S.E.P. SUPER SMART User manual

SUPER SMART

SUPER SMART Diesel

®

USE AND MAINTENANCE MANUAL

GB

GB

REVERSIBLE TWO-WHEEL TRACTOR

SUPER SMART SUPER SMART Diesel

BEFORE USING THE TWO-WHEEL TRACTOR

CAREFULLY READ THE INSTRUCTIONS

GIVEN IN THIS MANUAL

GB

2

TABLE OF CONTENTS

Page Page

INTRODUCTION.................................................... 3

SAFETY REGULATIONS ....................................... 3

GENERAL NOTICES............................................. 3

STARTING THE ENGINE ...................................... 4

OPERATING OF THE TWO-WHEEL TRACTOR ... 4

OPERATING OF ATTACHMENTS ........................ 4

MAINTENANCE..................................................... 4

IDENTIFICATION DATA ........................................ 5

TWO-WHEEL TRACTOR IDENTIFICATION .......... 5

ENGINE IDENTIFICATION.................................... 5

EC MARKING ........................................................ 5

TECHNICAL SPECIFICATIONS............................ 7

ENGINE.................................................................. 7

STARTING............................................................. 7

CLUTCH................................................................ 7

SPEEDS ................................................................ 7

POWER TAKE OFF (PTO) .................................... 7

COUPLING OF ATTACHMENTS .......................... 7

HANDLEBARS ...................................................... 7

WHEELS/TIRES .................................................... 7

ACCESSORIES..................................................... 7

MASS .................................................................... 7

DIMENSIONS........................................................ 7

SAFETY DEVICES ................................................. 8

REVERSE SPEED SAFETY DEVICE..................... 8

TRANSFER PRINTING - INSTRUCTIONS AND

SAFETY.................................................................. 9

TWO-WHEEL TRACTOR CONTROLS .................. 10

OPERATING THE CONTROLS ............................. 10

CONTROLS OF FRONT-MOUNTED ATTACH-

MENTS.................................................................. 11

OPERATING THE TWO-WHEEL TRACTOR.......... 12

STARTING THE ENGINE...................................... 12

STOPPING THE ENGINE..................................... 12

FITTING FRONT-MOUNTED

ATTACHMENTS ..................................................... 13

SAFETY DEVICE .................................................. 13

REVERSING THE HANDLEBARS ........................ 13

REVERSING THE WHEELS ................................. 13

COUPLING ATTACHMENTS TO

THE PTO................................................................. 14

MAINTENANCE...................................................... 14

ENGINE ................................................................ 14

GEARBOX ............................................................ 14

POWER TAKE OFF .............................................. 14

CHECKS AND ADJUSTMENTS............................. 15

CLUTCH LEVER ................................................... 15

ROTARY TILLER .................................................... 16

GENERAL............................................................. 16

ROTARY TILLER TECHNICAL

SPECIFICATIONS ................................................ 16

USING THE ROTARY TILLER............................... 16

ROTARY TILLER ADJUSTMENT .......................... 16

ROTARY TILLER MAINTENANCE ........................ 18

CUTTER BAR MOWER .......................................... 19

GENERAL............................................................. 19

CUTTER BAR MOWER TECHNICAL SPECIFICA-

TIONS................................................................... 20

OPERATING CUTTER BAR MOWERS................. 20

CUTTER BAR MOWER ADJUSTMENT................ 20

CUTTER BAR MOWER MAINTENANCE .............. 21

EC CERTIFICATE OF CONFORMITY

3

INTRODUCTION

• This manual provides Use and Maintenance in-

structions, technical specifications, and safety pre-

cautions for reversible two-wheel tractor:

− model SUPER SMART

in the versions with gasoline engine.

• The first section of this manual provides technical

specifications and gives instructions relevant to

the machine. The second section of the manual

gives further details on individual attachments,

and provides all specific operating instructions.

• Read this USE and MAINTENANCE Manual care-

fully before using your new two-wheel tractor. This

manual provides the most up-to-date information

on your two-wheel tractor available at the time of

going to press. Manufacturer reserves the right to

modify this document at any time without prior no-

tice.

• AFTER-SALES SERVICE. Use only original spare

parts. The use of non-original parts voids the war-

ranty. When ordering spare parts, specify:

− two-wheel tractor serial number;

− part code of spare part required;

− quantity or number of parts required.

SAFETY REGULATIONS

GENERAL NOTICES

Any engine driven machine can become dangerous if

used incorrectly. Pay particular attention to the in-

structions in this manual marked:

WARNING

This symbol means that failure to observe the regula-

tion could cause injury or even death to the operator.

PRUDENCE

Prudence is the Golden Rule to prevent accidents.

TRAINING

The two-wheel tractor must only be used by respon-

sible people trained in the use of the machine and

duly authorized to use it.

MACHINE AND

ENGINE MANUALS

Read those MANUALS carefully before starting, us-

ing, servicing, refuelling or carrying out any work on

the two-wheel tractor.

DECALS

Read all the decals attached to the two-wheel tractor

and follow their prescriptions before starting, driving,

refuelling or servicing the machine. Replace immedi-

ately any damaged or illegible decals.

SUITABLE CLOTHING

• Do not wear wide and flapping clothes that could

be caught in moving parts.

• Always wear robust gloves when servicing the

two-wheel tractor or coupling attachments.

• Do not operate your two-wheel tractor barefoot,

wearing sandals or shorts. Wear heavy shoes and

trousers.

PHYSICAL CONDITION

Do not drive the two-wheel tractor if your physical

condition is not suitable.

NOISE

In order to reduce the problems deriving from the

noise of the machine:

• Do not work with the engine at maximum RPM

range.

• Keep the blade head and the blade holder ad-

justed.

• When using the machine for a long time, use ear

protections.

ENGINE RPM

Do not change the injection system in an attempt of

increase max. engine Rpm.

FIRST AID

It is good operating practice to have a first aid box on

the two-wheel tractor.

SAFETY DEVICES

• Do not use the two-wheel tractor if the safety de-

vices are missing or defective..

• Do not interfere with safety devices.

4

STARTING THE ENGINE

•Disengage all control levers before starting the mo-

tor. Keep your feet clear of the attachments fitted to

the two-wheel tractor.

•Do not run the engine in a closed ambient where

the exhaust gases can collect. They contain car-

bon monoxide that is highly toxic.

•Do not interfere with safety device (engine shut-

off). Do not use the two-wheel tractor if this safety

device is missing or defective.

