Content

Introduction .............................................................................................................................................. 7

This symbol determines instructions non-observance of which can cause hazard to life or health of

people or can lead to mower damage. ................................................................................................ 7

1. General................................................................................................................................................. 7

1.1. Purpose and application ...................................................................................................................... 7

1.2. Restrictions ........................................................................................................................................ 8

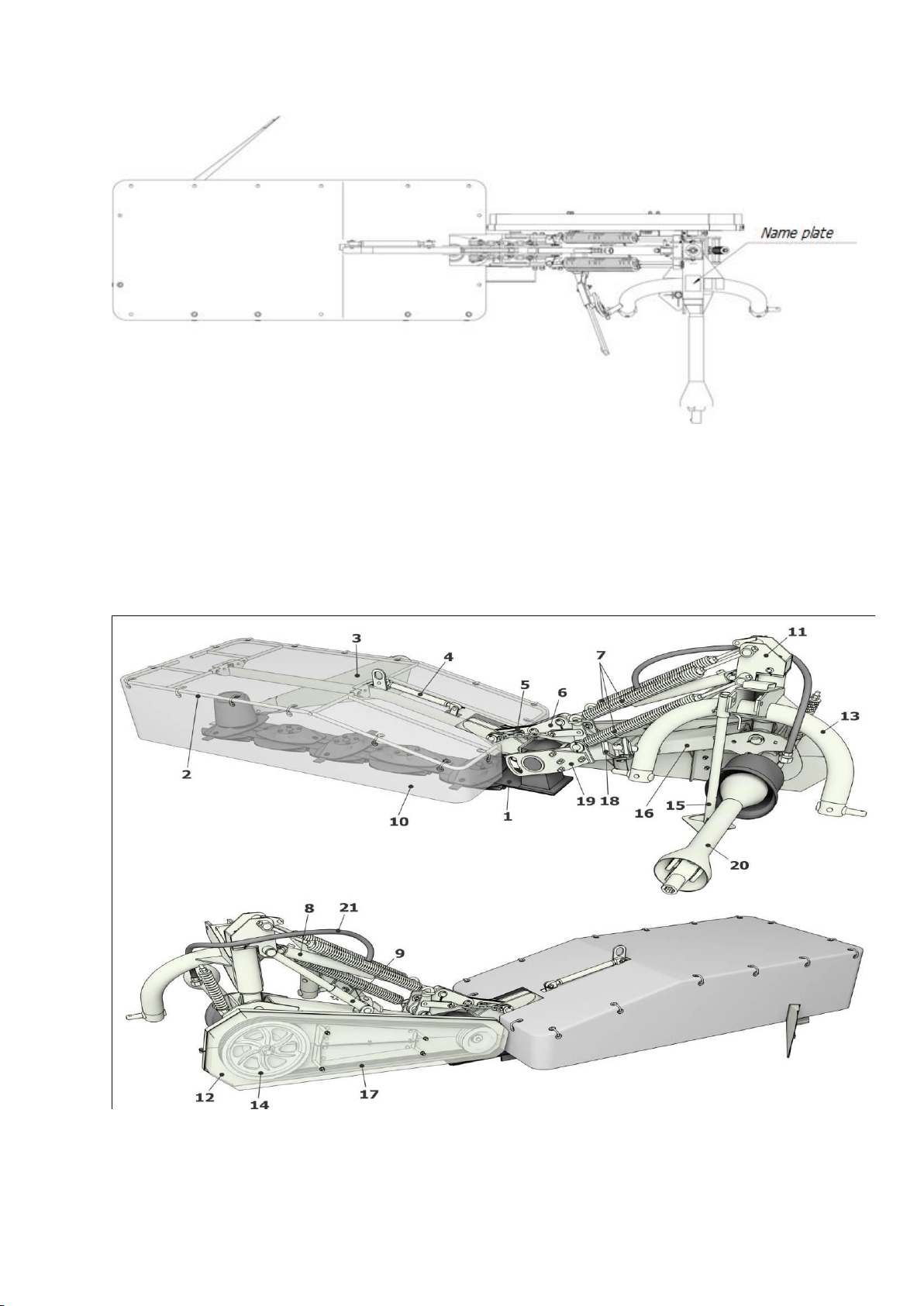

1.3. Mower name plate .............................................................................................................................. 8

1.4. General description of mower and its components ................................................................................ 9

1.5. Components description.....................................................................................................................11

2. Safety requirements..............................................................................................................................17

2.1.Safety requirements............................................................................................................................17

2.2. Warning plates ..................................................................................................................................18

3. Preparation for operation ......................................................................................................................23

3.1. Transportation...................................................................................................................................23

3.2. Final assembly...................................................................................................................................25

3.3. Tractor preparation for mower connection..........................................................................................25

3.4. Preparation of tractor hinged system ..................................................................................................25

3.5. Mower connection to tractor..............................................................................................................27

3.6. Mower haulage..................................................................................................................................27

4. Service and adjustment instructions.......................................................................................................28

4.1. Operation conditions ..........................................................................................................................28

4.2. Maintenance.....................................................................................................................................33

5. Maintenance ........................................................................................................................................34

5.1 General ..............................................................................................................................................34

5.2 Procedures performed during maintenance ..........................................................................................34

6. Storage................................................................................................................................................40

7. Apparatus recycling ..............................................................................................................................41

8. Delivery set ..........................................................................................................................................41

9. Manufacturer’s warranty .......................................................................................................................42

Appendix 1 ..............................................................................................................................................43

Appendix 2 ..............................................................................................................................................44

Appendix 3 ..............................................................................................................................................45

Appendix 4

..............................................................................................................................................46