-4-

Installation Instructions

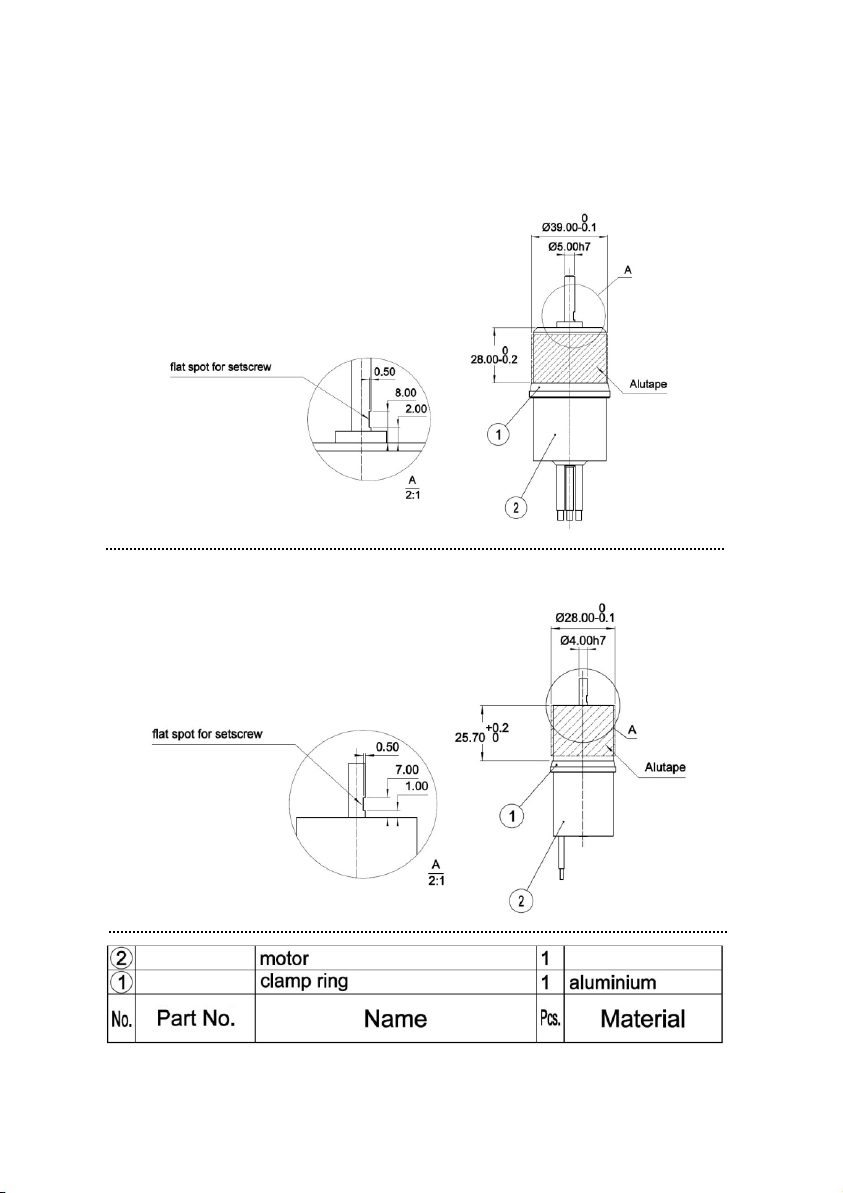

Drawing #1 (Assembly):

DS-30-AXI HDS:

DS-51-AXI HDS:

Information on Drawing #1:

• Prepare the motor according to drawing #3 and the

corresponding instructions (p.7).

• Insert the motor into the stator.

• Before, please apply some copper paste on the wrapped part of

the motor, so that a proper heat conduction between the motor

case and the stator unit can be guaranteed.

• Screw the motor and the stator together according to drawing #1.