OPERATING OF THE

TWO-WHEEL TRACTOR

•Make sure that you know how to stop the engine in

an emergency. Familiarize yourself with the con-

trols and learn how to use your two-wheel tractor

correctly.

•Do not allow children or inexperienced people to

operate it.

•Do not use your two-wheel tractor in proximity of

other people, and in particular of children. Do not

use it close to animals. Bear in mind that you are

responsible for any damage or injury caused to

people or things.

•Do not use the rotary tiller attachment without its

protection hood and guards.

•Use your two-wheel tractor only in daylight or with

good artificial lighting. Operate it at walking pace.

Do not run.

•Take particular care on slopes; operate only under

safe and stable conditions. Do not work uphill or

downhill; move across the slope instead. Take spe-

cial care when turning.

•For obvious reasons, never work on slopes steeper

than 30°.

•To ensure that gasoline fuelled engines are cor-

rectly lubricated, avoid working for long periods on

slopes steeper than 20°.

•Do not operate the two-wheel tractor if hoods or

other safety devices are missing or defective.

•Keep your hands and feet clear of all attachments.

•Do not lift or transport your two-wheel tractor with

the engine running.

•Inspect the ground before you start working. Clear

it from stones, wood, wires and any other foreign

objects.

OPERATING OF ATTACHMENTS

•Check that the attachment coupled to the PTO

functions correctly before starting the motor.

•Never use attachments coupled to the PTO in prox-

imity of children or animals.

•Keep your hands and feet well clear of the attach-

ment coupled to the PTO.

•Before using an attachment, make sure that the

reverse speed safety device has been set as re-

quired (this can be used when the front-mounted

attachments are fitted, and not when the tiller is ro-

tating).

•When a front-mounted attachment is installed, the

handlebars are rotated through 180°, hence the

gear and PTO levers are reversed.

•The manufacturer waives any responsibility arising

from improper use of the safety device.

Maximum

Recommended

20°

OK

45°

MF2037-2

MAINTENANCE

•Stop the engine and disconnect the spark plug

lead:

−before checking or repairing your two-wheel

tractor;

−in case of excessive vibrations (investigate

cause immediately).

•Stop the engine before leaving your two-wheel

tractor or adjusting attachments.

•Periodically check that all nuts and bolts are tight.

•Do not leave your two-wheel tractor in closed am-

bients with fuel in the tank. Fuel vapor is a potential

source of danger.

5

•Keep your two-wheel tractor clean. Do not let grass

and oil residues build up: these are a fire hazard.

•Fuel is highly flammable. Store fuel only in spe-

cifically designed containers. Refuel your two-

wheel tractor in the open. Do not smoke while re-

fuelling.

•Complete refuelling before starting the engine. Do

not remove the fuel cap or refuel when the engine

is running or hot. In case of fuel spillage, do not

start the engine. Push your two-wheel tractor some

distance away from where the spillage occurred

before starting it.

•Replace the exhaust pipe if it becomes worn or

damaged.

EC MARKING

The two-wheel tractor is marked EC in compliance

with the Directive of the European Community Coun-

cil 89/392/EEC and further amendments (see fig. 1,

part 2).

The summary of the EC marking related to the SU-

PER SMART model is indicated below.

IDENTIFICATION DATA

TWO-WHEEL TRACTOR IDENTIFICATION

The serial number is stamped on the engine side of

the gear box of your two-wheel tractor (see fig. 1, item

1).

ENGINE IDENTIFICATION

Refer to the engine Operation and Maintenance Man-

ual.

6

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

SUPER SMART

LGA 226

4 3600

70,000

BH10X00000

Engine:

LOMBARDINI LGA 226

cm. 50

Mass (weight):

with wheels 3.50-6

with rotary tiller

83,5

81,5

<2,5

Test conditions

- P.T.O.: Disengaged - machinestationary on a

concrete plane surface

Test conditions:

- P.T.O.: Engaged

Sound

pressure on

operator’s ears

dB(A)

Sound

pressure on

operator’s ears

dB(A)

(Macchine

stationary

on a grass

surface)

(Macchine

stationary on a

concrete surface

with an interposed

elastic layer)

(Machine

running on a

concrete surface

with an interposed

elastic layer)

Acoustic power

dB(A)

Acoustic power

dB(A)

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec

2

Acceleration

on hangrip

EN 1033 - 28662/1

m/sec

2

<2,5

89

87,5

104,5

102,5

11,75

11,75

With SICKLE BAR MOWER cm. 96

NOISE AND VIBRATIONS

TYPE OF MARKING

TWO-WHEEL TRACTOR

SUPER SMART - SUPER SMART Diesel

Models:

to

(punched on the gearbox)

SUPER SMART - SUPER SMART Diesel

A211408 A212096Progressiv unit number starting from

Progressiv unit number starting from AC00001

With SICKLE BAR MOWER cm. 96

With ROTARY TILLER cm. 50

With ROTARY TILLER cm. 50

-

-

Engine:

Mass (weight):

with wheels 3.50-6

with rotary tiller

HONDA GC 160

a cm. 50

Modello tipo:

N. Serie:

Mot.:

Potenza: 3,7 kW/ rpm

Anno di Fabbricazione:

Massa: kg

SUPER SMART

GC 160

3600

66,500

BH10X00000

87,5 6,1 NO NO

See NOTEWith ROTARY TILLER cm. 50

100 NO

Engine:

YANMAR L48

cm. 50

Mass (weight):

with wheels 3.50-6

with rotary tiller

Modello tipo:

N. Serie:

Mot.:

Potenza: kW/ rpm

Anno di Fabbricazione:

Massa: kg

SUPER SMART Diesel

L48

3,4 3600

83,500

BH10X00000

TR1017-4GB

NOTE: SUPER SMART Diesel model does not allow the use of front attachment.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

VALPADANA

42018 SAN MARTINO IN RIO

REGGIO EMILIA - ITALY

S.p.A.

S/N reading: type of machine

year of manufacturing

000 week of production

00 progressiv n° of production

X

00

000

BH10

GB

7

TECHNICAL SPECIFICATIONS

ENGINE

The two-wheel tractor may be fitted with the following

engines:

−HONDA GC 160; 4 stroke gasoline engine;

3,7 kW (5 CV); 160 cm3.

−LOMBARDINI LGA 226; 4 stroke gasoline engine;

4 kW (5,4 CV); 220 cm3.

−YANMAR L48; 4 stroke Diesel engine;

4 kW (5,4 CV); 212 cm3.

STARTING

Rewind start.

CLUTCH

Cone clutch, oil immersed with control lever.

SPEEDS

MAX SPEED (km/h)

POWER TAKE OFF (PTO)

Mounted attachments are driven via an independent,

single speed PTO engaged by a control lever on the

handlebars.

Maximum PTO speed: 923 rpm (clockwise rotation).

COUPLING OF ATTACHMENTS

Coupling of attachments to the PTO is obtained

through a quick change fitting that provides for fast

installation of the attachments, and does not require

the use of bolts, nuts or spanner.

HANDLEBARS

Adjustable in height and width. Rotate handlebars

through 180 when front-mounted attachments are

used.

WHEELS/TYRES

−Pneumatic tyres with agricultural tread.

−Available sizes: 3.50-6.

−Inflation pressure: 1.2 bar.

NOTE

The instructions covering track adjustment, based on

motor-mower model and type of wheel, are given in a

specific paragraph in this manual

ACCESSORIES

The two-wheel tractor can be fitted with a wide range

of additional easy-to-fit accessories. These are, for in-

stance, several types of iron wheels, watering pumps

and sprayers, snowploughs, ploughs, trailers, water

sprinkling trolleys, etc.

Refer to our catalogue for details about the various

accessories available.

MASS

Refer to the identification plate installed on the ma-

chine.

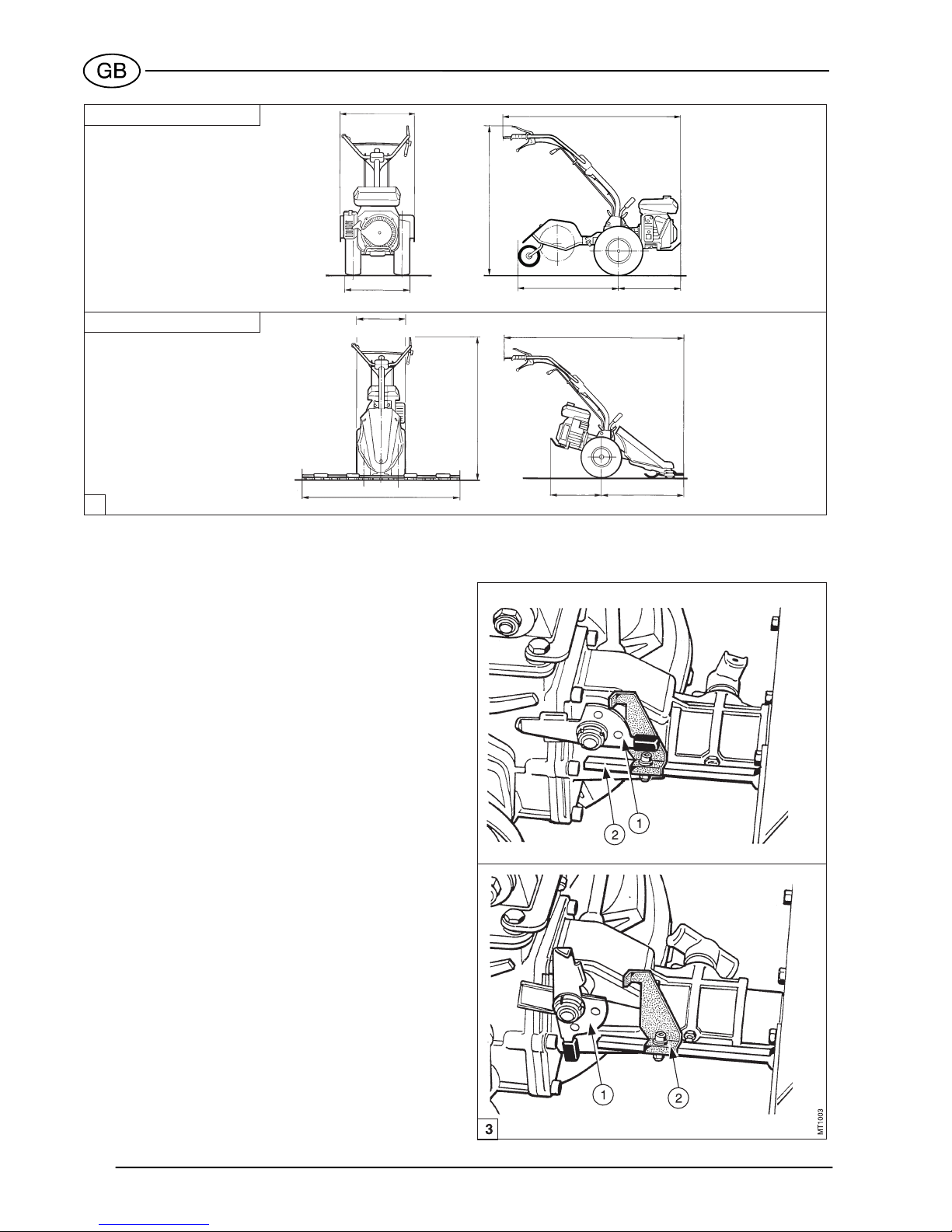

DIMENSIONS

The overall dimensions of the two-wheel tractor are

shown in fig.2.

8

2

MT1002-1GB

MOTOR-MOWER

TWO-WHEEL TRACTOR

490 1450

680

370 ÷ 400

950 ÷ 960 460 670

1500

830 ÷ 960 820 ÷ 1080

470

370 ÷ 400

SAFETY DEVICES

The two-wheel tractor is fitted with the following safety

devices to ensure maximum safety:

−Automatic PTO disengagement device. This is a

mechanical device that prevents shift into reverse

speed when the PTO is rotating (motor-mower

configuration only).

−Engine shut-off. This is an electrical device which

stops the engine as soon as the handlebars are

released (see fig. 4, item 2).

REVERSE SPEED SAFETY DEVICE

The two-wheel tractor is provided with an operator-

adjusted safety device (see fig. 3, item 1) that pre-

vents concurrent use of reverse speed and attach-

ment when the rotary tiller is fitted.

To use reverse gear it is necessary first to disengage

the power take-off control lever and then engage the

gear lever.

When installing the rotary tiller, check that the small

lever (1) is in the two-wheel tractor position; if not, the

pin (2) prevent complete engagement of the rotary

tiller at the linkage.

NOTE

Reverse gear cannot be engaged while the tines of

the rotary tiller are rotating.

9

TRANSFER PRINTING -

INSTRUCTIONS AND SAFETY

Please find below the adhesive transfer printing

shown on the machine.

For accident prevention purposes, they must always

be clearly readable. Should they be damaged, it is

compulsory to replace them by requesting the origi-

nal spare part from the Manufacturer.

10

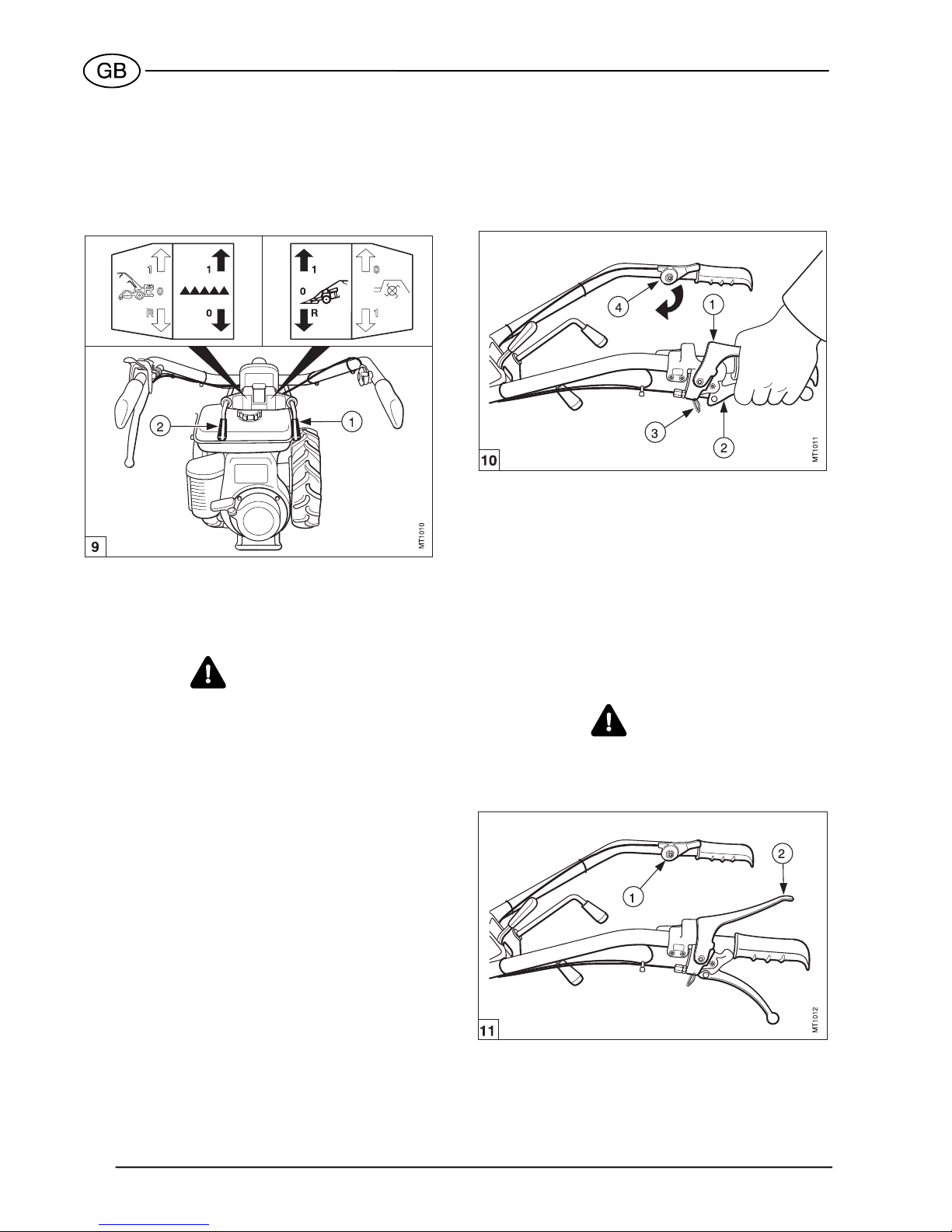

TWO-WHEEL TRACTOR CONTROLS

See fig.4.

1. Clutch lever.

2. Engine stop lever.

3. Gear lever. (Note 2)

4. Handlebar vertical lock release lever.

5. Handlebar sideway lock release lever.

6. PTO control lever. (Note 1).

7. Throttle control lever.

8. Attachments instant adaptor.

NOTE 1: When the machine is fitted with front-

mounted attachments, this lever becomes

the gear lever.

NOTE 2: When the machine is fitted with front-

mounted attachments, this lever becomes

the PTO control lever.

OPERATING THE CONTROLS

Clutch lever

(See fig. 5)

− Lever (1) pulled up: clutch disengaged.

− Lever (1) released: clutch engaged.

Engine stop lever

See figure 5.

− Lever (2) pressed down: engine running.

− Lever (2) released: engine stopped.

Throttle control lever

(See figure 5)

− Lever (3) in up position: engine at idle.

− Lever (3) in down position: max engine rpm.

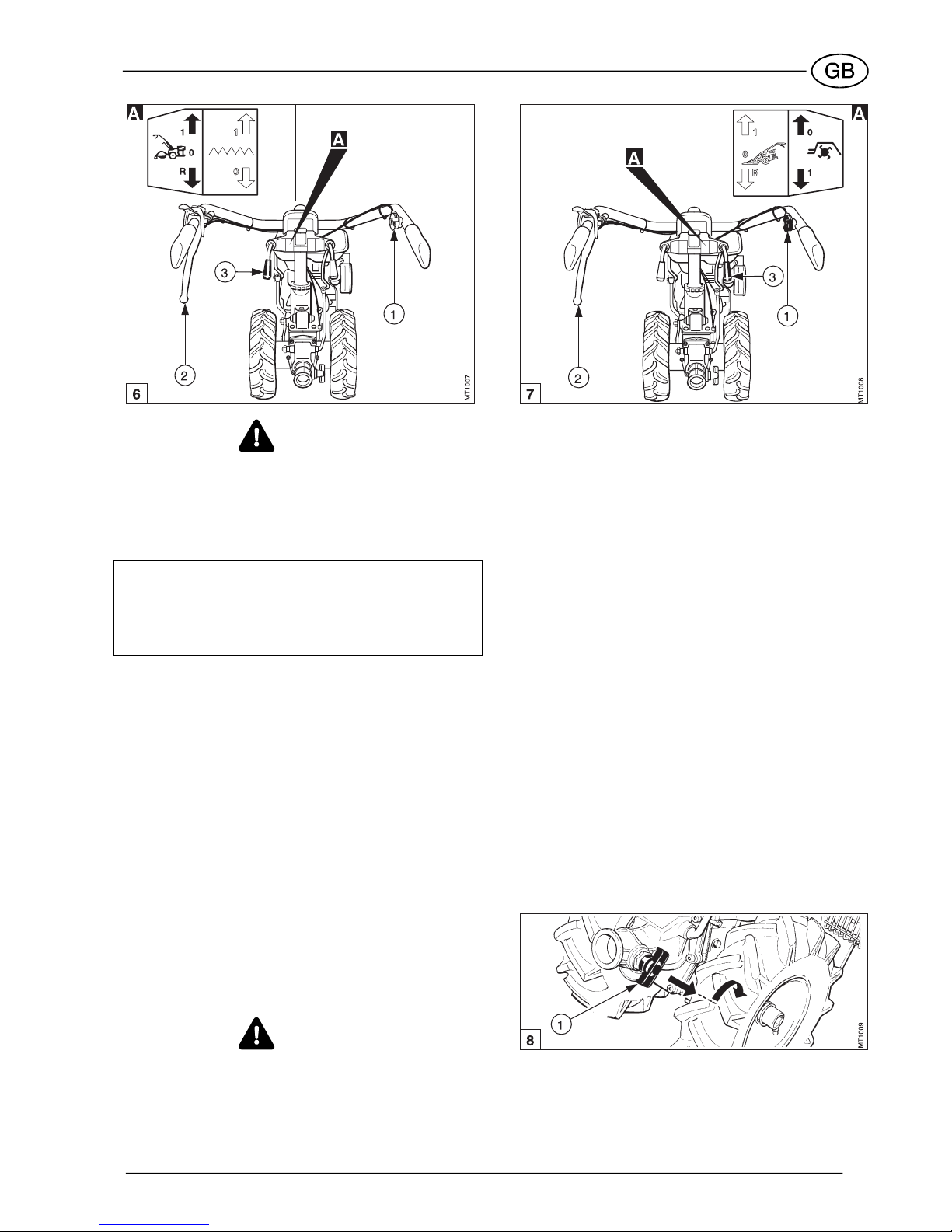

Gear lever (two-wheel tractor configuration)

CAUTION

When using the machine as a motor mower, the han-

dlebars must be rotated through 180. The gear and

PTO control levers therefore interchange position.

See page 11 for details.

Use the gear lever as shown below (see fig. 6):

a. Turn the throttle control lever (1) to idle position.

b. Pull up clutch lever (2).

c. Move the gear lever (refer to fig. 6, item 3) to the

required position (see the plate illustrated in detail

A), and release it as soon as the gear is engaged.

d. Gradually release the clutch lever while accelerat-

ing the engine.

e. To disengage gear, pull up the clutch lever (2) and

move gear lever (3) to the neutral position.

11

WARNING

A safety device does not permit reverse speed to be

engaged when the PTO is operating (rotary tilling)

Power Take Off (PTO) control lever (two-

wheel tractor configuration)

CAUTION

When using the machine as a motor mower, the han-

dlebars must be rotated through 180. The gear selec-

tor and PTO control levers therefore interchange posi-

tion. See page 12 for details

The Power Take Off (PTO) control lever engages the

drive to the attachment.

To engage and disengage drive, proceed as follows

(see fig. 7):

a. Turn throttle lever (1) to idle position.

b. Pull up clutch lever (2).

c. Pull PTO control lever (3) and release it when drive

is engaged (see plate in detail A.)

The lever (3) has two positions:

− 1: power take-off operating.

− 0: power take-off stopped.

d. Release the clutch lever while accelerating the en-

gine.

CAUTION

The clutch lever must be released slowly to prevent

damage to the drive. Do not start working with at-

tachment loaded (into the soil).

WARNING

A safety device prevents you from using the rotary til-

ler attachment in reverse gear. Do not use the two-

wheel tractor if this safety device is not correctly in-

stalled.

Handlebar vertical lock release lever

(See fig. 4, item 4)

This allows the handle to be vertically adjusted to suit

driving comfort and tilling depth.

Simply push down lever (1) to release handles.

Handlebar sideway lock release lever

(See fig. 4, item 5)

By releasing lock lever (5), you may rotate the han-

dlebars for the use of front mounted attachments.

PTO Instant adaptor

This allows attachments to be coupled and de-

coupled quickly and easily to and from the PTO. The

lever (fig. 8, item 1) has two positions.

− Free position: pull the lever (1) outwards and lock

in this position by turning it 90°.

− Locked position: turn the lever (1) 90°; if the cou-

pling with the attachment is correct, the lever will

automatically return to its original position, thereby

locking the attachment.

See page 13 for instructions on how to fit the attach-

ments.

CONTROLS OF FRONT-MOUNTED

ATTACHMENTS

When the machine is used with front-mounted at-

tachments, the gear and the PTO levers are reversed

12

with respect to when the machine is used as a motor-

mower.

This is due to reversal of the direction of motion.

Lever (fig. 9, item 1) becomes the gear lever, and

lever (2) becomes the PTO control lever. The symbols

shown in figure 9 and applied to the column, remind

the user about the functions of the levers.

OPERATING THE

TWO-WHEEL TRACTOR

WARNING

Before operating your reversible two-wheel tractor,

read carefully and commit to memory the instructions

given in the GENERAL SAFETY PRECAUTIONS para-

graph at the beginning of this manual.

