R+M Suttner easyfoam365+ User manual

www.rm-suttner.com

page 1, Ver. 01.2021

The injector ST-160.2 is used for admixing liquid detergents to the volume ow in the high-

and low-pressure range using the Venturi principle. The injector housing and the mounted

parts are made of stainless steel.

The injector includes a pair of nozzles. It features a connection for an air valve. For being

able to foam the admixed detergents, foam lances with and without air injector can be

used. For a good foaming result, the correct injector nozzles and inserts must be selected.

The injector is designed for suction of detergents and disinfectants. For details, please refer

to Directive 67/548/EEC.

The injector must only be used with uids of Group I (e.g. water).

All safety instructions and regulations for high-pressure cleaners such as DIN EN 60335-

79-2 and DIN EN 1829-1 are to be complied with.

The operator must only use the injector if it is in a proper technical condition, without any

structural alterations, as intended, being aware of safety and hazards, and complying with

this User Manual. Only adults familiar with the use of high-pressure cleaners are authorised

to use the injector.

The injector must not be operated using abrasive materials. In order to avoid damage to

the injector, install a ne lter with a recommended mesh size of 50 μm in the water supply

to the high-pressure cleaner. Install a suitable suction lter in the chemical agent hose.

Also comply with the operating instructions of the devices and accessories connected to

the injector and the regulations applying to the detergents.

