiler is installed in.to set it to will be determined by the type of heating system the boiler is installed in.

to set it to will be determined by the type of heating system the boiler is installed in.

The range of the aquastat is from 15 to 54º C (60 to 130º F).

Start Up

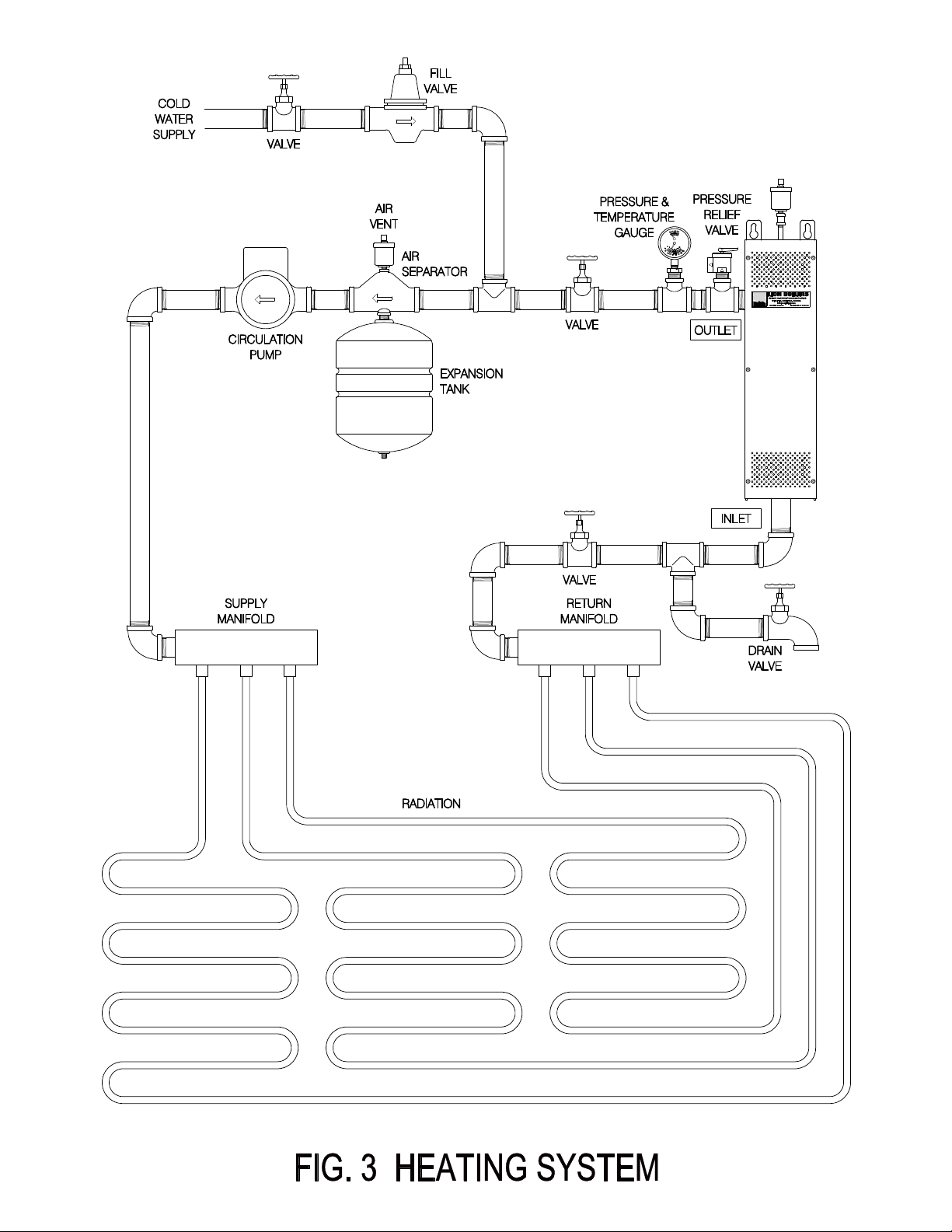

A new system must be thoroughly cleaned, flushed and drained, then refilled with

clean water. Foreign material circulating through the system could be detrimental to

the pump and to the heat transfer efficiency of the system and may lead to future

problems. The system must be thoroughly purged of air before it is energized for the

The system must be thoroughly purged of air before it is energized for theThe system must be thoroughly purged of air before it is energized for the

The system must be thoroughly purged of air before it is energized for the

first time. Elements will burn out if the boiler is not full of water when the boiler is

first time. Elements will burn out if the boiler is not full of water when the boiler isfirst time. Elements will burn out if the boiler is not full of water when the boiler is

first time. Elements will burn out if the boiler is not full of water when the boiler is

turned on. Do not connect the thermostat wires until the entire system is full of

turned on. Do not connect the thermostat wires until the entire system is full ofturned on. Do not connect the thermostat wires until the entire system is full of

turned on. Do not connect the thermostat wires until the entire system is full of

water, and thoroughly purged of air.

water, and thoroughly purged of air.water, and thoroughly purged of air.

water, and thoroughly purged of air.

