- 2 -

Contents

SERVICE MANUAL................................................................................. 1

Contents .................................................................................................. 2

Safety Instructions ............................................................................... 3

Safety Precautions............................................................................ 3

Product Safety Notice ..................................................................... 3

Service Personnel Warning ........................................................... 3

Specifications......................................................................................... 4

Circuit Protections................................................................................ 5

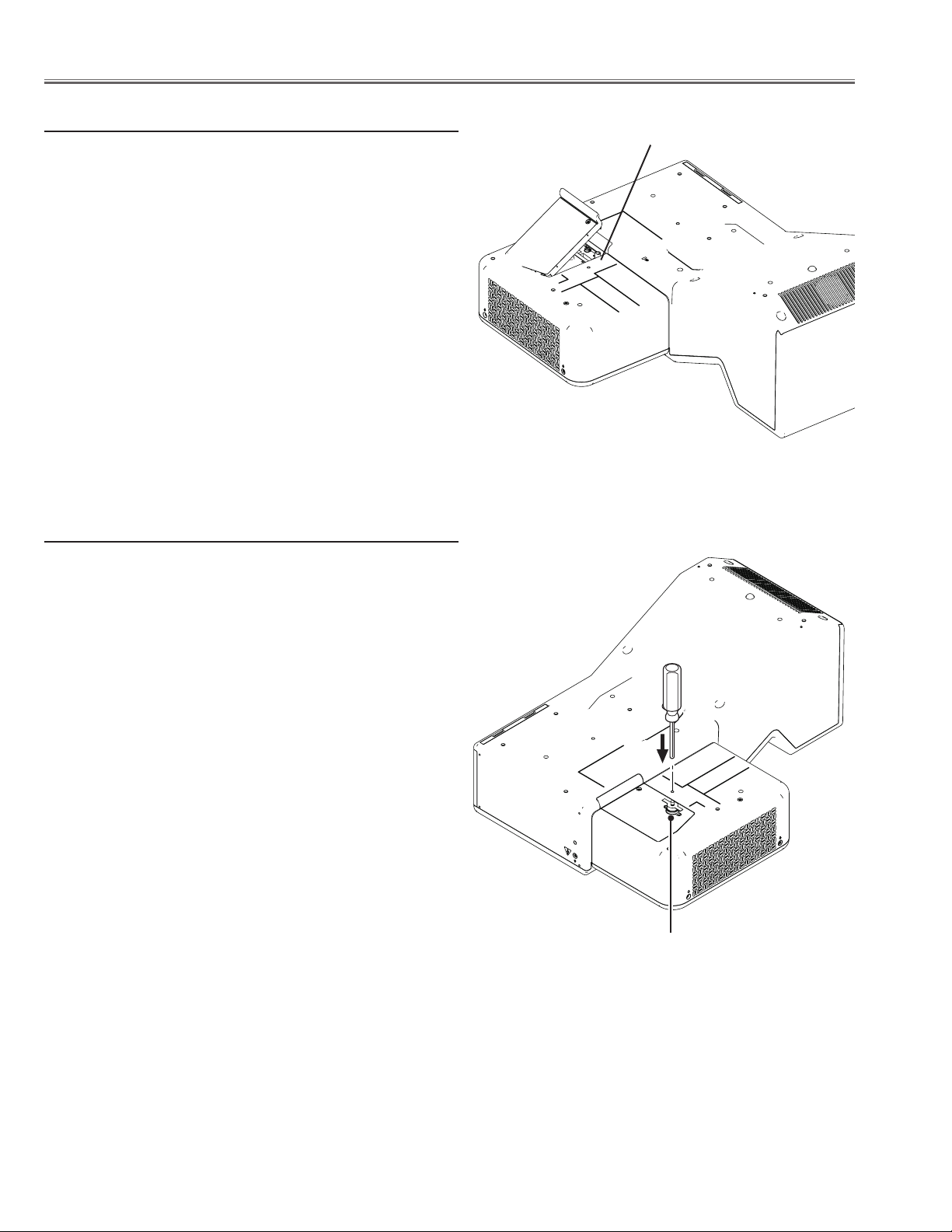

Fuse........................................................................................................ 5

Lamp cover switch ........................................................................... 6

Thermal switch .................................................................................. 6

Warning temperature and power failure protection........... 7

Maintenance and Cleaning............................................................... 8

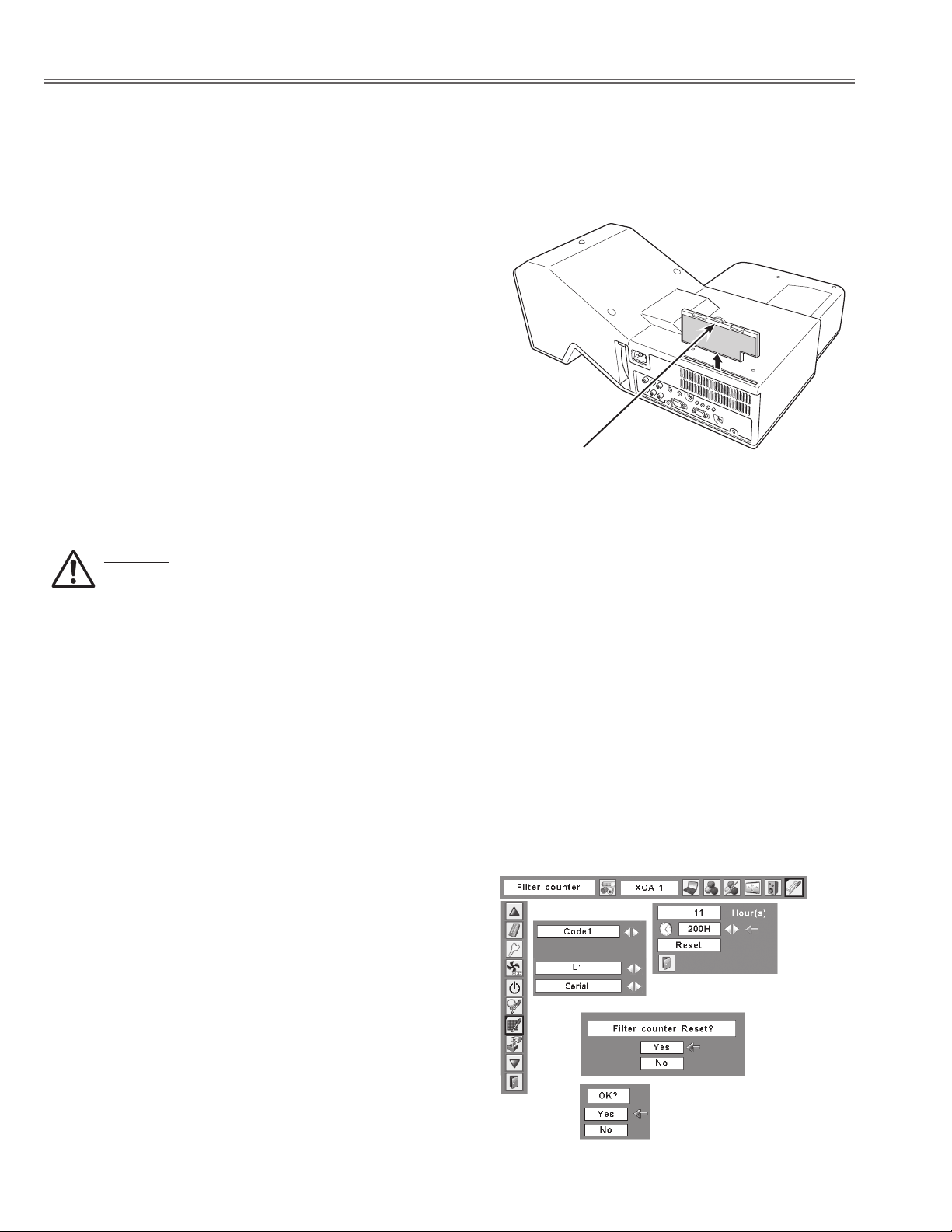

Cleaning the Air Filter ..................................................................... 8

Resetting the Filter Counter ......................................................... 8

Cleaning the Projector Window .................................................. 9

Cleaning.............................................................................................10

Lamp Replacement............................................................................11

Lamp Replacement Counter ......................................................12

How to check Lamp Used Time.................................................13

Security Function Notice and Standby mode notice ............14

Security Function Disable............................................................14

Antitheft Alarm Function Disable.............................................14

Standby mode .................................................................................14

Mechanical Disassembly..................................................................15

Optical Parts Disassembly...............................................................27

Optical Parts Location and Direction ......................................33

Adjustments.........................................................................................34

Adjustments after Parts Replacement ....................................34

Optical Adjustments .........................................................................35

Contrast adjustment......................................................................35

Integrator lens adjustment.........................................................36

Relay lens-Out adjustment .........................................................37

Projection Lens focus adjustment............................................38

Electrical Adjustments..................................................................40

Service Adjustment Menu Operation .....................................40

Circuit Adjustments.......................................................................41

Test Points and Locations............................................................46

Service Adjustment Data Table .................................................48

Chassis Block Diagram......................................................................63

Chassis over view............................................................................63

System control.................................................................................64

Lamp control....................................................................................65

Audio circuit .....................................................................................66

Power supply & protection circuit............................................67

Eco-Standby mode (Sub-CPU)...................................................68

Fan control circuit...........................................................................69

IIC bus control circuit ....................................................................70

Troubleshooting .................................................................................71

Indicators and Projector Condition..........................................71

No Power ...........................................................................................72

No Picture..........................................................................................73

No Sound...........................................................................................74

Control Port Functions .....................................................................75

Scaler I/O Port Functions (PW190) ...........................................75

IC Block Diagrams...............................................................................77

Electrical Parts List .............................................................................82

Electrical Parts Location ...............................................................83

Electrical Parts List..........................................................................84

Mechanical Parts List...................................................................... 105

Cabinet Parts Location............................................................... 105

Optical Parts Location................................................................ 105

Mechanical Parts List.................................................................. 109

Diagrams & Drawings ...................................................................... A1

Parts description and reading in schematic diagram .......... A2

Schematic Diagrams ........................................................................ A3

Printed Wiring Board Diagrams.................................................... A9

Pin description of diode, transistor and IC.............................A13

Note on Soldering...........................................................................A14