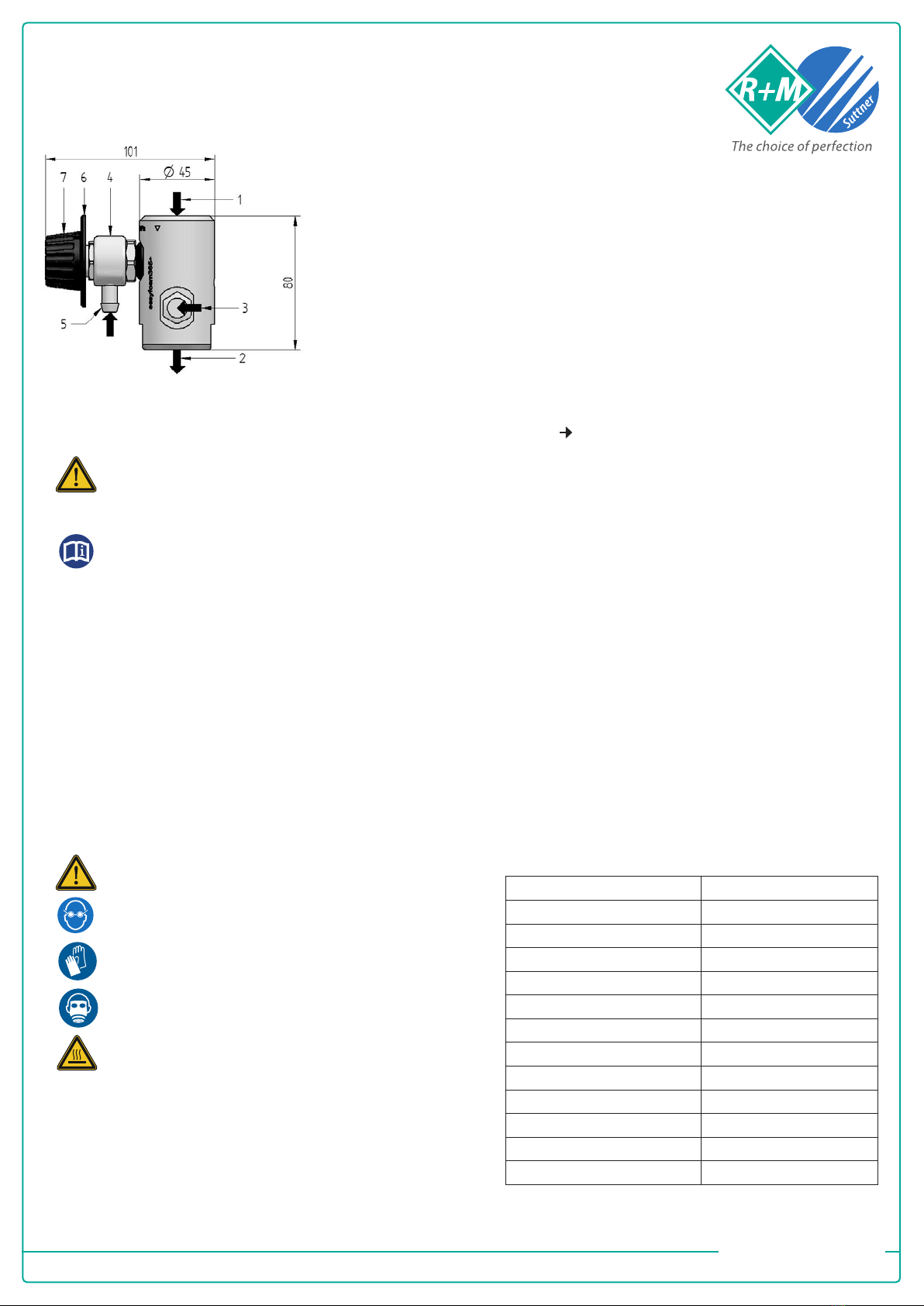

1 Inlet

2 Outlet

3 Compressed air connection

4 Housing dosing valve (rotating)

5 Chemical agent connection

6 Dosing scale

7 Adjusting wheel

Flow direction

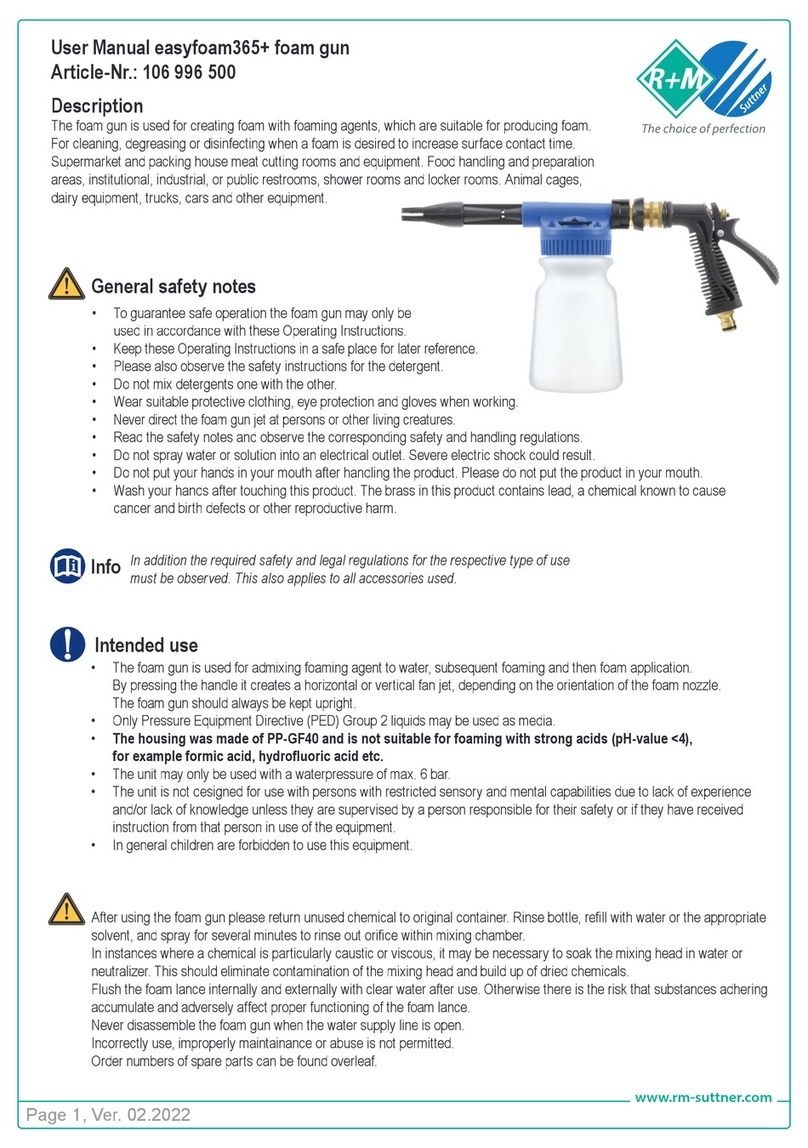

User Manual easyfoam365+

ST-160.2 foam and disinfectant unit. Product No.: 200 160 635

Description

Intended Use

Hazard! If these instruc-

tions are not complied with,

there is a risk of life and

limb and property damage!

The injector is designed for permanent use at a tempe-

rature of up to about 60 °C. In any case, the user has

to wear suitable protective equipment such as safety

gloves, shoes, and goggles. In general, the applicable

local safety regulations are to be complied with.

An aerosol may be formed by the foam and disinfectant.

In order to avoid inhalation, wear a suitable respiratory

protection!

Ensure sufcient ventilation!

IG: Female thread / AG: Male thread / G: Withworth pipe thread acc.

to DIN ISO 228, ident. BSP = British Standard Pipe / NPT: National

Pipe Thread (American Thread standard) / Kg: kilogram

Read this User Manual

thoroughly before using the

unit! Keep the User Manual

in a safe place for later re-

ference or the subsequent

owner!

This User Manual was

established using utmost

care. However, we do

not accept any liability for

possible mistakes in this

User Manual and their

consequences.

Safety

Risk of burns and scalds by hot media!

Formation of aerosol!

Specications

Maximum allowable pressure 350.0 bar / 35.00 MPa

Maximum volume ow 60.0 l/min

Water temperature, permanent 60 °C

Water temperature, temporary max. 90 °C

Ambient temperature up to 60 °C

Nozzle size 1.6 / 2.0

Connection inlet G 1/2 F

Connection outlet G 1/2 F

Connection compressed air M14

Connection chemical agent Ø 9 mm

Weight 1,207 g

Dimensions (W / H / D) 128 x 80 x 163 (with support)

Maximum size of solids 50 μm

www.rm-suttner.com

page 2, Ver. 01.2021

Normative References

This product is state-of-the-art and complies with the generally accepted safety regulations. However, there is a risk of proper-

ty damage and injury for the user and other persons due to the high pressures and temperatures. Comply with the present Un-

ser Manual and the relevant directives for liquid jet equipment by all means. Regarding personal protective equipment, please

refer to the German Accident Prevention Regulation UVV „Persönliche Schutzausrüstungen“ (Personal Protective Equipment)

(VBG101) currently available as draft). Among other things, personal protective equipment includes protective suits, head

protection, safety gloves with rm grip and non-slip boots, metatarsal protection, respiratory protection, ear protection, eye or

face protection.

User Manual easyfoam365+

ST-160.2 foam and disinfectant unit. Product No.: 200 160 635

▪ The product is a pressure-retaining equipment according to the Pressure Equipment Directive 2014/68/EU. Due to its

parameters of use, it is subject to the scope of Article 4 / Clause 3 of this directive („sound engineering practice“) and thus

a declaration of conformity and CE marking are not admissible!

▪ The product must not be installed in devices which have to comply with the Pressure Equipment Directive 2014/68/EU!

▪ The component is a standard component in terms of the Machinery Directive 2006/42/EC!

For Your Safety

▪ Do not use the device if people not wearing protective equipment are in the immediate vicinity.

▪ Before starting work, check the high-pressure system (spray unit, hoses, screwing, etc.) for leakages and damage.

▪ Immediately stop operation if leakages or malfunctions occur.

▪ The suction hoses must not show any kinks

▪ Check the amount to be dosed

▪ Rinse the cleaned surfaces with clear water

▪ Read and comply with the safety data sheets of the detergent manufacturers

▪ Check if the chemical agents used are suitable for the surfaces you want to clean

Installation

Modication

▪ Switch off the high-pressure generator before performing any installati-

on works on the high-pressure system.

▪ Protect the high-pressure generator from being switched on acciden-

tally.

▪ Switch off the water supply.

▪ Make sure that the system sections and lines to be opened are depres-

surised.

▪ Seal the screw connections according to the application using an

appropriate sealant such as Teon tape or liquid sealants (refer to R+M

catalogue, Chapter 06, Adhesives and sealing materials)

▪ Fasten the support rmly to a vertical surface.

▪ Suspend the injector in the support without any play and tighten the

screw on the back.

▪ Connect the high-pressure hoses to the inlet and outlet

▪ Pay attention to the markings for the ow direction

▪ Fasten the suction hoses (9 mm ID) using hose clamps

Any kind of modication of the injector is not allowed!

Compressed air supply (optional)

For foaming with a passive foaming lance, an appropriate tting can be inserted in the lateral port. Place the container with the

chemical agent under the injector. (max. suction height 3 m)

(Optional) Connect the compressed air hose.

1 Air valve basic seal 9 mm : M14 M 200 163 350

2 Dummy plug M14 200 163 345

3 Air valve 1/4“ M : M14 M 200 163 356

www.rm-suttner.com

page 3, Ver. 01.2021

10 Check valve

(optional) to protect

the compressed-air

system

4Disinfectant

Suction height

max. 3 m

9Shut-off

valve open

8 Pressure

reducer

5 Injector

2 Foam gun

ST-2725, ST-3100, ST-3300, ST-3225

1 Foam lance

ST-20: 310 060 5,

ST-20: 310 061 0,

ST-20: 310 063 0, 502 808

6 Pump

Pressure min. 5 bar.

Pressure max. 350 bar.

Flow min. 8 l/min. /

max. 30 l/min

11 Suction

hose 3 High-pressure hose

recommended nominal

width 12 mm

Length max. 20 m

7 Air com-

pressor

max. 3 m

Length max. 5 m

User Manual easyfoam365+

ST-160.2 foam and disinfectant unit. Product No.: 200 160 635

4Disinfectant

Suction height

max. 3 m

1 Foamlance:

ST-72, ST-74, ST-75

3 High-pressure hose.

Nominal width min. 8.

Length 20 m.

Recommended nominal

width 10. Length 20 m.

2 Spray gun:

ST-1500, ST-2300, ST-2700, ST-2320,

ST-2315,ST-2615, ST-2620

6 Pump

Pressure min. 80 bar.

Flow min. 8 l/min.

5 Injector

7 Suction

hose

max. 3 m

length max. 5 m

a) passive foamlance

Typical types of connection:

The air for foam generation is generated by the compressed-air generator (7)

b) active foam lance

The air for foam generation is

sucked in by the lance (1)

Setup: Lance with air injector:

Use the injector in the indicated pressure, volume ow, and temperature range, only. Before starting work, check the

values at the high-pressure generator and adjust them if required.

Foam quantity and concentration can be set using dosing inserts.

After studying the safety rules the use of the injector is very simple.

In order to clean the outside, use a lint-free cloth and do not use any aggressive cleaning agents.

Rinse the suction hoses using clear water to rinse the check valve.

After usage and prior to longer interruption of work (more than 1 hour), rinse the injector using clear water.

Operation

Cleaning

www.rm-suttner.com

page 4, Ver. 01.2021

User Manual easyfoam365+

ST-160.2 foam and disinfectant unit. Product No.: 200 160 635

Make sure that the injector is protected from soiling when transported and stored.

Protect the injector from frost. The action of frost may damage the injector in a way

that a proper operation cannot be ensured any longer.

Replacement

of nozzles: Injector nozzle (1) and counter nozzle (2)

Please dispose of old devices in an

environmentally friendly way. Old

devices contain valuable recycling

materials which should be forwarded

to a recycling facility. Therefore, please

dispose of old devices at appropriate

collection points.

Installation, maintenance, and repair work shall only be effected by persons trained in

maintenance and repair works on high-pressure systems. Use spare parts approved by

R+M / Suttner, only. Use only high-pressure components (hoses, couplings, etc.) appro-

ved for the respective pressure and temperature range.

After 1,000 operating hours or one year and/or after 500 operating hours or 6 months

in case of use of hot water (more than 60 °C) and chemical agent: Check the valve parts

(O-ring, back-up ring, hose clamps) for damage and replace them completely by a repair

kit if applicable.

After 3,000 operating hours or 3 years and/or after 1,500 operating hours or 18

months in case of use of hot water (more than 60 °C) and chemical agent:

Replace valve parts (O-ring, back-up ring, hose clamps) completely by a repair kit.

Transport and Storage

Maintenance

▪ Check on an annual basis whether the injector is in a safe state. Have defects elimi-

nated immediately by a skilled person.

▪ Are labels and markings legible?

▪ Do the check valves (4) close automatically?

▪ Does the injector show any mechanical damage?

▪ Check dosing irrespective of chemical agent and application at regular intervals.

▪ Does the sealant shell show any damage?

▪ Are the nozzles worn or the O-rings damaged?

▪ Check the nozzles (1 2 3) for dirt and wear.

Disposal

Operation Tool

Screw out the injector nozzle Allen key, size 4

Screw out the counter nozzle Slot-head screwdriver 7 x 1.2

Component Tool

Remove suction hose Manually

Remove dosing insert Pliers

This manual suits for next models

1

Other R+M Suttner Foam Machine manuals