The automatic air vent is to assist in removing air from the top of the tank to prevent

elements from burning out. It alone is not sufficient in removing air from the entire

heating system. Additional air vents must be installed throughout the system to

Additional air vents must be installed throughout the system toAdditional air vents must be installed throughout the system to

Additional air vents must be installed throughout the system to

eliminate any air that may enter the system.

eliminate any air that may enter the system.eliminate any air that may enter the system.

eliminate any air that may enter the system.

Check List

(1)Plumbing complete.

(2)System flushed.

(3)System free of air (purged).

(4)Pump rotates freely.

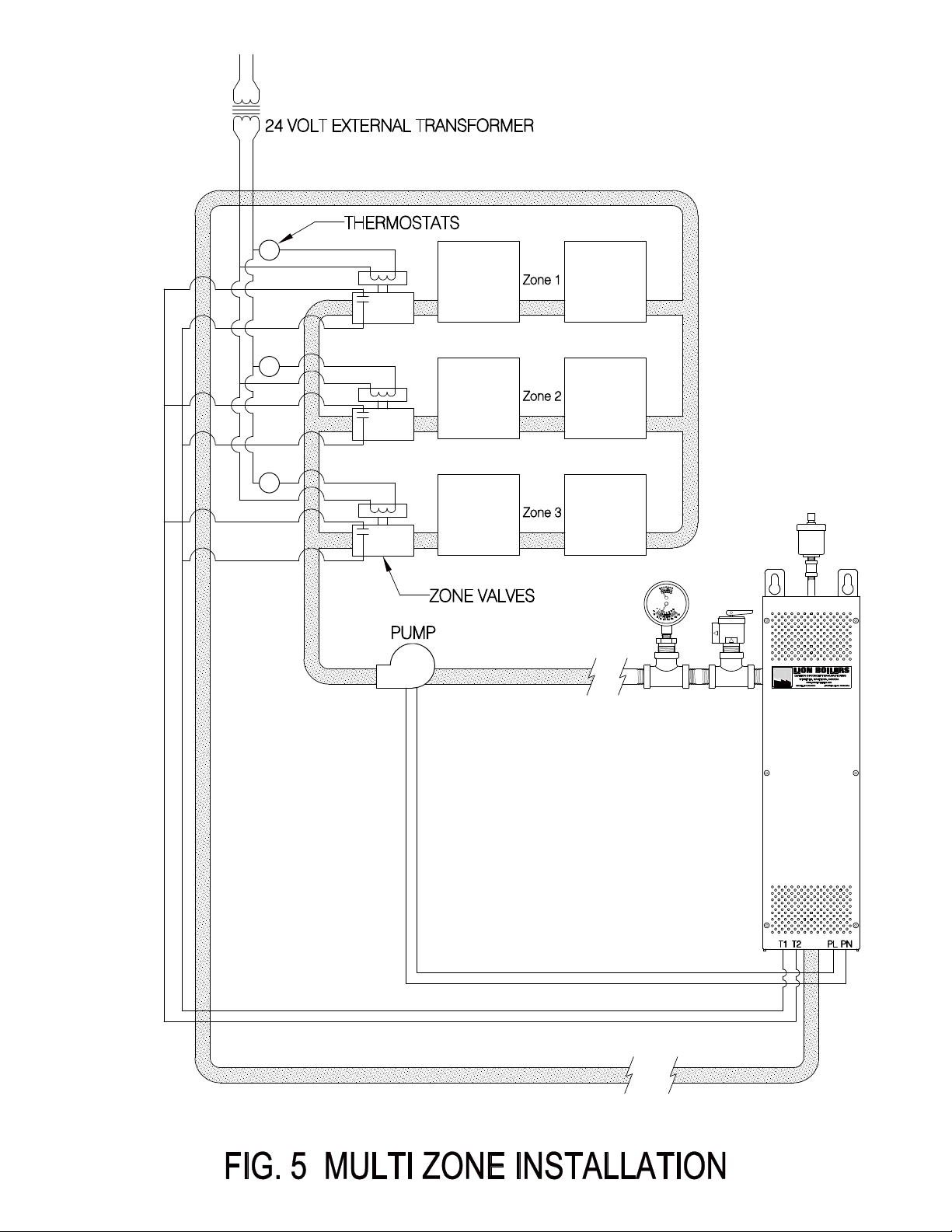

(5)Thermostat connected.

(6)Thermostat anticipator set.

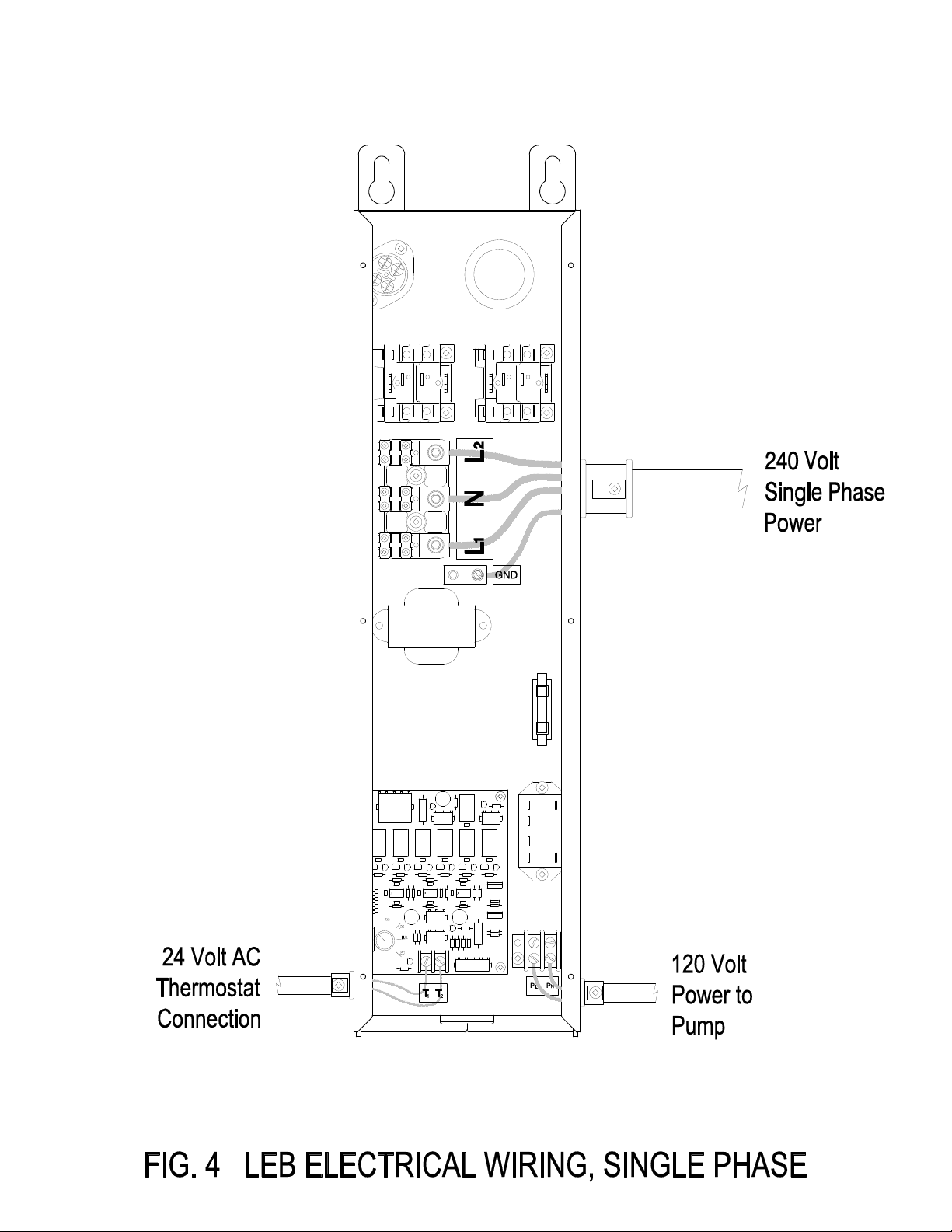

(7)Electrical supply connections complete.

Maintenance

At the start of each heating season it is advisable to have a qualified technician check

and inspect the boiler and the heating system for proper operation.

8