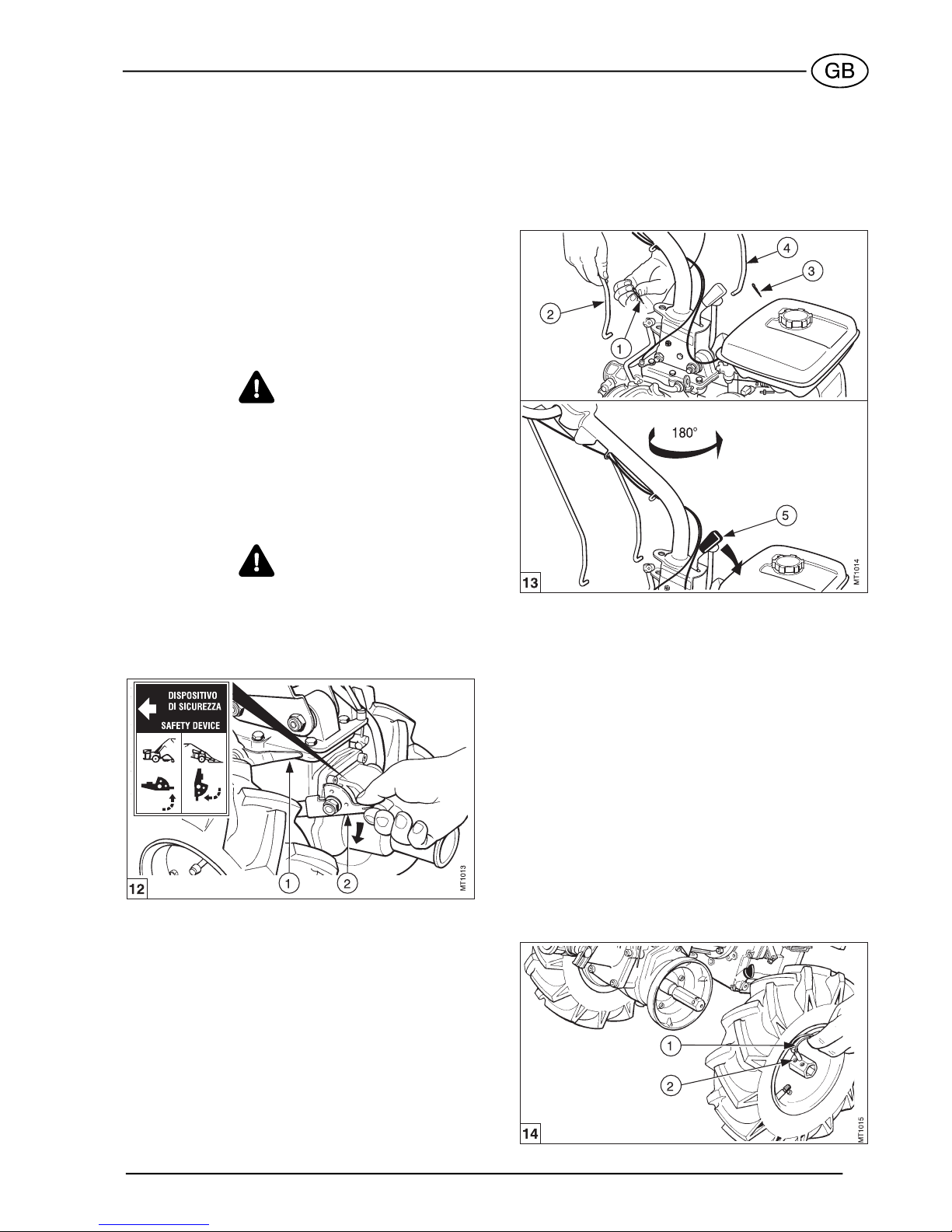

STARTING THE ENGINE

NOTE

See the engine Operating and Maintenance manual

for all information regarding the engine.

a. Disengage all control levers before starting the

engine

b. Open the fuel cock.

c. Position the small starter lever.

The position of the starter, for starting with a cold

engine, is shown on the appropriate plate. When

starting with a hot engine, the starter lever must be

kept in in-gear position.

d. Press down the engine stop lever (fig. 10, item 1).

e. Pull clutch lever (2) fully up.

f. Lock the clutch lever (1) in down position with

locking device (3).

g. Turn throttle lever (4) for 1/4 turn.

h. Grip the pull-rope handle and pull firmly and

quickly. When the engine starts, allow the rope to

wind back onto the reel slowly.

i. Turn the throttle lever (4) to idle position, and allow

the engine to warm up.

NOTE

Do not leave the clutch lever pulled up for an ex-

tended length of time after the engine has started.

This could cause damage to the clutch.

STOPPING THE ENGINE

a. Turn throttle lever (fig. 11, item 1) to idle position.

b. Release the engine stop lever (2).

c. If you plan not to use your two-wheel tractor for a

long time, shut off the fuel cock (if installed).

WARNING

The engine stop lever (2) also operates as a safety

device (emergency stop), and stops the engine as

soon as it is released.

13

FITTING FRONT-MOUNTED

ATTACHMENTS

Before fitting a front-mounted attachment (cutter bar

mower, rotary mower, snow thrower, etc.), adjust the

reverse speed safety device as required, reverse the

handlebars and the wheels.

CAUTION

SUPER SMART Diesel model does not allow the use

of front attachment.

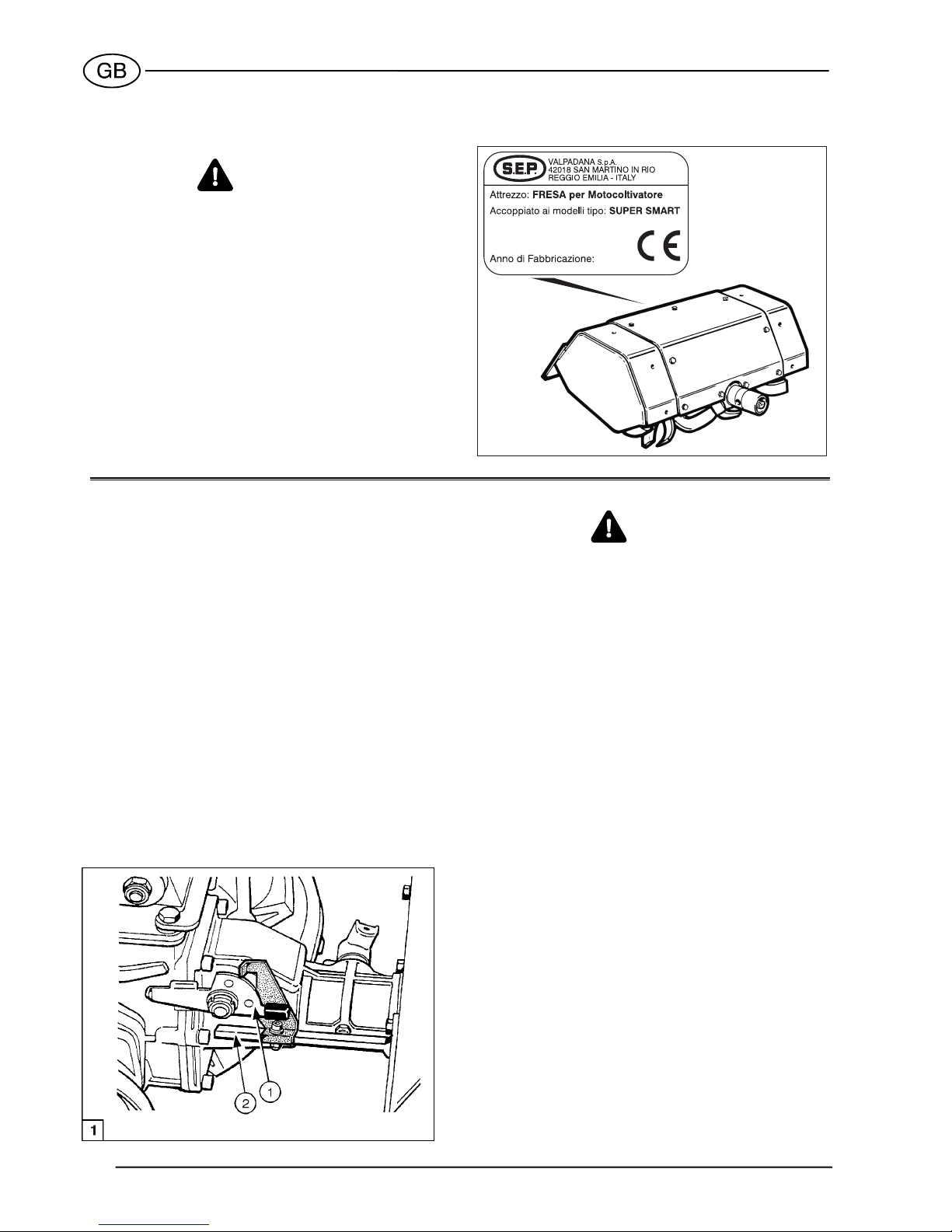

SAFETY DEVICE

Set the reverse speed safety device in the correct po-

sition as regards the direction of travel (see fig. 12).

WARNING

Before using the machine, check that is in correct po-

sition.

a. Move the lever (1) to give free movement of the

safety device.

b. Push the safety device lever (2) down (see the

plate showing the "motor mower") to allow reverse

gear to be engaged.

WARNING

When converting the machine back into the two-

wheel tractor version, to fit the rotary tiller, engage the

safety device by proceeding in the opposite way to

the way described above (see the plate showing the

"two-wheel tractor”).

REVERSING THE HANDLEBARS

Rotate the handlebars through 180° to operate the

machine in the changed direction of motion. Proceed

as follows:

a. Remove the pin (see fig. 13, item 1) locking the

gear control rod (2).

b. Remove the pin (3) locking the power take-off rod

(4).

c. Squeeze the lever (5) and rotate the handlebars,

180° anticlockwise; release the lever (5) and lock

the handlebars.

d. Connect again the gear (2) and PTO (4) control

rods to the corresponding control levers and se-

cure with pins (1) and (2).

NOTE

While reversing the handlebars, make sure that the

cables do not become tangled or caught.

REVERSING THE WHEELS

Every time you use a front-mounted attachment, the

wheels must be interchanged to keep the tread pat-

tern pointing in the right direction. Simply remove

each wheel from its hub and install it on the opposite

hub. An arrow on the sidewall of the tire indicates the

correct direction of rotation (see fig. 14).

a. Remove the pins (1).

b. Remove the wheels and put the right wheel on the

left and vice-versa.

c. Replace the pins (1).

Adjusting the track

Two different track sizes can be obtained as a result

of the double holes in the hub cap (2). To do this, fix

the wheel by means of the plug (1), which is inserted

into the desired hole.

14

COUPLING ATTACHMENTS TO

THE PTO

The PTO is fitted with an instant adaptor device to fit

attachments quickly and easily. Proceed as follows to

fit your attachments (see fig. 15):

a. Check that lever (1) is in disengaged position.

b. Push the shaft of the attachment into the PTO (2).

Make sure that it engages fully.

c. Rotate lever (1) clockwise to the engaged position.

Check that the attachment is correctly locked.

MAINTENANCE

To ensure continuing reliability, use only original

spare parts when overhauling or repairing your two-

wheel tractor.

ENGINE

Make sure you do comply with the safety precautions

contained in the engine Operation and Maintenance

Manual.

GEARBOX

After the first 50 hours (running in)

Change the oil (see fig. 16). Change the oil when the

engine is hot to facilitate draining of oil.

a. Remove the right wheel.

b. Remove the oil dip-stick (1).

c. Remove the oil drain plug (3) from the bottom of

the gearbox (right side) and let the oil drain out.

When fully drained, reinstall the plug (3).

d. Fill up with new oil (1.3 l) of the following types:

− SAE 90 for ambient temperatures between

-6 and +32°C;

− SAE 140 for ambient temperatures between

+32 and +60°C.

Every 20 hours

Check the oil level in the gearbox housing: to do this,

slacken the screw (2) and check that oil is coming out

from the screw position.

NOTE

Check the oil level with the motor cold and with the

two-wheel tractor on level ground.

Every 300 hours

Change the gearbox oil following the instructions

given in the above paragraph covering running in.

POWER TAKE OFF

Every 8 hours

Grease the PTO (see fig. 17, item 1).

Also grease the PTO every time you fit a new attach-

ment.

15

CHECKS AND ADJUSTMENTS

CLUTCH LEVER

The clutch lever must have a free play of about 5 to 6

mm before the clutch starts to disengage.

Insufficient play can cause clutch slip, while excess

play can lead to failure to disengage fully.

Adjust play by means of cable adjuster (see fig. 18,

item 1).

16

ROTARY TILLER

WARNING

• Do not use the rotary tiller without the hood.

• Do not proceed to tilling in proximity of children

and/or animals.

• Keep your hands and feet clear of the tiller at-

tachment when the motor is running. Stop the en-

gine before touching the tiller for any reason.

• Make sure that the reverse speed safety device is

installed correctly, via as described on page 12.

GENERAL

The rotary tiller is used to till gardens, orchards and

vineyards, to prepare seed beds and to break up ag-

ricultural ground in general.

Various sizes of rotary tiller can be fitted, from 40 to

50 cm.

Rotary tillers are fitted with hoods and side guards.

Hoods can be fixed or adjustable according to the

model. A wheel is also provided for easy transport of

the two-wheel tractor with the tiller attachment fitted.

ROTARY TILLER TECHNICAL

SPECIFICATIONS

− Transmission: bevel gears in oil bath.

− Max. rotation speed: 300 rpm.

− Working width: 40 to 50 cm, adjustable.

− Weight: 20,700 kg.

WARNING

The rotary tiller is provided with a safety device, fitted

to the attachment flange (fig. 1, item 2) which pre-

vents attachment installation when the machine is

configured as required for the use of the front-

mounted attachments (small lever (1) in “two-wheel

tractor” position).

USING THE ROTARY TILLER

The rotary tiller is driven via the PTO. Proceed as fol-

lows:

a. Pull up clutch lever and engage first speed with

gear lever.

b. Pull PTO control lever, and release it when drive is

engaged.

c. Slowly release the clutch lever to start tiller rotation

and at the same time accelerate engine speed by

means of throttle.

CAUTION

Release the clutch lever gradually. It is also advisable

to sink the tiller in the soil slowly.

ROTARY TILLER ADJUSTMENT

Tilling width adjustment

The adjustable tiller model allows you to set working

widths of 40 and 50 cm, to suit the type of crop.

Adjustment of tilling width is obtained by reversing

the position of the two pairs of outside tiller rotors of

17

each tilling element, and by removing or adding one

tiller rotor at the end of the two tillers.

Refer to fig. 2 to determine the tiller rotor configura-

tion required to obtain the desired tilling width, then

proceed as follows.

To reverse the position of the outside tiller rotor pairs

(fig. 3, item 1), remove the four attachment nuts (2)

and invert the position of the outside pair of tiller ro-

tors, fitting the left rotor to the right and vice-versa.

Make sure you keep the cutting edge of the rotors

facing the front of the machine.

Adjustment of protection guards

a. Adjust width of protection guards to suit new tilling

width. To do this, remove the screws (fig. 4, item

1), and install the two side extensions (2).

b. Adjust width of matching piece (3) by use of

screws (4).

Tilling depth adjustment

To vary tilling depth you must adjust the height of rear

tine (fig. 5, part. 1). Proceed as follows:

a. Remove nut and bolt (2).

b. Move the tine up or down until the slot on the

bracket corresponds to the desired hole on the

tine shank. Replace nut and bolt (2) and fully

tighten.

Ground adjustment

Adjust the position of the rotary tiller as follows to en-

sure correct movement over different types of ground:

HARD GROUND

If the tiller tends to jump on hard ground, lower the

tine to lift the rotary tiller.

SOFT GROUND

If the tiller tends to sink in on soft ground, lower the

tine to move the centre of gravity over the machine

wheels.

18

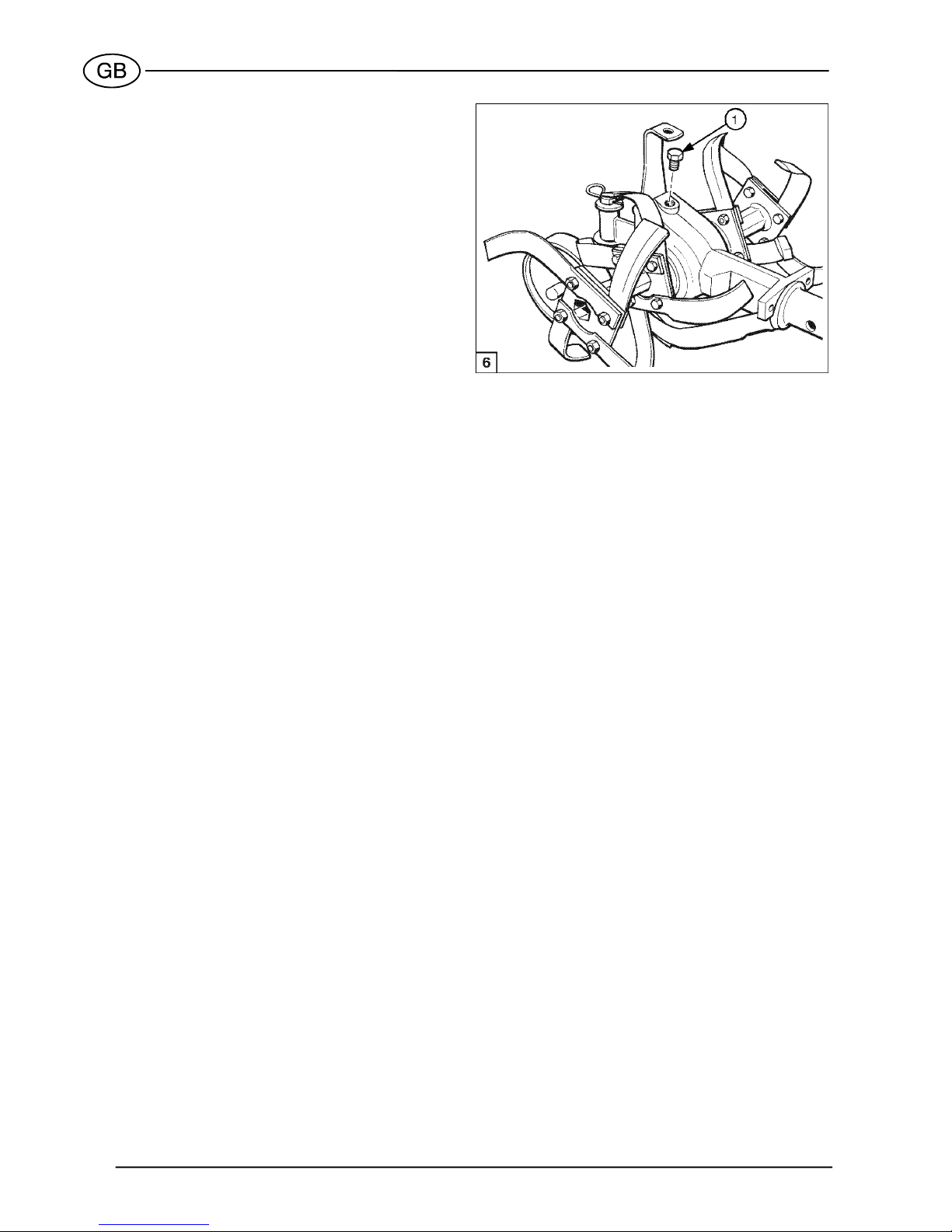

ROTARY TILLER MAINTENANCE

After the first 50 hours (running in)

a. Check that all nuts and bolts are secure. Tighten if

necessary.

b. Change the oil in the tiller drive unit as follows.

Remove plug (fig. 6, item 1) and turn the attach-

ment upside down to drain out the exhausted oil.

Return the attachment to the upright position, and

add 0.3 l of the same oil used for the machine

gearbox. Reinstall plug.

Every 300 hours

Change the tiller drive unit oil as instructed above.

This manual suits for next models

1

Table of contents

Other S.E.P. Lawn Mower manuals

Popular Lawn Mower manuals by other brands

Powersmart

Powersmart PSM2521SH instruction manual

Midwest

Midwest 179-2304 quick start guide

Mac allister

Mac allister MAC1700RMA Safety and operating manual

Powersmart

Powersmart PS2321SR instruction manual

Bad Boy

Bad Boy OUTLAW EXTREME Owner's, service & parts manual

Oleo-Mac

Oleo-Mac APACHE 92 Operators instruction book