Page 2 D5/6 Series Doors MFZ Part No 4801-5166 Rev 10-2014

Table of Contents

1Ratings and Specifications .....................................................................................................................................3

2Warnings (Avertissements)....................................................................................................................................4

3Limited Warranty...................................................................................................................................................9

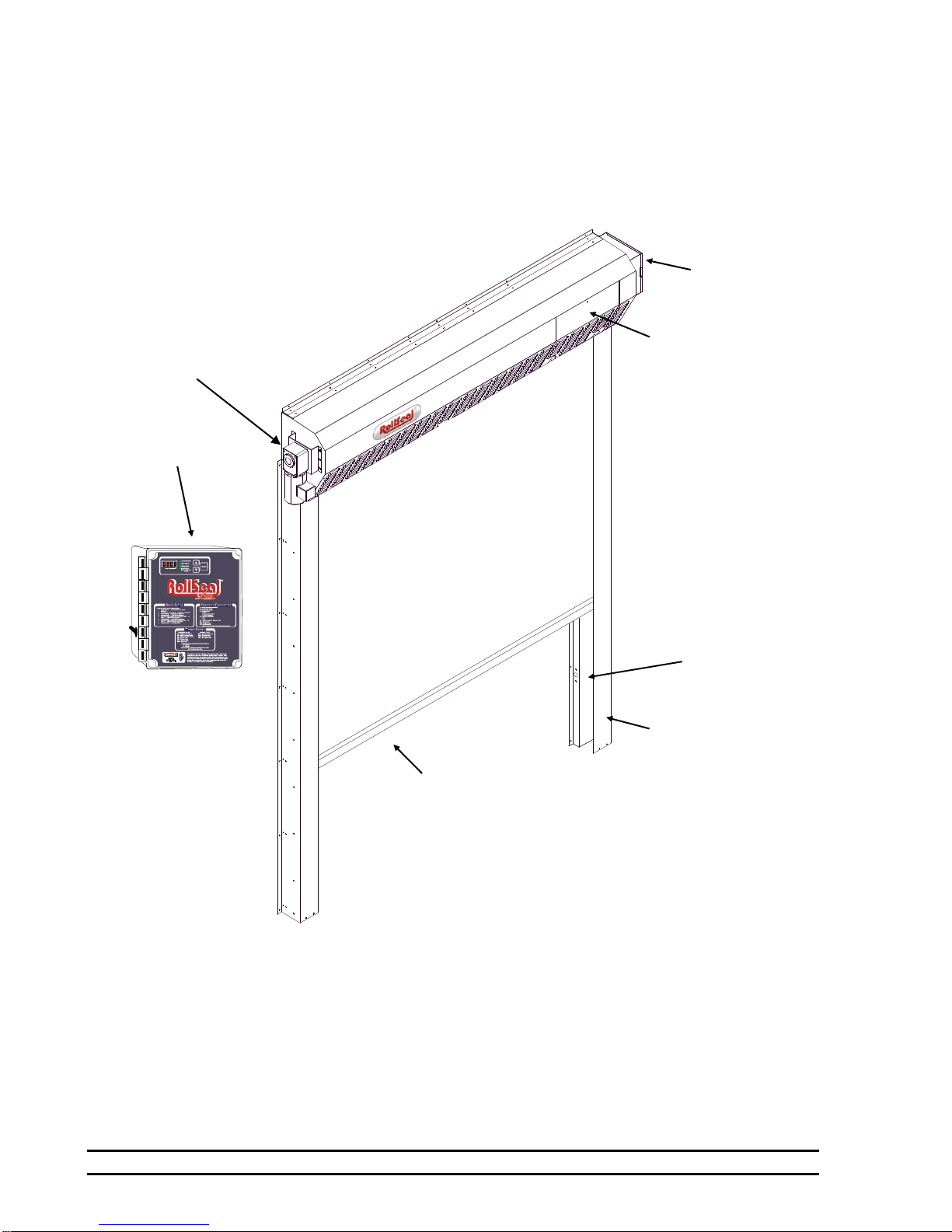

4Physical Description/Drawing..............................................................................................................................10

5Use of Equipment.................................................................................................................................................10

6Installation............................................................................................................................................................11

6.1 6.1 Tools Required....................................................................................................................................11

6.2 Overview ..................................................................................................................................................11

6.3 Adjusting the Clear Opening ....................................................................................................................11

6.4 Attachment Points of Door .......................................................................................................................12

6.5 Assembly of Parts.....................................................................................................................................13

6.6 Infrared Sensor Connectors ......................................................................................................................14

6.7 Fastening Door Assembly to Clear Opening ............................................................................................14

7Electrical Connections for RS500 Cooler Door...................................................................................................16

7.1 Connection of Controller to Head Unit.....................................................................................................16

7.2 Installing Prewired Switches ....................................................................................................................16

7.3 Power Connection with Disconnect..........................................................................................................17

7.4 Preparation for Operation .........................................................................................................................17

8Limit Switches .....................................................................................................................................................18

9Door Features.......................................................................................................................................................18

9.1 Warning Indicator Light ...........................................................................................................................18

9.2 Egress Strap ..............................................................................................................................................18

9.3 Egress Buzzer ...........................................................................................................................................18

10 Emergency Egress................................................................................................................................................19

10.1 Installation ................................................................................................................................................19

10.2 Exiting (Opening) The Door.....................................................................................................................19

10.3 Resetting (Closing) The Door...................................................................................................................20

11 Egress Strap Removal/Re-Installation..................................................................................................................21

11.1 Removal .......................................................................................................................................................21

11.1 Installation ................................................................................................................................................21

12 Manual Operation of Door...................................................................................................................................22

13 Adjustment of Brake ............................................................................................................................................23

14 Door Panel Adjustments.......................................................................................................................................24

15 Removal of existing Panel/Curtain Material........................................................................................................25

16 Installation of Replacement Curtain.....................................................................................................................26

17 RS-500 Door Wiring Diagram.............................................................................................................................27

Please Retain This Manual for Future Reference

Refer to SC-325 Controller Manual 4801-5156 and

D5/D6 Series Door Manual 4801-5154 for additional details.