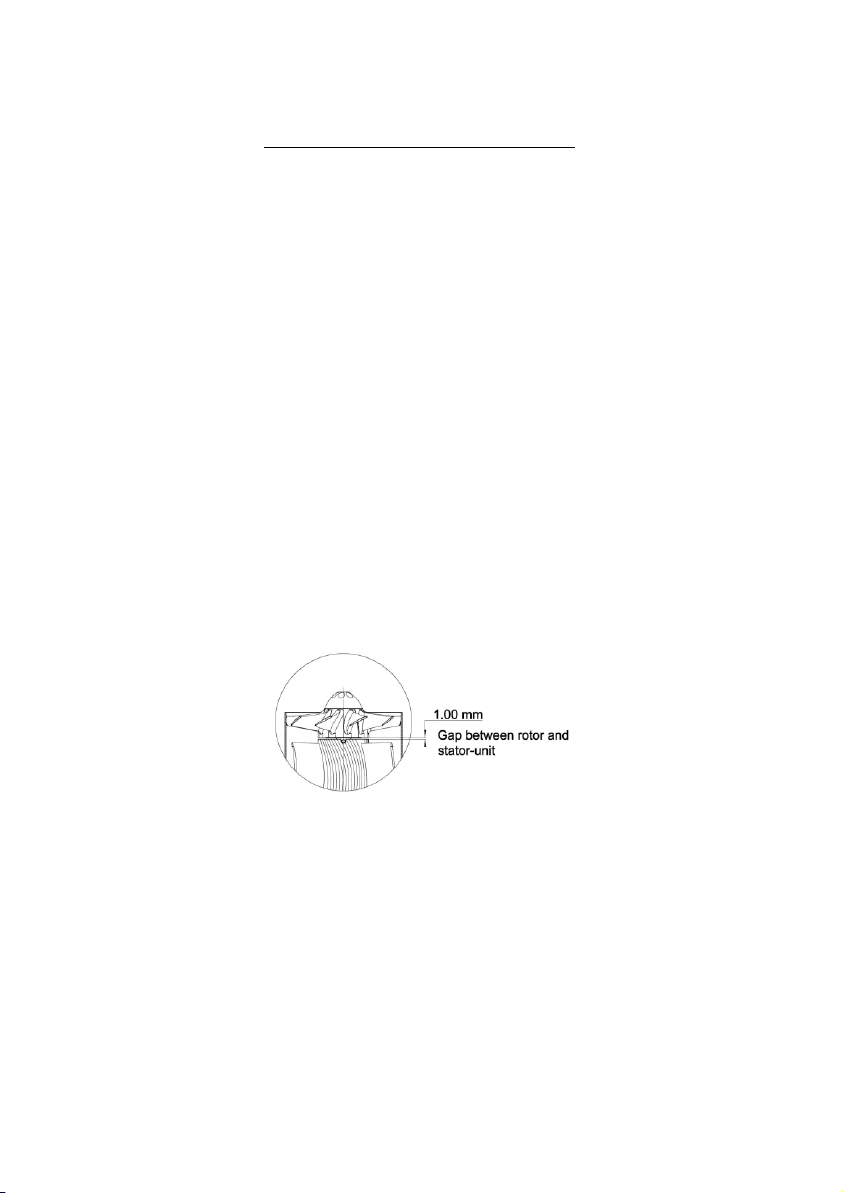

• The gap between stator and rotor is adjusted by appropriate

spacers, which will be removed after screwing (e.g. feeler gauge

stock).

•Put the rotor on the motor shaft according to drawing #1 and fix it

with 3 setscrews (pos. 3, drawing #1). In order to do this, please

put the appropriateAllen wrench in the existing bore.

• When fixing the screws, take care that the rotor and the motor

shaft don't stick together because of the screw lock.

• Don't tighten all setscrews at once, but build up fixture step-by-

step all round until you tighten all setscrews in the last round. By

doing this, a central position of the rotor on the motor shaft can be

guaranteed.

• Pay attention to the distance between rotor and stator, and also

to the position of a setscrew above the flat spot of the motor

shaft.

• Please rotate the integrated rotor by hand once. The rotor should

run smoothly (except for the cogging of the motor) and should not

exhibit any grinding noise.

• Please check the evenness of the gap between the rotorblades in

the backlight.

-5-

Drawing #2: